Risks of Channel Contamination and Cleaning Control Techniques in the Manufacturing Process of Liquid-Cooled Plates

As

the power density and heat generation of various electronic and power

products continue to rise, heat dissipation faces increasingly severe

challenges. Liquid cooling solutions are gradually becoming the

mainstream option due to their efficient heat dissipation, low energy

consumption, low noise, and high reliability.

Liquid cooling systems work by attaching cooling plates to battery packs (or other heat sources) and using circulating coolant to carry away the heat generated during operation. This heat is then transferred through one or more cooling circuit heat exchangers, ultimately dissipating the thermal energy of the energy storage system into the external environment.

Flanged style battery tray in BESS

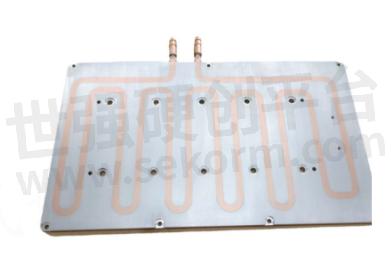

Cold plate in Solar inverter

As a core component of liquid cooling solutions, the liquid-cooled plate is an efficient heat dissipation component. Its primary function is to remove heat generated by the battery (or other heat sources) through the circulation of coolant, keeping the equipment operating within a safe temperature range. If the channels of the liquid-cooled plate are not clean, it can affect the uniformity of coolant flow. Larger foreign particles can block or impede coolant flow, leading to ineffective heat transfer and consequently impacting the heat dissipation efficiency and overall performance of electronic devices.

Moreover, if impurities remain in the channels, they may damage the oxidation protective film on the metal surfaces, causing corrosion or erosion of the liquid-cooled plate. Additionally, impurities in the channels can lead to poor component contact, potentially causing seal aging or damage, which increases the risk of leakage and affects the long-term stable operation of the system.

1-Cleanliness Requirements for Liquid-Cooled Plate Channels

Current energy storage liquid cooling solutions generally require that no foreign objects, aluminum chips, oil, or liquids are present in the channels. In some cases, specific quality requirements regarding the size of hard and soft particles may be defined.

2-High-Risk Contamination Phases in Liquid-Cooled Plate Manufacturing

During the processing and manufacturing of cold plates, the internal channels and cooling interfaces are particularly vulnerable. The manufacturing processes, including cutting and channel removal, can easily introduce foreign objects such as oil, cutting coolant, and machining chips into the channels. The machining operations occur at the channel entrances, making protection difficult, and once chips enter, they are hard to remove.

(Processing of Liquid-Cooled Plate Components: Channel Removal and Deburring)

After the processing of the cold plate channel, components such as plugs and water nozzles are welded to form closed channels. The channel structure is typically non-linear, which creates blind spots for flushing. After welding, the machining process requires a large amount of cutting coolant for the tools and workpieces, generating significant metal chips. This step is particularly prone to contamination from coolant, chips, and other pollutants, which are difficult to completely remove once they enter.

3-Cleaning and Protection of Liquid-Cooled Plate Channels

To ensure the reliability and performance of liquid-cooled plate components, strict cleaning operations are typically performed. High-pressure water jets are used to flush the internal channels of the liquid-cooled plate to remove any residues, particles, or other impurities. After flushing, the liquid-cooled plate components need to be dried to ensure no moisture remains in the channels.

(Processing of Liquid-Cooled Plate Components:flushing and degreasing)

If the cold plates and other liquid-cooled components are not adequately protected during manufacturing, they are susceptible to contamination from metal chips, oil, cutting coolant, etc., especially during the machining process. The handling process of the cold plates also easily allows foreign objects to enter. Generally, protective measures at the channel entrances are considered in advance, such as dust covers and rubber sleeves for water nozzles.

Thus, cleaning the internal channels of cold plates becomes a necessary measure to eliminate channel contamination and enhance channel cleanliness. In production practice, comprehensive preventive controls should be implemented throughout the process. Based on this, specific contamination control measures should be proposed for particular components and processes to effectively manage the contamination inside the cold plate channels.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由莫子若转载自Walmate Official Website,原文标题为:Risks of Channel Contamination and Cleaning Control Techniques in the Manufacturing Process of Liqui...,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

SUPU‘s Energy Storage Connector Products Shape Zero-carbon Future

SUPU, as a total solution provider of electrical connectivity, specializes in providing customers with safe and reliable energy storage connector products and solutions that are used in various energy storage system environments. With superior technology and full production capacity, SUPU‘s products are widely used by major energy storage customers.

