Automotive Buck/Reverse-Boost Converter with GaN for Efficient 48V Power Distribution

The trend towards increasing electrification in the automotive industry enables car makers both to deliver new innovations to market cost-effectively and to meet increasingly stringent emissions legislation. Raising the vehicle's main bus voltage to 48V helps meet the demands of power-hungry systems such as the start-stop motor/generator of a mild hybrid vehicle, as well as loads such as electric power steering, electric supercharging, and vacuum and water pumps.

Compared to the traditional 12V automotive power standard, 48V distribution can deliver four times the electrical power without increasing cable thickness, weight, and cost. By 2025, one in every 10 vehicles sold worldwide, is projected to be a 48V mild hybrid.

However, dropping established 12V electrical systems immediately is not an economical option. In practice, 48V and 12V infrastructures will coexist in vehicles for several generations to come. To make such a dual-voltage setup work satisfactorily, each being powered from 48V and 12V batteries respectively, a bidirectional DC-DC converter is needed to transfer power seamlessly between the two battery voltages. Depending on the vehicle, the required power rating of the converter can range from about 1.5kW to 6kW.

This artical demonstrates the design of a bi-directional DC-DC converter for automotive 48V power distribution, showing how GaN technology is a powerful enabler for efficient electrification.

The trend towards increasing electrification in the automotive industry enables car makers both to deliver new innovations to market cost-effectively and to meet increasingly stringent emissions legislation. Raising the vehicle's main bus voltage to 48V helps meet the demands of power-hungry systems such as the start-stop motor/generator of a mild hybrid vehicle, as well as loads such as electric power steering, electric supercharging, and vacuum and water pumps.

Compared to the traditional 12V automotive power standard, 48V distribution can deliver four times the electrical power without increasing cable thickness, weight, and cost. By 2025, one in every 10 vehicles sold worldwide, is projected to be a 48V mild hybrid.

GaN and Power Conversion

When designing an automotive converter, size, cost, and reliability are critical factors. To meet these criteria, the simplest bi-directional topology; the synchronous buck/reverse-boost converter, is chosen. Maximising energy efficiency is also paramount and, here, designers can take advantage of gallium nitride (GaN) technology to achieve significantly greater efficiency than is possible using traditional silicon power transistors. Gallium nitride benefits from exceptionally high electron mobility as well as low temperature coefficient, which allows power transistors to have very low on-resistance (RON) thereby minimising on-state conduction losses. The lateral transistor structure also results in exceptionally low gate charge (QG) with zero reverse-recovery charge (QRR). In addition, GaN FETs also have much lower output capacitance (COSS) than comparable MOSFETs.

GaN FETs suitable for 48V applications have about four times better figure of merit (die area x RON) compared to similar MOSFETs. For the same gate voltage of 5V, GaN FETs have at least five times lower gate charge than silicon MOSFETs. As a result, GaN FETs can operate more efficiently and at high switching frequencies than silicon MOSFETs, allowing designers to specify smaller capacitors and inductors in their designs. With lower losses across the switching and on states, the heatsink size can also be reduced, ultimately enabling smaller, slimmer module or permitting higher power ratings within the same footprint. Ultimately, this gives vehicle designers extra freedom to pack more new features within the tight space constraints presented by today's vehicles.

Designing the Converter

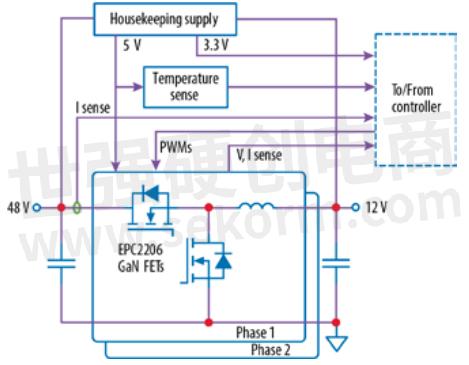

Figure 1 shows a simplified schematic block diagram for a 1.5kW bi-directional 48V/12V converter, which can be scaled to 3kW relatively easily by paralleling two converters to make it four phases. The two-phase design shown in the diagram can operate up to 1.5kW with a maximum current of 62.5A per phase on the 12V port. This is made possible by using the EPC2206 eGaN® (enhancement-mode GaN) AEC-Q101 qualified FET, which has 2.2mΩ RONand rated peak DC current of 90A. The two-phase design also reduces the required current rating of the inductors.

Figure 1: Simplified schematic of two-phase bi-directional converter with eGaN FETs.

In this design, the inductor values and switching frequency are determined using an analytical loss model so that the efficiency at 50% of full rated power is maximized. With the selected 2.2µH inductor, as shown, and 250kHz switching frequency, the peak inductor current is 70A.

