Coherent New High-power CO₂ Laser Modulator Unlocks Faster Processing Speeds

Pairing a unique electro-optic modulator and high-power CO₂ laser delivers the increased speed and precision needed to revolutionize many cutting, drilling, and engraving applications.

The latest breakthrough in laser modulator technology from COHERENT delivers increased throughput – and therefore lower cost – to some of the most demanding, high-volume materials processing tasks in microelectronics production, medical device manufacturing, and more. Specifically, the new Coherent CO₂ laser electro-optic switch enables the use of higher power lasers (up to 1 kW) to speed up many drilling, cutting, and engraving processes involving non-metals such as polymers, composites, organics, and ceramics.

Here we’ll learn something about how modulators work and see how this new technology can cut dramatically costs for many manufacturers.

Understanding Modulators

An optic modulator is a device used to control the temporal shape and/or power of a laser in response to an applied electric signal. In the simplest implementation, a continuous wave (constant output) laser beam may be blocked or transmitted on demand, with a variable level of transmission.

The two most widely used technologies for this purpose are the acousto-optic modulator (AOM) and the electro-optic modulator (EOM). The AOM contains a transparent crystal with an attached piezoelectric transducer. Applying a radio frequency signal to the transducer produces a sound (or acoustic) wave within the crystal. This, in turn, creates a periodic variation in the material’s refractive index which makes it act like a diffraction grating.

Varying the input signal changes the amplitude of the acoustic waves. This causes more or less of the light to be diffracted out of the main beam and into the diffracted orders. This is how modulation is achieved.

The EOM utilizes an electro-optic crystal. This is a material that rotates the polarization plane of input linearly polarized laser light when a voltage is applied to it. By putting a linear polarizer at the output end of the crystal, beam modulation is achieved when the applied voltage is varied.

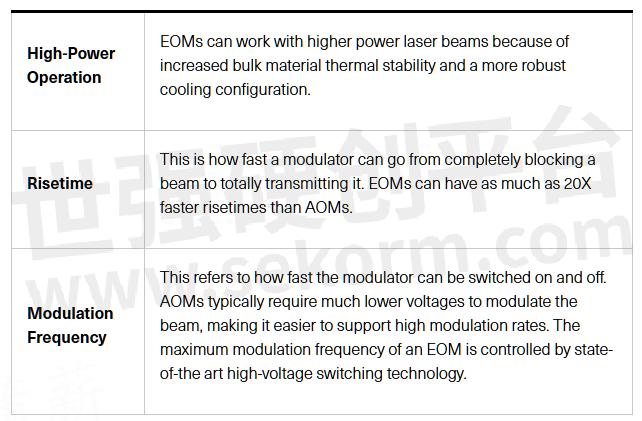

There are differences in nearly all the operating and practical characteristics of AOMs and EOMs. This makes each technology best suited for certain specific uses. Some of the key parameters relevant to high-throughput materials processing include:

