Introduce What is Battery Connectors

1.What is the size, current and voltage rating of this connector?

Battery connectors are essential components in electrical systems that facilitate the connection between batteries and various devices or circuits. These connectors come in a wide range of sizes, current ratings, and voltage ratings to accommodate different applications and requirements.

Battery connectors are available in various sizes, ranging from small connectors for portable devices to larger connectors for automotive or industrial applications. The size of the connector is often determined by factors such as the space available for installation and the current-carrying capacity needed for the application.

In terms of current rating, battery connectors are designed to handle different levels of electrical current based on the specific application requirements. The current rating of a connector is a crucial factor to consider to prevent overheating or damage to the connector due to excessive current flow. Battery connectors can have current ratings ranging from a few amps for small devices to hundreds of amps for high-power applications.

Similarly, battery connectors are designed to operate within specific voltage ranges to ensure safe and reliable performance. The voltage rating of a connector indicates the maximum voltage that can be safely applied across the connector without causing electrical breakdown or insulation failure. Battery connectors are available with voltage ratings ranging from low voltages for consumer electronics to high voltages for industrial or automotive systems.

When selecting a Battery Connector, it is important to consider the size, current rating, and voltage rating to ensure compatibility with the battery and the connected devices. Choosing a connector with the appropriate size, current rating, and voltage rating is crucial to maintaining the safety and efficiency of the electrical system.

In conclusion, battery connectors play a vital role in establishing secure and reliable connections between batteries and electronic devices. They are available in various sizes, current ratings, and voltage ratings to meet the diverse needs of different applications. By selecting the right battery connector based on size, current rating, and voltage rating, users can ensure the safe and efficient operation of their electrical systems.

2. Are there different socket types to choose from?

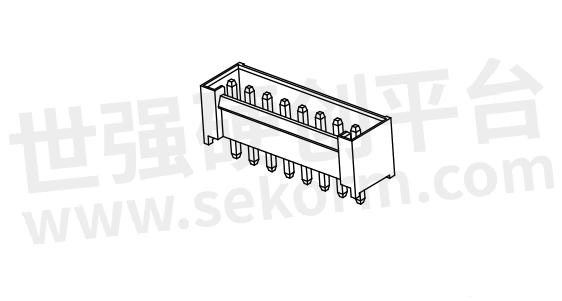

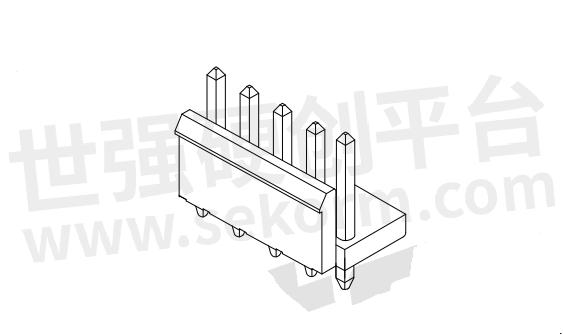

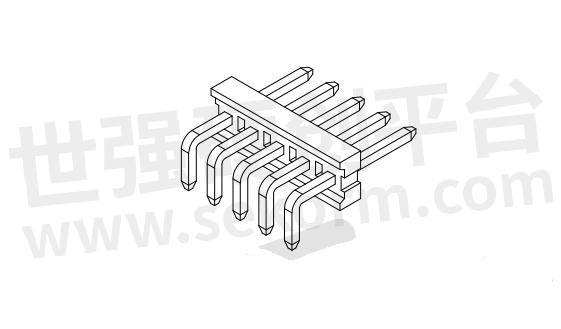

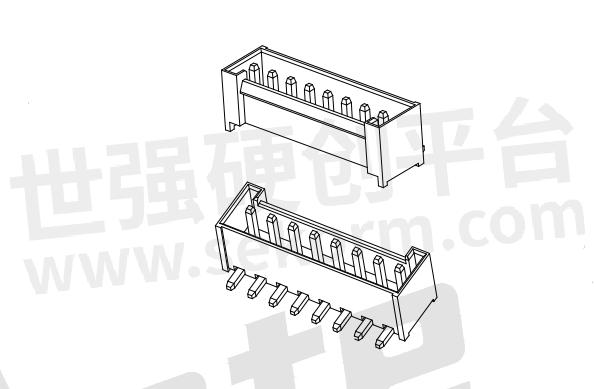

Yes, there are different socket types available for battery connectors, allowing users to choose the most suitable option for their specific application. These socket types differ in terms of their design, features, and compatibility with different battery sizes and configurations. Here are some common socket types for battery connectors:

