Top 5 Things You Might Not Know About PTFE Tapes

PTFE (Polytetrafluoroethylene) tapes, also known as high-performance fluoropolymer tapes, are indispensable across industries such as aerospace, automotive, chemical processing, and packaging. While these industrial PTFE tapes are renowned for their superior heat resistance, non-stick properties, and chemical inertness, there's more to these versatile materials than meets the eye.

High-performance PTFE tapes offer a range of benefits that often go unnoticed.

Here are the top five things you might not know about PTFE tapes that showcase their exceptional capabilities:

1. PTFE Tapes Exhibit Extreme Temperature Resilience from Aerospace to Automotive

PTFE tapes excel in high-temperature environments, but they are also able to withstand extremely cold temperatures.

PTFE tapes maintain their properties at temperatures ranging from –94 to 500°F (-70 to 260°C), making them ideal for applications like aerospace thermal shielding and automotive components that are exposed to intense temperature fluctuations. Keep in mind that temperature ranges may vary depending on capabilities of the tape’s adhesive, as tapes in general are limited to the adhesive capabilities regardless of tape type.

DeWAL® PTFE tapes exhibit exceptional temperature versatility. Their ability to perform consistently in both extreme heat and cold sets them apart from other materials, making them a go-to solution for industries facing the most demanding temperature challenges.

2. PTFE Tapes Offer Remarkable Chemical Resistance and Non-Stick Properties

While PTFE materials are famous for their non-stick properties, their chemical resistance is equally impressive.

Chemical-resistant tape solutions like DeWAL PTFE materials maintain durability in harsh chemical environments—whether exposed to acids, solvents, or bases. This makes them suitable for demanding applications in chemical processing, pharmaceutical manufacturing, and other corrosive environments.

From sealing and gasketing to lining applications, DeWAL PTFE materials maintain their integrity where other materials might fail.

3. Clean Removal: The Residue-Free Advantage of PTFE Tapes

One of the significant benefits of DeWAL PTFE tapes is their ability to be removed cleanly without leaving any residue.

These PTFE industrial tapes excel in process aid applications, designed for repeated use in extreme conditions and clean removal afterward. This feature is especially useful in mold release applications, industrial processes, sealing operations, and other scenarios where adhesive residue could compromise performance and product quality. The residue-free nature of PTFE tapes ensures consistent results and reduces maintenance time and costs.

4. PTFE Tapes Comply with Rigorous Industry Standards

PTFE tapes don’t just perform well; they also meet stringent industry standards.

DeWAL PTFE tapes meet various UL and MIL specifications, ensuring reliable performance in regulated industries such as aerospace, automotive, and electronics.

By meeting stringent industry standards, DeWAL PTFE tapes can be utilized in applications where safety, quality, and compliance are critical—like electrical insulation, composite manufacturing, and sealing applications.

5. Versatility in Action

Whether you need tapes for aerospace, automotive, or chemical processing, there’s a DeWAL PTFE tape specially designed for practically any requirement.

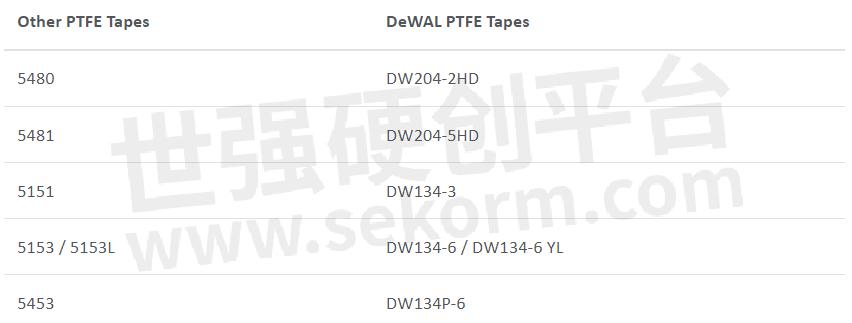

Looking for a New PTFE Tape Supplier?

If you've relied on other PTFE tape suppliers in the past and are having trouble sourcing PTFE tapes, ROGERS has you covered with a reliable DeWAL replacement. Use this cross-reference guide to find the DeWAL equivalent to your product:

Key Takeaways

PTFE tapes are more than just high-temperature materials; they are versatile, durable, and engineered to meet stringent industry standards. Whether you’re looking for a reliable supplier for PTFE tapes or just exploring new materials for demanding applications, DeWAL PTFE tapes offer an exceptional combination of performance and reliability.

