Precise Temperature Control for Microscopes

Introduction

Electron microscopes are a powerful laboratory tool used to observe samples across many scientific disciplines. These advanced analytical instruments enable researchers to qualitatively and quantitatively analyze samples in fields like metallography, metrology, anthropology, zoology, epidemiology and more. Temperature control plays a dynamic role in ensuring the proper operation of electron microscopes. This includes sample temperature stabilization (read Heating and Cooling of Incubator Chambers application note), as well as thermal control of sensitive equipment electronics. Thermal fluctuatio¬ns can degrade the quality of the microscopic imaging, and lead to a break down in the composition of the sample under examination.

Compressor-based chillers with integrated temperature control offers an advanced thermal management solution that keep sensitive electronics and samples at the optimum temperature for operation and examination respectively. However, because of new industry restrictions on hazardous refrigerants central in traditional chiller technology, electron microscope manufacturers now require a more environmentally friendly, efficient and maintenance-free chiller solution. The eco-friendly Nextreme™ Chiller quietly cools temperature sensitive components below ambient temperature to ensure optimum image quality.

Lab instrumentation tools such as electron microscopes

require an advanced thermal management solution for

precise temperature control of electronics and samples.

Background

An electron microscope uses a beam of accelerated electrons as a source of illumination to investigate the ultrastructure of a wide range of biological and inorganic specimens including microorganisms, cells, large molecules, biopsy samples, metals, and crystals.

Electron microscopes have a higher resolving power than light microscopes and can reveal the structure of smaller objects. While standard light microscopes are limited by diffraction to about 200 nm resolution and useful for magnifications below 2000X, a scanning transmission electron microscope has achieved better than 50 pm resolution in annular dark-field imaging mode and magnifications of up to about 10,000,000X. Modern electron microscopes produce electron micrographs using specialized digital cameras and frame grabbers to capture the images.

There are several types of electron microscopes with different configurations and techniques to analyze specimens. However, all electron microscopes use a high voltage electron beam to illuminate a specimen and create an image. The electron beam is produced by an electron gun. Depending on the type of electron microscope, the beam is sent through a combination of lenses, apertures, the specimen sample being analyzed, and a viewing screen where the camera is mounted to take the image.

Electrons behave like light only when they are manipulated in a vacuum. The whole column from gun to screen including the camera is evacuated. The highest vacuum is around the specimen and in the gun; a lower vacuum is found in the projection chamber and camera chamber. To improve image quality, OEMs implement thermal management systems that cool the digital cameras used for image creation. Active cooling is required to deliver optimal image resolution independent of the operating environment. In addition, advanced electron microscopes also have temperature control functionality for the specimen holder.

The electron beam can be controlled or manipulated via a magnetic field according to the left hand rule. Electromagnets create a magnetic field that allows for the formation of a magnetic lens of variable focusing power. The coils, which produce the magnetic field, are located within the lens yoke. The coils can contain a variable current but typically use high voltages and therefore require significant insulation in order to prevent short-circuiting the lens components. These coil windings require a thermal management solution to remove the heat generated when creating the magnetic field.

Application Challenges

Designers face a number of challenges when developing electron microscopes. As mentioned, several key microscope components, including the image recording electronics, the electromagnetic coils, and the sample port require stable thermal control below ambient temperatures. To go below ambient temperatures, refrigeration systems are required. This isn’t possible with other cooling technologies like liquid heat exchangers, which uses air to cool a cooling loop.

In addition to meeting thermal control requirements for these three electron microscope elements, cooling solutions must also meet smaller size, lighter weight and reduced power consumption requirements. To optimize lab space, OEMs continue to look for ways to decrease device size while increasing device functionality. As a result, more electronics are packaged into smaller housings, increasing the heat flux density and thermal challenges. This waste heat must be managed and dissipated efficiently in order to enhance the imaging capability of the electron microscope, while reducing power consumption and providing quieter operation (both lower noise and vibration). Electron microscope designs must also take airflow into account. Paths for incoming and exhaust air must be considered to maximize the cooling performance.