Blade or tab sockets: These sockets feature flat, blade-shaped contacts that provide a reliable connection with corresponding tabs on the battery. Blade sockets are widely used in consumer electronics, such as laptops and smartphones.

Pin sockets: These sockets have cylindrical or pin-shaped contacts that mate with corresponding pins on the battery. Pin sockets are commonly used in applications that require a high current-carrying capacity, such as electric vehicles and industrial equipment.

Snap-in or snap-on sockets: These sockets have a spring-loaded design that allows for quick and easy installation and removal. Snap-in sockets are commonly used in applications where batteries need to be replaced or interchanged frequently, such as in portable devices and medical equipment.

Screw terminals: These sockets feature screw-type connections that provide a secure and adjustable connection with the battery. Screw terminals are often used in applications that require a high level of reliability and vibration resistance, such as in automotive and marine systems.

SMT (Surface Mount Technology) sockets: These sockets are designed for surface mount PCB (Printed Circuit Board) assembly. SMT sockets allow for easy and efficient integration into PCB designs, making them suitable for compact electronic devices.

Custom or specialized sockets: In addition to the standard socket types mentioned above, there are also custom or specialized sockets available for specific battery configurations or unique application requirements. These sockets are designed to provide a precise and secure connection, ensuring optimal performance and safety.

When selecting a socket type for battery connectors, it is important to consider factors such as the size and shape of the battery, the desired level of connection reliability, and any specific requirements of the application. By choosing the right socket type, users can ensure a secure and efficient connection between the battery and their devices or circuits.

3. Main purposes and application areas

Battery connectors play a crucial role in establishing a secure and reliable connection between batteries and various electronic devices or circuits. They are essential components in a wide range of industries and applications due to their versatility and utility. Here are some of the main purposes and application areas of battery connectors:

Consumer Electronics: Battery connectors are commonly used in consumer electronic devices such as smartphones, laptops, tablets, and cameras. They provide a convenient and reliable way to power these devices and enable easy battery replacement when needed.

Automotive Industry: Battery connectors are essential in automotive applications for connecting batteries to various electrical systems in vehicles. They are used in cars, trucks, motorcycles, and other types of vehicles to ensure proper power distribution and functionality of electronic components.

Industrial Equipment: Battery connectors are widely used in industrial equipment and machinery to power control systems, sensors, and other electronic components. They help ensure a stable and secure power connection in industrial settings where reliability is crucial.

Renewable Energy Systems: Battery connectors are integral components in renewable energy systems such as solar panels and wind turbines. They facilitate the connection between batteries and the energy storage systems, enabling the storage and utilization of renewable energy sources.

Medical Devices: Battery connectors are used in various medical devices and equipment, including patient monitors, infusion pumps, and portable diagnostic devices. They provide a reliable power source for critical medical applications where accuracy and consistency are paramount.

Aerospace and Defense: Battery connectors play a vital role in aerospace and defense applications, where they are used in aircraft, satellites, communication systems, and military equipment. They ensure a secure and durable connection in demanding environments and high-performance systems.

Telecommunications: Battery connectors are essential in telecommunications infrastructure for powering communication equipment, data centers, and networking systems. They help maintain uninterrupted power supply and enable efficient data transmission in telecommunication networks.

In conclusion, battery connectors are versatile components that find widespread applications across various industries and sectors. Their main purposes include establishing reliable power connections, enabling easy battery replacement, and ensuring the efficient operation of electronic devices and systems. By choosing the right battery connectors for specific applications, users can achieve optimal performance, safety, and longevity in their electrical systems.