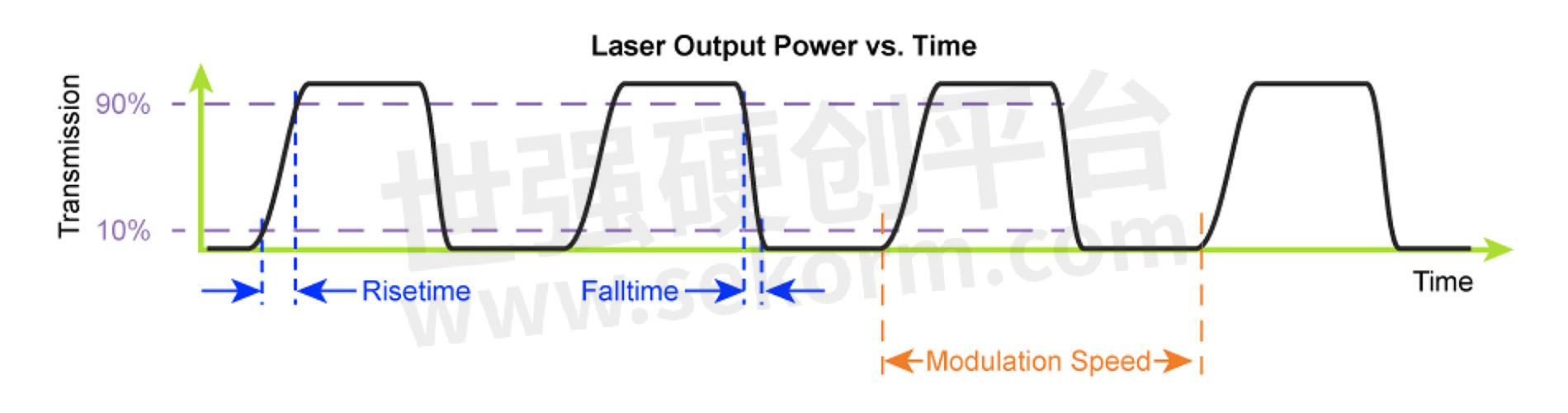

If may seem confusing that EOMs can have faster risetimes but lower modulation speeds than AOMs. The figure provides the definitions of these terms and should help clarify this.

Definitions of the main output parameters for a modulator. As can be seen, risetime and falltime are not related directly to modulation speed.

Via Drilling

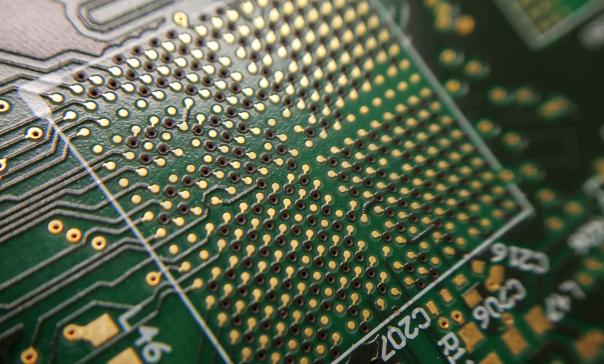

One application that can benefit from the particular characteristics of the EOM is “via” drilling in microelectronics manufacturing. Vias are tiny holes made in printed circuit boards (PCBs) that allow electrical connections to be made between their different layers.

PCB boards are shrinking to accommodate greater device miniaturization. This is especially true for devices like smartphones, 5G transceivers, and wearables. These more highly miniaturized devices often employ advanced packaging techniques – such as high-density interconnect (HDI) PCBs and IC substrates. The vias required for these are much smaller than can be achieved with traditional methods, but lasers excel at making the smaller holes needed for these newer electronic package types.

CO₂ lasers are widely used in commercial via drilling systems because they provide highly efficient processing of the materials used in many electronics packages, such as FR4, PTFE, glass-woven composites, and ceramics. And they can even ablate copper traces.

CO₂ lasers can drill vias down to about 30 µm in diameter. Using AOMs, these systems can operate at speeds of over 5,000 vias/second. While that may sound amazing, electronics manufacturers want to go even faster.

The reason for this is simple. Increased throughput means reduced cost.

Increasing Via Drilling Throughput

A typical high-speed via drilling system splits the laser beam into as many as four separate beams. This provides four times higher overall throughput than just using a single beam.

Splitting the beam into even more separate beams could further increase speed. But splitting the beam also divides the laser power amongst them. And it takes a certain amount of power in each individual beam to perform drilling.

The obvious solution is to increase the laser power. And this is where the AOMs used in most CO₂ laser via drilling systems becomes the limitation. Because AOMs simply can’t work with CO₂ lasers over about 300 W in power. And dividing a 300 W beam up more than four times doesn’t provide enough power in each beam for the drilling process.

A 1 kW CO₂ laser would supply sufficient power to divide the beam multiple times and get the throughput increase that semiconductor manufacturers require. But it would take a modulator that can handle about 1 kW of CO₂ laser power for this approach to work. Since there hasn’t been an AOM modulator available that could do that, Coherent turned to EOM technology for our CO₂ laser electro-optic switch.

Modulators for Every Application

AOMs and EOMs each have their uses. This is why Coherent offers lower power (<50 W) CO₂ lasers, like our DIAMOND Cx-10 and DIAMOND Cx-10LDE+ that directly integrate an AOM. These service applications that don’t require extraordinarily high throughput levels, or which are more cost-sensitive. And now, our CO₂ laser electro-optic switch enables system builders to support applications that require both very high throughput as well as high-powered (up to 1000 W) lasers. This EOM is further complemented by other products we manufacture, such as our spatter and debris resistant coatings which greatly extend the lifetime of CO₂ laser optics that require frequent cleaning from exposure to metal spatter and debris in drilling, cutting, and marking applications.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Ray转载自COHERENT Official Website,原文标题为:FASTER CO₂ LASER PROCESSING,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Coherent Announces New High-Power F-Theta Lens for Superior Remote Processing

Coherent Corp. introduces a new high-power F-theta lens for additive manufacturing, EV battery welding and laser cleaning. The lens design provides optimal optical performance for increased processing speeds.

