Solving Challenges Through the Fusion of Analog and Digital, New Options for Power Supply Control ICs in the Low to Medium Power Range-LogiCoA™ Power Supply Solution

New Options for Power Supply Control ICs in the Low to Medium Power Range

10/18/2024

Power control ICs are essential for the operation of all electronic products and equipment.

Selecting the right power control IC and implementing the appropriate design are crucial for ensuring that applications operate smoothly and efficiently. However, some engineers may assume that all power control ICs are pretty much the same. In this article, we will explore the fundamentals of power supply control ICs, revealing aspects you might not be aware of along with ROHM’s current efforts in pioneering new power technologies that will revolutionize the power supply control IC industry.

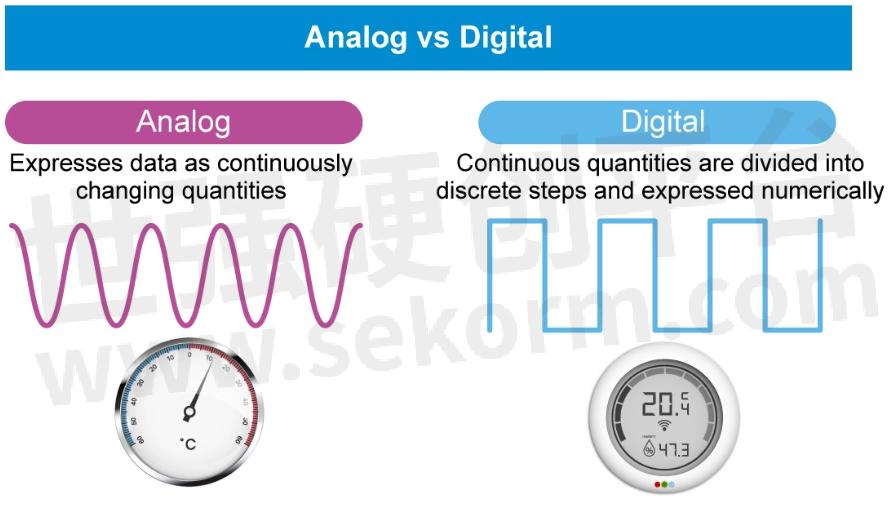

1. Analog vs Digital Control

Currently, there are two main methods used for power control ICs.

Those that utilize analog controllers for analog control and those that employ MCUs or similar devices for digital control.

As you may know, analog involves capturing data as smooth, continuous variations. In contrast, digital operates in a world of 0s and 1s, where continuous quantities are divided into steps and expressed numerically. Each method has its advantages and disadvantages, with power control ICs selected based on the specific requirements of each application.

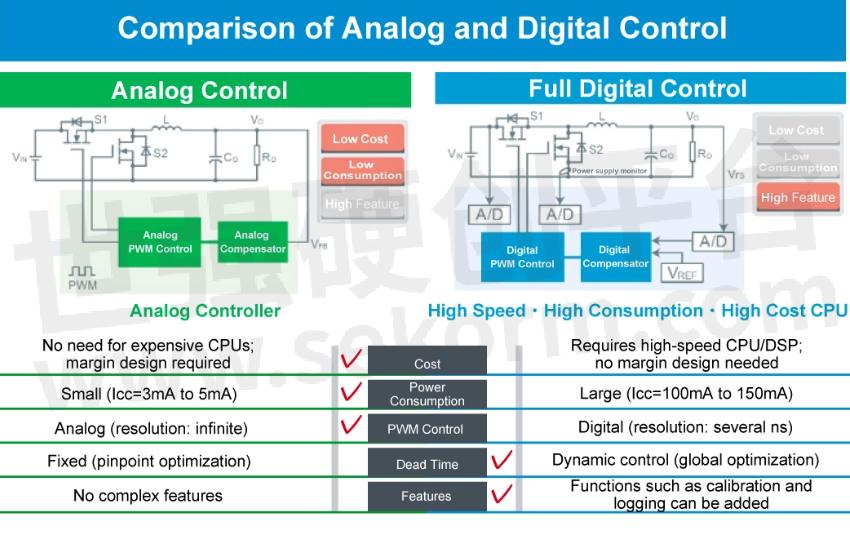

2. Pros and Cons of Each Approach

While both analog and digital control power supply ICs are available, their characteristics differ significantly. For example, analog control does not require costly CPUs or DSPs, resulting in lower costs and reduced power consumption compared to digital control. On the other hand, digital control enables precise adjustments tailored to the application, offering capabilities not possible with analog control, such as calibration and log acquisition.