4. How durable and reliable is it?

Battery connectors are known for their durability and reliability, making them a crucial component in various electronic systems and applications. The durability of a battery connector is often dependent on factors such as the materials used in its construction, the design of the connector, and the quality of its manufacturing process.

Battery connectors are typically made from materials that are chosen for their strength, conductivity, and resistance to environmental factors such as temperature, moisture, and corrosion. Common materials used in battery connectors include copper, brass, and various types of alloys that offer excellent electrical conductivity and mechanical strength. These materials are selected to ensure that the connectors can withstand the rigors of daily use and maintain a stable electrical connection over time.

The design of battery connectors also plays a significant role in their durability and reliability. Connectors are often engineered to provide a secure and snug fit between the battery and the device or circuit they are connecting to. This ensures that the connection remains stable even in high-vibration environments or under mechanical stress. Additionally, features such as locking mechanisms, strain relief, and insulating materials help to protect the connector from damage and prevent electrical failures.

Manufacturing processes for battery connectors are designed to meet stringent quality standards to ensure consistency and reliability. Connectors are often subjected to rigorous testing procedures to verify their performance under various conditions, such as temperature extremes, mechanical stress, and electrical load. This helps to ensure that the connectors meet or exceed industry standards for durability and reliability.

Overall, battery connectors are designed to provide a long service life and reliable performance in a wide range of applications. Their durability and reliability make them a preferred choice for powering electronic devices, industrial equipment, automotive systems, and other critical applications where a secure and stable connection is essential. By selecting high-quality connectors that are well-designed, made from durable materials, and manufactured to exacting standards, users can expect to achieve consistent and dependable performance from their electrical systems.

5. How does it work?

Battery connectors are essential components used to establish a secure and reliable electrical connection between batteries and various electronic devices or circuits. They play a crucial role in ensuring the efficient transfer of electric power from the battery to the device.

The working principle of a battery connector involves the use of conductive materials and a specific design to create a reliable electrical pathway. The connector consists of two main parts: the male connector and the female connector.

The male connector, also known as the plug or pin, features metal pins or blades that serve as the positive and negative terminals. These pins are designed to match the corresponding terminals on the battery. The female connector, also known as the socket or receptacle, contains metal sockets or slots that align with the pins on the male connector.

When connecting a battery to a device, the male connector is inserted into the female connector, ensuring proper alignment of the pins and sockets. As the connectors are joined, the pins make contact with the sockets, establishing an electrical pathway for current flow. The connection is typically secured through features like locking mechanisms or frictional force to prevent accidental disconnection.

The conductive materials used in battery connectors, such as copper or brass, enable the efficient transfer of electric current. These materials offer excellent electrical conductivity, minimizing resistance and voltage drop. This ensures that the power supplied by the battery reaches the device with minimal loss.

Additionally, battery connectors may incorporate additional features to enhance their functionality and reliability. For example, some connectors may have insulation materials or insulating barriers to prevent accidental short circuits or electrical shocks. Others may have strain relief components to protect the connection from mechanical stress and prevent cable damage.

The working of battery connectors is designed to be simple, efficient, and safe. They provide a reliable and secure connection that allows for the transfer of power from the battery to the device or circuit. The proper functioning of the battery connector is crucial for the overall performance and longevity of the electronic system.

In conclusion, battery connectors play a vital role in establishing a reliable electrical connection between batteries and electronic devices. Through the use of conductive materials and a well-designed interface, they ensure the efficient transfer of electric power. The connectors are designed to be secure, durable, and easy to use, making them essential components in a wide range of applications.

6. How to install and use?

Installing and using battery connectors is a simple process that requires attention to detail and proper handling. To ensure a successful installation and optimal performance, the following steps should be followed:

Pre-installation preparations:

Ensure that the power source is disconnected and the device is turned off to prevent any accidental electrical shocks or damage.

Inspect the battery connectors for any visible damage, such as bent pins, loose connections, or corrosion. If any issues are detected, replace the connectors with new ones before proceeding.

