Thermoelectric Chillers for Semiconductor Metrology & Inspection Systems

Introduction

The implementation of automated metrology systems has been a key to achieving cost effective semiconductor fabrication. The complex nature of semiconductor fabrication requires multiple tests between processing steps to inspect defects as well as measure dimensional properties including thickness, refractive index, resistivity and stress of the thin films. Because thermal noise can impact the image resolution of sensitive optical components in automated metrology systems, a thermal management system is required. Temperature fluctuations can also shorten the lifetime of thermally sensitive components, which can result in production downtime and revenue loss. Thermoelectric-based Recirculating Chillers offer precise temperature control of semiconductor metrology & inspection systems.

Background

Increasing demands for electronic devices has grown the semiconductor fabrication market into a $500 billion industry annually. The semiconductor fabrication process has been one of constant process improvements driving new equipment to allow for manufacturing of 5 nm semiconductors. The implementation of automated optical inspection systems has been the key to achieving cost effective high-volume production. These systems do not only measure the physical properties of the films but also feeds this measurement data back into the manufacturing process. Utilizing imaging sensors, modern metrology inspection systems provide live feedback of local process conditions to the process tool. This data can be used to control the process parameters of the system or to stop the line when an out-of-tolerance measurement occurs.

Enhanced manufacturing processes such as automated optical inspection systems have enabled production of 5 nm semiconductors.

Application Challenges

The need for higher quality, higher packaging density and repeatability combined with a high speed optical inspection system places ever increasing demands on the thermal management solution. Temperature fluctuations will lead to bad data, incorrect decisions or conclusions, and significant yield loss.

Temperature Control

Semiconductor automated optical inspection (AOI) systems often use lasers as the source for testing speed and accuracy. Lasers generate large amounts of heat that must be efficiently dissipated away to maintain the desired wavelength. Temperature fluctuations will impact the laser beam, affecting testing accuracy.

Metrology inspection systems based on CCD or CMOS imaging techniques also require tight temperature tolerances as image resolution degrades with increasing temperature. To provide maximum image resolution, sensors must be kept below ambient temperatures with a temperature stability of ± 0.5°C or better. Cooling laser optics and other key components will also reduce maintenance and increase equipment uptime, lowering the total cost of ownership.

Semiconductor automated optical inspection (AOI) systems typically require removal of up to 100 Watts or more and a temperature stability at 20℃ or below with stability greater than 0.01℃.

Reliability

Because automated semiconductor inspection systems often operate 24/7, the cooling system must provide high reliability with minimal downtime. Proper cooling will help maximize equipment uptime, reduce maintenance and lower the total cost of ownership by increasing the mean time between failure (MTBF). This combined with temperature stability of temperature control to very high precision as possible.

Noise & Vibration

Automated optical inspection tools require a cooling system to enable a steady flow coolant to the temperature sensitive components without pulsation. Temperature fluctuations can distort measurement resolution quality as well as the operational lifetime of components. Larger compressor-based systems are typically noisier and use larger pumps which tend to pulsate, which can generate noise and impact image resolution quality. Thermoelectric-based recirculating chillers are equipped with smaller pumps providing lower pulsation and minimizing impact to imaging system.

Environmental Regulations

Environmental regulations continue to phase out the use of harmful refrigerants tied to ozone depletion and global warming. Older compressor-based systems use environmentally harmful HFC refrigerants including R134a and R404A. Modern compressor-based systems uses natural refrigerants that have less impact on the environment. Thermoelectric Chillers do not use any refrigerants, resulting in zero global warming potential.

Thermoelectric Chiller Solutions

With the ability to cool to well below ambient temperatures, thermoelectric-based recirculating chillers are a better option than passive solutions such as heat sinks and fans or ambient liquid cooling systems. Because of their solid-state operation, they provide high reliability with low maintenance throughout the product lifetime. The plug and play design provides quick and easy installation to any semiconductor metrology equipment.

Utilizing thermoelectric cooling technology, thermoelectric chillers are able to provide very precise temperature control, which is required for spot cooling of metrology inspection system components.

How Does It Work?

