Creating Sensor Technology in Healthcare

When a new custom sensor for your medical device is needed, chances are you needed it yesterday.

Unfortunately, custom-created sensors don't just appear. And the chances of a sensor manufacturer having a custom sensor that somehow matches your medical device and its performance requirements already in stock and in volume are almost non-existent.

While it would be wonderful to have the exact sensor you need exactly when you needed it, the reality is custom sensor technology in healthcare takes time to conceptualize, design, and manufacture at scale.

Let's take a look at what it takes to make a custom sensor for your OEM medical device a reality.

7 Steps to Developing Custom Sensor Technology in Healthcare | Start to Finish

When it comes to creating a customized sensor solution for medical devices, the #1 thing to be aware of …

Actually, there are two #1 things: It takes time and it's an involved process.

Because a sensor that's created for your OEM medical device is completely unique, the process to make it is essentially cooking from scratch.

What does the process of developing a custom sensor solution look like?

In a general sense, there are seven steps to developing a custom medical sensor with a sensor manufacturer:

Initial consultation

Drawing exchange

Quoting

Prototype development

Sample performance review

Product qualification/certification testing

Full production

1. Initial Consultation

As the first step, this part of your journey to getting a sensor made for your device is the most important. Setting the stage for what you'll create, you'll go over all the details of your sensor and its application. This includes elements such as:

Sensor application – Exactly what will the sensor be used for? How will it be used?

Sensitivity requirements – While accuracy is critical, the level of required precision varies depending on the intended application

Temperature range – The thermal range your sensor needs to function effectively

Environmental considerations – How much moisture, dust, and other environmental factors will the sensor encounter?

Connectivity – Does the sensor need a wired or wireless connection for data transmission?

Intended lifespan – Is the sensor disposable or reusable? If reusable, what's the ideal useful life for the device?

Any special design considerations – e.g. material selection, size, housing

2. Drawing Exchange

With an understanding of what the final product should look like, the sensor design team gets to work on distilling that vision into an actual engineering drawing. After the drawing is completed, we'll send you a copy of it for your review. In almost all cases, there's an element of back-and-forth to further refine your sensor's plans.

In a certain respect, this is like going over proposed schematics for a custom home – you'll be looking at a very detailed plan.

In addition to the sensor's dimensions, you'll have other elements to review, such as material selection, wiring diagrams, and other finer points of the sensor's assembly.

And chances are you'll likely need a few rounds of tweaking and adjustment to get a design that meets – and exceeds – expectations.

3. Quoting

Having an agreed-upon design with the specifics for your sensor, your sensor manufacturer will draw up a quote.

The quote should include a breakdown of:

Unit cost at volume

Prototyping costs

Shipment logistics

Turnaround time (relative to the order's size)

Tooling cost considerations

Non-recurring engineering fees (if applicable)

4. Prototype Development

This is where the rubber starts hitting the road and you'll get your first real-world glimpse of what the final product will look like. It's also another layer of review.

Your manufacturer will use the CAD, BOM, and other product documents from the design phase to create physical prototypes. This is an important moment in development as you'll be able to interact with a physical version of your product before committing it to production.

With these initial samples, you'll be able to look at the critical-to-quality elements such as the biocompatible materials used or conduct preliminary tests for functionality and performance.

The prototype phase is also where you can make major tweaks or adjustments as needed.

5. Sample Performance Review

A step up from a prototype, a sample is the next closest thing to the final product.

Just like with the prototype, you'll review the sample for performance, functionality, and quality – but at a much more detailed level. More specifically, you'll evaluate:

The accuracy of the sensor in detecting and measuring data

The consistency and reliability of the sensor's performance over time

The durability of the sensor against the rigors of real-world use without breaking or malfunctioning.

The ease of use and user-friendliness so that it is intuitive and straightforward for medical professionals to use.

The size and fit of the device into its intended application.

While it's possible to make changes to the sensor before the final step, this is the last best chance to make adjustments without impacting your project's timeline or budget drastically.

6. Product Qualification/Certification Testing

Another layer of review, qualification and certification testing is designed to prove the sensor's ability to work safely and accurately in its intended environment.

This type of testing ensures that your medical device meets all applicable national, international, and industry standards set by the FDA, CE, or the EU's MDD. It's often completed by independent third parties, who review a wide variety of elements such as:

Radiofrequency emissions

Electromagnetic compatibility

Environmental conditions, including temperature and humidity resistance.

