Design of the Welding Process for Battery Storage Lower Housing

The battery storage housing plays a crucial role in energy storage systems, serving essential functions such as load protection, thermal uniformity, electrical installation, and waterproof sealing. With the increasing demands for battery energy density, aluminum alloy materials have become an effective solution to enhance battery system performance due to their higher thermal conductivity and lower density.

The integrated design of flow channels with the housing sidewalls can save welding work in critical load-bearing areas, thereby improving overall structural strength. This design ensures structural safety and stability under various conditions, including static loads, lifting, and random vibrations, while also improving the airtight performance of the housing to some extent. Furthermore, the integrated design helps reduce the number of parts and lower the weight of the housing. Made through extrusion molding, this process has low mold costs, is easy to process, and can be easily modified to meet flexible production needs.

1-Main Types of Aluminum Extruded and Welded Energy Storage Lower Housing

The liquid-cooled lower housing for energy storage typically has a width of 790-810 mm and a height ranging from 40-240 mm, divided into flat and flange types . The length of the liquid-cooled lower housing is related to the capacity of the energy storage product, with common specifications including 48s, 52s, and 104s.

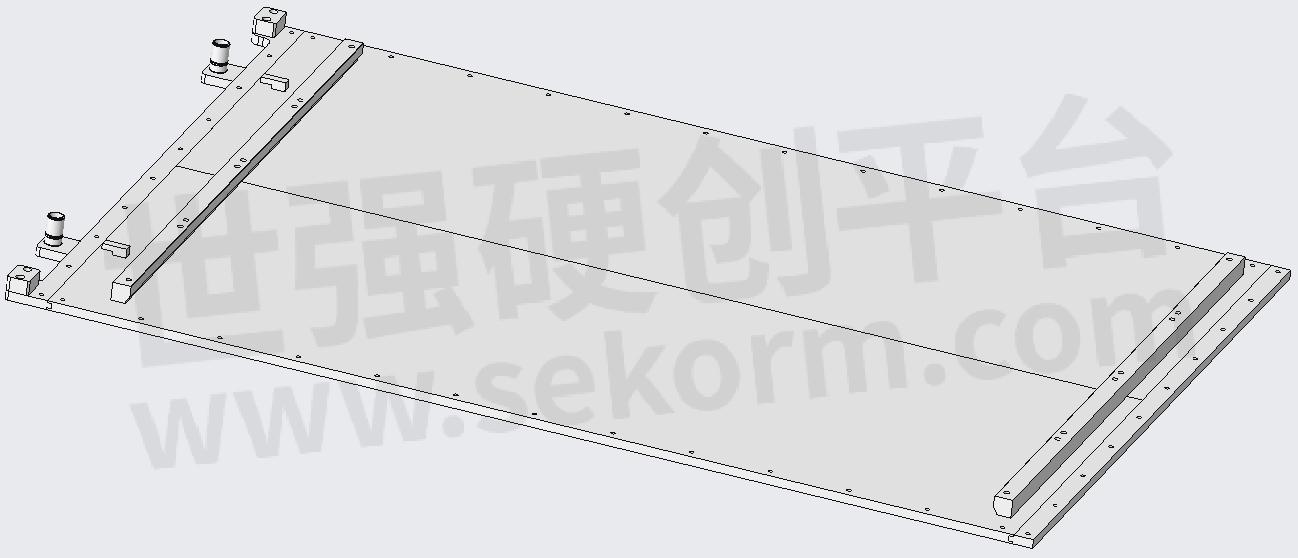

flat tray liquid-cooled lower housing

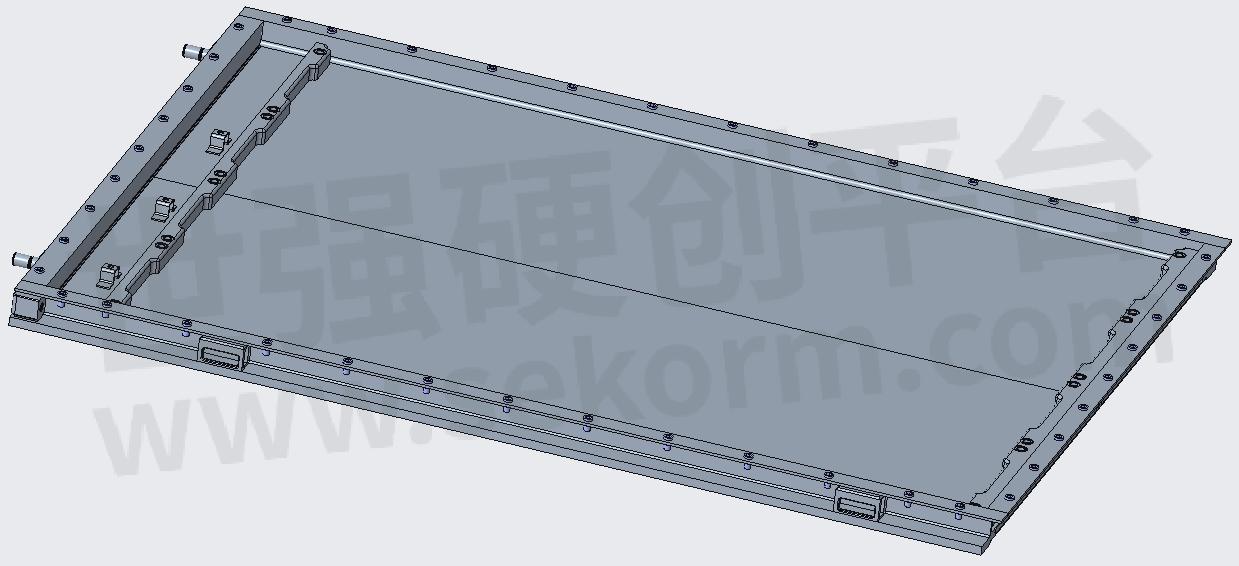

flanged battery tray liquid-cooled lower housing

2-Structural Form of Aluminum Extruded and Welded Energy Storage Lower Housing

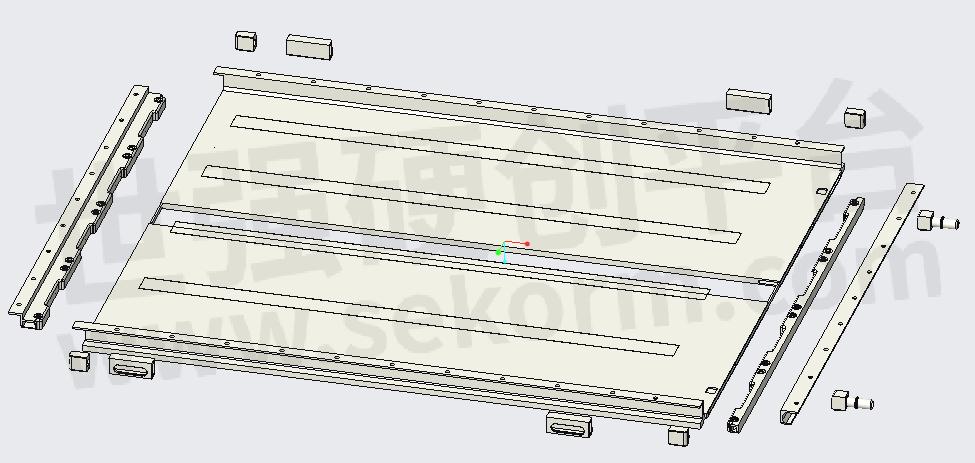

The liquid-cooled lower housing serves as the foundational structure of the entire battery pack, consisting of a bottom plate with flow channels, sealing strips, water nozzles, frames, beams, brackets, and lifting ears, all welded together to form a rectangular frame structure made entirely of aluminum alloy.

Explosive view of the battery lower tray

