Laird Thermal Systems Produces a Wide Array of Thermoelectric Coolers, Assemblies and Temperature Controller Combinations Optimized for Incubator Chambers

Introduction

Incubators, used for cell and tissue cultivation in hospital and laboratory settings, grow and maintain cell and tissue samples under controlled conditions for hours, weeks, or even months. They create the ideal environment for cell and tissue sample growth by maintaining optimum levels for temperature, humidity, carbon dioxide, and oxygen. Precision control of these factors enables research and experimental work in industries where cell culture is vital, such as zoology, microbiology, pharmaceutical research, food science, and cosmetics.

Accurate and precise control of temperature is especially important for cell growth. Excursions above and below the optimum mammalian body temperature of 37℃, even by as little as 6℃, negatively impact cell health. If too cold, growth slows, sometimes permanently; if too hot, sensitive proteins begin to denature.

Using thermoelectrics instead of compressor-based thermal management solutions provide a more efficient and cost-effective option. In addition, new government restrictions of traditional refrigerants central to compressor-based systems make thermoelectrics a more environmentally friendly solution for temperature stabilization in incubators.

Incubator Requirements

Control of temperature, humidity, carbon dioxide, and oxygen levels must be maintained in the incubators for proper cell culture to occur. The heat load requirements can range from 30 to more than 400 Watts based on chamber size. For CO2 incubators, relative humidity levels of 95 to 98 percent and specified CO2 concentrations ranging from 0.3 to 19.9 percent also must be maintained.

Design Challenges

Incubator manufacturers face many thermal management design challenges ranging from space constraints, airflow, moisture, and dust, to ease of cleaning.

Depending on the cabinet size the chamber will require a specific amount of cooling capacity to reach worst case cool down temperature. The higher the cooling capacity, the larger the cooling unit needs to be. However, the thermal solution must include an efficient heat exchanger with a thin profile that can operate in a confined space to maximize chamber volume. Therefore, thermal control units in space constrained incubators need to have high performance heat exchangers in order to reach the higher cooling capacity requirements.

Another challenge is ensuring consistent airflow throughout the chamber. Incubators feature fans to circulate air within the chamber. To minimize variability between samples they use air ducted shrouds to distribute air evenly throughout chamber. However, operating in a high humidity environment requires fans and other components to be protected from moisture that can cause corrosion and quickly degrade the performance of mechanical components. It can be difficult, however, to balance the high humidity levels needed for proper operation of the incubator with condensation forming inside the unit. Features such as gasket sealing, insulation, potting and routing of condensation can limit exposure to moisture degradation.

From an operational standpoint, dust environment in labs may be a concern. Depending on lab activity around where the incubator is stationed, dust can accumulate over time in the heat exchanger assembly and increase the thermal resistance. This will reduce performance and make the thermoelectric assembly work harder to achieve the same set point temperature. To maintain good thermal performance over time, it is ideal to keep air inlet away from the floor and consider using an air filter to capture dust from incoming air. The incubator design also must account for biohazard safety protocols by incorporating easy-to-clean and sterilize interiors and shelves. This may require the cooling unit to withstand elevated temperatures during the sterilization process.

Traditional Solutions

Typically, in a CO2 incubator, an air or water jacket maintains an even temperature. Since water has a much greater specific heat than air, water temperature changes much more slowly, thereby regulating the temperature inside the lab incubator. The water jacket, a water-filled casing surrounding the incubator, has inlet and outlet ports which circulate water through the chamber walls and to an external heating and/or cooling device. The water exchanges heat with the inner chamber via natural convection and provides a fairly uniform interior temperature and thermal buffer against outside air. The down side is water jackets may leak; and since they contain a significant volume of water, they are very heavy and usually need to be emptied before moving. After moving, the refill and restart process requires about 24 hours to return to a stable operating temperature, leading to significant downtime.

Using a similar casing to the water design, an electric coil or compressor-based system heats air within the jacket, which radiates heat directly to the cell cultures. Some air-jacketed models rely strictly on natural convection to distribute heat evenly inside the chamber, while others add fans. Forced convection, however, increases evaporation from the cultures, desiccating small samples, even when adding a humidity pan. In addition, compressor-based air jackets add unwanted vibration and noise to the lab environment, while generally occupying a large amount of space.

Recent government regulations restricting the use of specific refrigerants, particularly in Europe, are motivating incubator manufacturers to look at solid-state thermoelectric temperature control systems as an alternative to compressor-based systems. Older compressor-based systems utilize high global-warming-potential HFC refrigerants including R134a and R404A. Modern compressor-based systems now use a variety of natural refrigerants: R744 (carbon dioxide), R717 (ammonia), R290 (propane), R600a (isobutene), and R1270 (propylene). Each natural refrigerant, however, presents design challenges such as increased pressure, high toxicity, flammability, asphyxiation, and relatively poor performance. The flammable nature of some natural refrigerants makes them hazardous to transport and limits capacity.