3. Choosing Between Analog and Digital Control

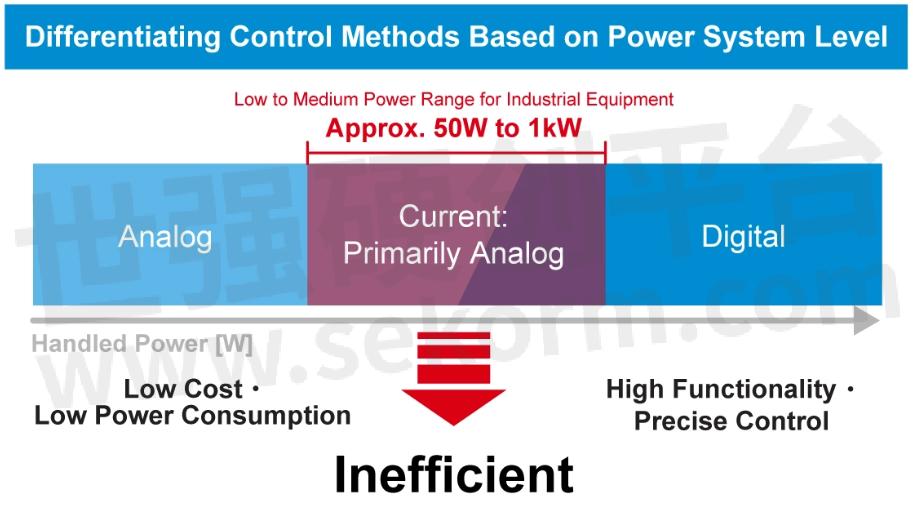

Currently, the decision to use analog or digital power control ICs depends on the power domain of the electronic device or electrical equipment.

Typically, analog control power ICs are employed in low to medium power applications up to 1kW, such as smartphones, PCs, tablets, robots, FA equipment, and manufacturing devices, while digital control power supply ICs are utilized in electrical equipment above 1kW, including solar power generation systems and EV chargers. This is due to the challenges analog control faces in handling the significant fluctuations in output power found in high-power applications.

However, many engineers engaged in the development of industrial equipment may question the distinction between the two.

4. Is it Acceptable to Continue Using Analog Control in the Low to Medium Power Range?

Analog control power supply ICs are currently the preferred choice for medium power industrial equipment. However, they are optimized for a single application, meaning the power circuit cannot be reused in its current form. When requirements such as the supply voltage and output power change, individual adjustments to the power circuit must be made, creating a barrier when developing derivative products that places a heavy burden on designers.

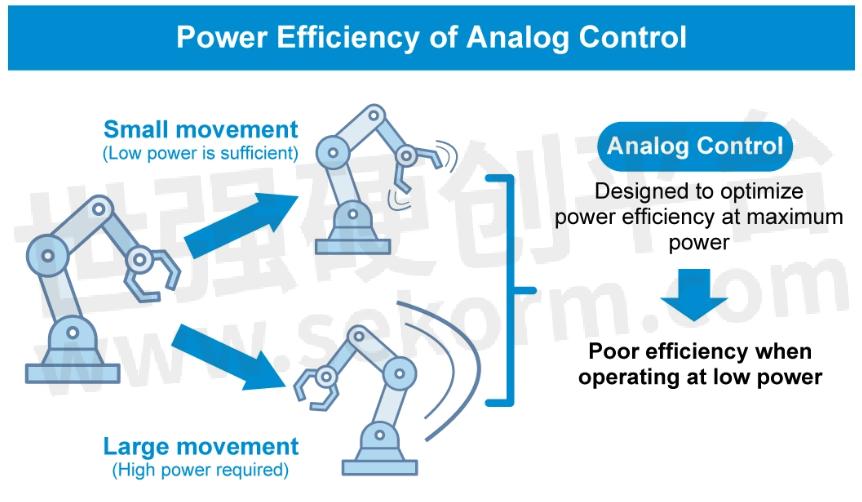

What’s more, analog control does not allow for fine adjustment of the output according to the power used, leading to poor power conversion efficiency (AC-DC). And when developing power supplies, component characteristics must be taken into account. Particularly for inductors and power devices that could be damaged if their ratings are exceeded, designs must ensure sufficient margins, further increasing the burden on the designer.

Depending on the application, employing analog control power supply ICs for industrial equipment in the low to medium power range can be time-consuming and inefficient for engineers. So why are analog power supply control ICs still utilized in these applications? The primary reasons are power consumption and cost.

Despite the growing demand for digital-controlled power supplies in the low to medium power range for industrial equipment, challenges related to power consumption and cost hinder the adoption of digital control in these power systems.

Additionally, ROHM believes that the differing design philosophies between analog and digital engineers play a significant role in the slow adoption of digital control technologies in the small to medium power range.

5. Digital Control for Low to Medium Power Supplies

As the electrification and automation of industrial equipment accelerates, shouldn’t power control ICs in the small to medium power range evolve as well? Isn't it feasible to develop a power supply control IC that combines the advantages of both analog and digital technologies, rather than having to choose between the two?