Materials safety/biocompatibility

Power usage / efficiency

Documentation and reporting processes are also critical components of the product certification process. Manufacturers must provide extensive documentation and data to demonstrate that their prototype medical sensors meet all necessary standards and regulations. This includes detailed technical files, labeling information, user manuals, and other data that demonstrate compliance with regulatory requirements.

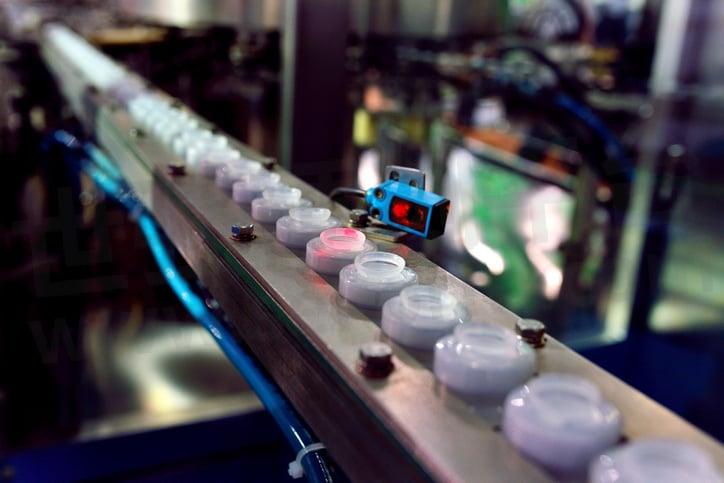

7. Full Production

After all of the above steps have been completed, your sensor is ready for full production!

That means your sensor manufacturer will now produce the sensors according to the agreed-upon quality, quantity, and timeline.

It's also important to note that during full production, manufacturers need to continuously monitor their manufacturing processes for product consistency and quality control purposes. This is a key step in producing a high-quality medical sensing solution that meets all regulatory requirements and customer expectations.

How Long does It Take to Make A Custom Medical Sensor?

Next to "How much does a sensor cost?" this is a question we field a lot – understandably so.

In general, the process outlined above takes about a year and a half to complete. That timeline however can be affected by several factors:

Your Level of Readiness – In most cases those we work with come to the table knowing many of the key details about the sensor they need, such as sensitivity, size, and intended lifespan. Others, however, are still in the early stages of their own product development and are a ways off from getting deep into the specifics of their sensor needs. In the case of the latter, it's simply going to take a longer time to get through the initial stages of conceptualization and development as sensor specs are still being ironed out in real-time.

Supply Chain Conditions – As we all learned during the pandemic, the global supply chain is extremely delicate. Though it's (mostly) recovered from the extremes it faced during lockdowns, it's still fragile. That said, no supply chain is impervious to outside factors causing disruptions – for instance, severe weather one day can create delays that span several weeks.

Meeting Compliance Requirements – Like the devices they're installed in, medical sensors need to meet certain requirements in order to be approved for use. Depending on where you're located, this could mean extra rounds of testing and evaluation. In some cases, it could mean traveling to the testing facility or having an inspector come on-site.

Custom Sensor Creation for Medical Devices | Worth the Wait

While creating a custom sensor for your OEM medical device doesn't happen with the snap of your fingers, the last thing you want is a component that fails to meet performance expectations.

Though indeed a process, working with a sensor manufacturer on a custom sensor solution through each step of production ensures the sensor(s) you receive are more than up to meeting the demands of application.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Vicky转载自AMPHENOL SENSORS Official Website,原文标题为:[TIMELINE] CREATING SENSOR TECHNOLOGY IN HEALTHCARE,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

HVAC System Upgrades and Optimization Via Sensors + 2 Checklists

Remote Monitoring and Control: In a certain respect, HVAC control system optimization strategies are no different than what we‘re seeing with other building management systems – you no longer need to be in the same room or even continent to control the system. Thanks to IoT (Internet of Things) technology, HVAC system managers can give the system attention no matter where they are.

Optimizing Fast Charging with Electric Vehicle Sensors

Fast-charging technology is making this shift possible as it meets a major concern head-on. Electric vehicle sensors are the unsung hero in making EV charging as uneventful as filling up a gas tank.

The Necessary Sensors for an Ev Battery Pack & Cell Connection System

In a typical Electric Vehicle, the battery pack may experience thousands of charge and discharge cycles throughout its life. The pack Battery Management System monitors voltage, current, and temperature of cells.