Peltier Heating/Cooling

Environmentally friendly thermoelectric temperature control systems offer accurate and precise heating and cooling inside the chamber in a compact form factor. There are many advantages of using thermoelectrics for thermal management including cooling or heating modes, precise temperature control and rapid cool-down or heat-up ramp rates. They also keep samples safe from temperature changes. All of this is accomplished without the use of any refrigerants—natural or synthetic.

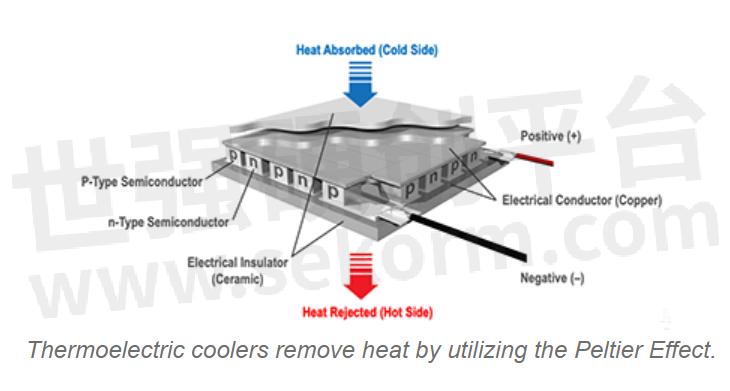

Thermoelectric coolers are solid-state heat pump devices which move heat via the Peltier effect. During operation, DC current flows through the thermoelectric cooler creating temperature differential across the module. While one side of the thermoelectric cooler gets cold (heat absorption), the other side heats up (heat dissipation). Thermoelectric coolers usually connect to forced convection heat sinks to the cold side to absorb heat from inside the cabinet, while the hot side heat sink rejects heat to ambient environment. By reversing the polarity of the thermoelectric cooler, it can also heat inside the cabinet. The ability to both heat and cool allows for precise temperature control.

Manufacturers of thermoelectric coolers define two specifications for thermoelectric coolers: ΔTMax and QcMax. ΔTMax is the maximum temperature differential with no heat flow (Qc = 0). QcMax is the maximum heat flow when no temperature difference exists (ΔT = 0). For most single-stage thermoelectric coolers, ΔTMax hovers near 70°C. However, a lot of this temperature differential can be lost thru thermal resistances of heat sinks. If greater cooling capacity is demanded, then more thermoelectric coolers are required. This can be done by wiring thermoelectric coolers in series or parallel to accommodate 12 or 24 VDC. Real-world operation of thermoelectric coolers and thermoelectric cooler assemblies involves the combination of ΔT and Qc to meet incubator heating and cooling requirements for temperature stabilization.

Thermoelectric cooler assemblies are compact units that allow design engineers to start with a basic set of building blocks mating fans and thermoelectric coolers to heat exchangers. They have a cooling capacity spectrum ranging from 10 to 400 Watts and are available in convection, conduction, or liquid heat transfer mechanisms.

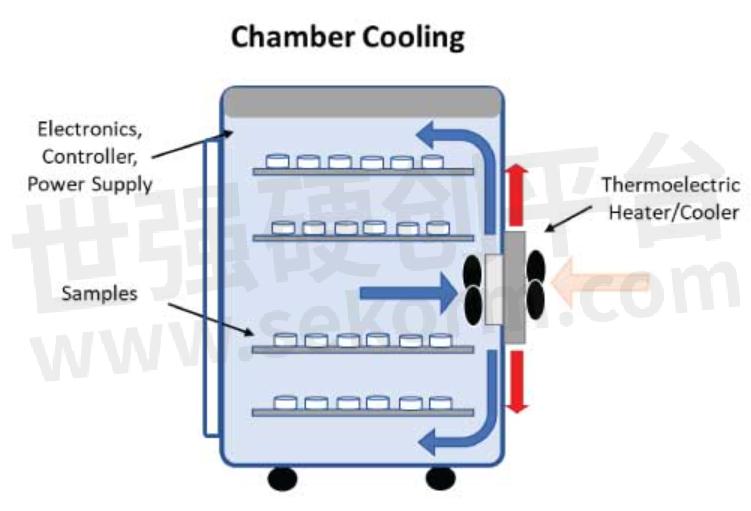

Below is an illustration on how a typical thermoelectric heater/cooler assembly is used to cool or heat an incubator chamber. The thermoelectric unit is mounted between two air heat exchangers. In cooling mode, air inside the chamber circulates across the cold side air heat sink and gets cold. The thermoelectric cooler absorbs the heat and pumps it out to the hot side heat sink. The hot side air heat exchanger circulates air to the ambient environment. In heating mode, the opposite occurs. To limit heat transfer to the ambient environment, the hot side fan is typically off in heating mode.

The combination of a closed-loop temperature controller with a thermoelectric cooler assembly creates a highly responsive, accurate and precise thermal management system. A temperature controller, specifically designed to control thermoelectric cooler assemblies, takes feedback from a temperature sensor to vary the output of the power supply to control the temperature of an enclosure. Temperature Controllers can accommodate a variety of control options to deliver energy savings and offer safety alerts. I/O contacts are available for fans, thermoelectric coolers, alarm/status LEDs, thermistors, fan tachometer sensors, and an overheat thermostat.

