Thermal Conductivity of Aluminum Alloy: Principles, Factors, and Applications in High-efficiency Heat Transfer Equipment

Aluminum alloy is the most widely used non-ferrous metal structural material in industry, especially in scenarios where the thermal conductivity of materials is of great concern, and in situations where efficient heat conduction is required, such as electronic equipment heat dissipation, electric vehicle three-power heat dissipation, and battery energy storage systems. In the fields of heat dissipation and aerospace, it is usually used to manufacture efficient heat transfer equipment such as radiators, heat conduction plates, and electronic components.

Thermal conductivity, also called thermal conductivity, is a parameter index that characterizes the thermal conductivity of materials. It indicates the heat conduction per unit time, unit area, and negative temperature gradient. The unit is W/m·K or W/m·℃. Aluminum alloy is an alloy material composed of aluminum and other metals. Its thermal conductivity is very excellent, and the thermal conductivity coefficient is usually between 140-200W/(m·K). As the metal with the highest content in the earth's crust, aluminum has a relatively low thermal conductivity coefficient. It is favored because of its high height, low density and low price.

1-Thermal conductivity principle of aluminum alloy materials

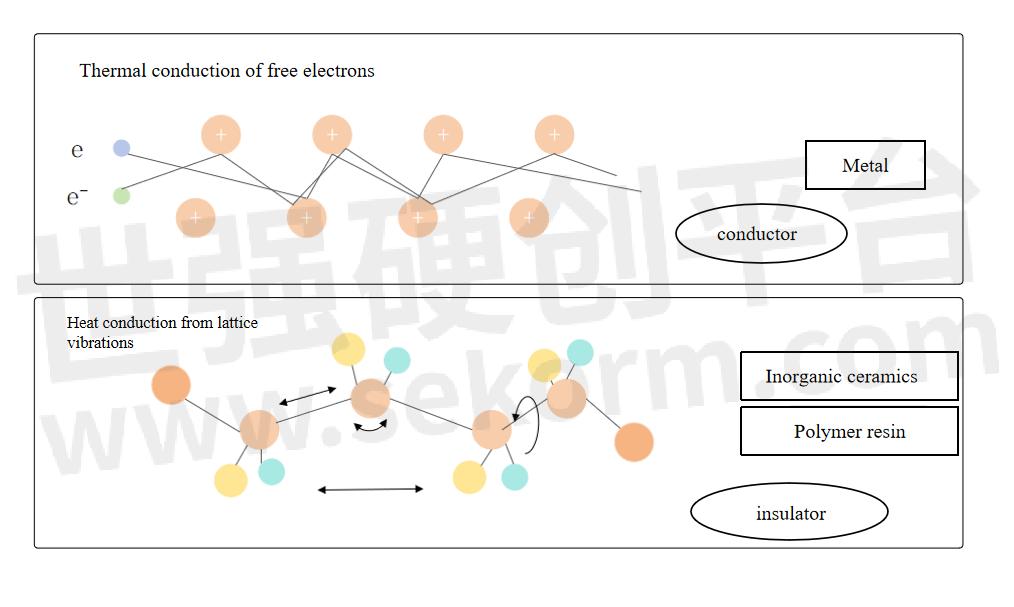

When there is a temperature difference between adjacent areas of a material, heat will flow from the high-temperature area to the low-temperature area through the contact part, resulting in heat conduction. There are a large number of free electrons in metal materials. Free electrons can move quickly in the metal and can quickly transfer heat. Lattice vibration is another way of metal heat transfer, but it takes a back seat compared to the free electron transfer method.