Electron microscopes are sensitive to disturbances in the surrounding environment like vibration. Some liquid pump models cause more vibration as a result of higher pulsations in the fluid lines. This is the case with a rotary vane pump or centrifugal pump. Turbine pumps have significantly less pulsation, which results in better imaging by the microscope.

The thermal management system also provides condensation protection for the electronic microscopes. Moisture forms on cold surfaces as temperature drops below the dew point. If this moisture seeps into the electronics, or onto the lenses, it can cause deterioration and ultimately failure of the electronics and affect image quality. Using properly designed insulation materials can provide a cooling solution resistant to moisture intrusion.

Electron microscopes must follow UL61010-1 or IC 61010-1 lab safety standards. These standards include specifications for electromagnetic compatibility and electromagnetic emissions to ensure electron microscopes can operate in the same room as other electronic equipment without interference. When designing an electron microscope OEMs will either ask for a certification from the chiller manufacturer, or certify it themselves as part of the installed system.

In addition, many governments continue to develop strict environmental legislation aimed at curbing climate change, which restricts usage of refrigerants in several refrigeration and freezer systems. The phase down on environmentally harmful refrigerants, like HFC refrigerants including R134a and R404A, has led to the development of new, eco-friendly refrigeration systems. These systems use natural refrigerants that have a reduced eco-footprint. However, the flammable nature of some natural refrigerants can make them hazardous to transport, and each one presents design challenges such as increased pressure, high toxicity, flammability, asphyxiation, and relatively poor performance. Another restriction in Europe is ROHS (Reduction of Hazardous Substance), which means that you cannot use led, mercury, cadmium and other heavy metals in electronic products.

Comparing Cooling Technologies

Modern compressor-based liquid cooling systems meet the electron microscope design requirements mentioned above. Compressor-based liquid cooling systems, which are self-contained units that recirculate coolant to a predefined temperature set-point, allow for optimal thermal stabilization and more precise temperature control. Standard and custom liquid cooling systems are able to dissipate the large amount of heat generated in densely packed electronic environments like electron microscopes.

Compressor based refrigeration systems offer a high coefficient of performance (COP). If they are cooling a heat load of 3 kW, they only require 1 kW of energy to do the work to cool it, which is more efficient compared to other technologies like thermoelectric cooling. Compressor-based systems tend to be smaller than alternative technologies like liquid-air-heat exchangers when achieving set-points near ambient temperatures because they make use of the refrigerant’s latent energy to increase heat exchanger efficiency. Thermoelectric devices on the other hand are smaller, but as mentioned, they are less efficient.

If the product is operating in ambient temperature, liquid-heat-exchangers are more efficient. However, liquid-to-air heat exchangers do not cool below ambient like compressor-based and thermoelectric systems.

Central facility cooling systems is another option previously used to cool electron microscopes. Since these systems are used to cool equipment in the entire building it can be difficult to satisfy all of the instrumentation’s cooling requirements with one centrally controlled system. In addition, it cannot guarantee a constant temperature and flow rate.

Laird Thermal Systems Solution

The Nextreme™ Chiller Platform from Laird Thermal Systems offers reliable and precise temperature control for electron microscopes. Utilizing high-performance variable speed motors, it offers lower noise operation and reduced energy consumption by up to 50% compared to conventional compressor-based systems.

The Nextreme™ Chiller offers precise temperature control, achieving an accuracy of ±0.1°C as the unit heats and cools fluid to maintain the thermal set point. Electron microscope imaging systems, electromagnetic coils and test samples benefit greatly from the precise temperature control, ensuring the development of high quality images.

By using environmentally-friendly R513A refrigerant, the Nextreme™ Chiller achieves similar performance with half the Global Warming Potential (GWP) compared to traditional hydrofluorocarbon (HFC) refrigerants. The chillers not only meet CE and RoHS requirements, but UL61010-1 and IC 61010-1 lab safety standards as well.

Featuring a LCD touchscreen display, the Nextreme™ Chiller Platform is designed with the laboratory technician in mind. It allows the technician to control temperature setpoints, coolant type, flow and alarm settings while coolant level is easily monitored through the indicator window located on the front panel. For maximum uptime, the Nextreme™ Chiller can be equipped with the optional “hot swappable” 5-micron water filter for filtering particulates from the coolant circuit, which means that the system can operate also during maintenance.

