What‘s Next for the Internet of Things?

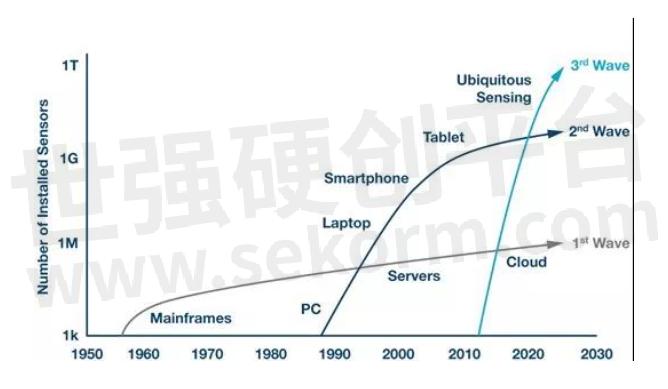

The initial technology maturity curve for iot development is only based on an increase in the number of deployed and potential sensors. Today, we can look to the future and explore some important success factors. Future trends in the Internet of things, including iot applications, will bring economic benefits to end users. There is also a trend towards longer battery life, lasting for years. In any wireless iot monitoring system, data transmission consumes power. Therefore, the perception and processing take place at the edge nodes through intelligent partitioning, and the amount of data is reduced (in a more sporadic or shorter period) through local decisions, thus bringing significant added value to the iot system. Finally, the key element of the future is the ability to operate safely and reliably. Therefore, for successful iot systems, the focus of iot design will shift to key performance indicators such as trusted sensors and system uptime. Analysts estimate that low - cost development systems are currently in the Peak of expectation inflation. In the next two to five years, differentiated or specialized high - precision sensors and analog signal chains will become the mainstream and truly push the Internet of things market into the future.

>> importance of good data

A key process in iot systems is the conversion of analog signals into digital signals. Simply put, the better the transformation, the more useful the data. Silicon technology innovates to transform and interpret the world around it, bridging the real and digital worlds through detection, measurement, interpretation, and connectivity.

The most effective iot deployment is the ability to use this data to determine change. And best change is the biggest value for end customer, such as higher efficiency and higher security, such as in factories, machine learning is not only able to identify when may need to machines for predictive maintenance in the future, but also can identify the details and reach a higher level of recognition, to determine what action to take (for example, to identify specific ball bearing in motor wear).

Therefore, the first stage of any iot system is to detect, measure, and then convert real-time signals into analytical data. How well this stage is completed will lay the foundation for future success. If the wrong information data is entered, the results obtained from any iot analysis cloud platform will also be wrong. Therefore, the most successful iot systems have to have measurement and reporting levels that other systems cannot.

This need to improve measurement and reporting makes good hardware essential. A recent Gartner report said the same. Report that they are low cost iot development look fast into the bubble period of disillusionment (trough of disillusionment. This may be due to the plethora of low-cost development platforms available. But I think it's more likely that we're focusing on more challenging iot applications that have more real economic value. These applications rely on data results that rough measurements simply cannot support.

>> partition between iot system nodes and cloud

Cloud technology supports the adoption of extended multiple signal chains, including analytics and big data. Iot applications mainly in edge nodes achieve high intelligence - this is the result of many factors, including the transmission of all data to the cloud bandwidth (or more precisely: error - free transmission of the data transmission rate limit), or delay problem, namely node required action speed means that the system can't waiting for the response returned from the cloud. Therefore, multiple control loops are required on nodes, intermediate gateways, and in the cloud. The cloud is able to consolidate data for a large number of sensors and adjust edge Settings based on that data. McKinsey reckons that only 1% of cloud data is actually used, and that security threats mean it is better to keep data local.

The implementation of intelligent partitioning and embedding algorithm in the sensor can interpret the most critical data at the source in real time. Algorithms embedded in smart sensors and the cloud can read data deeper than silicon chips. In fact, this makes it possible to predict future system behavior. Accelerating the adoption of iot solutions in mission - critical applications depends on the ability to build secure systems, which smart partitioning can do.