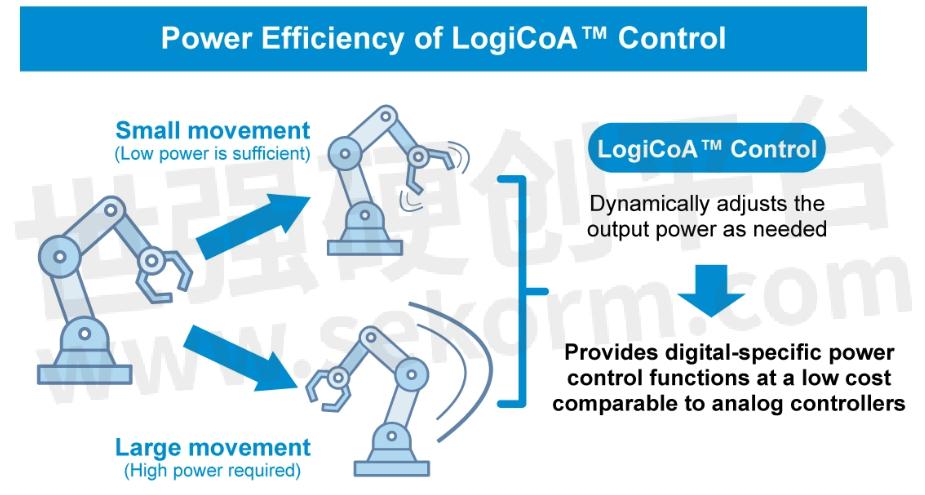

To address the challenges of power supply control in the small to medium power range, ROHM developed the LogiCoA™ power supply solution, the industry's first ‘analog-digital hybrid control’ type using LogiCoA™ MCUs.

LogiCoA™ Brand

LogiCoA™ embodies a design philosophy that fuses digital elements to maximize the performance of analog circuits - an area where ROHM excels. By integrating the strengths of analog circuitry with those of digital control, it is possible to fully realize the potential of circuit topologies, contributing to more efficient power utilization.

*LogiCoA™ is a trademark or registered trademark of ROHM Co., Ltd.

LogiCoA™ Power Supply Solution

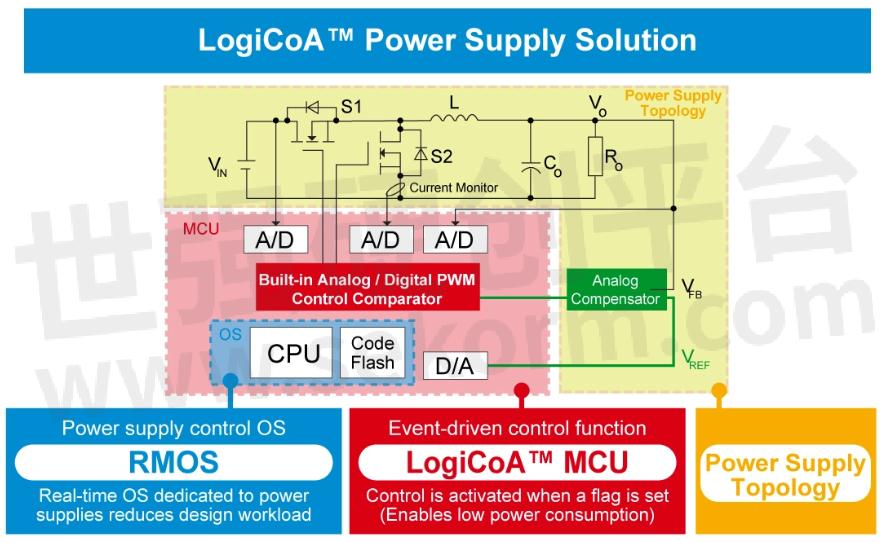

A new power solution that achieves exceptional functionality while reducing cost and power consumption, the LogiCoA™ power supply combines 3 elements: a power topology, power control OS, and LogiCoA™ MCU.

LogiCoA™ Power Supply Solution Features

Along with the LogiCoA MCU – a key feature of this new power solution – all necessary analog and digital circuits required for power supply control are integrated into a single package. This makes it possible to achieve the same functionality as digitally controlled power supplies while maintaining the lower power consumption and cost levels of analog power solutions.

In addition to power consumption and cost benefits, the solution incorporates a low-cost low-speed CPU with a 3ch analog comparator and DA converter for digital parameter control. This enables easy adjustment of the output power and other parameters by simply changing them on a PC, dramatically reducing the burden on engineers.

In short, the LogiCoA™ power solution represents a groundbreaking innovation that merges the advanced power control capabilities of digital technology with the cost-effectiveness of analog controllers.

6. New Possibilities in the Realm of Analog Control

The LogiCoA™ power solution is set to transform power control ICs that until now have only been available in analog or digital options. While it may seem a bit exaggerated, the LogiCoA™ power solution has the potential and appeal to bring about significant advancements.