Comparison of heat conduction methods between metals and non-metals

2-Factors affecting the thermal conductivity of aluminum alloys

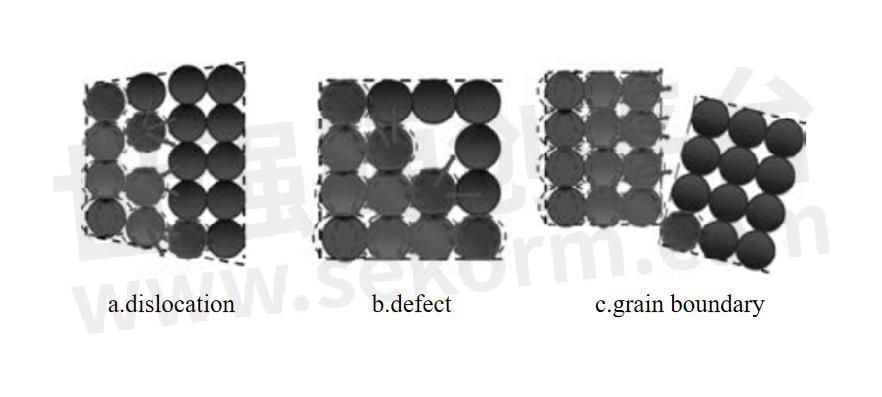

a.Alloying is one of the main factors affecting thermal conductivity. Alloying elements exist in the form of solid solution atoms, precipitated phases and intermediate phases. These forms will bring crystal defects, such as vacancies, dislocations and lattice distortion. These defects will increase the probability of electrons having three colors, resulting in a reduction in the number of free electrons, thus Reduce the thermal conductivity of the alloy. Different alloying elements produce different degrees of lattice distortion on the Al matrix, and have different effects on thermal conductivity. This difference is the result of multiple factors such as the valence of the alloying elements, the difference in atomic volume, the electron arrangement outside the nucleus, and the type of solidification reaction.

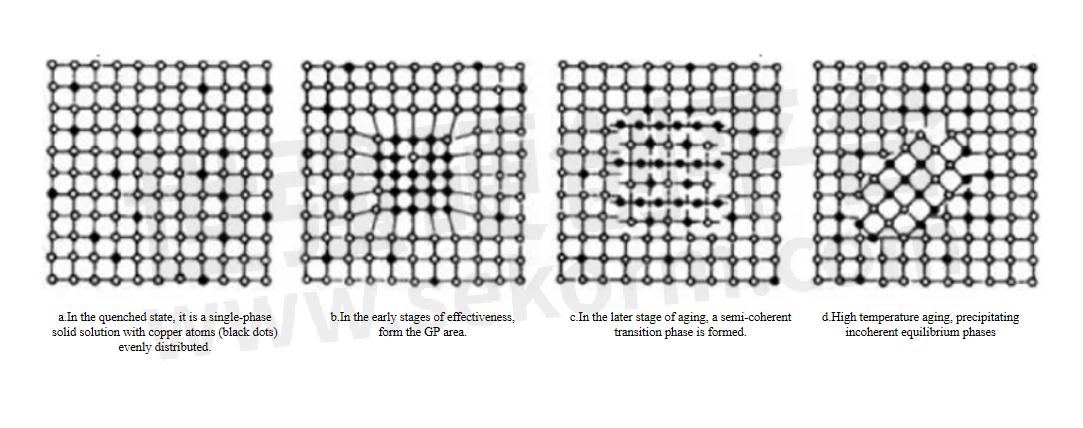

b.Heat treatment is a very important step in the processing of aluminum alloys. By changing the microstructure and phase transformation of aluminum alloys, its thermal conductivity can be significantly affected. Solid solution treatment is to heat the aluminum alloy to a certain temperature to fully dissolve the solute atoms in the matrix, and then quickly cool it to obtain a uniform solid solution. This treatment improves the material's mechanical properties but usually reduces its thermal conductivity. Aging treatment is through appropriate cold deformation and reheating after solid solution treatment, which can optimize the microstructure of the alloy and improve its overall performance. The aging treatment takes into account the mechanical properties and thermal conductivity of the alloy, so that the alloy maintains high strength while also having good thermal conductivity. Annealing improves the microstructure of the alloy by maintaining it at a lower temperature to precipitate and redistribute the second phase in the alloy. Annealing treatment can improve the plasticity and toughness of aluminum alloys, but the effect on thermal conductivity varies depending on the specific situation.

Schematic diagram of crystal structure changes during the aging process of Al-Cu alloy

c.Other factors influence, impurities and second phase particles: Impurities and second phase particles (such as oxides, carbides, etc.) in aluminum alloys can scatter hot carriers (electrons and phonons), thereby reducing thermal conductivity. The higher the impurity content, the coarser the second phase particles and generally the lower the thermal conductivity. The grain size of aluminum alloys also affects thermal conductivity. Generally speaking, the smaller the grain size, the more grain boundaries there are and the lower the thermal conductivity. In addition, the processing method of aluminum alloy (such as rolling, extrusion, forging, etc.) will affect its microstructure and residual stress state, thereby affecting the thermal conductivity. Work hardening and residual stresses reduce thermal conductivity.