Cloud computing draws insights from this connection between a large number of preliminary sensor readings and correlates a variety of different sensor readings based on time, location, and other sensors. This consists of two parts: the ability to detect changes in data (for example, the drift of machine performance) and the ability to create a "digital twin" of a software model of a real object (such as a motor) or system. These digital twins can be used to proactively repair equipment or plan production processes. This is part of the outlook for explosive growth in sensors over the next few years, as well as the ability to monetize software and services.

In industrial automation, active machine monitoring can fundamentally improve uptime efficiency, achieve real - time optimization and intervention locally, and integrate information across multiple factories and systems in the cloud for analysis and response, thus improving productivity.

So smart iot system partitioning can ensure effective utilization of the cloud.

> > reliable data is key

The final piece of what is crucial to the Internet of things is the creation of wireless networks. The vast majority of networked objects are wirelessly connected back to the cloud using radio and microwave frequencies. The operation mode is various, the operation range is from short to long, and the data rate is from low to high. Some devices may not communicate for months or years, while others need to operate across critical business security networks. Many sensor nodes are also powered by batteries or energy collectors, so efficient operation will be key. Communication networks are critical to the transmission of intelligence from sensors to the cloud on demand.

But reliable operation will be the most critical element for the successful implementation of the iot system. All of these different requirements put a lot of emphasis on communication networks for sensor to cloud intelligence delivery. Reliable operational capability is particularly challenging in harsh environments, such as factories built of metal and concrete. What customers need most is low - cost, low - power, low - latency technology. They also want the sensor layout to expand unchecked. Creating a reliable network without relying on wireless protocols is to maintain this high reliability by using alternative paths and channels to overcome interference.

Article source website, reprint indicate the source.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由wenxia转载自RF-STAR Official website,原文标题为:What's next for the Internet of things?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Electrical Terminal Blocks in Industrial Automation

Terminal blocks are modular insulating blocks that hold two or more wires together. The factory uses terminal blocks to secure and terminate wires. In its most basic form, a terminal block consists of several individual terminals arranged in a long strip. Terminal blocks are best used for grounding wiring, with hundreds of millions in use today and more being installed every day.

The Advantages and Specific Applications of WiFi Modules in Industrial Automation

WiFi modules are widely used in industrial automation due to their advantages such as wireless connection, high bandwidth, wide coverage, easy integration and expansion, and cost-effectiveness. They are widely used in remote monitoring and management of industrial equipment, wireless sensor networks for smart factories, navigation control for AGVs and mobile robots, data collection and transmission for production lines, and connection and communication for industrial IoT platforms, effectively promoting the development of industrial automation.

Key Applications of IoT Modem in Industrial Automation

This article will explore in detail the key applications and functional advantages of IoT Modem in industrial automation, and analyze its application effect in practical scenarios through specific case studies.

信驰达USB Dongle&模组选型表

信驰达提供以下Sub-1G模组,USB Dongle,Wi-Fi模组,Zigbee模组,低功耗蓝牙模组,多协议无线模组,国产芯片低功耗蓝牙模组和无线模组的参数选型,工作电压(V):1.7 V ~ 5.5 V,推荐3.3 V,GPIO:7~48,工作温度(℃):-40 ℃ ~ +125℃等。

|

产品型号

|

品类

|

芯片型号

|

内核

|

天线类型

|

RAM(KB)

|

Flash(KB,MB)

|

支持协议

|

工作电压(V)

|

工作频段(GHz,MHz)

|

最大发射功率(dBm)

|

接收灵敏度(dBm)

|

功耗

|

GPIO

|

工作温度(℃)

|

储存温度(℃)

|

通信距离(m)

|

模块尺寸(mm)