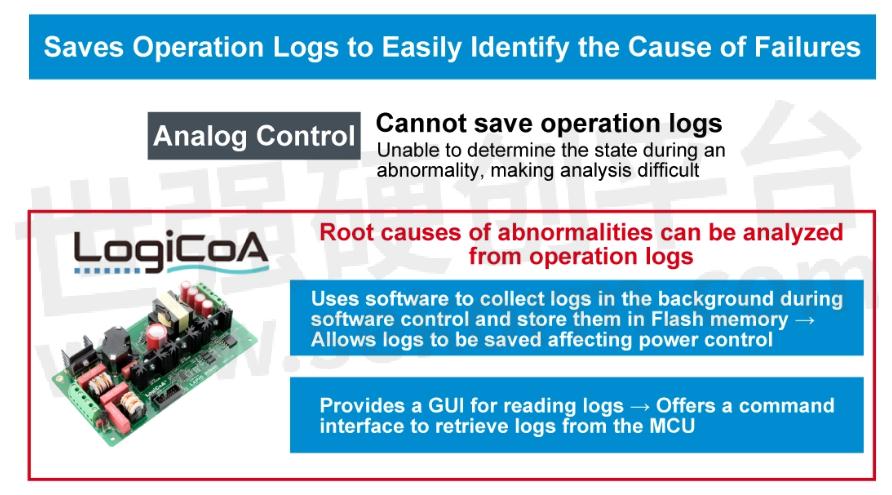

① Operation logs can be saved

For instance, in the area of analog control, it has been difficult to analyze customer complaints or failures due to the inability to determine the state at the time of an anomaly. However, with the LogiCoA™ power supply solution, log data such as input voltage, output voltage/current, and temperature can be stored in Data Flash, allowing for the analysis of the root cause of anomalies from the operation logs. A command interface for reading logs from the MCU is also provided.

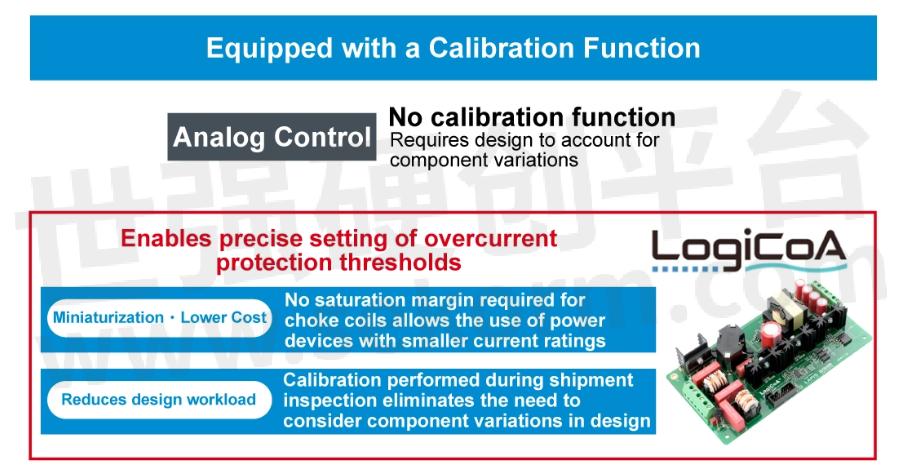

② Calibration is performed during outgoing inspection

The built-in calibration function not found in low-performance analog control power ICs eliminates the need for margin design to account for component variations, streamlining the design process.

The calibration function allows for precise setting of overcurrent protection thresholds. Eliminating saturation margins required for choke coils enables the use of power devices with lower current ratings, supporting smaller inductors and power devices to achieve greater miniaturization with lower costs.

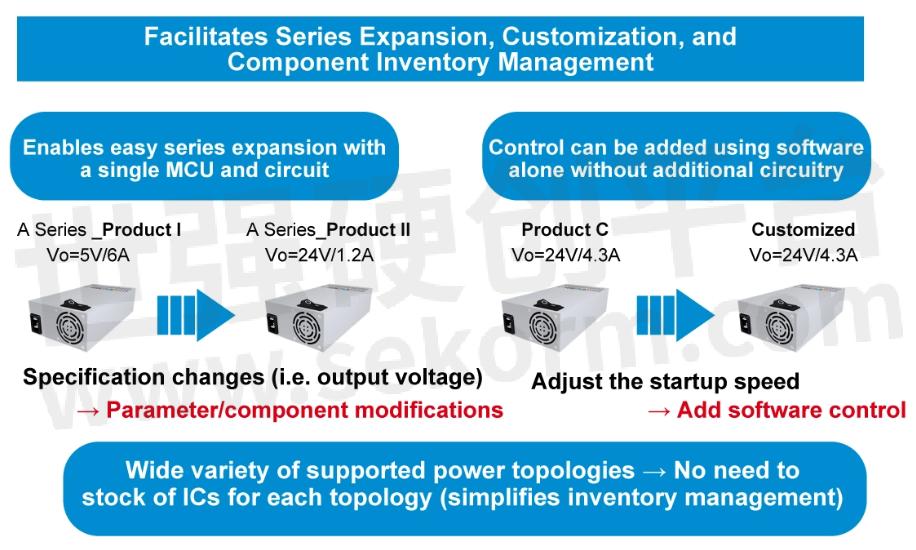

③ Simplifies derivative product development, custom development, and inventory management

The LogiCoA™ power supply solution makes it possible to modify specifications such the output voltage by adjusting parameters, allowing a single MCU and circuit to flexibly accommodate various needs, such as derivative product development, custom development, and series expansion. At the same time, control functions can be added by simply changing the software without requiring additional circuits, creating an environment conducive to developing more derivative products.

Furthermore, the extensive range of supported power supply topologies removes the necessity of stocking power control ICs for each topology, greatly simplifying inventory management. Incidentally, ROHM plans to release reference designs (circuits) for various power topologies in the future.