The Nextreme™ Chiller features an optical fluid level sensor with no moving parts, which increases reliability and uptime when compared to chillers equipped with mechanical fluid switches. If the fluid level drops below normal operating conditions, the user will be alerted by the programmable alarm. The chiller will also alert users when low- or high-pressure limits have been exceeded in order to protect the equipment. In addition, the Nextreme™ Chiller utilizes a low pulse turbine pump to ensure low vibration operation for superior image quality.

The Nextreme™ Chiller Series is available in three standard cooling capacities including 1600W, 2800W and 4900W models. All Nextreme™ Chiller models are configurable in order to meet specific application requirements.

The Nextreme™ recirculating chiller platform is available in three different capacities, 1600W, 2800W and 4900W.

The Nextreme™ Chiller can operate on 208-240VAC, 60Hz and 200-230VAC, 50Hz. While many other manufactures have a different model for Europe and North America, the single Nextreme™ Chiller can be purchased and operated globally. This is important for when a company chooses to test equipment in one country before shipping to a different region. It also means that companies can carry less inventory as a single chiller can ship anywhere.

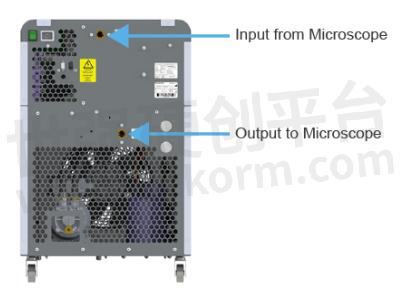

The Nextreme™ Chiller input and output connections

Conclusion

Properly cooling an analytic instrument like an electron microscope requires a sophisticated thermal management system. Modern compressor-based refrigeration systems are more advanced and efficient than previous versions. Compact chiller systems offer a higher coefficient of performance with maximum uptime and minimal power consumption compared to the application’s heat load. The versatile Nextreme™ Chiller provides quiet operation in a smaller and lighter package compared to previous models. The Nextreme™ recirculating chiller platform enables more focused and improved performance resulting in a precise image with better resolution.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由samsara转载自Laird Thermal Systems Official Website,原文标题为:Precise Temperature Control for Microscopes,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Laird Thermal Systems Produces a Wide Array of Thermoelectric Coolers, Assemblies and Temperature Controller Combinations Optimized for Incubator Chambers

Laird Thermal Systems introduces thermoelectric solutions for incubator chambers, emphasizing precise temperature control without refrigerants. The HiTemp ETX Series and SuperCool X Series provide efficient heating and cooling, crucial for cell culture in labs. These systems offer a compact, reliable, and low-maintenance alternative to traditional incubator thermal management.

针对投影激光器的热电制冷器:莱尔德热系统UltraTEC™ UTX系列,运行噪音低,能耗降低多达50%

热电制冷器可提供局部点冷却,以保证卓越的温度稳定性,从而保持激光器和光电子器件的峰值性能。由于其固态运行,像Laird Thermal Systems UltraTEC UTX系列这样的热电冷却器可实现低维护和长寿命运行。通过在先进材料科学方面的突破,与标准热电冷却器相比,该产品系列能够提供更高的性能和更高的性能系数。

Laird Thermal Systems Offers Thermoelectric Coolers, Thermoelectric Cooler Assemblies and Temperature Controllers for Refrigerated Centrifuges

Centrifuges are crucial for separating mixtures in medical and food processing labs. They face thermal challenges like temperature stability and noise levels. Thermoelectric coolers, like those from Laird Thermal Systems, offer an efficient and reliable solution for precise temperature control in centrifuges, reducing power consumption and maintenance costs. Laird‘s CP Series and temperature controllers provide stable cooling capacities and accurate control, making them ideal for various centrifuge applications.