|

封装方式

|

OTA升级

|

蓝牙Mesh

|

Long Range模式

|

2Mbps高速模式

|

AoA/AoD支持

|

透传协议

|

产品特点

|

应用场景

|

|

RF-BM-2642QB1I

|

低功耗蓝牙模组

|

CC2642R-Q1

|

48 MHzARM® Cortex®-M4F

|

IPEX/邮票孔

|

88 KB

|

352 KB

|

BLE 5.2

|

1.8 V ~ 3.63 V,推荐3.3 V

|

2.4 GHz

|

+5 dBm

|

-97 dBm @ BLE 1M PHY-105 dBm @ 125 kbps LECoded PHY

|

TX:25.58 μA@0 dBm 1000ms广播间隔睡眠功耗:2.49 uA

|

31

|

-40 ℃ ~ +105 ℃

|

-40 ℃ ~ +125 ℃

|

200 m @ 1M PHY 300 m @ LE Coded PHY

|

17.0 x 21.5 x 2.2

|

SMT(邮票半孔)

|

OTA升级

|

蓝牙Mesh

|

Long Range模式

|

2Mbps高速模式

|

AoA/AoD支持

|

主从一体,一主七从

|

AEC-Q100车规级,外置天线,抗干扰性能高

|

汽车(汽车门禁和安全系统、高级驾驶辅助系统、远程信息处理控制单元),音箱主机,工业(工业运输-资产跟踪、工厂自动化和控制)

|

选型表 - 信驰达 立即选型

信驰达(RF-star)无线通信模块选型指南

信驰达(RF-star)是一家专注于低功耗无线射频应用的高新技术企业,致力于为客户提供基于 BLE、Wi-Fi、 UWB、Zigbee、Thread、Matter、Sub-1G、Wi-SUN、LoRa等核心技术的软硬件设计与制造,APP及物联网云后台开发、大数据分析、以及OEM与ODM服务,其产品及服务广泛分布于新能源汽车、消费电子、医疗电子、工业物联网、智慧能源等领域。公司于2010年在深圳成立,并陆续在香港、成都、北京,苏州设立分部。