To ensure accurate phase-current balancing, current sensing using a precision shunt resistor is preferred over inductor DCR current sensing. However, shunt resistors that are rated for above 70A usually have a large footprint and therefore also high parasitic inductance that can result in high noise, which can saturate the current-sense amplifier and thus void the measurement. A simple

solution to overcome this problem was to add an RC filter network with a matched time constant that cancels the shunt inductance. This design uses a current-sense amplifier with a maximum bandwidth of 500kHz and 50V/V gain, which results in 10mV/A total current-sensing gain when used with a 200µΩ shunt resistor.

It is also critical to ensure a symmetrical layout between the two phases, so that phase currents are balanced and any effects due to mismatching of gate drive delay, switching transition speed, overshoot, or other parameters, are minimised. The internal vertical loop approach when designing with GaN power devices is to place decoupling capacitors close to the FETs and position a solid ground plane beneath. The microcontroller chosen for this application has a high-resolution PWM module that allows accurate control of the duty cycle and dead-time of 0.25ns, permitting these to be optimised to take full advantage of the GaN FETs performance.

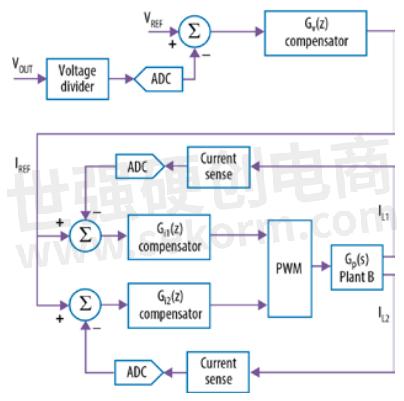

Digital average current mode control is implemented for both buck and boost modes. The control block diagram is shown in Figure. 2. Using the same current reference, IREF, for the two independent current loops regulates the current in both inductors to the same value. The bandwidth of the two inner current loops is set to 6kHz, and the outer voltage loop bandwidth is set to 800Hz.

Figure 2: Digital average current mode control diagram

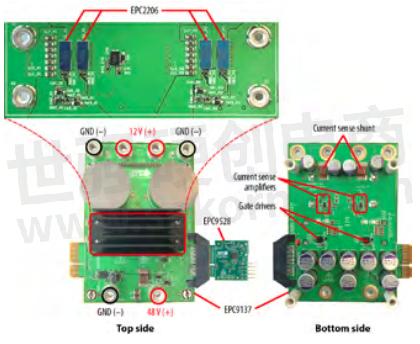

Figure 3: Photo of the EPC9137 converter with the EPC2206 GaN FETs

The GaN FETs require a heatsink to operate at the full output power of 1.5kW. A standard commercially available 1/8th-brick heatsink is used. Four metal spacers are installed on the PCB to provide the appropriate clearance for the heatsink mounting. An electrically insulating thermal interface material (TIM) with thermal conductivity of 17.8W/mK was applied between the FETs and heatsink.

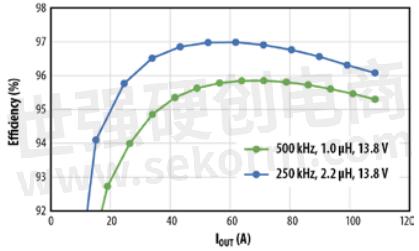

Figure 4: Measured converter efficiency of the EPC9137 at 250kHz and 500kHz, 48V input and 13.8V output.

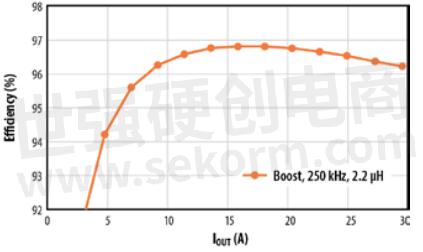

Figure 5: Measured EPC9137 converter efficiency at 250kHz, 13.8V input and 48V output.

Performance Analysis

Figure 3 shows a photo of the EPC9137 converter. With the heatsink installed and 1700 LFM airflow, the converter was operated at 48V input, 13.8V output and tested at both 250kHz and 500kHz. Figure 4 shows the efficiency results. At 250kHz, using a 2.2µH inductor, the converter achieved a peak efficiency of 97%. When operated at 500kHz, using a 1.0µH inductor, the peak efficiency was 95.8%.

The EPC9137 converter was also tested at 13.8V input and 48V output for boost-mode operation, as shown in Figure 5. At full load, EPC eGaN FETs can operate with 96% efficiency at 250kHz switching frequency, enabling 750W/phase compared to silicon-based solutions, which are limited to 600 W/phase due to the limitation on the inductor current at the 100kHz maximum switching frequency.