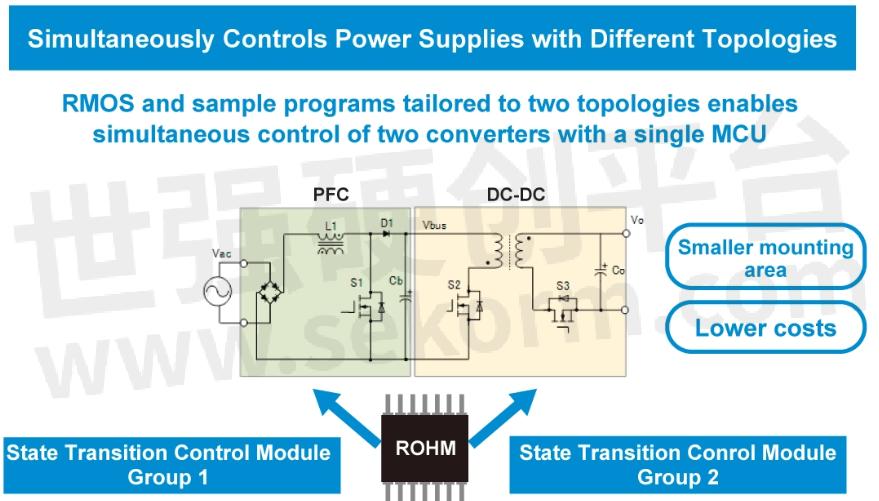

④ Simultaneous control of two converters with one MCU is possible

The real-time operating system RMOS, designed for state transition control suitable for power management, coupled with sample programs tailored to the two different topologies enables simultaneous control of two converters using a single MCU. This contributes to reducing both mounting area and costs.

⑤ Comprehensive support system facilitates the start of customer evaluations

ROHM’s LogiCoA™ power supply solution is set to revolutionize power control ICs in the small to medium power range. However, introducing new technologies often brings a degree of uncertainty. Specifically, engineers who have primarily worked in the analog field may be resistant to adopting digital control.

To alleviate the concerns and burdens of engineers, ROHM provides support for the LogiCoA™ power solution through the community on our engineer-focused technical site ‘Engineer Social Hub™’ (Japanese only). As many engineers are already progressing with their evaluations, we encourage you to take advantage of this solution.

*Engineer Social Hub™ is a trademark or registered trademark of ROHM Co., Ltd.

And for those exploring new power designs, we plan on releasing an AC-DC (current-critical PFC + pseudo-resonant flyback) evaluation kit. We invite you to experience the LogiCoA™ power solution that offers adjustment functions and setting changes via communication GUI – features not possible with analog control.

7. Conclusion

The LogiCoA™ power solution excels at embedded processing across a diverse array of applications, including industrial equipment, automotive systems, industrial IoT, edge computing, and autonomous vehicles.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由samsara转载自ROHM Official Website,原文标题为:Solving Challenges Through the Fusion of Analog and Digital,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

通过模拟和数字的融合解决问题!中小功率电源控制IC的新选择——LogiCoA™电源解决方案

“电源控制IC”是确保各种电气产品和电气设备正常运行的不可或缺的器件。要使应用产品正常高效地运行,电源控制IC的选择和合理设计是非常重要的。然而,貌似有很多工程师认为“使用哪种电源控制IC应该不会有太大的差异吧?”所以,在本文中,将为大家介绍以为知道了但实际上并未真正了解的电源控制IC基础知识,以及ROHM目前正在挑战的旨在“带来电源控制IC革命”的新电源技术。

【元件】ROHM开始提供业界先进的“模拟数字融合控制”电源—LogiCoA™电源解决方案

ROHM公司推出了针对中小功率工业和消费电子设备的LogiCoA™电源解决方案。LogiCoA™微控制器作为此解决方案的核心,提供了高性能同时维持低功耗的优势。ROHM官网提供了评估参考设计“REF66009”以及其他相关工具。

ROHM Offers LogiCoA™: the Industry‘s First* Analog-Digital Fusion Control Power Supply Solution

ROHM has established LogiCoA™, a power supply solution for small to medium power industrial and consumer equipment (30W to 1kW class). It provides the same functionality as fully digital control power supplies at low power consumption and cost equivalent to analog power types.

【选型】ROHM(罗姆)LAPIS 8/16/32bit微控制器(MCU)选型指南(英文)

目录- Microcontrollers introduction 16bit General-Purpose MCUs 16bit Low Power MCUs 8bit Low Voltage MCUs 8bit Audio Playback MCUs 32bit USB Inter Face and Security Fanction MCUs 8bit/16bit MCU Development Support System MCUs Specification and Part Number Explanation