Amphenol Sensors(安费诺)/Thermometrics 温度传感器选型指南

目录- 温度传感器产品介绍及应用领域 NTC热敏电阻/PTC热敏电阻 探针和组件 其他技术和附件

型号- T5D,HM,YA,YB,YC,P60,YD,YF,P65,YG,YH,RL40,YK,YL,YP,YR,EC95,GC32,YS,RL45,GC16,B35,UD20,RL30,3006,AB6,MELF,JA,YS4019,JB,JTC,JC,JD,RL35,JE,JF,MF65,SP85,JS2945,JI,B43,JL,JM,JP,FP10,JR,JTR,CTR100,FP14,P85,JW,M,NDK,T,NDM,CTR65,NDL,ZTP,BB07,PT1000,0706,BB05,NDP,YS4020,NDU,YSM 4021,CL,CTR85,BR16,KU,BR14,KY,BR11,TC,FP07,1403,NHQM,YSM,TH,R100,TM,MA400,PTSM,TP,1803,BB11,EVAP,P100,MA100,DK,SC30,R60,BR23,P20,R65,HVAC,P25,YM120,PT200,EVAPA1450,MS,DKM,MT,CTR60,P30,RL1004,BR32,A1447-A1450,ND,PTA,NK,EVAPA1447,1703,PTE,PTD,SP100,PTF,DC95,PTH,B05,B07,PTO,EVAP A1424,SC50,R85,BR42,C100,2006,JYA,NHQ,NHQMM,GC11,GC14,GE,RL20,M2000,B10,PT100,B14,GT,BR55,MC65,SP60,TK95,SP65,RL14,RL060628,RL10

NPA系列|压力传感器应用指南

描述- 本指南详细介绍了Amphenol Advanced Sensors的NPA系列压力传感器的应用。内容涵盖传感器的一般描述、输出特性、模拟和数字输出选项、未校准版本、封装尺寸、压力端口连接、PCB焊盘布局、焊接和设备标识。指南重点介绍了传感器的压力测量功能、输出特性、数字输出协议、诊断功能和睡眠模式,为用户提供了全面的应用指导。

型号- NPA SERIES,NPA-600 SERIES,NPA-601 SERIES,NPA-100 SERIES,NPA-500 SERIES,NPA-100,NPA-500M-001D,NPA-500,NPA-730,NPA-730 SERIES,NPA-300,NPA TYPES,NPA-600,NPA-700,NPA-601,NPA

Amphenol Sensors(安费诺)温度传感器/MEMS压力传感器/C〇2、湿度、灰尘传感器选型指南

目录- Sensors Temperature Sensors Pressure Sensors CO2, Humidity & Dust Sensors

型号- DK SERIES,NDP SERIES,NHQ SERIES,AAS-AQS-UNO-RH-CO2,RL40,T5D SERIES,FMA SERIES,GC32,EC95,AB6 SERIES,RL45,GC16,GT SERIES,DKM SERIES,CTP65,M SERIES,UD20,S SERIES,CTP60,RL30,AIT SERIES,GE-1935,TH SERIES,NDL SERIES,3006,MELF,YS4019,RL35,HM SERIES,GE-2102,GE-2103,JS2945,T6715,T6613-X,AAS-AQS-UNO,TM SERIES,R85 SERIES,SM-UART-04L,YSM SERIES,FP10,NPI-15,T6715-X,FP14,NPC-120,HS12SP,NPI-19,B35 SERIES,T6713,BB07,SUF SERIES,NK SERIES,BB05,YS4020,T6703,YSM 4021,YR SERIES,BR16,A-1737,BR14,T6700,BR11,T SERIES,FP07,1403,NHQM,P85 SERIES,ZTP SERIES,JF SERIES,NDK SERIES,JS8741,NPH SERIES,JS8746,R100,JR SERIES,PTSM,MA400,SM-PWM-01C,JB SERIES,1803,BB11,B05 SERIES,T6616,EVAP,YF SERIES,JA SERIES,P100,YD SERIES,YH SERIES,MF65 SERIES,YG SERIES,MA100,JIC SERIES,YB SERIES,B43 SERIES,T9602,NPC-100,YA SERIES,YC SERIES,SC30,CTP100,BR23,T6613,PTD SERIES,PTE SERIES,YM120,HVAC,JTC SERIES,JTR SERIES,MS SERIES,YK SERIES,WTF083B001,P30 SERIES,YL SERIES,YP SERIES,PTA SERIES,PTH SERIES,ND SERIES,B07 SERIES,PTF SERIES,PTO SERIES,P60 SERIES,JM SERIES,YS SERIES,T6600,RL1004,BR32,JS6780,JI SERIES,HS30P,JW SERIES,A1447-A1450,JS SERIES,TP SERIES,JE SERIES,JC SERIES,GE-1856,1703,B14 SERIES,T6615-X,GE SERIES,R65 SERIES,DC95,JYA SERIES,T3000,EVAP A1424,SC50,BR42,A-1266,C100,GE-1923,NPP-301,706 SERIES,2006,NKA SERIES,AS SERIES,B10 SERIES,P25 SERIES,NHQMM,GC11,RL20,CL SERIES,P20 SERIES,GC14,GE-1920,NPC-1220,JP SERIES,P65 SERIES,ES SERIES,CTP85,T6713-X SERIES,BR55,MC65,KU SERIES,TK95,NDM SERIES,R60 SERIES,NDU SERIES,NPC-1210,TC SERIES,JL SERIES,RL14,JD SERIES,RL060628,RL10