GRL DNESS Energy Storage Fuses—The Reliable Guardian of High-Current Protection

GRL‘s DNESS Energy Storage Fuses are specialized protective devices for Energy Storage Systems (ESS), offering robust overcurrent protection. Unlike traditional fuses, they handle high voltage and current demands, especially in DC environments. GRL‘s DNESS series simplifies solutions, enhances reliability, and is cost-efficient, supporting the future of ESS across various sectors.

Get the Most out of Solar Inverter with Vincotech’s 300A Three-level NPC Module

Get the most out of your solar inverter with Vincotech’s three-level NPC module. The integrated on-board capacitors enable higher DC-Link voltages and smaller passive components by reducing 40% the voltage overshoot.

Trend towards Liquid Cooling Systems

A liquid-cooled system is a hydraulic circuit that typically consists of a cold plate that interfaces with a heat source in a device, hoses, and pumps that circulate fluid through the system, and a heat exchanger that rejects heat into the ambient environment. These integrated systems provide highly efficient cooling capable of keeping high-power applications running reliably at peak performance; however, there are some limitations.

ITT储能产品介绍 (ITT Energy Storage products introduction)

描述- 本资料介绍了ITT公司在储能产品领域的解决方案,包括分布式储能和集中式储能解决方案。详细介绍了单芯大电流连接器、堆叠连接器、液冷连接器和通信连接器与线缆产品。资料还涵盖了产品特征、优势、参数和订购指南,旨在为用户提供全面的储能连接解决方案。

型号- 132089-2006,132089-1841,132089-0102,132089-1821,IESSC1012-PAK1A-(2X),132089-1141,132089-2022,132089-2012,132089-2013,132089-1221,132089-1541,132089-0203,132089-2005,132089-1521,132089-0202,132089-0103

新能源系统电路保护-太阳能、风能逆变器、PCS、BESS赛尔特过压、过流、过温产品保护解决方案

描述- 该资料介绍了厦门赛尔特电子有限公司提供的新能源系统电路保护解决方案,涵盖了太阳能、风能和储能系统等多个领域。资料详细阐述了不同类型逆变器系统(如集中式、组串式、微型逆变器系统)的电路保护产品,包括过温、过电压和过电流保护等。此外,还介绍了针对BESS储能系统的保护方案,以及相关产品的特点和优势。

型号- SMBJ,THU145,LFR15XL2,LFR15XL3,SMDJ,SD25TXXXL306,SP0080TBLC,TKS150,AYH,TG125C,TZ231A,TFMOV25M,SCF6125,SD20RXXXA404,TZ091A,SCF1032,RSK140,5.0SMDJ,LFR15 690 VAC,SD25TXXXA203,SMCJ,SD25TXXXA404,SFV20D,ALW125,SD25TXXXL211PV,LFR15,TFMOV20M,TKT150,TFMOV10M,MTP1560,TRR150,RJ,SX091,SD25TXXXL312PV,8.0SMDJ

Energy Storage Market for UAVs by Product and Geography - Forecast and Analysis 2022-2026

The “Energy Storage Market for Unmanned Aerial Vehicles (UAVs) by Product and Geography - Forecast and Analysis 2022-2026“ report has been added to Technavio‘s offering.

What are ESS DC Energy Storage Fuses?

The DC energy storage fuse is a critical component in ensuring the safety and reliability of modern energy storage systems. By providing fast-acting protection against overcurrents and short circuits, these fuses help maintain the integrity of energy storage systems in various applications, from residential solar setups to large-scale industrial energy solutions.

Bringing Network Transformers, Photovoltaic Energy Storage Transformers and More, Mentech Announced a Distribution Agreement with Sekorm

Mentech signed an distributor agreement with Sekorm, authorizing Sekorm to represent its network transformers, photovoltaic energy storage transformers, power inductors and other products. The relevant information and product information of Mentech has been launched, and you can get relevant information by searching.

Key Points in Designing Aluminum Profiles Used in New Energy Vehicles and Energy Storage Battery Packs

The battery pack is a key component of new energy vehicles, energy storage cabinets and containers. It is an energy source through the shell envelope, providing power for electric vehicles and providing consumption capacity for energy storage cabinets and containers. In combination with actual engineering needs, this article summarizes the key points of profile design for battery packs by analyzing the requirements of mechanical strength, safety, thermal management and lightweight of battery packs.

