What is the Advantages of Infrared Thermal Imaging Cameras Applied to Fiber Laser?

Infrared thermal imaging cameras are widely used, and the fiber optic industry is also closely related to infrared thermal imaging.

Fiber laser has the advantages of good beam quality, high energy density, high electro-optical conversion efficiency, good heat dissipation, compact structure, maintenance-free, flexible transmission, etc., and has become the mainstream direction of laser technology development and the main force of application. The overall electro-optic efficiency of a fiber laser is about 30% to 35%, and most of the energy is lost in the form of heat.

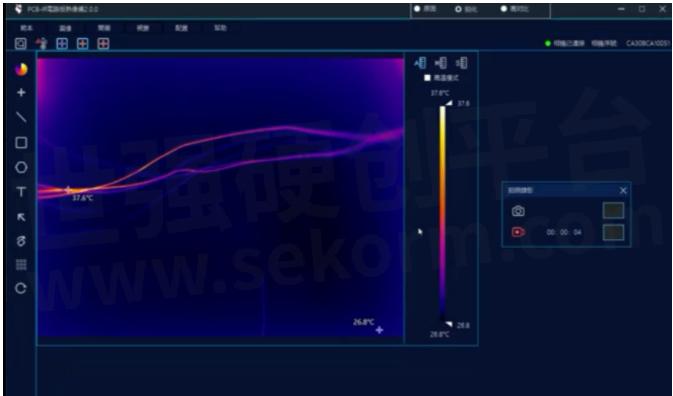

Therefore, temperature control during the working process of the laser directly determines the quality and service life of the laser. The traditional contact temperature measurement method will destroy the structure of the laser body, and the single-point non-contact temperature measurement method cannot accurately capture the fiber temperature. The use of infrared thermal imaging cameras to detect the temperature of optical fibers, especially the fusion joints of optical fibers, during the production process of optical fiber lasers can effectively guarantee the development and quality control of optical fiber products. During the production test, the temperature of the pump source, combiner, pigtail, etc. must be measured to ensure product quality.

Infrared thermal imaging temperature measurement on the application side can also be used for temperature measurement in laser welding, laser cladding, and other scenarios.

The unique advantages of infrared thermal imaging cameras applied to fiber laser detection:

1. Thermal imaging camera has the characteristics of long-distance, non-contact, and large-area temperature measurement.

2. Professional temperature measurement software, which can freely select the monitoring temperature area, automatically obtain and record the highest temperature point, and improve test efficiency.

3. The temperature threshold, fixed-point sampling, and multiple temperature measurements can be set to realize automatic data collection and curve generation.

4. Support various forms of over-temperature alarms, automatically judge abnormalities according to the set values, and automatically generate data reports.

5. Support secondary development and technical services, provide multi-platform SDK, and facilitate the integration and development of automation equipment.

In the manufacturing process of high-power fiber lasers, there may be optical discontinuities and defects of a certain size in the fiber fusion joints. Severe defects will cause abnormal heating of the fiber fusion joints, causing damage to the laser or burning hot spots. Therefore, temperature monitoring of fiber fusion splicing joints is an important link in the manufacturing process of fiber lasers. The temperature monitoring of the fiber splicing point can be realized by using the infrared thermal imager, so as to judge whether the quality of the measured fiber splicing point is qualified and improve the product quality.

The use of online thermal imaging cameras integrated into automation equipment can test the temperature of optical fibers stably and quickly so to improve production efficiency.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Vicky转载自DYT News,原文标题为:Thermal imaging to fiber optic industry,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

What’s the Difference between Infrared Thermometer and Thermal Camera?

This article, it is talking about the five main differences between an Infrared thermometer camera and a thermal camera. The infrared thermometer only has a single-point measurement function, while the infrared thermal imager can capture the overall temperature distribution of the measured target.

How many type of thermal camera at present?

According to different uses, thermal camera can be divided into two types: imaging and temperature measurement: imaging thermal imagers are mainly used for target tracking and monitoring, and are mostly used for national defense, military, and field monitoring.

【技术】点扬科技介绍挑选红外热成像仪的重点

点扬科技介绍挑选热像仪的重点,重要的是心脏—红外热成像仪的核“芯”。电脑的心脏是CPU,热像仪的心脏是红外探测器。探测器分为制冷和非制冷,非制冷体积小功耗低,目前民用市场干流选用的都对错制冷红外焦平面探测器,而作为感知红外辐射与输出信号间的桥梁。

65 Unique Uses of Infrared Thermal Imaging Cameras

The article DIANYANG presents 65 market applications for thermal imaging cameras, including thermal imaging cameras for mechanical inspection and preventive maintenance and so on.