Verify the compatibility of the connectors with the battery and the device they will be connected to. Make sure the connectors are the correct size and type for a proper fit.

Installation process:

Identify the positive (+) and negative (-) terminals on both the battery and the device. Usually, the positive terminal is indicated by a "+" symbol, while the negative terminal is indicated by a "-" symbol.

Align the male connector (plug or pin) with the female connector (socket or receptacle) and insert the pins into the corresponding sockets. Ensure that the pins are properly aligned before inserting them.

Gently push the connectors together until they are fully engaged. Be careful not to use excessive force, as this can damage the connectors or the terminals.

If the connectors have a locking mechanism, such as a latch or a screw, use it to secure the connection and prevent accidental disconnection. Ensure that the locking mechanism is properly engaged.

Usage considerations:

Avoid applying excessive force when connecting or disconnecting the battery connectors. Excessive force can damage the pins or sockets, leading to poor electrical contact and potential connection failures.

Route the cables and wires appropriately to prevent strain on the connectors. Use cable ties or strain relief components if provided to ensure cable stability and prevent damage to the connectors or cables.

Keep the area around the connectors clean and free from dust, dirt, or any other contaminants. These can interfere with the proper functioning of the connectors and compromise the electrical connection.

Regularly inspect the battery connectors for any signs of loose connections, corrosion, or damage. If any issues are found, promptly replace or repair the connectors to maintain a reliable and secure connection.

Follow the manufacturer's recommendations for specific cleaning and maintenance procedures if applicable. This can help ensure optimal performance and extend the lifespan of the connectors.

By following these installation and usage guidelines, battery connectors can be installed and used effectively, providing a reliable and secure electrical connection. Always prioritize safety and attention to detail when handling battery connectors to avoid any potential issues or failures.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由梨花落风转载自ANTENK Official Website,原文标题为:What is battery connectors ?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

What are the Three Common Connectors?

Connectors are essential components in various electronic systems, enabling the transfer of power, data, and signals between different devices. Whether in consumer electronics, industrial machinery, or automotive applications, connectors ensure reliable connections and efficient system operation. In this article, we will explore the three most common types of connectors used in electronics: USB connectors, HDMI connectors, and SMA connectors.

Common Automotive Connector Types and How to Use Them

In modern vehicles, automotive connectors are crucial components that ensure smooth and safe operation by linking electrical systems. With advancements in vehicle electronics, selecting the right connectors can make a big difference in terms of performance, reliability, and safety. This guide covers the various types of automotive connectors, their features, and tips on choosing the right connectors for specific applications.

What is D Sub Connectors Right Angle Mount ?

D Sub Connectors Right Angle Mount are versatile, durable connectors available in various sizes and socket types, offering secure and reliable connections between electronic devices and systems. They are widely used in industries such as industrial machinery, telecommunications, computers, and automotive systems due to their high performance, including high current and voltage handling, low resistance, and minimal signal loss. Antenk Electronics produces a range of UL-certified connectors meeting EU environmental standards.

Nextron‘s 1000BASE-T1 Automotive Ethernet Solution:4 way SPE circular connectors

Nextron’s SPE products are one of the very few 4 way SPE circular connectors available on the market. It can support up to 1000Base-T1 (1Gbit/s) with 15m UTP unshielded/40m STP shielded cable.

AIMMET(祥峰实业)FAKRA SMB车用连接器选型指南

描述- The AIMMET connectors are specially designed for automotive applications. They are based on the SMB connector interface and comply with the DIN and UScar car standard.