信驰达 - USB加密狗,低功耗蓝牙模块,ZIGBEE模组,SUB-1G模组,WI-FI模组,USB DONGLE,无线模组,低功耗BEACON蓝牙信标,低功耗蓝牙模组,多协议无线模组,无线通信模块,RF-BMPA-2541B1,RF-DG-52PA,RF-WM-20DNB1,RSBRS02AI,RF-WM-3235A1S,RF-SM-1277B2,RF-SM-1277B1,RF-BM-ND04I,RSBRS02AA,RF-WM-10AFB1,RF-BM-ND04C,RF-BM-S01,RF-BM-S02,RF-BM-2652P2I,RF-WM-3200B3,RF-WM-3200B1,3B32_V102,RF-BM-4044B5,RF-WM-20CMB1,RF-BM-ND05I,RF-BM-4044B2,RF-BM-4044B4,RF-SM-1077B2,RF-BM-4044B3,RF-SM-1077B1,RF-BM-2642B2,RF-BM-2642B1,RF-DG-40A,RF-BM-BG22B1,RF-ZM-2530P1I,RF-BM-BG22B3,RF-BM-BG22A3,RF-WM-3235B1S,RF-B-SR1,RF-BM-ND02C,RF-BM-4077B1,RF-BM-4077B2,RF-BM-MG24B2,RF-BM-MG24B1,RF-BM-ND04A,RF-BM-2652P7,VL-LE01B,VL-LE01A,RF-BM-2340T1,WE1005,RF-BM-2340T3,RF-BM-2340T2,RF-BM-BG22C3,RF-BM-2652P2,RF-BM-2652P3,RF-BM-2652P4,RF-BM-4077B1L,RF-BM-2652P1,RF-ZM-2530B1,RF-WM-ESP32B1,RSBRS02ABR-01,RF-BM-ND09A,RF-WM-11AFB1,RF-DG-22A,RF-BM-4055B1L,RF-BM-2340QB1,RF-BM-ND04CI,RF-BM-2340C2,RF-DG-52PAS,RF-B-AR3,RF-B-AR4,RF-B-AR1,RF-B-AR2,RF-BM-2652B1,RF-ZM-2530P1,RF-BM-2642QB1I,RF-BM-2652B2,RF-BM-BG22A1,RF-TI1352B1,RF-ZM-2530B1I,RF-NBE01,RF-BM-2340A2I,RF-BM-BG22A1I,RF-BM-2340B1,RF-BM-2652RB2,RF-WM-3235B1,RF-BM-2340B1C,RF-BM-S02A,RF-CC2540A1,RSBRS02ABR,RF-BM-ND10,RF-BM-S02I,RF-DG-32B,RF-BM-BG24B1,RF-BM-ND01,RF-BM-ND02,RF-BM-ND04,RF-BM-ND05,RF-BM-ND06,RF-BM-ND07,RF-BM-ND08,RF-BM-ND09,RF-SM-1044B2,RF-SM-1044B1,RF-BM-2340A2,RF-BM-2340B1I,RF-SM-1044B4,RF-TI1352P1,RF-WM-3235A1,RF-TI1352P2,RF-BM-2652P4I,RF-BM-ND08C,RF-BM-S01A,RF-BM-ND08A,RF-WM-3220B1,RF-BM-2651B1,RF-BM-BG24B2,RF-BM-BG22A3I,RSBRS02ABRI,患者监测,智能手表,保健传感器,门锁,温度计,低功耗无线传感网络,智能照明,人机界面,个人健身,照明系统,音箱主机,资产标签,电梯,智能出行,物品追踪,无线通信,物联网,健身房器械,便携医疗器械,智能建筑,智能插头,保健,无线音频,住宅自动化,智能跟踪器,家庭影院,生活方式传感器,可穿戴应用,智能射频标签,MESH 