Conclusion

Car makers facing demands to increase the pace of vehicle electrification, both to compete in the marketplace and to meet toughening environmental legislation. This design example for a bi-directional DC-DC converter shows how EPC's automotive-qualified eGaN FETs, such as the EPC2206, can help integrate a 48V bus, needed to electrify power-hungry loads and meet rising power demands throughout the vehicle. When transferring power between 48V and 12V domains, the EPC9137 converter achieves maximum efficiency greater than 96% with 250kHz switching frequency, and above 95% at 500kHz.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由董慧转载自EPC,原文标题为:Automotive Buck/Reverse-Boost Converter with GaN for Efficient 48 V Power Distribution,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

【经验】GaN FET在激光雷达驱动器中的参数设计指导

本文中给出的激光雷达驱动器采用EPC公司的开发板EPC9126进行设计。EPC9126/EPC9126HC采用最优的PCB layout,EPC9126采用GaN FET—EPC2016C,在极短的4ns脉冲宽度,给三接面激光产生35A脉冲。EPC9126HC为大电流演示系统,在 8ns脉冲宽度可产生65A脉冲。文中给出了具体设计的参数指导。

设计经验 发布时间 : 2020-06-13

Use the Superior Power Density of Gallium Nitride FETs to Design a USB PD3.1 Power Supply with a 240 W, Universal AC Input

EPC‘s EPC9171 is a demonstration board. It features a low stage count approach for a universal AC voltage Input to 15V through 48V DC output with a load current limit of 5A suitable for USB PD3.1 power supplies.

设计经验 发布时间 : 2022-08-16

How to Use the GaN FET Thermal Calculator to Boost Reliability and Shorten Time-To-Market in Power Electronics System Designs

This article tells about how to use EPC‘s GaN FET Thermal Calculator to boost reliability and shorten time-to-market in Power Electronics System Designs. they are smaller, they switch faster, and have lower on-resistance resulting in greater efficiency than their silicon counterparts.

设计经验 发布时间 : 2022-05-18

EPC(宜普)eGaN® 氮化镓晶体管(GaN FET)和集成电路及开发板/演示板/评估套件选型指南

目录- eGaN FETs and ICs eGaN® Integrated Circuits Half-Bridge Development Boards DrGaN DC-DC Conversion Lidar/Motor Drive AC/DC Conversion

型号- EPC2212,EPC2214,EPC2059,EPC2216,EPC2215,EPC2218,EPC2016C,EPC2050,EPC2052,EPC2051,EPC2054,EPC2053,EPC2055,EPC9086,EPC2218A,EPC90153,EPC9087,EPC90154,EPC2069,EPC2102,EPC2101,EPC2104,EPC2103,EPC2106,EPC2105,EPC2107,EPC9018,EPC2065,EPC90151,EPC90152,EPC21702,EPC2100,EPC2067,EPC2221,EPC21701,EPC2066,EPC90150,EPC9097,EPC90145,EPC90142,EPC9098,EPC90143,EPC9099,EPC9092,EPC90148,EPC90149,EPC90146,EPC9094,EPC90147,EPC2219,EPC9091,EPC2619,EPC2036,EPC2035,EPC2038,EPC2037,EPC2014C,EPC2039,EPC9507,EPC2030,EPC9067,EPC2032,EPC2031,EPC9068,EPC2152,EPC2033,EPC9063,EPC9186,EPC9066,EPC8010,EPC9180,EPC2204A,EPC9181,EPC9061,EPC2308,EPC2307,EPC9005C,UP1966E,EPC2203,EPC9004C,EPC2202,EPC2204,EPC2015C,EPC2207,EPC2206,EPC2040,EPC2045,EPC2044,EPC9194,EPC2012C,EPC2019,EPC9049,EPC9203,EPC9204,EPC9205,EPC2252,EPC9166,EPC9167,EPC9047,EPC9201,EPC9041,EPC9162,EPC9163,EPC9165,EPC7020,EPC9160,EPC9040,EPC2024,EPC8009,EPC2302,EPC2001C,EPC2029,EPC2304,EPC2306,EPC2305,EPC8002,EPC2021,EPC9177,EPC2020,EPC9057,EPC9167HC,EPC2023,EPC9179,EPC9058,EPC8004,EPC2022,EPC9059,EPC9173,EPC9174,EPC9055,EPC9176,EPC9170,EPC9050,EPC9171,EPC9172,EPC2010C,EPC2034C,EPC7007,EPC7002,EPC9148,EPC2071,EPC7001,EPC23101,EPC23102,EPC23103,EPC9144,EPC90140,EPC23104,EPC2111,EPC7004,EPC2110,EPC7003,EPC90133,EPC90132,EPC9022,EPC9143,EPC90137,EPC90138,EPC90135,EPC90139,EPC7019,EPC7018,EPC9038,EPC9159,EPC9039,EPC2007C,EPC21603,EPC9156,EPC9036,EPC9157,EPC9037,EPC2088,EPC7014,EPC21601,EPC9158,EPC90122,EPC9151,EPC9031,EPC90123,EPC90120,EPC9153,EPC9033,EPC90121,EPC9154,EPC90124,EPC9150,EPC90128