Ready to explore the reliability of DeWAL PTFE Tapes for yourself?

- |

- +1 赞 0

- 收藏

- 评论 0

本文由samsara转载自ROGERS Official Website,原文标题为:Top 5 Things You Might Not Know About PTFE Tapes,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

DEWAL®DW500R产品数据表

描述- DeWAL® DW500R是一种单层耐磨等离子胶带,由红色硅橡胶和玻璃布背衬组成,涂有强粘性的高温硅胶粘合剂。该产品能承受砂光处理和等离子喷涂工艺,且可干净去除。DW500R具有比大多数其他等离子屏蔽胶带更高的粘性,使其容易适应最复杂的形状。

型号- DEWAL® DW500R

Rogers高性能胶带

描述- Rogers Corporation提供高性能胶带产品,包括ARLON自粘硅橡胶胶带、BISCO硅泡沫胶带和DeWAL聚四氟乙烯和UHMW胶带。这些产品广泛应用于航空航天、汽车、电子、医疗等领域,具有高可靠性、耐高温、耐化学腐蚀等特点。Rogers提供全面的技术支持和全球物流支持,以满足客户的需求。

型号- HT-870,HT-875,204-2HD,ARLON®,BF-2000,204-5HD,A2040-R004-12,A3020-R004-12,204-3,T2020-B004-12,DEWAL®,BF-2005,BF-1005,497,410,BF1000WHT .375X36X10 NT,BF-1000,A3030-R012-12,MOX-TAPE®,BISCO®,A1010-R004-12,A2020-R004-12,215-2HD,T1020-B004-12,BF1005WHT .375X36X10 AT,HT-840,HT-820,HT-800,215-5,HT-845,HT-825,HT-805,A1020-R004-12,101T,500,T1010-B004-12,T3020-B004-12,504,T2040-B004-12,T3030-B012-12

罗杰斯公司推出DeWAL®Plasma X等离子喷涂遮蔽胶带

DeWAL Plasma X等离子喷涂遮蔽胶带具有高达260°C(500°F)的耐高温性、自生产之日起12个月的保质期,以及强力而清洁的粘合剂剥离性能,可轻松承受重型喷涂工艺的严苛要求。

DeWAL®DW405BNC刮削UHMW-PE薄膜产品数据表

描述- DeWAL® DW405BNC是一种经过碳黑复合的超高分子量聚乙烯(UHMW-PE)薄膜,具有耐紫外线、耐磨和导电性低的特点。该产品适用于磨损表面、软管外覆层和防噪音带。

型号- DEWAL® DW405BNC,DEWAL®DW405BNC

DEWAL®DW212PO产品数据表

描述- DeWAL® DW212PO是一种经过钠萘蚀刻处理的PTFE薄膜,具有非粘表面、低摩擦、优异的化学和高温抵抗能力。该产品适用于多层隔膜、橡胶类应用增强表面耐磨性以及胶粘剂层压(压力敏感胶带)。

型号- DEWAL® DW212PO

【产品】DeWAL®DW235 MSPU-Gray复合材料具有优异的尺寸稳定性和不粘特性,用于扁平电缆结构

Rogers的DeWAL®DW235 MSPU灰色复合材料与聚氨酯粘合,其具有卓越的低收缩率、尺寸稳定性、低摩擦系数、优异的柔韧性和不粘特性。拉伸强度、总厚度以及伸长率均符合ASTM-D6040标准。

DeWAL®DW232PA多孔烧结聚四氟乙烯,用于汽车电池通风应用

描述- DeWAL® DW232PA是一种全烧结多孔聚四氟乙烯(PTFE)薄膜,具有优异的热稳定性和化学稳定性。该产品适用于汽车电池通风应用,能够在封闭空间中进行通风和压力平衡,同时抵抗热循环疲劳。

型号- DEWAL® DW232PA,DW232PA

DeWAL®DW244-2HD产品数据表

描述- DeWAL® DW244-2HD是一种由PTFE薄膜制成的高温硅粘合剂涂层产品。该产品具有高强度、低延伸率和高介电强度,适用于线圈缠绕、绝缘分隔器、变压器、槽衬和电缆包覆等电气应用。