型号- ML62Q1713,ML610Q419C-NNNTBXXXX,ML62Q1714,ML610Q409P,ML62Q1557,ML62Q1711,ML62Q1712,ML62Q1555,ML62Q1556,ML62Q1710,ML62Q1723C,ML62Q1553,ML610Q429,ML62Q1554,ML62Q1551,ML62Q1552,ML62Q1550,ML62Q1300 GROUP,ML610Q431,ML610Q438,ML620Q503H,ML610Q439,ML610Q436,ML610Q435,ML62Q1704,ML610Q432,ML62Q1724,ML610Q408P,ML62Q1725,ML62Q1722,ML62Q1723,ML62Q1323,ML62Q1566,ML62Q1720,ML62Q1567,ML62Q1721,ML62Q1734C,ML62Q1325,ML62Q1564,ML610Q418,ML62Q1324,ML62Q1565,ML610Q419,ML62Q1563,ML610Q436A,ML62Q1544C,ML62Q1700 GROUP,ML610Q409A,MWU16,ML610Q306,ML610Q428,ML610Q412P,ML610Q304,ML610Q426,ML610Q305,ML610Q300,ML620Q504H,ML610Q421,ML610Q422,ML62Q1533,ML610Q409,ML62Q1733C,ML62Q1534,ML62Q1531,ML610Q407,ML62Q1532,ML610Q408,ML62Q1543C,ML62Q1530,ML610Q435A,ML610Q407D,ML610Q419C,ML610Q407A,ML610Q411P,ML610Q412,ML610Q411,ML610Q407P,ML62Q1702,ML62Q1703,ML620Q500,ML62Q1700,ML62Q1701,YQPACK064SA,ML62Q1544,ML62Q1300,ML62Q1542,YQPACK064SD,ML610Q407PA,ML62Q1543,ML62Q1540,ML62Q1554C,ML62Q1541,ML610Q418C,MODEL308,ML62Q1800 GROUP,ML610Q482,ML62Q1000 SERIES,ML610Q422P,ML610Q400,ML62Q1878,ML62Q1879,MODEL404E+,ML630Q400,MODEL400E+,ML62Q1553C,MODEL408E+,EASE1000 V2,NQPACK064SA,ML610Q421P,ML610482,ML610400,ML610Q411PA,ML62Q1748,ML62Q1869,ML62Q1749,LEXIDE-U16,MODEL416E+,ML62Q1800,ML62Q1366,ML610Q432A,ML62Q1367,ML62Q1714C,ML62Q1000,ML62Q1365,ML62Q1564C,ML62Q1500 GROUP,ML62Q1735,ML62Q1736,ML62Q1733,ML62Q1734,ML62Q1335,ML62Q1577,TEC-064SD-KC,ML610Q431A,ML630Q464,ML62Q1333,ML62Q1575,ML62Q1713C,ML62Q1334,ML62Q1576,ML630Q466,ML62Q1573,ML62Q1574,ML62Q1563C,DR.1000,ML62Q1728,ML62Q1729,ML62Q1726,ML610Q439P,ML62Q1727,ML62Q1746,ML62Q1747,ML62Q1868,ML610482P,ML62Q1744,ML62Q1745,ML62Q1346,ML62Q1500,ML62Q1347,ML62Q1743,ML62Q1724C,ML62Q1345,TEC-064SA-KC,ML610Q426C,DR1000-FLQ-64,ML610Q482P,MODEL400E+SERIES,NQPACK064SD-ND,ML62Q1739,ML62Q1737,ML62Q1858,ML62Q1738,ML62Q1859

PMICRO Launched PL51 Series Chips with ADC Function, Integrated Real EEPROM MCU and Built-in Single Cycle ET8051 Core

PMICRO launched a pl51 Series 003 product line with ADC function, integrated real EEPROM MCU, and built-in high-performance single cycle et8051 core. Excellent anti-interference and ESD protection ensure that the single-chip microcomputer can operate reliably in the harsh electromagnetic interference environment.

【选型】ROHM(罗姆)LAPIS 8/16/32bit微控制器(MCU)选型指南(中文)

目录- LAPIS微控制器产品介绍 通用微控制器(16bit) 低功耗微控制器(16bit) 低工作电压微控制器(8bit) 语音播放微控制器(8bit) USB、安全微控制器(32bit) 低功耗微控制器(8bit/16bit)开发支援系统 微控制器产品选型表