Laird Thermal Solutions for Incubators

Laird Thermal Systems produces a wide array of thermoelectric coolers, assemblies and temperature controller combinations optimized for this application.

Assembled with advanced thermoelectric materials, the new HiTemp ETX Series of thermoelectric coolers offers a 10% boost in cooling capacity compared to standard thermoelectric coolers. It also features a higher thermal insulating barrier, creating a maximum temperature differential (ΔT) of 83°C. The HiTemp ETX thermoelectric cooler is designed for high-temperature environments and for applications where both heating and cooling is required such as incubators. Learn more about the HiTemp ETX series.

Another option is any of the SuperCool X thermoelectric cooler assembly series outfitted with a SR-54 or PR-59 temperature controller. All options feature a high-performance heatsink design, incorporating heat pipes to improve heat dissipation and fan shroud assembly. Lowering the thermal resistance of the heat exchanger increases the heat-pumping ability, so these thermoelectric cooler assemblies can operate at a higher coefficient of performance (COP), reducing power consumption relative to competing technologies. The SuperCool X series utilizes next-generation high-performance thermoelectric coolers, offering up to a 20% improvement in cooling capacity compared to the legacy edition. All this capability is packed into a compact form factor.

The Series gives design engineers three different heat transfer mechanisms with three standard thermoelectric cooler assemblies: Liquid-to-Air, Direct-to-Air, or Air-to-Air. These assemblies offer cooling capacities of 115 to 407 Watts when measured at ΔT = 0°C with a nominal operating voltage of 24 VDC. They can be easily mounted onto vertical walls using fastening machine screw hardware. Learn more about the SuperCool X Series of thermoelectric cooler assemblies.

Combining a SuperCool X Series thermoelectric cooler assembly with a temperature controller offers significant design advantages over traditional technologies. The SR-54 programmable microcontroller provides thermal stability to within ±0.13°C of the set point in both heating and cooling modes. This controller allows the incubator to reach the set-point temperature quickly without overshooting. Its monitoring capabilities track potential issues, including problematic fans, thermoelectric coolers, and thermostats for quick fault troubleshooting, maximizing incubator uptime. Variable fan speed reduces operational noise since the fans only run on high speed during the initial temperature ramp and then lower their speed when the incubator temperature has reached steady-state.

Another option is the PR-59 temperature controller with power regulation that is selectable and user-configurable for PID (proportional-integral-derivative), thermostat ON/OFF, or POWER, protecting equipment and optimizing performance. The PR-59 programmable microcontroller delivers control stability to within ±0.05°C of the set point in both heating and cooling modes. By connecting to a PC with associated software, temperature set points and other parameters can be selected. Learn more about temperature controller options here.

Laird Thermal Systems can customize thermoelectric solutions based on specific application needs. Customers usually begin with a standard thermoelectric cooler assembly and adjust the form factor by modifying heat sinks, mounting locations, and air flow passages to work around obstructions. Barrier protection around the thermoelectric cooler cavity prevents condensation issues from impacting thermoelectric cooler assembly operation. Laird Thermal Systems understands how to modify designs to boost performance or efficiency, optimizing for the desired thermal-management effect. Many years of experience have stocked a large library with reference designs for similar applications, enabling quick response with new custom designs.

Conclusion

Using thermoelectrics for incubator temperature control, rather than traditional technologies, achieves an efficient, thermally stable, compact, reliable, low-maintenance and low-cost-of-ownership solution to CO2 incubator thermal management.

Laird Thermal Systems can partner closely with customers across the entire product development lifecycle to reduce risk and accelerate time to market. Depending on the customers' needs they can provide various levels of vertical integration. Some customers purchase Laird Thermal Systems’ thermoelectric cooler assemblies and build their own custom solutions while others design their own solutions and use Laird Thermal Systems as a contract manufacturer to build them. Still, others prefer the entire solution, from design to manufacturing.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由唯独你没懂转载自Laird Thermal Systems Official Website,原文标题为:Heating and Cooling of Incubator Chambers,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Laird Thermal Systems Offers Thermoelectric Coolers, Thermoelectric Cooler Assemblies and Temperature Controllers for Refrigerated Centrifuges

Centrifuges are crucial for separating mixtures in medical and food processing labs. They face thermal challenges like temperature stability and noise levels. Thermoelectric coolers, like those from Laird Thermal Systems, offer an efficient and reliable solution for precise temperature control in centrifuges, reducing power consumption and maintenance costs. Laird‘s CP Series and temperature controllers provide stable cooling capacities and accurate control, making them ideal for various centrifuge applications.