型号- 3666NTGXXE2,3901NTGXXD1,3658NTGXXC1,3661TTG00C4,8011,5021,3663NTGXXDD,3640,3002,3614TTG00I1,3651NTGXXK5,4301NTYXXE1,4902TTG00C2,3638,3639,4102NTGXXC1,3631,3859NTGXXE1,3632,3633,3634,3635,3636,3637,3661TTG00B5,6002,3601NTGXXA1,3617NTGXXL1,4903TTG00C2,3641,3642,3615TTG00K1,3813TTG00Z1,9001,3664NTGXXC1,9005,3671TTG00G1,3662NTGXXG1,3679TTG00D1,3815TTG00E1,4302NTYXXB1,3659NTGXXZ1,3699NTG00Z1,3807TTG00C1,4303NTYXXL1,4003,3811NTGXXB1,3677TTG00A3,1001,3623NTGXXC2,6019,3680TTG00Z1,3701,3657NTGSPF1,3643TTG00C1,3667NTGXXA2,3660NTGXXI1,3670TTG00I1,3601NTG26A1,3604TTG00K3,3812NTGXXZ1,3675TTG00B4,3673NTGXXC1,3604TTG00L2,3611NTGXXG1,3614TTG00F3,3604TTG00D1,36030,3610TTG00F1,3602,1027,3676TTG00Z1,3602NTGXXB1,3665NTGXXK2,3656NTGXXE1,3807TTG00G3,3604TTG00E6,3701NTGXXK5,3606TTG00Z2,2003,3610TTG00C7,4101NTGXXZ1,3808NTGXXF1,3624NTGXXB3,3610TTG00C8,3618TTG00D1,3668GTG00Z1,3603NTGXXC2,3654NTGXXB2,3669TTG00C1,3655NTGXXD1,7031,3626,3625,3622,3621,5005,3612TTGXXH1,3858NTG14Z1,3629,3628,3627

ILME(意尔玛)工业用多极连接器选型指南(英文)

目录- Company Profile Practical Advices for Consulting the Catalogue Multipole Connectors Introduction Industrial Multipole Connectors Inserts Industrial Multipole Connectors MIXO Inserts Industrial Multipole Connectors Enclosures Industrial Multipole Connectors Accessories Appendix