The liquid-cooled lower housing must possess sufficient load-bearing capacity and structural strength, which imposes high requirements on welding quality, including welding processes, weld grade control, and welder skills, to ensure safety and reliability in actual applications. Liquid cooling technology demands high airtightness for the liquid-cooled housing, including the airtightness of the lower housing and the liquid cooling flow channels. Additionally, the liquid cooling flow channels must withstand the pressure of the coolant flow, necessitating even higher airtightness requirements.

3-Welding Quality Requirements

Generally, the liquid-cooled bottom plate is welded using friction stir welding, and the end caps of the flat liquid-cooled lower housing also employ friction stir welding. Typically, the weld depression for friction stir welding should be ≤0.5 mm, and there should be no detachment or metallic foreign objects that could fall off under vibration conditions.

Liquid cooling flow channels, frames, water nozzles, lifting ears, beams, and accessories are often welded using TIG or CMT welding. Considering the performance requirements of different components, full welding is used for liquid cooling flow channels, frames, water nozzles, and lifting ears, while segment welding is applied to beams and accessories. The flatness of the front and rear battery module beam areas should be <1.5 mm for a single module and <2 mm overall, with frame flatness allowing ±0.5 mm for every additional 500 mm of frame length.

Weld surfaces must be free from defects such as cracks, incomplete penetration, lack of fusion, surface porosity, exposed slag inclusions, and incomplete filling. Generally, the height of the water nozzle weld should be ≤6 mm, and other welds should not extend beyond the lower surface of the housing. The internal welds of the front and rear module beams must not protrude from the inner surface.

The weld penetration must meet relevant standard requirements. For arc-welded joints, the tensile strength should not be less than 60% of the minimum tensile strength of the base material; for laser and friction stir welded joints, the tensile strength should not be less than 70% of the minimum tensile strength of the base material.

Additionally, the welding of the lower housing must meet the airtightness standard of IP67. Therefore, post-welding treatment generally requires the weld slag and seams in the front and rear module beam areas to be ground flat. External welding on the tray should not be ground, and the sealing surfaces at the welds need to be smooth, with no significant height differences from the frame.