Coherent AVIA LX 355-30 纳秒紫外 (UV) 激光器具有高输出功率、可靠性和长使用寿命特性

Coherent AVIA LX 355-30 纳秒紫外 (UV) 激光器具有无与伦比的高输出功率、可靠性和长使用寿命,极大地提高了高精度切割、钻孔和微结构任务的生产效率,尤其是在微电子生产领域。AVIA LX 在 355 nm(脉冲能量高达 500 μJ)下输出 30 W,并提供了无与伦比的 20,000 小时连续三倍频晶体寿命,没有任何光斑偏移。这将提高工艺一致性,缩短维护停机时间。

【仪器】COHERENT推出新型模拟光多链路模块,有可拆卸的陆基网格阵列(LGA)接口

COHERENT宣布推出其创新的新型模拟光多链路模块,阿尔法样品已可获取,该模块具有可拆卸的陆基网格阵列(LGA)接口。这一尖端产品平台支持下一代模拟光链路,可达到Ka波段,针对地面和空间应用。这些模块以低功耗为特点,专注于射频光纤(RFoF)应用,旨在满足各种行业对高吞吐量射频系统不断增加的需求。

非线性光学晶体

本文介绍了Coherent公司在非线性光学晶体领域的领先地位。文章涵盖了多种高性能非线性晶体的生长、设计和制造,包括BBO、LBO、KTP和LiNbO3等。这些晶体在绿色激光、UVC和USP激光器中有广泛应用,具有高转换效率、高损伤阈值和长寿命等特点。

COHERENT - BETA-BARIUM BORATE CRYSTALS,NLO,PHOTOP KTP CRYSTAL,非线性光学晶体,POTASSIUM TITANYL PHOSPHATE CRYSTAL,NONLINEAR OPTICAL CRYSTALS,KTIOPO4 CRYSTALS,光控KTP晶体,铌酸锂晶体,LBO CRYSTALS,BBO晶体,Β-硼酸钡晶体,LITHIUM TRIBORATE CRYSTALS,KTIOPO4晶体,三硼酸锂晶体,Β-BAB2O4晶体,LBO晶体,LINBO3 CRYSTALS,LN晶体,KTP晶体,LN CRYSTALS,KTP CRYSTAL,非线性光学,BBO CRYSTALS,NON-LINEAR OPTICAL CRYSTAL,Β-BAB2O4 CRYSTALS,磷酸氧钛钾晶体,OPA,ND:YLF激光器,ALEXANDRITE LASERS,波导基片,准相位匹配器件,DYE LASERS,ND:YVO4 LASERS,掺钕激光器,LIDAR,Q开关,商用激光器,光纤隔离器,OPCPA,OPO,FIBER ISOLATORS,ND:YVO4激光器,SURFACE ACOUSTIC WAVE WAFERS,SHG,测距仪,军用激光器,OPTICAL COMMUNICATION,波克尔细胞,MODULATORS,ND:YAG激光器,表面声波晶片,光通讯,医疗系统,CIRCULATORS,调制器,USP激光器,固体激光器,MEDICAL SYSTEMS,WAVEGUIDE SUBSTRATES,COMMERCIAL LASERS,绿色激光,FIBER OPTICS,ND:YAG LASERS,LABORATORY,INDUSTRIAL SYSTEMS,光参量振荡器,循环器,SOLID STATE LASERS,工业系统,QPM设备,POCKEL CELLS,QUASI-PHASE-MATCHED DEVICES,泰格,翠绿宝石激光器,集成光学,UVC LASERS,QPM DEVICES,POCKELS CELL,RANGE-FINDERS,OPTICAL PARAMETRIC AMPLIFIERS,THG,SAW WAFERS,PHASE MODULATORS,普克尔盒,实验室,INTERGRATED OPTICS,E-O DEVICS,ND-DOPED LASER,钛宝石激光器,相位调制器,E-O设备,USP LASERS,OPTICAL PARAMETRIC OSCILLATORS,LIDAR,锯片,GREEN LASERS,UVC激光器,氩激光器,Q-SWITCHES,运算放大器,TI:SAPPHIRE LASERS,ND:YLF LASERS,纤维光学,染料激光器,MILITARY LASERS,E-O调制器,光参量放大器,ARGON LASERS,E-O MODULATORS

Coherent Introduces Industry-first Pump Laser Diode with Record 65W Power

Coherent Corp, a leader in high-power semiconductor lasers, announced the introduction of its next-generation pump laser diode, with 65W of output power for fiber lasers in industrial and consumer applications.