Laird Thermal Systems(莱尔德热系统)液体冷却系统产品选型指南

目录- Introduction Benefits & Applications of Liquid Cooling Systems Nextreme™ Recirculating Chillers Liquid Heat Exchangers Custom Liquid Cooling Systems Featured Application: Medical Imaging

型号- 1510.00,WL1500,385901-001,VRC2400,VRC4500,NRC5000,WL3004,387008451,1550.00,LA5000,WL1000,385911-015,1520.00,387009925,OW4002,385910-043,387010178,387010179,NRC2400,1505.00,38701 0181,1264.00,1155.00,1104.00,VRC1200,WW5001,387002779,NRC400,WW3001,1515.00,WL500,WL2000,387005774,387005598,OL4503,385912-029,NRC1200,385910-015

TC-XX-PR-59温度控制器

描述- 该资料介绍了TC-XX-PR-59型温度控制器,这是一种用于精确控制热电偶组件温控的设备。它支持制冷和加热模式,具有用户可选择的调节方式(PID、开/关、功率),并具备两个可编程风扇输出和一个报警输出继电器。控制器可通过RS-232接口实时读取和控制参数,并提供PC软件进行编程和可视化审查。此外,还提供了技术规格和应用领域。

型号- TC-XX-PR-59

How do I determine the best thermal solution for my application?

Laird Thermal Systems has developed the Thermal Wizard — a quick and easy selection tool helping customers determine the optimum cooling solution. To begin the selection process, users can input two application performance requirements; the required cooling power (Qc) and the desired temperature change (ΔT). If you know these specifications the Thermal Wizard product search will show thermoelectric coolers, thermoelectric cooler assemblies or liquid cooling systems that meet your application demands.

Laird Thermal Systems‘ Nextreme™ Value Chillers Provide Economical, High Reliability OEM Cooling Solution

The Extreme Value Chiller Series uses high-performance components to cool well below ambient temperatures to control processes or dissipate heat away from thermally sensitive equipment.

What's the difference between standard and custom products?

Our standard products can be found in our product portfolio: Thermoelectric Coolers, Thermoelectric Cooler Assemblies, Liquid Cooling Systems, Temperature Controllers. These units have specific heat transfer methods, cooling capacity ranges or size constraints and can be ordered upon request from our distribution partners. If the capacity, size or other parameters of our standard products do not meet your application requirements you may need a customized solution. Laird Thermal Systems has the ability to customize our entire product range, however MOQ’s apply. To optimize performance and long-life operation, an application could require a customized thermal management solution. Also cooling capacities above 5 kW typically require a custom solution. Laird Thermal Systems designs and manufactures customized, thermal management solutions for performance-critical applications to optimize your product’s performance. Laird Thermal Systems offers strong engineering design services with a global presence that supports onsite concept generation, thermal modeling, mechanical and electrical design and rapid prototyping. The company also offers validation test services to meet unique compliance standards for each industry, such as UL, Telcordia, or a unique standard specific to a medical, industrial or semiconductor application.

The Nextreme™ Performance Chiller Series from Laird Thermal Systems Offers Reliable Temperature Control for Laboratory Equipment

Modern lab equipment is getting smaller and more efficient, with chillers like the Nextreme series providing precise temperature control for various applications. These chillers are compact, portable, use eco-friendly refrigerants, and meet global safety standards, helping labs save costs, space, and ensure reliable results.

热电冷却器组件和温度控制器

描述- Laird Thermal Systems提供多种热管理解决方案,包括热电制冷器组件和温度控制器。这些产品适用于医疗、工业、交通和电信等多个领域。热电制冷器组件具有紧凑的设计,适用于多种应用,如激光二极管封装、医疗和工业仪器中的激光、电子外壳、医疗诊断和分析仪器中的样品存储室以及各种汽车和电信应用中的电池。Laird Thermal Systems提供标准产品系列和定制解决方案,以满足不同应用的需求。