In summary, aluminum alloy is an ideal choice for high thermal conductivity materials. Factors such as the type of alloy elements in aluminum alloys and their forms, heat treatment methods, impurities, grain size, and molding methods will all affect the thermal conductivity of aluminum alloy materials. Comprehensive considerations should be taken when designing material composition and process planning.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由梨花落风转载自Walmate Official Website,原文标题为:Why aluminum alloy has become the first choice material for liquid cooling plates and radiators: Ana...,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Key Points in Designing Aluminum Profiles Used in New Energy Vehicles and Energy Storage Battery Packs

The battery pack is a key component of new energy vehicles, energy storage cabinets and containers. It is an energy source through the shell envelope, providing power for electric vehicles and providing consumption capacity for energy storage cabinets and containers. In combination with actual engineering needs, this article summarizes the key points of profile design for battery packs by analyzing the requirements of mechanical strength, safety, thermal management and lightweight of battery packs.

Application of Friction Stir Welding Technology in Battery Tray Manufacturing

At present, the lightweight effect of the aluminum alloy battery tray and plastic top cover scheme is significant and has been adopted by many car manufacturers. The battery tray adopts a scheme of aluminum extrusion profile+friction stir welding+MIG welding, which has low comprehensive application cost, meets the performance requirements, and can achieve the integration of the circulating water channel of water-cooled batteries.

热设计挑战与散热器加工制造

散热器是电子设备热设计中最常用的散热强化部件,其强化原理是增加换热面积,设计时一般要考虑发热源的热流密度、发热元器件温度要求、产品内部空间尺寸、散热器安装及外观设计等要求。

电池热管理和汽车轻量化制造商迈泰热传授权世强硬创代理

迈泰热传(Walmate)的热管理和轻量化设计和产品,已成功应用在电机、电控、电池和储能等模块上,成为国内诸多汽车主机厂和电池Pack厂和商业储能的首选供应商。

Rhyton Releases New Ultra-Soft Thermal Absorbing Material HiTMA4018, Best for Electromagnetic Wave Shielding from 10-30GHz

Rhyton HiTMA4018 is a kind of high-performance material with thermal conductivity and absorbing functions. Its applied methods and scenarios are similar to traditional thermal pads, which can be directly applied between high power chips and radiators or metal shell.

Waermtimo, a New Composite Cooling Material Supplier, Anounced a Distribution with Sekorm to Enrich Carbon Fiber Thermal Conductive Materials and More

Waermtimo focuses on developing various new composite heat dissipation materials. It has more than 10 kinds of patented technologies, including two-component thermal conductive silicon sheet, PET film with spherical graphite layer, high-density graphene radiators, heat dissipation materials, and their preparation methods, to provide customers with heat conduction materials with high thermal conductivity and low thermal resistance.

Sekorm Became an Official Authorized Distributor of Aavid

Sekorm is an official distributor of Aavid, acting for its heat dissipation materials, radiators, heat pipes and hot plate heat dissipation components, water cooling plates, ultra-thin uniform temperature plates, etc.

液冷板气密性检测合格,为何仍会出现渗液问题?

在液冷板生产制造过程中经过严密气密性测试,针对液冷板出现的渗液问题,本文分析了该问题产生的原因,并提出了相关的预防措施。

无硅导热凝胶系列[导热填缝剂]数据表

描述- 本资料介绍了HFC品牌的无硅热导凝胶系列产品,该产品是一种不含低分子硅氧烷的热界面材料,适用于对硅油敏感的环境。产品具有高热导率、低热阻、无硅油挥发和污染等特点,适用于半导体、散热器、光学精密设备、汽车电子、LED和医疗电子等领域。

型号- HTG-500SF,HTG-300SF

A Guide on Aluminium Extrusion

In recent times, there has been an increased demand for Aluminium Extrusion in product manufacturing and design. This led to an increase in the demand for a professional and reliable Aluminium Extrusion manufacturer.In the course of this article, we will talk about Aluminium Extrusion in detail. Aluminium Extrusion is a process that manufacturers use to create components and parts having certain cross-sectional profiles. To enhance both the properties and appearance of the aluminum, the manufacturer uses different mechanical and surface enhancement processes.

Waermtimo Offers High-strength Thermal Conductive Pad and Thermal Pad for High-speed Optical Module Heat Dissipation

To solve the heat dissipation problem of the optical module, the heat dissipation panel must meet the two conditions of heat conduction and heat dissipation. The heat dissipation of chip components mainly uses high thermal conductive materials with a certain degree of flexibility.

Heat Sink Selection and Mechanical Criteria

Heat sink selection, taking into account mechanical conditions and requirements other than thermal criteria, is also decisive for the long-term reliable function of devices, modules, or systems.

Discussion on the Development of Battery Tray for New Energy Vehicles

The three major focuses of current new energy vehicle development - safety, lightweighting, and reliability - are closely related to the battery pack, and the battery housing is the load-bearing component of the battery system, which has a significant impact on the collision, energy consumption, and other aspects of the battery pack and even the entire vehicle.

登录 | 立即注册

提交评论