组网,照明控制,电子销售终端,AR,消费型电子,智慧能源,射频远程控制,多协议设备,A4WP设备,可穿戴设备,蓝牙遥控玩具,传感网络节点,资产跟踪,机顶盒,IP网络摄像头,接近感应玩具,自行车传感器,价格标签,电子玩具,恒温器,智能灌溉,FACP,安全警示标签,网关,LED灯具,可穿戴产品,电子销售网点,高级遥控器,网络化家居,婴儿监控器,建筑安全系统,农业机器人,安全系统,媒体系统,生产制造自动化,健身追踪器,汽车检测设备,电子锁,远程控制,游戏手柄,智能家用电器,燃气表,销售点,智能扬声器,阿达斯,LED 照明,工厂自动化,开关,家庭动化,访问控制,仪表计量,汽车电子,电子游戏,安全锁,IP 网络传感器节点,汽车,交流充电桩,语音远程控制,RF4CE远程控制系统,心率监视器,室内外导航,医疗传感器,集线器,CPAP机,心率计,能量收集,已联网家用电器,工业遥控,无线环境传感器,电池供电医疗器械,家庭自动化,家电控制,机顶盒设备,PEPS,智能插座,专业照明,演示笔,消防安全系统,IP摄像机,玻璃破裂探测器,零售餐饮,活动监视器,电子门锁,工业总线,电子货架标签,自动抄表,环境传感器,火警控制面板,水表,VR,工业运输,网络处理器,HVAC 控制器,智能能源,钥匙查找器,热量探测器,楼宇安防系统,暖通空调,IP 网络摄像机,资产管理,车库门开启器,消费电子,无线控制传感器,手环,IP 网络摄像头,智能显示器,防火安全,工业物联网,智能家居,运动检测器,机器人玩具,游戏,电动牙刷,健身设备,智能服装,CE遥控器,工业,玩具,POS系统,工业控制,灯具,简单网络处理器,智慧农业,计算器外设,虚拟现实,医疗电子,零售,健身,遥控器,通信设备,健康监测,家用电器,鼠标,定点设备,人员管理,运动手表,HVAC 系统,健康,通用低功耗 IOT 数据记录器,电脑周边,互动娱乐设备,家庭保健,无线LAN,远程信息处理控制单元,WI-FI 接入点,个人护理,气体检测仪,便携式医疗设备,蓝牙网状网络低功耗节点,网络音乐播放器,团体运动装备,服务机器人,安防系统,智能温室大棚,交流充电站,血糖仪,零售自动化,交互式娱乐设备,无线医疗保健,通用蓝牙产品,工业机器人,SPO2,自动扶梯,家庭娱乐,室内导航,SRD 系统,通用低功耗 IOT 传感器集线器,应收账,RKE,视频监控,隐藏,网络广播,HVAC系统,防火安全系统,智能电网,WI-FI 音箱,计算机外围设备,电视,促红细胞生成素,信息推送,智能仪表,智能手环,物联网应用,无线LED显示系统,运动设备,智能按钮,一次性医疗器械,低功耗摄像头,健身传感器,门窗传感器,小型企业路由器,便携式 POS 终端,手写笔,ESL,升降机,无线 LAN,HID,WI-FI,助听器,自动扶梯控制装置,唤醒词检测,互联网网关,楼宇自动化,工业监控,零售支付,个人局域网,脉搏血氧计,支付应用,体重秤,手表,I/O器件,工业自动化,智能玩具,ISM 系统,遥控玩具,键盘,紧急按钮,健康设备,传感器,智能追踪器,医疗保健,观众响应系统,个人电子产品,资产追踪,高级驾驶辅助系统,医学,建筑自动化,照明,ADAS,MESH网络,智能家居产品,电脑游戏控制器,BLE智能灯,HVAC,工业MESH网络,密钥,楼宇安全系统,远程显示,遥测,工厂控制,消费电子远程控制,手机配件,建筑,热量分配表,医疗器械,边缘路由器,接近警示标签,汽车门禁,设置盒遥控器,广告,血压监测仪,增强显示,POS 系统,蓝牙键盘,跑步,电梯主控板,HVAC 系统控制器,热分配表,预测性维护,ZIGBEE系统,蓝牙智能应用程序,医疗,玻璃破碎检测,血糖监测仪,电子智能锁,患者诊断,支付系统,A4WP无线充电器,血压计,家庭,远距离传感器,定位服务,联网健康设备,安防,有线网络,实时定位系统,多点触摸板,智能家电,传感器网络,音频流媒体设备,日光传感器,低功耗蓝牙,高级个人健身设备,虚拟显示,电脑外设,政治公众人物,可穿戴健身活动监测仪,接入点,智慧城市基础设施,电子温度计,电表,电器,游戏控制器,车库门系统,自动化数据采集,电网基础设施,HMI,2.4GHZ IEEE 802.15.4系统,零售应用,音频设备,新能源汽车,电动汽车充电基础设施,手写板,OTT 电视盒,无线传感器网络,可视门铃,EPOS,室内定位,电网通信,烟雾探测器,物流,监控器,联网手表,数据采集