Amphenol Sensors(安费诺)/All Sensors 压力传感器选型指南(简版)

目录- 传感器解决方案及产品优势介绍 传感器技术介绍 单芯片压力传感器 双芯电路交叉耦合补偿压力传感器 双芯电路和气路交叉耦合补偿压力传感器 传感器应用领域介绍 压力单位换算 传感器通用名词解释

型号- DLH,ADCX,ACPC-C,AXCA,ACPC,BLV,DLV,ACPC-H,AXCA-PRIME,AXCA-MIDDLE,MAMP,MLV,SAMP,ACPC-P,BLC,ADUX,BLVR,MAMP-/P,ADCA,DLH,DLVR,DLVR,BLCR,MAMP-P,MDCX,ADO,BLV,AXCX-PRIME-INCH,DLHR,DLHR,AXCX,MLV,AXCA-MIL,BLC,DLC,ADO-MIL

通道簧片液位传感器的应用

描述- Reed Level Sensors是一种用于检测液体水平变化的传感器。它由带有内置磁铁的浮球和安装在轴上的Reed开关组成。Standex Electronics提供多种材料设计、开关配置、轴长度和浮球,以满足不同液体系统的需求。这些传感器适用于汽车、家庭、工业、医疗设备、实验室技术、航空航天和HVAC等多个领域。Standex Electronics还提供定制化的解决方案,以满足客户的特定要求。

Amphenol Sensors(安费诺)建筑及工业应用传感器选型指南

目录- Chip Cap 2完全校准的温湿度传感器 Telaire Ventostat®T8700壁挂式温湿度变送器 Telaire Ventostat®T8031 CO2小型风管式C02传感器 Telaire®T8041/T8042 分管式C02传感器 Telaire T8100-R系列挂壁式C02和温度变送器(带继电器) Telaire®7000室内空气品质监测器 Telaire VaporstatTM 9002红外露点变送器 Telaire®配件 Telaire HumiTrac™温湿度变送器 T9602湿度与温度传感器 AAS-53系列水管型温度变送器 ADT/AOT/AIT温湿度变送器使用说明书

型号- P40250128,CC2D265,P40250129,P40250126,P40250127,P40250125,P40250122,P40250123,DC95F302W,P40250120,P40250121,T8031,CC2D255,EHR-4,T8100-D-R,P40250139,K53,T8700,CC2A23,PT1000A,AIT,PT1000B,CC2A25,P40250133,P40250131,T2075NG,P40250130,T804K0-10V,T1508,T8200-D-5P,T8042-5VI0-5V,T9602-5-A-1,NI1000,9002,T9602-3-A-1,T5100,P40250149,CC2A35,T8700-E-D,P40250147,0-5000PPM,P40250144,PT100A,T7001I,P40250145,PT100B,P40250142,P40250143,T8100,S4B-EH,CC2A33,P40250141,CC2D235,CC2D355,T7001,PT1000,T2072,T7001D,CC2D25,T9602-3-A,T8042I0-10V,CC2D23,P40250156,T8041,T8100-R,P40250151,T8042,P40250150,T9602-3-D,NTC10K,CC2025,7000,T9602-3-D-1,CC2D35,T9602,CC2D33,ADT,NTC15K,T8200,CC2D335,CHIPCAP 2,NTC10K-II,T2090,T1551,T1552,MPNT3D03750M4,NTC20K,T2007,T8700-D,T8700-E,T8100,T2080,T8100-EC,P40250109,PA0250118,T8100-E-D-GN-5P-R,PA0250115,T1505,P40254275,P40254276,P40254277,P40250189,P40250186,P40250184,P40250185,T8300,P40250182,P40250183,P40250181,AAS-53,8000,PT100,T7001SK,P40250119,NTC10K-A,AOT,P40250117,T9602-5-A,P40250113,P40250114,P40250111,P40250112,DC95F103W,T2076NG,P40250110,P40250193,T9602-5-D,T8001,P40250191,7001D,P40250192,T8002,T9602-5-D-1,MPNV12R30M 16004616,B4B-EH-A,P40250190,T8041-5VI0-5V,RS485,NTC10K-III