Laird Thermal Systems Thermoelectric Coolers Offer a Solid-State Heat Pump Solution to Medical & Cosmetic Lasers

Medical lasers, used in various surgeries, require precise temperature control to minimize tissue damage and enhance recovery. Thermoelectric coolers efficiently manage this by dissipating heat, maintaining a stable 20±0.5°C temperature, and offer benefits like low maintenance and compact size, making them ideal for medical laser systems.

莱尔德热系统一系列热电制冷器、组件和温度控制器组,提供用于培养箱的热管理解决方案

培养箱是实验室和医疗环境中用于细胞和组织样本培养的关键设备,需要精确控制温度、湿度、二氧化碳和氧气水平。热电技术提供了一种高效、环保的热管理解决方案,优于传统的压缩机系统。莱尔德热系统提供的热电制冷器和温度控制器组合,能够满足培养箱的热管理需求,提供精确的温度控制和快速响应,同时减少维护成本和提高可靠性。

Laird Thermal Systems(莱尔德热系统)热电冷却器选型指南(英文)

LAIRD THERMAL SYSTEMS - THERMOELECTRIC COOLERS,热电冷却器,430478-502,HTX20-31-F2A-0909-11-W2.25,64979-501,CP085-127-06-L1-W4.5,UTX15-24-F2-5252-TA-W6,CP14-31-10-L1-W4.5,ETX7-3-F1-2020-TA-RT-W6,9360001-301,7050045-502,71061-504,ETX14-12-F1-6262-TA-W6,PCX SERIES,UTX6-24-F1-5555-TA-W6,HTX15-31-F2A-0909-TB-W2.25,PCX7-156-F2-1672-TA-RT-W6,387008429,SH08-28-05-L1-W4.5,PCX6-12-F1-4040-TA-RT-W6,CP14-71-10-L1-W4.5,ULTRATEC™ UTX SERIES,PCX8-12-F1-4040-TA-W6,9340006-301,71092-501,ETX4-7-F1-2323-TA-W6,PCX7-16-F1-4040-TA-W6,ETX15-28-F2-5252-TA-RT-W6,387008431,CP14-127-10-L1-W4.5,387007103,CP14-35-045-L1-W4.5,430705-503,ETX4-7-F2-3030-TA-RT-W6,387007106,387007227,387007108,HTX12-65-F2A-1312-TB-RT-W2.25,OPTOTEC™ HTX,430874-503,71062-514,387007231,CP08-63-06-L1-W4.5,387007112,387007113,9350004-301,387007115,430052-501,387007117,MS5-257-10-15-11-W8,ETX2.5-12-F1-3030-TA-RT-W6,CP08-127-05-L1-W4.5,PCX10-223-F1-3172-TA-RT-W6,CP14-127-045-L1-W4.5,HITEMP ETX SERIES,430922-501,387007120,387007123,387007122,9320002-301,MS3-119-20-15-11-W8,ETX11-12-F1-4040-TA-RT-W6,MS SERIES,56760-505,ETX15-12-F2-4040-TA-RT-W6,MS2-192-14-20-11-18-11-W8,ETX6-12-F1-4040-TA-RT-W6,56590-502,SH10-23-06-L1-W4.5,71036-505,56610-502,MS4-108-10-20-11-W8,ETX4-12-F1-3030-TA-W6,430027-501,PCX12-248-F1-5040-TA-RT-W6,PT4-7-F2-3030-TA-W6,430848-502,OTX12-65-F2A-1312-11-W2.25,430848-504,PCX8-7-F2-3030-TA-RT-W6,MS2-068-14-14-15-15-11-W8,CP14-71-045-L1-W4.5,PCX,OTX20-66-F0-1211-11-W2.25,PCX4-6-F1-2040-TA-RT-W6,HTX,PCX5-16-F1-4040-TA-W6,56430-501,OTX19-23-F1N-0608-11-W2.25,HTX SERIES,UTX9-28-F2-4040-TA-W6,PCX15-7-F1-4040-TA-RT-W6,PT4-12-F2-3030-TA-W6,CP12-161-04-L1-W4.5,16506-302,430875-503,PCX8-6-F1-2040-TA-RT-W6,ETX4-3-F1-2020-TA-RT-W6,43280-503,66100-501,66156-505,71063-505,44440-501,71020-505,56550-501,MS3-052-10-17-11-W8,387004692,387005660,71012-506,SH10-125-05-L1-W4.5,387005662,ETX2.3-4-F1-1919-TA-RT-W6,ETX5-6-F1-2040-TA-RT-W6,387005663,ETX4-12-F2-4040-TA-RT-W6,387005664,387004697,387005665,387005667,387005669,OTX12-66-F0-1211-11-W2.25,430097-507,ETX2.6-12-F1-2525-TA-W6,PCX9-3-F2-2525-TB-RT-W6,387005671,387005672,MS2-102-22-22-17-17-11-W8,387005673,387005674,387005676,387005677,387005678,387005679,387005318,CP10-254-06-L1-W4.5,ETX9-3-F2-2525-TA-W6,CP10-71-05-L1-W4.5,430026-503,430511-504,56910-502,OTX20-66-F0-1211-11-EP-W2.25,387005681,387006650,56995-501,387006891,387005683,CP10-31-05-L1-W4.5,ETX6-19-F1-4040-TA-RT-W6,387006893,387005685,387005686,387006534,387