型号- ML62Q1713,ML610Q419C-NNNTBXXXX,ML62Q1714,ML62Q1711,ML62Q1557,ML62Q1712,ML62Q1555,ML62Q1710,ML62Q1556,ML62Q1723C,ML610Q429,ML62Q1553,ML62Q1554,ML62Q1551,ML62Q1552,ML62Q1550,ML610Q431,ML610Q438,ML620Q503H,ML610Q439,ML610Q436,ML610Q435,ML62Q1704,ML610Q432,ML62Q1724,ML62Q1725,ML62Q1722,ML62Q1723,ML62Q1323,ML62Q1720,ML62Q1566,ML62Q1721,ML62Q1567,ML62Q1734C,ML62Q1325,ML610Q418,ML62Q1564,ML62Q1324,ML610Q419,ML62Q1565,ML62Q1563,ML62Q1544C,MODEL400E+系列,MWU16,ML610Q306,ML610Q428,ML610Q304,ML610Q426,ML610Q305,ML610Q300,ML620Q504H,ML610Q421,ML610Q422,ML62Q1533,ML610Q409,ML62Q1733C,ML62Q1534,ML62Q1531,ML610Q407,ML62Q1532,ML610Q408,ML62Q1543C,ML62Q1530,ML610Q412,ML610Q411,ML62Q1702,ML62Q1703,ML620Q500,ML62Q1700,ML62Q1701,ODEL416E+,ML62Q1544,ML62Q1300,ML62Q1543,ML62Q1540,ML62Q1554C,ML62Q1541,ML610Q418C,ML610Q482,ML610Q400,ML62Q1878,ML62Q1879,MODEL404E+,ML630Q400,ML62Q1553C,ML62Q1367□-NNNTBXXXX,MODEL408E+,EASE1000 V2,ML610482,ML610400,ML62Q1869,ML62Q1748,AF9201,ML62Q1749,ML62Q1800,ML62Q1366,ML62Q1367,ML62Q1714C,ML62Q1000,ML62Q1365,ML62Q1564C,ML62Q1735,ML62Q1736,ML62Q1733,ML62Q1734,ML62Q1335,ML62Q1577,ML62Q1333,ML62Q1713C,ML62Q1575,ML62Q1334,ML62Q1576,ML62Q1573,ML62Q1574,ML62Q1563C,ML62Q1728,ML62Q1729,ML62Q1726,ML62Q1727,ML62Q1746,ML62Q1868,ML62Q1747,ML62Q1744,ML62Q1745,ML62Q1500,ML62Q1346,ML62Q1347,ML62Q1743,ML62Q1724C,ML62Q1345,ML62Q1000系列,ML62Q1739,ML62Q1737,ML62Q1859,ML62Q1738

罗姆(LAPIS)单片机开发环境和开发工具介绍

LAPIS的MCU已低功耗和抗干扰能力强著称,而且LAPIS自己也在做LCD驱动芯片,所以MCU也有支持段码和点阵驱动的版本,而且新一代的ML62Q1000系列支持IEC60730家电安全功能,所以LAPIS的MCU在仪表市场和家电市场有广泛的应用。现在介绍一下LAPIS单片机的开发工具,以作抛砖引玉。

Wireless Power Design Kit –Medium PowerOrder Code: 760308MP, Version 1.0 Transmitter Module, Receiver Moduleand LED Load Modulecompliant to Qi v1.2.2

型号- BD6142AMUV,ML610Q112,760308MP,ML610Q772-B03,BD57020MWV,760 308 102 207,BD57015GWL,760 308 110,TX MODULE,RX MODULE,BD9E151NUX

I have a question about the reset status register (RSTAT). It is described that the content of RSTAT register should be set to 00H in advance in order to identify the reset cause with this function. How should I initialize the content of RSTAT to 00H to identify the reset cause at MCU startup?

To initialize RSTAT, please follow the procedure below: 1. Start your MCU. 2. Read RSTAT with software. 3. Identify the reset cause. 4. Write 0x00H for the purpose of identification of the next reset cause. 5. Initialize RSTAT to 00H. Related Products: ML610(Q)40x, ML610(Q)42x, ML610(Q)47x, ML610(Q)48x, ML610Q10x, ML610Q11x, ML610Q17x, ML610Q30x, ML610Q35x, ML610Q36x, ML610Q38x, ML610Q41x, ML610Q43x, ML610Q46x, ML620Q13x, ML620Q15x, ML620Q416/ML620Q418, ML620Q503H/ML620Q504H/ML620Q506H, ML62Q12xx, ML62Q13xx, ML62Q14xx, ML62Q15xx/ML62Q18xx, ML62Q16xx, ML62Q17xx

ROHM(罗姆) MCU微控制器选型指南(中文)