Coherent Introduces the Industry’s First Commercially Available 50W Pump Laser Diodes for Fiber Lasers

The new laser diodes from Coherent achieve 50 W of output power, 40% more than that of the existing product, enabling high-power industrial fiber laser designs with fewer pump laser diodes.

所有USP激光器均在COHERENT GLASGOW实现量产

Coherent Glasgow已经成为一家专注于精益制造的先进批量生产工厂,并且最近为了满足这一重要统一工作要求而进行了扩建。现在,旗舰飞秒激光器(如Coherent Monaco)和皮秒激光器(例如Rapid和HyperRapid系列)都将在格拉斯哥制造。扩建卓越中心以进行变革,将实现令人难以置信的跨产品协同以及组件和流程标准化,并将实现集成资源规划。

Coherent SMARTWELD + 助力TEAMTECHNIK填补量产焊接空白

当teamtechnik签约开发一个量产焊接系统时,他们寻求Coherent的激光专业知识。通过使用Coherent的SmartWeld + 加工头和1 kW单模光纤激光器,成功完成了所有工艺。这种工具适合热敏材料和异种材料的焊接。此外,它还能处理传统上不适合激光焊接的材料。合作使teamtechnik能够专注于自动化领域,而Coherent持续提供支持以应对材料变化带来的挑战。

Coherent Paladin激光器助力先进陀螺仪实现质的飞跃

Coherent Paladin激光器,是离子捕获领域不可或缺的部分。Paladin激光器能产生超快、高功率的激光脉冲,研究人员利用激光能够创造和操纵离子的叠加态,从而实现量子力学的突破性实验。其独特的性能使其成为驱动离子跃迁的理想光源,这对于物质波干涉的研究和先进陀螺仪的开发至关重要。

Coherent HighLight FL-ARM系列光纤激光器告诉你,为何电动汽车焊接要讲究技巧,而不仅靠力量

Coherent HighLight FL-ARM系列光纤激光器的总功率高达10kW。这一功率量级对于以高效的产量的所有应用已经绰绰有余。事实上,大多数高精度、要求最高的产品通常使用的量不到该功率量级的一半。因此,Coherent高意公司ARM激光器能够在必要时将足够的激光功率精确地定向传递到焊接位置。

Coherent Launches CT-Series Thermoelectric Coolers for Enhanced Thermal Management

Coherent Corp. announces the launch of its CT-Series thermoelectric coolers. This new product line delivers exceptional thermal performance, reliability, as well as cost-efficiency for demanding applications in life sciences, medical and industrial markets.

Coherent Held Industry-First Live Demonstration of 200G PAM4 Mach-Zehnder Modulated Laser Technology at OFC 2023

Coherent, a leader in optical communications components and subsystems, announced that it held a live demonstration of its 200G four-level pulse amplitude modulation (PAM4) Mach-Zehnder modulated laser technology at OFC 2023 in San Diego, March 7-9, booth #3815.

Coherent Introduced 2x1000mW Dual-Chip Pump Laser Module for Optical Amplification in Optical Networks

Coherent, a leader in pump laser technology for erbium-doped fiber amplifiers (EDFAs) deployed in optical networks, today announced the industry’s first dual-chip pump laser module with up to 1000mW of output power per fiber in a 10-pin butterfly package.

电子商城

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥138.0250

现货: 1,250

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥485.0000

现货: 710

品牌:COHERENT

品类:Single-Stage Thermoelectric Module

价格:¥745.0191

现货: 600

品牌:COHERENT

品类:Single‐Stage Thermoelectric Module

价格:¥192.4021

现货: 524

品牌:COHERENT

品类:Single‐Stage Thermoelectric Module

价格:¥252.6552

现货: 518

品牌:COHERENT

品类:Single-Stage Thermoelectric Cooler

价格:¥1,971.8640

现货: 500

现货市场

登录 | 立即注册

提交评论