006897,HTX15-30-F2A-0610-11-W2.25,OTX12-65-F2A-1312-TB-W2.25,RH14-14-06-L1-W4.5,ETX2-12-F2-3030-TA-W6,PCX8-6-F1-3518-TA-RT-W6,MS2-102-14-14-17-17-11-W8,387006784,UTX15-288-F2-5252-TA-W6,387005696,387006544,387005698,387005699,ETX4-12-F1-4040-TA-RT-W6,SH14-125-10-L1-W4.5,CP14-71-06-L1-W4.5,9340001-301,HTX12-18-F2A-0606-11-RT-W2.25,ETX,387006791,387006795,CP2-127-10-L1-W4.5,387006798,63604-511,CP14-199-06-L1-W4.5,PCX6-24-F1-5555-TA-RT-W6,OTX20-65-F2A-1312-11-W2.25,PCX5.6-19-F1N-3030-TA-RT-W6,ETX15-24-F2-5252-TA-W6,MS3-231-10-15-11-W8,SH14-125-045-L1-W4.5,62910-510,POWERCYCLING PCX,387005354,PCX24-128-F2-5555-TA-RT-W6,HTX15-65-F2A-1312-TB-W2.25,POWERCYCLING PCX SERIES,CP10-131-04-L1-TOW-W4.5,OTX08-18-F0-0505-11-W2.25,HTX12-18-F2A-0606-GG-W2.25,CP14-199-045-L1-W4.5,CP2-71-06-L1-W4.5,ETX4-6-F2-2143-TA-RT-W6,OTX20-68-F1A-1313-11-W2.25,71212-502,OPTOTEC™ OTX SERIES,CP SERIES,CP2-31-06-L1-W4.5,63595-501,POLARTEC™ PT SERIES,PCX4-4-F1-1515-TA-RT-W6,ETX8-12-F2-2525-TA-RT-W6,HTX12-65-F2A-1312-11-W2.25,OTX08-31-F1-0707-11-RT-W2.25,PT8-12-F2-4040-TA-W6,ETX4-12-F2-3030-TA-RT-W6,CP10-71-06-L1-W4.5,OTX08-66-F0-1009-11-RT-W2.25,CP14-17-10-L1-W4.5,ETX11-12-F2-3030-TA-RT-W6,ETX3-3-F2-1518-TA-W6,PCX4-7-F1-2020-TA-RT-W6,387004970,MS2-190-10-10-12-12-11-W8,387005700,CP10-127-06-L1-W4.5,ETX2.5-12-F1-4040-TA-RT-W6,9340002-301,MS2-065-04-04-11-11-11-W4,71049-501,9350007-301,POLARTEC™ PT,387006926,PT4-12-F2-4040-TA-W6,387006928,387006927,PCX11-12-F2-3030-TA-RT-W6,RH14-32-06-L1-W4.5,MS2-051-22-25-22-25-11-W8,ETX14-3-F1-3030-TA-RT-W6,MS4-115-14-15-11-W8,PCX8-176-F2-7528-TA-RT-W6,SH14-15-06-L-W4.5,PCX7.5-13-F1-4023-TA-RT-W6,OTX15-68-F1A-1313-11-W2.25,CP2-127-06-L1-W4.5,ETX6-7-F2-3030-TA-RT-W6,OTX08-08-F0-0303-11-W2.25,PCX6-28-F2-4040-TA-RT-W6,44530-501,MS2-049-10-10-15-15-11-W8,16503-310,475010-313,ETX3-48-F1-1212-GG-W6,UTX8-288-F2-5252-TA-W6,ETX2.6-6-F1-1225-TA-W6,UTX6-19-F1-4040-TA-W6,430436-504,OPTOTEC™ OTX,387006832,387006834,387006836,387006837,9350006-301,387006839,HTX20-65-F2A-1312-11-W2.25,9380001-301,MS3-070-20-25-11-W8,9340003-301,MS2-192-14-20-15-25-11-W8,MS4-129-10-15-11-W8,PCX2-12-F1-3030-TA-RT-W6,ETX2-6-F1-1225-TA-RT-W6,ETX4-3-F1-1515-TA-RT-W6,387005513,387006845,387005514,387005515,387006847,387005516,ETX25-12-F1-6262-TA-W6,ETX1.6-12-F2-3030-TA-RT-W6,OTX12-66-F0-1211-TB-RT-W2.25,430023-507,9350001-301,HITEMP ETX,387004679,57180-501,CP10-63-06-L1-W4.5,71035-505,PCX4-139-F1-1850-TA-RT-W6,ETX SERIES,UTX8-12-F2-2525-TA-W6,430474-501,MS2-107-10-10-12-12-11-W8,ETX8-12-F1-4040-TA-RT-W6,UTX11-12-F2-3030-TA-W6,387004680,ETX6-3-F1-2020-TA-RT-W6,OTX SERIES,387004685,387005659,PCX15-128-F,医学,电信,智能闪电,MOLECULAR DIAGNOSTICS (PCR),TELECOM ENCLOSURES,INDUSTRIAL,售货亭,MEDICAL LASERS,TRANSPORTATION,光纤通信收发模块,离心机,HIGH POWERED PROJECTORS,CENTRIFUGES,SMART LIGHTNING,LIQUID CHROMATOGRAPHY,OPTICAL TRANSCEIVERS,交通运输,电信外壳,HEADS-UP DISPLAYS,分子诊断(PCR),INCUBATORS,IMAGING SENSORS,工业,样品储存室,医用激光器,BATTERY BACKUP SYSTEMS,孵化器,数字彩色印刷系统,计量仪器,备用电池系统,TELECOM,DIGITAL COLOR PRINTING SYSTEMS,液相层析,SAMPLE STORAGE COMPARTMENTS,MEDICAL,医学诊断学,成像传感器,平视显示器,KIOSKS,INDUSTRIAL LASER SYSTEMS,MEDICAL DIAGNOSTICS,高功率投影仪,工业激光系统,METROLOGY INSTRUMENTATION