型号- TUNNEL SERIES,DA-075-24-02-00-00,POWERCOOL SERIES,DA-034-24-02-00-00,POWERCOOL,AAC-050,SUPERCOOL SERIES,DA-014-12-02-00-00,AA-150-48-44-00-XX,AA-200-48-22-00-00,DAT-105-24-02-00-00,SLA-400,AA-200,DAT-040-12-02-00-00,SLA-140-24-02-00-00,AA-060-12-22-00-00,AA-100-,AAT-032-12-22-00-00,AA-040-24-22-00-00,DAT-065-24-02-00-00,DA-115-24-02-00-00,CASCADE SERIES,387000639,LL-120-24-00-00-00,AA-200-24-22-00-00,AA-150-24-44-00-XX,SLA-400-24-02-00-00,SAA-170-24-22-00-00,DA-044-24-02-00-00,DL-210,DL-120-24-00-00,DA-045-24-02-00-00,AA-150-24-22-00-00,387000624,DA-024-24-02-00-00,OUTDOOR COOLER SERIES,AAT-027,LA-115-24-02-00-00,AA-250-24-44-00-XX,ATT-027-12-22-00-00,AAT-085-12-22-00-00,LA-024-12-02-00-00,LA-045-12-02-00-00,QE-50,387000612,DL-060,DA-280-48-02-00-00,NRC400,387003326,387003325,AA-480,387003324,DA-160-24-02-00-00,TUNNEL,AA-230,SR-54,DA-075-12-02-00-00,LL-060-12-00-00-00,ATT-055-24-22-00-00,AA-024-12-22-00-00,LA-075-24-02-00-00,DAT-029-12-02-00-00,DAC-035-12-02-00-00,AAT-055-12-22-00-00,DA-033-12-02-00-00,AA-100-24-22-00-00,SDA-195,DA-034-12-02-00-00,SAA-170,387004253,DL-060-24-00-00,DA-025,SAA-110-24-22-00-00,DAT-065-12-02-00-00,AA-230-48-D44-00-XX,DAT-105-12-02-00-00,AA-040-12-22-00-00,DA-044 -12-02-00-00,DA-280-24-02-00-00,AA-070-24-22-00-00,LIQUID SERIES,QC-50,DA-135-24-02-00-00,AA-060-24-22-00-00,DAC-060-24-02-00-00,NRC400-T0-00-PC1,AA-250-48-44-00-XX,AA-250,AA-019-12-22-00-00,SDA-195-24-02-00-00,LL-210-24-00-00-00,AA-100-48-44-00-XX,PR-59,OUTDOOR COOLER,DA-045-12-02-00-00,DA-044-12-02-00-00,AAC-050-24-22-00-00,AA-150,DA-024-12-02-00-00,AA-100-24-44-00-XX,DA-045,SUPERCOOL,AAT-085-24-22-00-00,AA-230-24-D44-00-XX,SLA-205-24-02-00-00,SDA-130-24-02-00-00,CASCADE,AA-200-48-44-00-XX,DA-011-05-02-00-00,DA-280,LA-024-24-02-00-00,LA-160-24-02-00-00,LL-060,AA-480-24-44-00-XX,AA-040,LA-045-24-02-00-00,AA-200-24-44-00-XX,LL-210,LIQUID,AA-024-24-22-00-00,DL-210-24-00-00,AA-034-12-22-00-00,AA-480-48-44-00-XX,DL-060-12-00-00

nExtreme™高性能制冷机

描述- Laird Thermal Systems推出Nextreme™性能冷却器平台,提供高效、节能的冷却解决方案。该平台包括空气冷却和热电冷却两种类型,适用于医疗、工业、交通和电信等多个领域。产品特点包括高性能、低噪音、环保制冷剂、用户友好的操作界面等。平台提供多种型号,满足不同应用需求。

型号- NRC5000,NRC400,NRC1200,NRC2400,NRC2400-A1-20-ST1

Laird Thermal Systems‘ SR-54 Temperature Controllers Monitor and Protect Medical Equipment

One popular cooling solution that enables OEMs to meet these design challenges is the use of programmable temperature controllers with thermoelectric cooler assemblies. The temperature controller compliments the thermoelectric cooler assembly to deliver a precise thermal management system.

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

提供稳态、瞬态、热传导、对流散热、热辐射、热接触、和液冷等热仿真分析,通过FloTHERM软件帮助工程师在产品设计初期创建虚拟模型,对多种系统设计方案进行评估,识别潜在散热风险。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论