描述- 低功耗、高性能、出色的抗噪性能,且符合国际安全标准IEC/UL60730。作为硬件具备"14种安全功能",作为软件具备"10种自我诊断功能"。

型号- ML62Q1713,ML62Q1714,ML62Q1557,ML62Q1711,ML62Q1712,ML62Q1555,ML62Q1556,ML62Q1710,ML62Q1723C,ML62Q2524,ML62Q1553,ML62Q1554,ML62Q2522,ML62Q1551,ML62Q1552,ML62Q2000,ML62Q20XX,ML62Q1550,ML62Q1704,ML62Q1724,ML62Q1725,ML62Q1722,ML62Q1723,ML62Q1323,ML62Q1566,ML62Q1720,ML62Q2534,ML62Q1567,ML62Q1721,ML62Q1734C,ML62Q1325,ML62Q1564,ML62Q2532,ML62Q1324,ML62Q1565,ML62Q1563,ML62Q1544C,ML610Q306,ML610Q305,ML610Q300,ML62Q2747,ML62Q2745,ML62Q2504,ML62Q2746,ML62Q1533,ML62Q1733C,ML62Q1534,ML62Q2502,ML62Q1531,ML62Q1532,ML62Q2500,ML62Q1543C,ML62Q1530,ML62Q2066,ML62Q2065,ML630Q400系列,ML62Q1702,ML62Q1703,ML62Q1700,ML62Q1701,ML62Q2502□-NNNTBXXXX,ML62Q1544,ML62Q1300,ML62Q1542,ML62Q1543,ML62Q1540,ML62Q1554C,ML62Q1541,ML62Q1878,ML62Q2725,ML62Q1879,ML62Q2726,ML62Q2723,ML62Q2722,ML630Q400,ML62Q1553C,ML62Q2045,ML62Q2043,ML62Q1367□-NNNTBXXXX,ML62Q1748,ML62Q1869,ML62Q1749,ML62Q2736,ML62Q2737,ML62Q1800,ML62Q2735,ML62Q1366,ML62Q2000系列,ML62Q1367,ML62Q1714C,ML62Q1000,ML62Q1365,ML62Q1564C,ML62Q2055,ML62Q2056,ML610Q300 GROUP,ML62Q2045□-NNNGDXXXX,ML610Q300 GROUP系列,ML62Q2727,ML62Q1735,ML62Q2703,ML62Q1736,ML62Q1733,ML62Q1734,ML62Q2702,ML62Q1335,ML62Q1577,ML62Q2700,ML630Q464,ML62Q1333,ML62Q1575,ML62Q1713C,ML62Q1334,ML62Q1576,ML630Q466,ML62Q1573,ML62Q1574,ML62Q1563C,ML630Q464□-NNNTBXXXX,ML610Q339,ML610Q338,ML62Q1728,ML62Q1729,ML62Q1726,ML62Q1727,ML62Q1746,ML62Q1747,ML62Q1868,ML62Q1744,ML62Q2712,ML62Q1745,ML62Q2713,ML62Q1346,ML62Q1500,ML62Q1347,ML62Q1743,ML62Q1724C,ML62Q1345,ML62Q2035,ML62Q2033,ML62Q1000系列,ML610Q306□-NNNGDXXXX,ML610Q327,ML62Q1739,ML62Q1737,ML62Q1858,ML62Q1738,ML62Q1859

ROHM(罗姆)LAPIS 无线通信LSI/模块选型指南 (英文)

目录- Wireless Communication LSIs/Modules Product Introduction Bluetooth® Modules Specified Low Power Wireless LSIs LPWAN (Low Power Wide Area Network) Wireless LSI Specified Low Power Wireless System LSI with Built-in MCU Wi-SUN Modules 13.56MHz Wireless Charger Chip set Wi-Fi Modules EnOcean® Modules Specifications

型号- ML7436N,ML7416N,ML7344CY,EDK 400J,STM 429J,ML7386X,MK74Q0410,BP35C1-J11-T01,BU1805AGU,MK71511A,STM 300,BP35C0-JXX,TCM 310,MK71521-NNN,BP35C5,TCM 410J,ML7416S,ML7396E,ML7396D,ML7396B,BP35C5-T01,ML7631,BP359B-T01,BP3591-T02,ML7630,BP3591-T03,USB 400J,BP3580,PTM 210J,STM 431J,ML7344XT,BP359F,MK71511A-NNN,MK71511,BP359D,BP359C,BP359B,ML7345D,ML7345C,ECO 200,BP3595-T02,BP3595-T03,BP3599,BP35C0-J11-T01,ML7345,MK715X1EK1A,BP3595,ML7386,MK71521A,BP3591,STM 431T,HSM 100,ML7406T,BP35C2-J11-T01,BP35A1,BP3622-T01,USB 500T,BP35C2,BP3621-T01,BP35C0,BP35C0-T01,MK71521,ML7386B,STM 400J,ML7344XY,MK71521A-NNN,PTM 330,ML7404,MK715X1EK1,STM 329,ML7396X,PTM 210,ML7414,USB 300,ML7345X,MK71511-NNN,STM 331,ML7406Y,PTM 430J,BP35C0-J11,BP35A7A,ML7344JY

Geehy APM32F407 Industrial HMI Solution Enhances Interactive Experience

The solution adopts APM32F407 high-performance MCU, 8080 interfaces, LCD, and I²C touch screen as the main control. It offers flexibility, convenience, and efficiency in meeting the specific requirements of equipment parameter display and control parameter setting.

能产生500KHZ的PWM且能被单片机控制的芯片有哪些??

世强代理的PWM脉冲发生器有ROHM品牌:【产品】用于LCD面板的PWM脉冲发生器BD9478F,通过产生可调PWM脉冲来控制LED状态如果要实现PWM输出,还可以选用带PWM功能的MCU:8位MCU EFM8 Busy Bee Family EFM8BB1 Data Sheet

电子商城

现货市场

服务

可定制显示屏的尺寸0.96”~15.6”,分辨率80*160~3840*2160,TN/IPS视角,支持RGB、MCU、SPI、MIPI、LVDS、HDMI接口,配套定制玻璃、背光、FPCA/PCBA。

最小起订量: 1000 提交需求>

可烧录IC封装SOP/MSOP/SSOP/TSOP/TSSOP/PLCC/QFP/QFN/MLP/MLF/BGA/CSP/SOT/DFN;IC包装Tray/Tube/Tape;IC厂商不限,交期1-3天。支持IC测试(FT/SLT),管装、托盘装、卷带装包装转换,IC打印标记加工。

最小起订量: 1pcs 提交需求>

登录 | 立即注册

提交评论