Why Infrared Thermal Imaging Equipment Is So Popular In The Thermal Industry?

More and more infrared products are used in the thermal industry, steam pipes, hot air ducts, dust collector flues, coal silos in thermal power plants, boiler thermal insulation parts, coal conveyor belts, valves, transformers, booster stations, motor control centers, electrical The control is accurate and intuitive, and this non-contact temperature measurement method is more conducive for personnel to perform operations.

红外热成像系统产品及定制服务供应商点扬科技授权世强先进代理红外热像仪、热分析仪产品

2021年12月1日,深圳点扬科技有限公司(以下简称“点扬科技”)与世强先进(深圳)科技股份有限公司(下称“世强先进”)签署代理协议,授权世强先进代理其旗下红外热像仪、热分析仪等产品。 点扬科技是一家专门致力于红外热成像系统定制服务的技术型企业,为广大企业客户提供专业的基于红外热成像产品,以及各种操作简单、功能全面、技术专业的各种解决方案,其产品广泛应用于工业、制造业与消费电子等领域。

Coherent Introduces ARM FL20D Fiber Laser, Setting New Standards for High-Power Welding

Coherent today announced the launch of the ARM FL20D fiber laser. This new offering in the highly successful ARM laser family features a new higher power level of 20 kW and a unique dual ring beam configuration.

红外热成像系统定制服务供应商——点扬科技(DIANYANG)

点扬科技(DIANYANG)是一家专门致力于红外热成像系统定制服务的技术型企业,也是一家研发、设计、生产、热像仪技术的企业,通过视频和温度分析进行测量和诊断的检测系统,主营业务包括产品定制开发服务及红外热成像产品家族,能够为客户提供机器视觉、个人视觉、无人机红外及机芯模组等产品和解决方案。

Coherent High-Power Diode Laser System, Bringing Laser Cladding to Indonesia

Coherent provided Laser Indonesia with a HighLight DL4000HPS in December, 2020. This is a compact, 4 kW, fiber-coupled diode laser system with integrated chiller. Coherent also equipped the laser with focusing optics that produce a 3 mm diameter beam on the work surface and a gas-delivered powder delivery head. The support from Coherent enables Laser Indonesia to become one of the first in their country to offer on-site cladding services.

Photon Automation and Coherent Teamwork Improves Precision Laser Welding

Tight coordination between the Photon Automation and Coherent applications teams enabled rapid development of an advanced laser welding process.

【技术】点扬科技介绍红外热成像仪结构

点扬科技介绍红外热成像仪结构:红外热像仪一般由光机组件、调焦/变倍组件、内部非均匀性校对组件(以下简称内校对组件)、成像电路组件和红外探测器/制冷机组件组成。光机组件主要由红外物镜和结构件组成,红外物镜主要实现景物热辐射的会聚成像。

Application Alley Sensors - Laser Welding and Stainless Steel Fabrication Why Standex-Meder(斯丹麦德) Laser Welding and Stainless Steel Fabrication?

描述- Standex-Meder Electronics提供定制化产品开发服务,擅长不锈钢制造和激光焊接技术。公司利用这些技术生产适用于各种环境的传感器和其他组件,满足汽车、工业、医疗、实验室和食品饮料等领域的需求。Standex-Meder Electronics强调其激光焊接系统的优势,包括精确性、成本效益和快速响应时间,同时提供自动化程度高、无腔焊接和高生产深度的解决方案。

Teamwork Between Photon Automation and Coherent Applications Teams Improves Precision Laser Welding

Working in close consultation with Coherent gave Photon Automation access to our in-depth knowledge of the exact workings of the ARM fiber laser. This enabled them to fully optimize the performance of their new controller. Tight coordination between the Photon Automation and Coherent applications teams enabled rapid development of an advanced laser welding process.

Coherent Introduces the Industry’s First Commercially Available 50W Pump Laser Diodes for Fiber Lasers

The new laser diodes from Coherent achieve 50 W of output power, 40% more than that of the existing product, enabling high-power industrial fiber laser designs with fewer pump laser diodes.

How to Achieve Precise Connection of Optical Fibers with Fiber Connectors?

When two optical fibers are connected, due to the difference in position, shape, and structure of the two optical fibers, the energy cannot pass 100% from one optical fiber to the other optical fiber, that is, connection loss occurs. To minimize connection losses, the two optical fibers must be precisely aligned.

登录 | 立即注册

提交评论