Tiangong Measurement and Control WiFi Module: A Powerful Assistant for Industrial Automation Applications

Industrial automation is the core of modern manufacturing, aimed at improving production efficiency, reducing costs, enhancing product quality, and ensuring the stability of the production process. With the rapid development of information technology, WiFi modules, as a key wireless communication technology, are playing an increasingly important role in the field of industrial automation. It provides a convenient and efficient solution for the interconnection and intercommunication between industrial equipment, promoting industrial automation towards intelligence and networking.

Sub-1G物联网五大应用场景及信驰达主流无线模组推荐

Sub-1G是一种强大且具备多功能的无线技术,可提供远距离、强穿透力和低功耗通信,被广泛应用智能电表、工业控制、家庭自动化、智慧农业、智慧城市等各个领域。作为行业领先的无线射频模块厂商,信驰达科技可根据客户项目需求提供高性能Sub-1G模块和无线物联网整体解决方案。随着无线通信的快速发展,Sub-1G有望在IoT和其他无线应用中发挥越来越重要的作用。

【选型】Silicon Labs BG22、xG24、BG27无线SoC比较及信驰达无线模块选型指南

作为安全、智能无线技术领域的前沿品牌,Silicon Labs在最近几年陆续推出了EFR32BG22、EFR32xG24、EFR32BG27等系列无线SoC。RF-star作为物联网行业领先的无线通信模组厂商,基于Silicon Labs的无线SoC推出了RF-BM-BG22x系列串口转蓝牙透传模块、RF-BM-BG24x旗舰系列低功耗蓝牙模块和RF-BM-MG24x旗舰系列并发多协议无线模块。

信驰达推出低功耗蓝牙胎压监测系统(TPMS)解决方案,实时监测胎压、温度和电量,预置自动定位功能

信驰达基于车规级高精度胎压传感监测芯片SNP746,推出一体式后装蓝牙TPMS解决方案,整套方案包括内置胎压传感器PCBA+嵌入式软件+移动端APP,适用于蓝牙4.0以上智能手机,配合四个安装在车胎上的内置蓝牙胎压传感器,APP端可实时接收每个轮胎的压力和温度,在汽车行驶过程中对轮胎的压力和温度数据进行监测,当轮胎状态出现异常时可及时报警,确保行车安全。