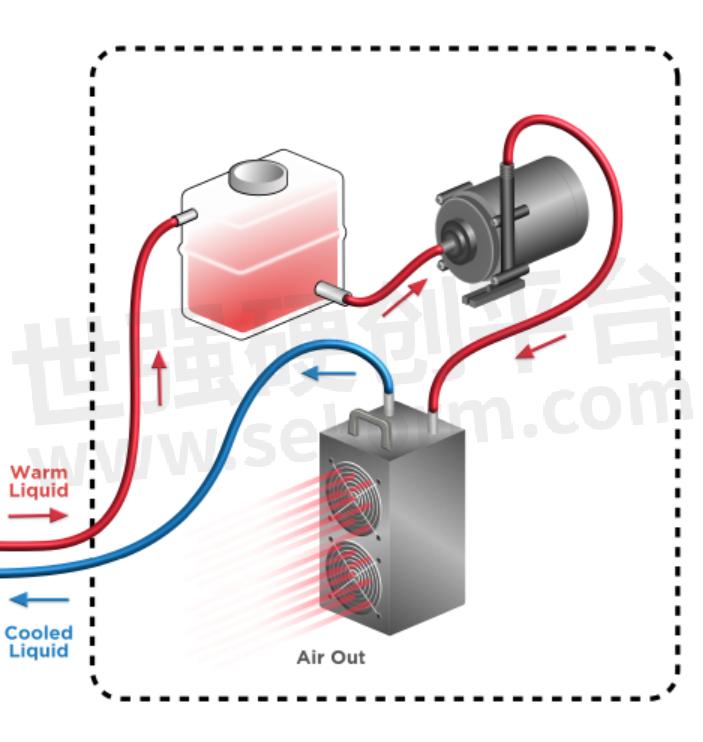

A thermoelectric chiller can cool a metrology imaging tool down to 18℃ while room temperature may fluctuate between 20 and 30℃. Heat from the system is absorbed by the liquid coolant and flows to a reservoir tank by a pump. The pump pushes coolant thru the Liquid-to-Air thermoelectric engine, which then cools the temperature of the coolant circuit while exhausting waste heat into the surrounding environment. The coolant then flows back to the camera system at a set point temperature where the cold plate is mounted. This is a semi-closed system which reduces algae from building up over time. An ethanol glycol water mixture is recommended to use as coolant to further prevent microbial growth.

Laird Thermal Systems Solution

The NRC400 Nextreme™ Performance Chiller is a thermoelectric-based chiller featuring high performance thermoelectric coolers and heat exchanger technology. Utilizing thermoelectric coolers with next generation material, the NRC400 delivers 400 Watts of cooling power and a temperature accuracy of ±0.05°C under steady state conditions.

Compared to previous models, the NRC400 offers a higher coefficient of performance (COP) and lower noise for semiconductor fabrication facilities. Solid-state thermoelectric technology reduces the number of moving parts providing low maintenance requirements throughout the product lifetime.

Traditional compressor-based systems are often large and heavy. Modern cooling systems such as thermoelectric-based chillers are designed with portability in mind, which means that it can be used to cool multiple pieces of equipment in the facility.

The NRC400 features an intuitive easy-to-use LCD touchscreen display that allows users to easily control temperature setpoints and alarm features. The semi-closed system is equipped with a large reservoir tank, requiring less refilling during operation and better temperature stability.

The NRC400 has been approved by UL for industrial lab use, reference UL 61010-1 and has CE marking. It is also RoHS compliant and environmentally friendly as no harmful HFC refrigerants are being used. It operates on a universal power supply, making it easy to source one-part number for global use.

Conclusion

Complex wafer processing has increased the demand for metrology in between the various processing steps. Semiconductor automated optical inspection (AOI) systems require a highly reliable thermal management system that can operate 24/7 and deliver precise temperature control. Thermoelectric-based recirculating chillers are becoming more popular in semiconductor manufacturing processes due to higher reliability and lower operating costs compared to conventional compressor-based systems. A recirculating chiller system utilizing thermoelectric coolers can both heat and cool resulting in better temperature stability for critical applications. The NRC400 thermoelectric chiller maximize performance, reduce maintenance and lower the overall cost of ownership for semiconductor automated optical inspection systems.