Below:Extrusion+FSW battery tray for ESS

- |

- +1 赞 0

- 收藏

- 评论 0

本文由梨花落风转载自Walmate Official Website,原文标题为:Design of the Welding Process for Battery Storage Lower Housing,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

What are ESS DC Energy Storage Fuses?

The DC energy storage fuse is a critical component in ensuring the safety and reliability of modern energy storage systems. By providing fast-acting protection against overcurrents and short circuits, these fuses help maintain the integrity of energy storage systems in various applications, from residential solar setups to large-scale industrial energy solutions.

Key Points in Designing Aluminum Profiles Used in New Energy Vehicles and Energy Storage Battery Packs

The battery pack is a key component of new energy vehicles, energy storage cabinets and containers. It is an energy source through the shell envelope, providing power for electric vehicles and providing consumption capacity for energy storage cabinets and containers. In combination with actual engineering needs, this article summarizes the key points of profile design for battery packs by analyzing the requirements of mechanical strength, safety, thermal management and lightweight of battery packs.

Application of Three Terminal Fuses in Energy Storage

Three terminal fuse is a special type of fuse commonly used in energy storage systems to protect batteries and energy storage devices from damage caused by faults such as overcurrent and short circuit. Here is some information about the application of three terminal fuses in energy storage.

Vincotech Introduces a New Multi-sourced FlowPACK 1 H6.5 Family Power Module for Single-phase PV and ESS Systems

Vincotech‘s latest additions extends the family for bidirectional ESS applications. Engineered for applications from 3 kW up to 10 kW, these power modules are housed in 12mm, low-inductance flow packaging.

ITT储能产品介绍(ITT Energy Storage products introduction)

描述- 本资料介绍了ITT公司提供的储能产品,包括分布式和集中式储能解决方案。资料详细介绍了SC堆叠电池端口系列、液冷连接器、通信连接器与线缆等产品,并阐述了其特征、优势、参数和应用。此外,还提供了订购指南和产品对比,以帮助客户选择合适的产品。

型号- 132089-1841,132089-0102,132089-1821,IESSC1012-PAK1A-(2X),132089-1141,132089-1221,132089-1541,132089-0203,132089-1521,132089-0202,132089-0103

Energy Storage Market for UAVs by Product and Geography - Forecast and Analysis 2022-2026

The “Energy Storage Market for Unmanned Aerial Vehicles (UAVs) by Product and Geography - Forecast and Analysis 2022-2026“ report has been added to Technavio‘s offering.

【产品】1200V三电平NPC功率模块,太阳能、UPS和ESS应用首选

Vincotech最新推出了两款flowNPC系列功率模块,开关频率高达50KHz,损耗降低了6%,成本降低了10%,可广泛应用于开关模式电源(SMPS)、太阳能逆变器和不间断电源(UPS)等领域。

Bringing Network Transformers, Photovoltaic Energy Storage Transformers and More, Mentech Announced a Distribution Agreement with Sekorm

Mentech signed an distributor agreement with Sekorm, authorizing Sekorm to represent its network transformers, photovoltaic energy storage transformers, power inductors and other products. The relevant information and product information of Mentech has been launched, and you can get relevant information by searching.

Design and Analysis of a Bidirectional DC-DC Converter for Energy Storage Systems

One of the key components of an ESS is the bidirectional DC-DC converter, which is responsible for converting the DC voltage of the battery to the appropriate voltage level for the load or grid, and vice versa. The article discusses the design and analysis of a bidirectional DC-DC converter for energy storage systems.

爱仕特新款碳化硅功率模块EasyPACK,适用于1500V太阳能系统和ESS应用的快速开关

深圳爱仕特科技有限公司推出新款碳化硅功率模块EasyPACK,为适用于储能系统(ESS)这样的快速开关应用,有助于提高太阳能系统的额定功率和能效,并满足对1500V DC-link太阳能系统与日俱增的需求。

GRL DNESS Energy Storage Fuses—The Reliable Guardian of High-Current Protection

GRL‘s DNESS Energy Storage Fuses are specialized protective devices for Energy Storage Systems (ESS), offering robust overcurrent protection. Unlike traditional fuses, they handle high voltage and current demands, especially in DC environments. GRL‘s DNESS series simplifies solutions, enhances reliability, and is cost-efficient, supporting the future of ESS across various sectors.

SUPU‘s Energy Storage Connector Products Shape Zero-carbon Future

SUPU, as a total solution provider of electrical connectivity, specializes in providing customers with safe and reliable energy storage connector products and solutions that are used in various energy storage system environments. With superior technology and full production capacity, SUPU‘s products are widely used by major energy storage customers.

WIMA PowerBlocks Energy Storage Solutions with Long Lifetime >90,000 Hours

The design of the WIMA PowerBlock energy storage modules has from the beginning been developed to fulfill the requirements in mobile heavy duty applications. Modular design allowing the flexibility to fit the product into application needs. Designed especially for highly cyclical loads in heavy mobile work machines.

登录 | 立即注册

提交评论