Laird Thermal Systems Launches the SuperCool X Series with Next-Gen Thermoelectric Cooling Technology

Laird Thermal Systems has launched a new high-performance thermoelectric cooler assembly series that utilizes next-generation thermoelectric coolers with advanced semiconductor materials. This enhancement boosts cooling performance by up to 10% over previous models.

莱尔德热力系统应用笔记:培养箱的加热和冷却

本资料主要讨论了孵化器腔室的加热和冷却技术,特别是针对细胞和组织培养的实验室和医院环境。资料强调了精确控制温度、湿度和气体浓度对于细胞培养的重要性,并探讨了传统冷却系统(如水套和压缩机)的局限性。资料介绍了热电技术作为替代方案的优势,包括高效、环保和紧凑的设计。此外,还详细介绍了Laird Thermal Systems提供的热电冷却器、模块和温度控制器,以及它们在孵化器设计中的应用。

LAIRD THERMAL SYSTEMS - TEMPERATURE CONTROLLER,固态热泵装置,SOLID-STATE HEAT PUMP DEVICES,THERMOELECTRIC COOLER ASSEMBLY,闭环温度控制器,可编程微控制器,THERMOELECTRIC COOLERS,CLOSED-LOOP TEMPERATURE CONTROLLER,热电冷却器,PROGRAMMABLE MICROCONTROLLER,温度控制器,热电冷却器组件,SAAX-175-24-22,PR-59,SDAX-220-24-02,SR-54,SLAX-215-24-02,HIGH-TEMPERATURE ENVIRONMENTS,动物学,孵化室,PHARMACEUTICAL RESEARCH,孵化器,药物研究,MICROBIOLOGY,微生物学,高温环境,医院,INCUBATORS,COSMETICS,化妆品,LABORATORY,HOSPITAL,FOOD SCIENCE,食品科学,实验室,INCUBATOR CHAMBERS,ZOOLOGY

Laird Thermal Systems(莱尔德热系统)TEA和温度控制器选型指南

Thermoelectric cooler assemblies are compact units that control the temperature of a wide variety of applications, such as laser diode packages in active optics, lasers in medical and industrial instrumentation, electronic enclosures, sample storage chambers in medical diagnostics and analytical instruments and batteries in various automotive and telecom applications.