型号- CZAP 25 LS221,CQEE SERIES,CSHF 06,CHI 16 YC,CAP 16 CP29,CFV 32G,TMAV 10 G25,CGI 24 SERIES,CL POF SC,CHV 32.42,MZOW 25 L25,CHPW 48 LS,CHCS 06 SL,MZOW 25 L20,CSAH-SQUICH® SERIES,CAV 16 G29,CYG 06H1010,CNE 06,CKAW 03 V,RVP 06 L20,CMSH,CMSE,CAV 16 X29,MAV 10 YX40,CR 16 SC,TAPW 24.40,MAV 10 YX32,CYG 06H1006,CKAXW I,MAOR 06 L32,CGC 06 B,CDFA 1.0,CX 01 YF/M,CFV 06 LG29,CGO 24.36,CQ 05 SERIES,CKA 03 VGS,CHPR 48 LS,MK VA20,CGO 10.21 B,CFV 06 LG21,CHP 50.21,MAV 16 X32,MZ7PE 25L225,CNE 24,CC..AN,MGV 24.32 B,CDFA 1.5,CL 230 SC,CWH J6 10MA,CR 16 SS,CR 16 ST,CZOW 15 L,CCM2D 4.0,MAV 16 G25,MGV 16.225 B,TMAV 10 G32,CHP 50.29,CKA 03 C,CYR 16.3,CNE 16,CTSF 40 R,CKA 03 I,CVP 24 LS,CKAXW 03 IA,RQEE SERIES,CNE 10,CTSF 40 L,MAV 16 X40,MZAOW 25 L25,CW 5 JM4/2,CVP 24 LP,TMAP 10.25,CZ7I 25 LS,CAP L,TCHC 16 G,CAV 16.21,CVP 24 L2,MAP 24 CP240,CAV 16.29,TCHC 16 S,RX 12/2,MFVE 16.32M,CWKA 10 J2M8,CHCN 06 LG,MAV X,MHP 32 L40,CGO 24.29,CAP 06 L229,CGO 24.21,CX 08 B,MFVN 24.32,MAV G,CX 08 C,CKAXR 03 IA,MAV L,MAPS 06 L32,MZ7P 15 LS225,MAP 24 CP232,CSH ... S SERIES,CHVR 10,MHPW 32.50,CCFD 1.0,MKAX IAP25,MHVR 16.25,CLK 04 SC,CHVR 16,AT 8IFT,MVAV 16 G32,CCFD 1.5,CX 12/2,CHP 32 L42,CQ 08 C,MZV 25 LG20,CDMA 1.5,CDMA 1.0,CKX IA,CZAP 25 LS2,MGI 16 SERIES,MKAX IAP20,TAPH 24.32,CGP 06.29,MHP 10.220,CHVR 24,CQ 08 V,TAPH 24.40,TMAP 10.32,CHPX 32 L,CAP 24 CS2,CQ 08 I,MAOE 06 L32,CHP 32 L29,CBC 06 L,MVAV 16 G25,CWC J5 10M,CK 03 VS,CW 1 J2M87,CR 25 AD2,CR 25 AD1,CX 02 P SERIES,MAOE 24.40,CQEEF 64,CHOR 06 L13,CNEF 24 RYN,CHO 48 L42,MFO 06 L32,CAV 16 GYC21,CWH J6 0.5M,RVP 24 L25,CX CFM,MVFV 10 LG25,MAOE 24.32,MBV 24.50,TAPC 06 L32,AVC 24 G32,MHV 10 LG25,CHP 50 CS2,CSH SERIES,MFV 16 GYC25,MHVE 24.25M,MFO 06 L40,CVFV LG,MVAP 06 LS40,MHP 32 L50,MBV 24.40,CAP 24 CP2,CQV 24,MGOE 24.32,CDD 24,CHPX 32 L29,MFV 16 GYC32,CWC J5 15M,CQEEF 40,MAP 10 CS240,TCH SERIES,CKAXW 03 AP,MHOE 16.32M,CHC 06 LG,CAV 16 GYC29,CC 2.5 AN,MGOE 24.40,THCC LG,CVP LP,MAP 10 CS232,CKAX 03 VGS,CHC 06 LC,MFV 16 GYC40,CKX VG,CAP 24 L229,CVP LS,MAV 16 G32,CFV 24 L21,CYPZ LOC,MGOE 24.50,MHVW 16.25,CDD 42,CNEF 16 TXN,C7IE 10,CDD 38,MHO 24 X25,CKA 03 VAS,MVP 16 LP25,MAV 16 LG25,CNE 48,C7IE 16,CAV 16 YX21,MZFO L,CPT 24,CLDL DD,CAV 16 YX29,MAP 06 L40,CR K04R,CKAXR 03 AP,MHV 10 L25,RHV 16 L32,CVI LSP,CKA ILSA,MAV 16 G40,CVAP 24 LS,C7IE 24,MHV 32 L40,MVAP 24 LS32,CFV 24 L29,CNE 32,MHV 10 L20,CNEM 10 RY,MHO 24 X32,CR K04G,CAF 16.221,MGV 06.32 B,MKAX AP20***,CZAO 15 L21,CDCM 16,CR..CX,CDCM 10,CH1ES,MAV 24 YX32,CLK 04 SCF-H,MVFV 10 LG32,TAPC 06 