WIMA PowerBlocks Energy Storage Solutions with Long Lifetime >90,000 Hours

The design of the WIMA PowerBlock energy storage modules has from the beginning been developed to fulfill the requirements in mobile heavy duty applications. Modular design allowing the flexibility to fit the product into application needs. Designed especially for highly cyclical loads in heavy mobile work machines.

太阳能逆变器和电池储能系统(Bess)

描述- 本文档探讨了太阳能逆变器与电池储能系统(BESS)的架构和应用。内容包括不同类型的太阳能逆变器拓扑结构及其应用场景,如微型逆变器、串式逆变器和中央逆变器。此外,还分析了太阳能逆变器市场和BESS市场的增长趋势,并介绍了Littelfuse公司在这些领域的解决方案和产品组合。

型号- KLC,SMBJ,LSIC2SD065C10A,LSIC2SD065N80PA,TMOV,LSIC2SD065A20A,LSIC2SD065C06A,L50QS,LSIC2SD065A16A,LSIC1MO120T160,LSIC2SD120C05,501A,X3-CLASS,AQ05C,LSIC2SD120C08,MHS,LSIC2SD120D20,EL731,GEN2,LSIC2SD065D20A,SPXI,LSIC2SD065E40CCA,LSIC2SD065D16A,SP2555NUTG,SMF,L60S,RA,IXGT6N170,RB,881,LSIC2SD120D15,521,885,LSIC2SD170B25A,SP3130,LSIC2SD065E16CCA,LSIC2SD120E40CC,LSIC1MO120E0040,LSIC1MO120E0160,SPXV,SM20,SE-601,LSIC2SD120D10,LSIC2SD065A06A,CNN,SPD2 PV,SMDJ,LSIC2SD065A10A,SM712,LSIC2SD065C08A,L70QS,LSIC2SD170B50A,SD,LSIC2SD170B10A,KLKD,LSIC2SD120A20,LSIC2SD120E10CC,LSIC1MO120G0040,MS7H1500C,LSIC1MO120G0160,LSIC2SD065D10A,LSIC2SD065B32A,JLLN,LSIC2SD065B20A,SMCJ,KR,IXTH3N150,IX4340,LSIC2SD065D06A,LSIC2SD065B16A,L50S,LSIC2SD065N128PA,LSIC2SD120A15,LA,AQ24CAN,LSIC2SD120A10,LSIC2SD065A08A,LSIC2SD065N40PA,MLA,TPSMA6L,L25S,SPF,SPXIXXXTXB,SZ1SMB,LSIC2SD120A05,LSIC2SD120E15CC,LSIC1MO170E1000,LSIC2SD065E32CCA,SZ1SMA,LSIC1MO120T080,LSIC2SD120A08,LSIC1MO120G0025,LFNH,LSIC2SD120E30CC,LFJ1000,438,LSIC1MO120T120,ULTRAMOV,USP16673,LSIC2SD065B10A,441A,LSIC2SD065D08A,SP712,PSR,LSIC1MO170T0750,440,LPHV,LSIC2SD065E12CCA,PSX,LSIC1MO120E0120,IX4351NE,AF0100,LSIC1MO120E0080,L15S,SZP6SMB,LSIC2SD065E20CCA,LFPXV,LSIC2SD065C20A,SPFI,SPFJ,LSIC2SD065C16A,438A,SPXVXXXT-,LSIC1MO120G0120,215,LSIC1MO120G0080,TLS,LSIC1MO170H0750,P6KE,TPSMC,TPSMB,L70S,SPNH,466,LSIC1MO120E0025,LSIC2SD065B40A,MS3H100C,LSIC2SD120E20CC,LSIC2SD120C10

Advanced Battery Energy Storage Systems (BESS) Solutions: Parker Chomerics 6.0W/m-K THERM-A-FORM CIP 60

Parker Chomerics introduced THERM-A-FORM CIP 60, a two-component (2k) dispensable thermal gap filler and cure-in-place material with 6.0 W/m-K thermal conductivity. With a Shore 00 hardness of 50 at full cure, it is designed to be an alternative to hard-curing dispensable materials. Lower hardness means that CIP 60 can serve as a vibration dampening agent and also simplify the reworking process.

登录 | 立即注册

提交评论