LAIRD THERMAL SYSTEMS - DIRECT-TO-LIQUID ASSEMBLIES,THERMOELECTRIC CHILLER,直接对空气组件,OUTDOOR COOLER,室外冷却器,液-液组件,直接到液体的组件,PROGRAMMABLE PID CONTROLLER,TEMPERATURE CONTROLLERS,液体-空气组件,DIRECT-TO-AIR ASSEMBLIES,SINGLE DIRECTIONAL THERMOSTATIC,可编程PID控制器,AIR-TO-AIR ASSEMBLIES,THERMOELECTRIC COOLER ASSEMBLIES,空对空组件,LIQUID-TO-AIR ASSEMBLIES,单向恒温,热电冷却器,热电冷却器组件,温度控制器,LIQUID-TO-LIQUID ASSEMBLIES,LA-045,DA-075-24-02-00-00,DA-034-24-02-00-00,AAC-050,LA-160,DA-014-12-02-00-00,AA-150-48-44-00-XX,AA-200-48-22-00-00,DAT-105-24-02-00-00,SLA-400,AA-200,DAT-040-12-02-00-00,AA-060-12-22-00-00,AA-100-,AAT-032-12-22-00-00,AA-040-24-22-00-00,DAT-065-24-02-00-00,DA-115-24-02-00-00,LL-120-24-00-00-00,AA-200-24-22-00-00,SDAX-135-24-02-00-00,Q SERIES,AA-150-24-44-00-XX,SLA-400-24-02-00-00,SAAX-215,DA-044-24-02-00-00,DL-210,DL-120-24-00-00,DA-045-24-02-00-00,SLAX-140,AA-150-24-22-00-00,385901-001,DA-024-24-02-00-00,AAT-027,SAAX-175,LA-115-24-02-00-00,AA-250-24-44-00-XX,ATT-027-12-22-00-00,AAT-085-12-22-00-00,LA-024-12-02-00-00,LA-045-12-02-00-00,QE-50,SAAX-175-24-22-00-00,DL-060,DA-280-48-02-00-00,NRC400,AA-480,SDAX,DA-160-24-02-00-00,387006702,AA-230,387006704,387006703,387006706,SR-54,387006708,SAAX-115-24-22-00-00,DA-075-12-02-00-00,LL-060-12-00-00-00,387006707,ATT-055-24-22-00-00,AA-024-12-22-00-00,LA-075-24-02-00-00,DAT-029-12-02-00-00,DAC-035-12-02-00-00,SLAX-215-24-02-00-00,AAT-055-12-22-00-00,DA-033-12-02-00-00,AA-100-24-22-00-00,DA-034-12-02-00-00,387004253,DL-060-24-00-00,DA-025,DAT-065-12-02-00-00,AA-230-48-D44-00-XX,DAT-105-12-02-00-00,AA-040-12-22-00-00,DA-280-24-02-00-00,AA-070-24-22-00-00,QC-50,DA-135-24-02-00-00,AA-060-24-22-00-00,DAC-060-24-02-00-00,NRC400-T0-00-PC1,AA-250-48-44-00-XX,AA-250,SDAX-220-24-02-00-00,AA-019-12-22-00-00,LL-210-24-00-00-00,AA-100-48-44-00-XX,PR-59,PR SERIES,DA-044-12-02-00-00,DA-045-12-02-00-00,AAC-050-24-22-00-00,X SERIES,AA-150,DA-024-12-02-00-00,AA-100-24-44-00-XX,DA-045,AAT-085-24-22-00-00,AA-230-24-D44-00-XX,AA-200-48-44-00-XX,DA-011-05-02-00-00,DA-280,LA-024-24-02-00-00,LA-160-24-02-00-00,LL-060,AA-480-24-44-00-XX,SLAX-215,SDAX-220,SAAX-140,AA-040,LA-045-24-02-00-00,SLAX-145-24-02-00-00,AA-200-24-44-00-XX,LL-210,AA-024-24-22-00-00,DL-210-24-00-00,AA-034-12-22-00-00,AA-480-48-44-00-XX,DL-060-12-00-00,医学,MEDICAL,TELECOM ENCLOSURES,汽车,AEROSPACE DEFENSE,离心机,HIGH POWERED PROJECTORS,AUTOMOTIVE,高功率激光二极管,LIQUID CHROMATOGRAPHY,HIGH POWERED LASER DIODES,光电子学,电信外壳,INCUBATORS,航空航天防御,样品储存室,BATTERY BACKUP SYSTEMS,OPTOELECTRONICS,孵化器,计量仪器,液相层析,ANALYTICAL INSTRUMENTATION,SEMICONDUCTOR FABRICATION,SAMPLE STORAGE COMPARTMENTS,医学诊断学,KIOSKS,半导体制造,METROLOGY INSTRUMENTATION,电池冷却,电信,售货亭,MEDICAL LASERS,无线通讯,CENTRIFUGES,医疗诊断室,TELECOMMUNICATIONS,交通运输,工业,分析仪器,医用激光器,数字彩色印刷系统,FOOD&BEVERAGE,食品和饮料,MEDICAL DIAGNOSTICS CHAMBERS,TRANSPORTATION,备用电池系统,TELECOM,INDUSTRIAL,DIGITAL COLOR PRINTING SYSTEMS,BATTERY COOLING,INDUSTRIAL LASER SYSTEMS,MEDICAL DIAGNOSTICS,高功率投影仪,工业激光系统

DL-210-24-00液体系列热电冷却器组件

该资料介绍了Liquid Series DL-210-24-00热电制冷组件的性能和应用。它是一种紧凑型液体冷却器,适用于医疗诊断、工业激光器和分析仪器等领域。该组件采用液冷方式转移热量,具有高效率和高可靠性的特点。

LAIRD THERMAL SYSTEMS - THERMOELECTRIC COOLER ASSEMBLY,热电冷却器组件,DL-210-24-00,DL-210-24-00-00-00,MEDICAL LASERS,ANALYTICAL INSTRUMENTATION,工业激光器,医学诊断学,INDUSTRIAL LASERS,MEDICAL DIAGNOSTICS,分析仪器,医用激光器

培养箱的加热和制冷 Laird Thermal Systems™ 应用指南

本文介绍了培养箱在细胞和组织培养中的应用,强调了精准温度控制的重要性。文章探讨了传统制冷技术的局限性,并介绍了热电技术在培养箱温度控制中的应用优势。详细阐述了热电制冷器的工作原理、性能参数以及与温度控制器的结合使用,最后介绍了莱尔德热系统在培养箱热管理领域的解决方案和定制化服务。