信驰达(RF-star)物联网射频模组选型指南

信驰达 - WI-FI 蓝牙二合一模组,无线串口收发模块,低功耗BEACON蓝牙信标,低功耗蓝牙模组,多协议无线模组,蓝牙SOC,小型USB设备,USB加密狗,ZIGBEE模组,无线SOC,SUB-1G模组,WI-FI模组,USB DONGLE,自研国产芯片低功耗蓝牙模组,无线模组,多协议模块,RF-BM-ND09A,RF-WM-11AFB1,RF-DG-22A,RF-WM-20DNB1,RF-WM-3235A1S,RF-BM-ND04CI,RF-SM-1277B2,RF-WM-RTL8720DNB1,RF-BM-ND04I,RF-SM-1277B1,RF-BM-2340C2,RF-BM-ND04C,RF-DG-52PAS,RF-BM-2652P2I,RF-WM-3200B3,RF-WM-3200B1,RF-B-AR4,RF-B-AR1,RF-BM-2652B1,RF-ZM-2530P1,RF-BM-BG22A1,RF-BM-2652B2,RF-TI1352B1,RF-BM-4044B5,RF-ZM-2530B1I,RF-WM-20CMB1,RF-BM-2340A2I,RF-BM-BG22A1I,RF-BM-ND05I,RF-BM-2340B1,RF-BM-4044B2,RF-BM-4044B4,RF-SM-1077B2,RF-BM-4044B3,RF-SM-1077B1,RF-WM-3235B1,RF-BM-2642B2,RF-DG-40A,RF-BM-BG22B1,RF-BM-ND10,RF-BM-BG24B1,RF-ZM-2530P1I,RF-DG-32B,RF-BM-BG22A3,RF-BM-ND04,RF-WM-3235B1S,RF-BM-ND05,RF-BM-ND06,RF-BM-ND08,RF-B-SR1,RF-BM-2340B1I,RF-BM-2340A2,RF-BM-4077B1,RF-BM-4077B2,RF-BM-MG24B2,RF-BM-MG24B1,RF-TI1352P1,RF-WM-3235A1,RF-BM-ND08C,RF-BM-2652P4I,RF-BM-ND08A,RF-BM-2652P7,RF-WM-3220B1,RF-BM-2651B1,RF-BM-BG22C3,RF-BM-BG24B2,RF-BM-2652P2,RF-WM-RTL8720CMB1,RF-BM-2652P3,RF-BM-BG22A3I,RF-BM-2652P4,RF-ZM-2530B1,智能手表,TPMS,智慧农场,智能楼宇,个人护理,便携式医疗设备,智能汽车,门锁,智能照明,智能医院,智能停车,计算机外设,智能穿戴,医疗传感器贴片,互联网医疗设备,零售自动化,血糖仪,智能插头,洁面仪,打印机,智能消防,隐藏,照明控制,电子销售终端,智能水表,逆变器,智慧能源,智能电网,无线鼠标,可穿戴设备,智能医疗,资产跟踪,信息推送,智能手环,自行车传感器,互联健康行业,智能安防,信标,网关,照明管理,智慧路灯,智能燃气表,存储,手写笔,智能游戏,智能电表,ESL,腕带,HID,血糖监测,唤醒词检测,无线传感器,楼宇自动化,脉搏血氧计,蓝牙标签,无线传感网络,智能健康,智能玩具,LED 照明,智能物联网,开关,门诊护理,蓝牙网关,传感器,个人电子产品,资产追踪,遥控装置,家庭网络,建筑自动化,智能计量行业,智能安全,语音远程控制,室内外导航,照明,集线器,头戴式显示器,胎压监测系统,WBMS,家庭自动化,楼宇安全,PEPS,边缘路由器,安防监控,智能汽车充电站,智能太阳能光伏系统,预测性维护,电子货架标签,无线抄表,无线键盘,医疗,玻璃破碎检测,工业空调,定位服务,工业检测,资产管理,消费电子,胰岛素泵,智能家电,新能源汽车行业,光伏储能充电站行业,工业物联网,扫地机器人,电子销售点,政治公众人物,智能家居,远程传感器,电动牙刷,游戏,智能计量,智能服装,游戏控制器,玩具,智能抄表,互联医疗设备,工业控制,灯具,电池储能系统,充电桩,电动汽车充电站,远程患者检测,新能源汽车,医疗电子,零售,零售EPOS,无线医疗,鼠标,人员管理,电动剃须刀,光伏储能充电站

【IC】信驰达基于ESP32-C3推出低功耗Wi-Fi蓝牙双模模块RF-WM-ESP32B1,工作频率高达160MHz

2023年5月,领先的无线物联网通信模块厂商深圳信驰达科技RF-star推出基于ESP32-C3 SoC的低功耗WiFi/BLE双模通信模块——RF-WM-ESP32B1。采用乐鑫SoC芯片ESP32-C3。

Kinghelm KH-BS2430-1 Battery Connector, with 30MΩ MAX Contact Resistance, Revolutionizing Industrial Automation with Precision

This article introduced the Kinghelm KH-BS2430-1 Battery Connector – a compact, high-performance sensor designed specifically for industrial automation and monitoring applications. With its high precision and sensitivity, this sensor can rapidly respond to and accurately capture changes in target parameters, ensuring the accuracy and real-time nature of measurements.

【经验】解析信驰达RF-BM-BG22系列模块作openmcu开发时无法烧录固件如何解决

信驰达RF-BM-BG22系列模块使用的是Silicon Labs的EFR32BG22系列芯片,不少开发者为了省去硬件开发周期,会直接选择使用信驰达的模块进行openmcu开发,但会出现无法正常烧写程序的情况,本文将介绍如何将模块恢复为可正常可烧写状态。

信驰达RF-DG-40A:国产化nRF52840 Dongle的改进与优势分析

Dongle最早由Nordic公司在2018年推出,信驰达科技推出了基于nRF52840的Dongle产品RF-DG-40A,帮助用户对无线硬件设备进行测试。本文将介绍RF-DG-40A的优势。

电子商城

登录 | 立即注册

提交评论