型号- DEWAL® DW244-2HD

【产品】DeWAL®DW235 MSPU复合材料,具有优异的耐化学性和抗压性,可用于扁平电缆结构

DeWAL®DW235 MSPU是一种与聚氨酯(TPU)粘合的挤出稳定膨胀PTFE复合材料。它具有PTFE的固有优势,具有卓越的耐化学性、抗压性、低收缩率、尺寸稳定性、低摩擦系数、优异的悬垂性和不粘特性。

DEWAL®DW351-5产品数据表

描述- 本资料介绍了DeWAL® DW351-5和DeWAL® DW351-1两种铝箔涂覆聚四氟乙烯(PTFE)和压力敏感硅酮粘合剂的胶带产品。这些产品具有高温范围、化学抵抗力、低摩擦系数等特点,适用于高温热封应用、制造和转换过程、食品包装以及电子应用的EMI/RFI屏蔽。

型号- DEWAL® DW351-5,DEWAL® DW351-1

用于工业通风应用的DEWAL®DW353V膨体聚四氟乙烯(ePTFE)薄膜

描述- DeWAL® DW353V系列是一种热稳定的、单向取向的膨胀聚四氟乙烯(PTFE)膜产品。该系列产品具有较低的密度,具备PTFE的所有优点,如优异的化学抗性、尺寸稳定性、极宽的温度范围(从-450°F到+500°F)、低摩擦系数、出色的悬垂特性和不粘性质。其可控孔径和天然疏水性使其适用于需要液体和颗粒物防护的应用,同时允许蒸汽释放和压力平衡。

型号- DW353V-03,DEWAL® DW353V,DEWAL® DW353V SERIES

DEWAL®DW235 MSPU-灰色层压板

描述- 本资料介绍了Rogers Corporation(罗杰斯公司)的一款弹性材料解决方案。该材料具有良好的柔韧性,适用于扁平电缆设计,提供粘合层和保护层功能。

型号- DEWAL®DW235 MSPU-GRAY

DEWAL®DW402B削片UHMW-PE薄膜产品数据表

描述- DeWAL® DW402B 是一种碳填充的超高分子量聚乙烯(UHMW-PE)薄膜,具有优异的抗磨损能力和导电性。该产品适用于视频磁带隔垫和静电耗散等应用。

型号- DEWAL® DW402B

DEWAL®DW FST压敏胶带产品数据表

描述- DeWAL® DW FST是一种采用高度拉伸的PTFE薄膜和高温硅粘合剂的压敏胶带。该产品具有极高的单位抗拉强度、韧性和耐温性。

型号- DEWAL® DW FST

DeWAL®DW601 Dynaglide®PTFE材料产品数据表

描述- DeWAL® DW601 是 Dynaglide® 系列中的一款特殊填充聚四氟乙烯(PTFE)复合材料。该材料以玻璃纤维为填料,成品呈朱红色。其厚度范围在 12.7mm 至 305mm 之间。具有增强耐磨性、提高承载能力、柔韧性和低摩擦系数等特点。

型号- DEWAL® DW601

电子商城

品牌:ROGERS

品类:High Frequency Circuit Materials

价格:¥550.8681

现货: 2,000

品牌:ROGERS

品类:Circuit Materials

价格:¥2,479.9453

现货: 1,286

品牌:ROGERS

品类:Antenna Grade Laminates

价格:¥2,989.4355

现货: 429

品牌:ROGERS

品类:High Frequency Circuit Materials

价格:¥554.2134

现货: 385

品牌:ROGERS

品类:Liquid Crystalline Polymer Circuit Material

价格:¥1,485.0299

现货: 253

品牌:ROGERS

品类:Antenna Grade Laminates

价格:¥2,571.9097

现货: 250

品牌:ROGERS

品类:High Frequency Circuit Materials

价格:¥2,669.6313

现货: 250

品牌:ROGERS

品类:PTFE/Woven Fiberglass Laminates

价格:¥16,030.1502

现货: 201

品牌:ROGERS

品类:High Frequency Circuit Materials

价格:¥2,393.1651

现货: 200

登录 | 立即注册

提交评论