Amphenol Sensors(安费诺) 汽车传感器选型指南

目录- 汽车传感器解决方案介绍 车厢空气质量系列传感器 排放处理系列传感器 新能源汽车传感器应用 测量汽车应用中最为关键的参数

型号- SM-UART-01L,PT200,T6703,TPMS,DPS,G-CAP2,SM-UART-01D,A2103,NPI-19,T6713,A-2102,EGR,A-2103,NPP-301,GE-1935,A-2121,ZTP,DPF,SM-UART-01L+,SM-PWM-01C,NPX1

Keeping Cool with Data Center Temperature Sensors

Data center temperature sensors are the eyes and ears of your climate control system. These tiny devices provide real-time data on temperature and some insight into potential humidity levels throughout your facility. They come in various forms, each suited to different applications.

Amphenol Sensors(安费诺) 医疗传感器选型指南

目录- NPA贴片式压力传感器系列 NTC AB6 型 "SC/MC"系列专为医疗设汁 MA100系列 ZTP-148SR系列 ZTP-101T系列 NPC-100系列一次性医疗压力传感器 NPC-1210系列 NPG-1220系列中压传感器 NPI-12卫生型压力传感器、不锈钢介质隔离压力传感器 NPI-15系列电流激励高压、介质隔离压力传感器 NPI-15VC系列电压激励、高压、介质隔离压力传感器 NPI-19系列电流激励、中压、介质隔离压力传感器 NPI-19系列电压激励、中压、介质隔离压力传感器 NPP-301系列贴片封装压力传感器

型号- NPP-301B-700AT,NPC-1001000,NPI-12-101G,MC65F103C,NPP-301A-100AT,NPI-19X-YYYZZ,NPI-15X-YYYZZ,NPI-19J-XXX,B35,ZTP-148SR,NPI-19A-XXX,MC65F103A,NPP-301A-200A,MC65F103B,AB6,NPA-300,NPI-19H-XXX,NPA-700,AB6E8,B43,NPP-301B-200A,NPI-12,NPI-19X-XXXXV,NPI-15,SC30F103W,NPP系列,NPP-301B-200AT,SC30F103V,MA100BF103C,NPI-19,SC30F103A,SC,MA100BF103B,MA100BF103A,NPI-15B-XXX,MA100GG232C,NPI-15C-C00903,NNP301B,NNP301A,MA100GG103CN,NPP-301B-700A,BR16,BR14,BR11,NPC-1210XXXX-YZ,ZTP-101T,NPC-100T,MA100GG103BN,MA100,NPP-301A-100A,NPC-100,NPI-19A-C01864,BR23,P20,P25,AB6B4,MC65F232A,MC,AB6B2,MC系列,NPI-19A-002GV,MA100GG103AN,AB6A8-BR16KA103N,NPI-15VC,NPP-301A-200AT,P30,BR32,NPA-100,NPC-1220XXXX-YZ,NPA-500,SC50F103W,NPP-301B-100A,NPA,NPP-301B-100AT,MC65F502B,NPI-15A-XXX,B05,B07,SC30Y103W,NPI-15J-XXX,NPP,NPP-301A-700A,BR42,NPP-301,MA100GG103B,NPI-19B-XXX,NPI-12-101GH,MA100GG103A,MC65G503B,MA100GG103C,NPC-1220,NPP-301A-700AT,B10,NPI-15H-XXX,B14,NPI-15XXXXXX,NTC AB6,BR55,NPC-1210,SC系列