L25,MHP 16 CS25,MVAP 06 LS32,CZFV 25 L16,CHO 48 L29,MVAP 24 LS40,CDMJD 1.5,CZAOW 15 L21,CHP 32.2,CDMJD 1.0,MAV 16 LG40,CKA APS,CKR 65D,MHO 16.32,CAP 10.29,MHVW 16.32,CR 15/16,CAP 10.21,CKAX 03 IA4*,CZVW 25 L,MZVE 25 L20,RDF2D 1.5,CKX 03 IAP,RDF2D 1.0,MAV 16 LG32,CZAO 15 L16,CHI 50 CS,CR 20 D,CZFV 25 L21,MVAP L,MHO 16.25,CSHM 24 SN,MAV 10.220,MAO 50.32,CR 16 AT,CHO 06 LX16,CBC 24,MFV 32 LG40,MKAXXS IAP25,MAP 10 CP232,CKAXW 03 I,CBC 16,MAVE 24.40,CW J5 15M,CHC 10 LG,CDSHF NC 06,CNEM 24 RYN,MFV 06 L32,MGPE 06.32,CVFV 16 LG29,CXFA 10,CX 7/10 CA,CZI 15 SERIES,CZ7IS 15 L,RDF2D 2.5,CAP 06 LS2,MHOR 16.25,MFV 06 L25,CYG 06H10,CHCS 16 S,MAO 50.25,CX7MA 10,CX7MA 16,MFON 24.32,M7AP 06 LS232,CZ7PW 15 L2,CHCS 16 G,CX 01 B SERIES,CHP 32 L,MVAP 10 L232,CHSDS,MHOW 16.32,MAP 06 L25,MHVE 24.32M,CGC 10 B,CCMJD 3.0,CHV 48 L42,MGVE 24.240,CYG 06H06,MHVW 32.40,CKAX CXA,MKAG,CX7MA 25,MVAP 10 L240,M7AP 06 LS240,C7A,CX 01G SERIES,CDSH-SQUICH®,C7AP 06 L229,MKAX,MAP 10 CP240,CQ4F 02 H,C7I,CCMA 2.5,CVAP 16 LS29,CGO 10.29 B,CHI 24 SERIES,MHOW 16.25,MAP 06 L32,CR 16 DF,MFV 06 L40,CQF 04/2,C7P,MGVE 24.232,RXM2D 6.0,TAVH 16 G40,CQ4M 02 H,MGV 16.25 B,CKAG VA,CIVES,THIH L,CXL 2/4 PMH,MAP 24 L40,MGV 24.50 B,CX 20 CF,CHIN 24,CTSEF 24 RN,COB 24 BC,MZFV 25 L220,CHV 48 L29,TAVH 16 G32,CR 16 FS,CX 20 CM,CK VS,CFF 24.21,CVP 16 L,CGV 24.21 B,CXL 2/4 SERIES,CFF 24.29,CX 02 BF/M,CQ 21 SERIES,CAP 10 L229,CSHF/M 16 S,CQM 04/2,CYD 70 C,CZ7IE 15 L,MKAXX AP,MVI 10 LAP32,MQ VO,CGO 10.16 B,MGO 10.32,CX 25 IF/M,MAP 10 CP32,CX 02 7F/M,MKAG V,CVFV 16 LG21,CFO 06 L21,CVP 10 LS2,CK 03 IAPS,MAOR 16.40,CFO 06 L29,CX 04 X SERIES,MAP 24 L32,CHIN 24 CH,CX 02 GFN,CHC C,MAVE 24.32,CHCW 16 S,MAP 10 CP40,CHIN 10,CW 15 J2M87,CHC G,CAP 10 L,CMSE SERIES,MZP LS,CHC L,CHIN 16,CHCW 16 G,MGO 10.25,CIV 24 YX36,MKAW VA,MHP 10 LS220,CHCE 16 S,CHVW 24 G,CX 25I,TAPC 24.32,CXL PM,CW 10 J2M4E,CVI 16 L,CHIN 06 L,CHI LCS,CHCE 16 G,CHO 16,MHPW 50.240,MZVW 25 L20 .,CZ7CW 15 LG,CIMD 0.2,CIMD 0.3,CHO 10,CFV 32,CIMD 0.5,MHV 24 LG32,CIMD 0.7,CAP 24 L29,MVFV 24 LG25,CHI 10 CH,CZP LS,TAPC 24.40,CYG 4/2 JFA,MAF 16.225,CGV 24.229 B,MQO 24.40,CW 7.5 J2M87,CCMD 0.5,CCMD 0.3,CHI LCP,CCMD 0.7,CZAV 15 L16,CZFO 25 L21,CHI 10 CP,CHC 10 SL,MAP 16 YC232,CHI 10 CS,CK 03 IAN,CGV 10.16,CKSHF 04,CZFO 25 L16,CKSHF 03,CW 1 SC9,MVFV 24 LG32,CG 06 FL,CDAF 10 X,MAP 24 CP32,CVAP 10 L29,CGV 10.29,CZAV 15 L21,MGI 10 SERIES,CVAP 10 L21,CGV 10.21,CVP 10 LP2,M7AP 06 L32,CDFD 0.5,CDFD 0.3,MHV 24 X25,CX 01 U SERIES,MAP 24 CP40,CDFD 0.7,CXL PF,CK...RY 04,M7AP 06 L40,CK...RY 03,