More information on the NRC400 can be found on the Laird Thermal Systems website.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由samsara转载自Laird Thermal Systems Official Website,原文标题为:Thermoelectric Chillers for Semiconductor Metrology & Inspection Systems,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Spot Cooling for Industrial Lasers & Optics

This application note will focus on how thermoelectric coolers can be used for spot cooling of industrial laser optics. Deal for spot cooling on industrial laser applications, the UltraTEC UTX Series utilizes advanced thermoelectric materials for higher heat pumping capacity compared to standard semiconductor materials.

应用方案 发布时间 : 2024-10-18

Offering A High Heat Pumping Capacity Up to 400 Watts and A Temperature Stability of ±0.05°c, The NRC400 Maximize Image Resolution in Digital Microscopes

Nextreme™ Thermoelectric Chiller offering a high heat pumping capacity up to 400 Watts and a temperature stability of ±0.05°C, the NRC400 maximize image resolution in digital microscopes. Solid-state thermoelectric devices have less moving parts, reducing maintenance and the total cost of ownership for analytical imaging equipment.

应用方案 发布时间 : 2024-10-09

Laird Thermal Systems‘ Nextreme™ Value Chillers Provide Economical, High Reliability OEM Cooling Solution

The Extreme Value Chiller Series uses high-performance components to cool well below ambient temperatures to control processes or dissipate heat away from thermally sensitive equipment.

应用方案 发布时间 : 2022-11-15

Laird Thermal Systems(莱尔德热系统)液体冷却系统产品选型指南

目录- Introduction Benefits & Applications of Liquid Cooling Systems Nextreme™ Recirculating Chillers Liquid Heat Exchangers Custom Liquid Cooling Systems Featured Application: Medical Imaging

型号- 1510.00,WL1500,385901-001,VRC2400,VRC4500,NRC5000,WL3004,387008451,1550.00,LA5000,WL1000,385911-015,1520.00,387009925,OW4002,385910-043,387010178,387010179,NRC2400,1505.00,38701 0181,1264.00,1155.00,1104.00,VRC1200,WW5001,387002779,NRC400,WW3001,1515.00,WL500,WL2000,387005774,387005598,OL4503,385912-029,NRC1200,385910-015

【产品】莱尔德热系统推出新一代制冷机Nextreme NRC400,温度控制精准,性能系数更高

莱尔德热系统(Laird Thermal Systems)推出的Nextreme NRC400是下一代台式循环冷却器,它利用固态热电技术为分析和工业设备提供精准的温度控制。

产品 发布时间 : 2022-05-18

【产品】莱尔德热系统热电冷却器NRC400 Nextrem™,采用便携式设计,实现温控精度±0.05°C

NRC400 Nextrem™性能冷却器基于高性能热交换器技术,质量上乘,性能优越。通过利用下一代热电冷却器,NRC400 Nextrem™ 在稳态条件下提供400瓦冷却能力,实现温控精度±0.05℃。

产品 发布时间 : 2023-01-02

Laird Thermal Systems(莱尔德热系统)TEA和温度控制器选型指南

描述- Thermoelectric cooler assemblies are compact units that control the temperature of a wide variety of applications, such as laser diode packages in active optics, lasers in medical and industrial instrumentation, electronic enclosures, sample storage chambers in medical diagnostics and analytical instruments and batteries in various automotive and telecom applications.