Amphenol Sensors(安费诺)/Nova Sensor 压力传感器及敏感元件选型指南

目录- P1300低压硅压力传感器芯片 P1302低压硅压力传感器芯片 P111中压硅压力传感器芯片 P883(5~15000 PSI)硅压力传感器芯片 P1602硅压力传感器芯片 P122 高压硅压力传感器芯片 NPC-100系列一次性医疗压力传感器 NPC-1210系列低压系列固态压力传感器 NPC-1220系列中压传感器 NPH系列固态压力传感器(中低压) NPI-12卫生型压力传感器、不锈钢介质隔离压力传感器 NPI-15VC系列电压激励、高压、介质隔离压力传感器 NPI-15系列电流激励高压、介质隔离压力传感器 NPI-19系列电压激励、中压、介质隔离压力传感器 NPI-19系列电流激励、中压、介质隔离压力传感器 NPI-19低压不锈钢介质隔离压力传感器 NPP-301系列贴片封装压力传感器 NPA贴片式压力传感器 NPR-101系列复杂介质压力传感器 Modus T系列微差压力传感器 压力变送器IPT1000/2000系列

型号- NPP-301B-700AT,IPT1000,51243,51245,51003,51244,NPP-301A-100AT,51005,51367,51004,51007,51006,51009,NPI-19X-YYYZZ,51008,51407,51406,NPI-15X-YYYZZ,51409,51408,NPP-301A-200A,NPH-XYYY-ZZ,51010,51012,51254,51011,51253,51013,NPA-300,NPR-101,51137,NPA-700,NPH系列,NPP-301B-200A,NPI-12,NPI-19X-XXXXV,P1602,NPI-15,NPP-301B-200AT,NPI-19,NPA100,NPI-15X-XXXXX,51142,MODUS T,51421,NPI-15X-XXXXXX,51304,51303,NPI-15C-C00903,NPP-301B-700A,51391,NPC-1210XXXX-YZ,51151,51393,51392,51395,NPI-19A-031GH,T10,51394,51031,51397,51399,51313,51433,51314,NPC-100T,51317,51318,NPP-301A-100A,P1302,NPC-100,P1300,51041,51283,NPI-19A-021GH,51282,T20,51045,51322,51046,51445,51324,51444,51323,51326,51325,51328,51327,51329,NPI-19A-002GV,NPI-15VC,NPP-301A-200AT,IPT2000,T30,NPC-1220XXXX-YZ,51298,51331,NPA-500,51330,51333,51299,51332,51335,51334,NPI-19X-XXXXXV,51337,51336,51339,51338,NPP-301B-100A,NPP-301B-100AT,NPA,T系列,P122,P883,NPH,NPI-19A-C01841,NPI-19A-C01840,NPP-301A-700A,T40,51340,NPP-301,51342,51187,51341,NPI-12-101GH,NPI-1,NPC-1220,NPP-301A-700AT,P111,51076,NPC-1210,51114

EV Battery Pack Water Detection Sensor from Amphenol Sensors

With the sharp growth of electric vehicles, many OEMs are using a water cooling system for the EV battery system. When water escapes the system and leaks into the battery pack, dangerous conditions are created. Amphenol Advanced Sensors‘ Water Detection Sensor monitors for water leakage by constantly checking resistance values. If a leak is detected in the EV battery pack, this sensor technology provides immediate notification.

电子商城

品牌:AMPHENOL SENSORS

品类:Surface Mount Pressure Sensors

价格:¥97.5000

现货: 51

品牌:AMPHENOL SENSORS

品类:Air Quality Sensors IR LED Dust Sensor

价格:¥40.5000

现货: 35

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥253.8839

现货: 30

品牌:AMPHENOL SENSORS

品类:Low Pressure Compact Sensors

价格:¥125.9778

现货: 25

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥253.8839

现货: 25

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥227.5314

现货: 25

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥227.5314

现货: 25

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥227.5314

现货: 25

品牌:AMPHENOL SENSORS

品类:Board Mount Pressure Sensors

价格:¥227.5314

现货: 25

现货市场

服务

可定制板装式压力传感器支持产品量程从5inch水柱到100 psi气压;数字输出压力传感器压力范围0.5~60inH2O,温度补偿范围-20~85ºС;模拟和数字低压传感器可以直接与微控制器通信,具备多种小型SIP和DIP封装可选择。

提交需求>

可定制温度范围-230℃~1150℃、精度可达±0.1°C;支持NTC传感器、PTC传感器、数字式温度传感器、热电堆温度传感器的额定量程和输出/外形尺寸/工作温度范围等参数定制。

提交需求>

登录 | 立即注册

提交评论