HFM® High-Speed FAKRA-Mini – is the Excellent Performing System of “Mini-Coax” Connectors for the Automotive Industry

Rosenberger HFM® - High-Speed FAKRA-Mini – the best performing system of “Mini-Coax” connectors for the automotive industry.

9155-000 BATTERY CONNECTORS Standard 2.5mm Pitch

型号- 9155 SERIES,9155,00915500X00X01X,00915500X05X01X,9155-000

AIMMET(祥峰实业)车用高速传输连接器选型指南

描述- AIMMET Industrial Co., Ltd. is formed in 1996 by a group of technicians and specialists that are devoted themselves to RF coaxial and Automotive Fakra connectors. Make communication together.

型号- 690203XXXXXX,530509XXXXXX,5801-H,690308XXXXXX,5801-A,5864-D,530502XXXXXX,5901-K,560303XXXXXX,5862-B,530905XXXXXX,560902XXXXXX,530309XXXXXX,5890-B,530208XXXXXX,5602021000AB,530902XXXXXX,560909XXXXXX,560205XXXXXX,530508XXXXXX,6902021000XX,530305XXXXXX,690803XXXXXX,5807-Z,5868-Z,560302XXXXXX,690302XXXXXX,5807-O,530908XXXXXX,5901-D,5302,530302XXXXXX,5303,560905XXXXXX,5305,530505XXXXXX,5308,5309,530803XXXXXX,5360,5361,5806-C,690208XXXXXX,5906-O,690303XXXXXX,530209XXXXXX,6902021000AB,5863-C,530805XXXXXX,560203XXXXXX,530809XXXXXX,530308XXXXXX,530802XXXXXX,5801NTG53A1,5906-Z,5302021000AB,560209XXXXXX,530303XXXXXX,690202XXXXXX,560903XXXXXX,560202XXXXXX,530503XXXXXX,5865-Z,530903XXXXXX,530909XXXXXX,690808XXXXXX,690802XXXXXX,530202XXXXXX,5806-K,530808XXXXXX,6601-Z

Reduced 2.5mm Pitch 9155-250 BATTERY CONNECTORS

型号- 00915500X25100X,00-9155-003-251-006,00-9155-002-251-006,00-9155-005-251-006,9155-250,00-9155-004-251-006

Application of FPC/FFC Connectors in Automotive Industry

The use of FPC/FFC connectors in the automotive industry is growing rapidly as vehicles become increasingly reliant on complex electronic systems. These connectors offer a combination of flexibility, reliability, and cost-effectiveness that makes them an ideal choice for a wide range of automotive applications.

Hosiden Strengthened Sales of MIPI A-PHY-supported Automotive Connectors and Harnesses

Hosiden will strongly contribute to the enhanced safety and security of vehicles by offering quality connectors and harness assemblies. We believe the interoperability with MIPI A-PHY that we confirmed will surely help to assure an even stronger supply chain of car manufacturers and Tier 1 suppliers, as well as improving ECU performance.

Insulation Failure Analysis of Automotive Connectors

The insulation resistance refers to the resistance value presented by the surface or internal leakage current of the insulation part when a voltage is applied to the insulating part of the automotive connector. In this article Greenconn will share the insulation failure analysis of automotive connectors.

How Are Industrial Connectors Classified?

How are industrial connectors classified? Voltage classification: The current of industrial plugs and sockets is generally specified as 16a, 32a, 63A, 125A, and other series.Voltage regulation: 110V, 220V, 380V, and other series.Voltage regulation: 110V, 220V, 380V, and other series.

What is Vertical Mount Power D-SUB Connectors?

The Vertical Mount Power D-SUB Connectors are widely used in various electronic applications due to their reliable performance and versatility. These connectors have a compact and durable design, making them ideal for high-density applications where space is limited.

电子商城

现货市场

登录 | 立即注册

提交评论