LAIRD THERMAL SYSTEMS - 热电制冷器,固态热泵设备,闭环温度控制器,温度控制器,热电制冷器组件,SAAX-175-24-22,PR-59,SDAX-220-24-02,SR-54,SLAX-215-24-02,动物学,化妆品,药物研究,微生物学,培养箱,实验室,食品科学,医院

Laird Thermal Systems Launches PCX Thermoelectric Cooler Series to Increase Reliability of PCR Cycling

This paper mainly introduces the advantages of Laird Thermal Systems with regard to their PCX series Thermoelectric Coolers applications

PR-59温度控制器和LT-接口

本手册介绍了TC-XX-PR-59可编程控制器及其LT-Interface软件的使用。控制器用于精确控制热电偶组件的温度,具有PID调节器、开关控制和算法模式,以及两个可编程风扇输出和报警输出继电器。软件支持Windows操作系统,提供实时数据监控、参数配置和日志记录功能。手册详细说明了软件的安装、连接、参数设置和错误处理等内容。

LAIRD THERMAL SYSTEMS - PROGRAMMABLE CONTROLLER,TEMPERATURE CONTROLLER,可编程序控制器,温度控制器,PR-59,TC-XX-PR-59

Laird Thermal SystemsLaunches the OptoTEC™ MBX Series, a New Line of Micro Thermoelectric Coolers for High-performance Space-constrained Optoelectronic Applications

Laird Thermal Systems launches the OptoTEC™ MBX Series, a new line of micro thermoelectric coolers for high-performance space-constrained optoelectronic applications. The latest design innovation includes a compact footprint, with the smallest model measuring just 1.5 x 1.1 mm and profiles as thin as 0.65 mm.

SDA-195-24-02超冷系列热电制冷器组件

该资料介绍了SuperCool Series SDA-195-24-02直接空气热电制冷器组件。这是一种高性能的热泵,适用于医疗诊断或分析仪器中的小型温控腔室。它具有紧凑的设计、高效率的热交换机制、耐湿绝缘材料,并支持液体冷却选项。该设备在室内实验室环境中运行,提供高效的冷侧热量泵送和热侧散热。

LAIRD THERMAL SYSTEMS - THERMOELECTRIC COOLER ASSEMBLY,高性能热电热泵,HIGH PERFORMANCE THERMOELECTRIC BASED HEAT PUMP,直接对空气热电冷却器组件,DIRECT-TO-AIR THERMOELECTRIC COOLER ASSEMBLY,热电冷却器组件,387000624,SDA-195-24-02,BEVERAGE COOLING,冷冻离心机,孵化室,SPECT SCANNERS,PET扫描仪,PET SCANNERS,REFRIGERATED CENTRIFUGES,SPECT扫描仪,INCUBATOR CHAMBERS,饮料冷却

医疗激光冷却用热电冷却器和组件

本文介绍了热电制冷器和组件在医疗激光冷却应用中的作用。文章阐述了医疗激光器产生的热量及其对性能的影响,并强调了散热的重要性。文中详细说明了热电制冷器的原理、特点和应用,包括Laird Thermal Systems的CP系列和UltraTEC™ UTX系列产品。此外,还讨论了热电制冷器组件的设计和优势,特别是针对医疗激光应用的Tunnel、PowerCool和SuperCool X系列产品的特点和配置。最后,总结了热电制冷器和组件作为稳定医疗激光系统温度的理想解决方案的优势。

LAIRD THERMAL SYSTEMS - THERMOELECTRIC COOLERS,SOLID-STATE HEAT PUMPS,THERMOELECTRIC COOLER ASSEMBLIES,热电冷却器,热电冷却器组件,固态热泵,SLA-400,MEDICAL LASER COOLING,医用激光冷却,MEDICAL LASER,医用激光

LL-120-24-00液体系列热电冷却器组件

LL-120-24-00热电制冷组件是一款紧凑型液体冷却器,通过液体制冷技术转移热量。该组件适用于医疗诊断、工业激光器和医学激光等领域,提供可靠的固态操作和精确的温度控制。

LAIRD THERMAL SYSTEMS - THERMOELECTRIC COOLER ASSEMBLY,热电冷却器组件,LL-120-24-00-00-00,LL-120-24-00,MEDICAL LASERS,ANALYTICAL INSTRUMENTATION,工业激光器,医学诊断学,INDUSTRIAL LASERS,MEDICAL DIAGNOSTICS,分析仪器,医用激光器

电子商城

服务

提供稳态、瞬态、热传导、对流散热、热辐射、热接触、和液冷等热仿真分析,通过FloTHERM软件帮助工程师在产品设计初期创建虚拟模型,对多种系统设计方案进行评估,识别潜在散热风险。

实验室地址: 深圳 提交需求>

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论