型号- LA-045,DA-075-24-02-00-00,DA-034-24-02-00-00,AAC-050,LA-160,DA-014-12-02-00-00,AA-150-48-44-00-XX,AA-200-48-22-00-00,DAT-105-24-02-00-00,SLA-400,AA-200,DAT-040-12-02-00-00,AA-060-12-22-00-00,AA-100-,AAT-032-12-22-00-00,AA-040-24-22-00-00,DAT-065-24-02-00-00,DA-115-24-02-00-00,LL-120-24-00-00-00,AA-200-24-22-00-00,SDAX-135-24-02-00-00,Q SERIES,AA-150-24-44-00-XX,SLA-400-24-02-00-00,SAAX-215,DA-044-24-02-00-00,DL-210,DL-120-24-00-00,DA-045-24-02-00-00,SLAX-140,AA-150-24-22-00-00,385901-001,DA-024-24-02-00-00,AAT-027,SAAX-175,LA-115-24-02-00-00,AA-250-24-44-00-XX,ATT-027-12-22-00-00,AAT-085-12-22-00-00,LA-024-12-02-00-00,LA-045-12-02-00-00,QE-50,SAAX-175-24-22-00-00,DL-060,DA-280-48-02-00-00,NRC400,AA-480,SDAX,DA-160-24-02-00-00,387006702,AA-230,387006704,387006703,387006706,SR-54,387006708,SAAX-115-24-22-00-00,DA-075-12-02-00-00,LL-060-12-00-00-00,387006707,ATT-055-24-22-00-00,AA-024-12-22-00-00,LA-075-24-02-00-00,DAT-029-12-02-00-00,DAC-035-12-02-00-00,SLAX-215-24-02-00-00,AAT-055-12-22-00-00,DA-033-12-02-00-00,AA-100-24-22-00-00,DA-034-12-02-00-00,387004253,DL-060-24-00-00,DA-025,DAT-065-12-02-00-00,AA-230-48-D44-00-XX,DAT-105-12-02-00-00,AA-040-12-22-00-00,DA-280-24-02-00-00,AA-070-24-22-00-00,QC-50,DA-135-24-02-00-00,AA-060-24-22-00-00,DAC-060-24-02-00-00,NRC400-T0-00-PC1,AA-250-48-44-00-XX,AA-250,SDAX-220-24-02-00-00,AA-019-12-22-00-00,LL-210-24-00-00-00,AA-100-48-44-00-XX,PR-59,PR SERIES,DA-044-12-02-00-00,DA-045-12-02-00-00,AAC-050-24-22-00-00,X SERIES,AA-150,DA-024-12-02-00-00,AA-100-24-44-00-XX,DA-045,AAT-085-24-22-00-00,AA-230-24-D44-00-XX,AA-200-48-44-00-XX,DA-011-05-02-00-00,DA-280,LA-024-24-02-00-00,LA-160-24-02-00-00,LL-060,AA-480-24-44-00-XX,SLAX-215,SDAX-220,SAAX-140,AA-040,LA-045-24-02-00-00,SLAX-145-24-02-00-00,AA-200-24-44-00-XX,LL-210,AA-024-24-22-00-00,DL-210-24-00-00,AA-034-12-22-00-00,AA-480-48-44-00-XX,DL-060-12-00-00

Laird Thermal Systems Offers Eco-Friendly Temperature Stabilization Solutions for OEMs’ Climate Action Goals

Laird Thermal Systems offers eco-friendly temperature stabilization solutions for various industries, moving away from high-GWP refrigerants like R134a and R404A. Their refrigerant-free thermoelectric coolers and chillers with natural refrigerants like R-290 provide sustainable alternatives, complying with environmental regulations and reducing GWP. Laird‘s Nextreme Series chillers and NRC400 thermoelectric chiller deliver efficient cooling without ozone depletion or global warming potential, supporting climate change initiatives.

产品 发布时间 : 2024-09-20

Thermoelectric Cooler Assemblies & Temperature Controllers

型号- TUNNEL SERIES,DA-075-24-02-00-00,POWERCOOL SERIES,DA-034-24-02-00-00,POWERCOOL,AAC-050,SUPERCOOL SERIES,DA-014-12-02-00-00,AA-150-48-44-00-XX,AA-200-48-22-00-00,DAT-105-24-02-00-00,SLA-400,AA-200,DAT-040-12-02-00-00,SLA-140-24-02-00-00,AA-060-12-22-00-00,AA-100-,AAT-032-12-22-00-00,AA-040-24-22-00-00,DAT-065-24-02-00-00,DA-115-24-02-00-00,CASCADE SERIES,387000639,LL-120-24-00-00-00,AA-200-24-22-00-00,AA-150-24-44-00-XX,SLA-400-24-02-00-00,SAA-170-24-22-00-00,DA-044-24-02-00-00,DL-210,DL-120-24-00-00,DA-045-24-02-00-00,AA-150-24-22-00-00,387000624,DA-024-24-02-00-00,OUTDOOR COOLER SERIES,AAT-027,LA-115-24-02-00-00,AA-250-24-44-00-XX,ATT-027-12-22-00-00,AAT-085-12-22-00-00,LA-024-12-02-00-00,LA-045-12-02-00-00,QE-50,387000612,DL-060,DA-280-48-02-00-00,NRC400,387003326,387003325,AA-480,387003324,DA-160-24-02-00-00,TUNNEL,AA-230,SR-54,DA-075-12-02-00-00,LL-060-12-00-00-00,ATT-055-24-22-00-00,AA-024-12-22-00-00,LA-075-24-02-00-00,DAT-029-12-02-00-00,DAC-035-12-02-00-00,AAT-055-12-22-00-00,DA-033-12-02-00-00,AA-100-24-22-00-00,SDA-195,DA-034-12-02-00-00,SAA-170,387004253,DL-060-24-00-00,DA-025,SAA-110-24-22-00-00,DAT-065-12-02-00-00,AA-230-48-D44-00-XX,DAT-105-12-02-00-00,AA-040-12-22-00-00,DA-044 -12-02-00-00,DA-280-24-02-00-00,AA-070-24-22-00-00,LIQUID SERIES,QC-50,DA-135-24-02-00-00,AA-060-24-22-00-00,DAC-060-24-02-00-00,NRC400-T0-00-PC1,AA-250-48-44-00-XX,AA-250,AA-019-12-22-00-00,SDA-195-24-02-00-00,LL-210-24-00-00-00,AA-100-48-44-00-XX,PR-59,OUTDOOR COOLER,DA-045-12-02-00-00,DA-044-12-02-00-00,AAC-050-24-22-00-00,AA-150,DA-024-12-02-00-00,AA-100-24-44-00-XX,DA-045,SUPERCOOL,AAT-085-24-22-00-00,AA-230-24-D44-00-XX,SLA-205-24-02-00-00,SDA-130-24-02-00-00,CASCADE,AA-200-48-44-00-XX,DA-011-05-02-00-00,DA-280,LA-024-24-02-00-00,LA-160-24-02-00-00,LL-060,AA-480-24-44-00-XX,AA-040,LA-045-24-02-00-00,AA-200-24-44-00-XX,LL-210,LIQUID,AA-024-24-22-00-00,DL-210-24-00-00,AA-034-12-22-00-00,AA-480-48-44-00-XX,DL-060-12-00-00

Advanced Liquid Cooling for Rheometers

Rheometers are scientific instruments used for studying the stress-strain relationship of polymers, fluids, and other soft materials to understand their flow/deformation properties. Rheometers are applied in a wide range of applications, such as in the development of new materials, quality control, and process optimization. Any rheometer that operates at elevated temperatures or measures temperature-dependent material properties requires a cooling system to maintain a precise temperature during testing.

技术探讨 发布时间 : 2024-09-15

Nextreme™ Recirculating Chiller Platform

型号- VRC1200,VRC2400,VRC4500,NRC5000,NRC400,NRC1200,NRC2400,NRC2400-A1-20-ST1

MRC150/300 Benchtop Recirculating Chiller Specification and User Manual Rev 13

型号- MRC300_ _ _-HT-DV_,MRC300,MRC 150,MRC150,MRC 300

Laird Thermal Systems Expands Nextreme™ Performance Chiller Platform with New Thermoelectric-based Unit

This paper introduces the advantages of Laird Thermal Systems in the application of NCR series products in industrial fields and analytical instruments

产品 发布时间 : 2024-09-14

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

提供稳态、瞬态、热传导、对流散热、热辐射、热接触、和液冷等热仿真分析,通过FloTHERM软件帮助工程师在产品设计初期创建虚拟模型,对多种系统设计方案进行评估,识别潜在散热风险。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论