【IC】EPC提供100V GaN FET助力实现更小的电机驱动器,用于电动自行车、机器人和无人机

EPC推出三相BLDC电机驱动逆变器参考设计EPC9194,工作输入电源电压范围为14V~60V,可提供高达60Apk的输出电流。此电压范围和功率使该解决方案非常适合用于各种三相BLDC电机驱动器,包括电动自行车、电动滑板车、无人机、机器人和直流伺服电机。

产品 发布时间 : 2023-11-07

EPC将在PCIM Asia 2024展示先进的氮化镓电源解决方案

作为全球增强型氮化镓 (GaN) FET 和 IC 的领导者,EPC 很高兴宣布将参加 PCIM Asia 2024。该活动将于 8 月 28 日至 30 日在中国深圳举行。EPC 的 GaN 专家将在 PCIM Asia 期间展示最新一代的 GaN FET 和 IC,涵盖包括 AI 服务器、机器人等在内的各种实际应用,探索业内最全面的 GaN 电力转换解决方案组合。

原厂动态 发布时间 : 2024-08-26

【视频】EPC发挥其GaN技术优势,将帮助实现高效能电机驱动应用和DC/DC转换器

型号- EPC9173,EPC2302,EPC2304,EPC2306,EPC2305,EPC2308,EPC2307,EPC23102

【IC】EPC新推基于GaN FET的150A电机驱动器EPC9186,适用于电动出行、叉车和大功率无人机

EPC新推EPC9186,这是一款采用EPC2302 eGaN®FET的三相BLDC电机驱动逆变器。EPC9186支持14V~80V的宽输入直流电压。大功率EPC9186支持电动滑板车、小型电动汽车、农业机械、叉车和大功率无人机等应用。

新产品 发布时间 : 2023-05-10

【元件】使用EPC新款50V GaN FET设计更高功率密度的USB-C PD应用,尺寸仅为1.8 mm²

EPC推出了50V、8.5mOhm的EPC2057 GaN FET,尺寸仅为1.5mm x 1.2mm,为USB-C PD应用提供了更高的功率密度。加利福尼亚州埃尔塞贡多—2024年6月—EPC是增强型氮化镓(GaN) 功率FET和IC的全球领导者,推出了50V、8.5mΩ的EPC2057。该GaN FET专为满足高功率USB-C设备的不断发展需求而设计,包括消费电子、车载充电和电动出行设备。

产品 发布时间 : 2024-06-26

EPC GaN FET助力DC/DC转换器实现功率密度和效率基准

EPC GaN FET与Analog Devices驱动器和控制器相结合,为客户简化氮化镓基设计、提高其效率、降低散热成本、助力计算、工业和消费类应用的DC/DC转换器实现最高功率密度。

应用方案 发布时间 : 2024-02-29

【元件】EPC推出首款具有最低1mΩ导通电阻的GaN FET EPC2361,采用紧凑型QFN封装(3mmx5mm)

EPC推出采用紧凑型QFN封装(3mmx5mm)的100V、1mOhm GaN FET(EPC2361),助力DC/DC转换、快充、电机驱动和太阳能MPPT等应用实现更高的功率密度。

产品 发布时间 : 2024-02-29

Design Higher Power Density USB-C PD Applications with New 50V GaN FET in Tiny 1.8mm² Footprint from EPC

EPC, the world’s leader in enhancement-mode gallium nitride (GaN) power FETs and ICs, launches the 50 V, 8.5 mΩ EPC2057aN FET is specifically designed to meet the evolving needs of high-power USB-C devices including those used in consumer electronics, in-car charging, and eMobility.

产品 发布时间 : 2024-06-13

【元件】EPC新推80V氮化镓晶体管EPC2204A/EPC2218A,具有较低的栅极电荷,可用于自动驾驶激光雷达

EPC推出了两颗新的80V AEC-Q101认证的氮化镓晶体管(GaN FETs),为设计者提供了比硅MOSFET更小、更高效的解决方案,可用于汽车48V-12V DC-DC转换、信息娱乐和自动驾驶的激光雷达。

新产品 发布时间 : 2022-12-29

【应用】EPC车规级GaN场效应管EPC2203应用于激光雷达,脉冲电流可达17A,漏源耐压值可达80V

本文主要介绍EPC汽车级GaN场效应管EPC2203在激光雷达上的应用,主要用在激光雷达发射部分,用于控制激光器的快速开关,优势:漏源耐压值可达80V;持续电流1.7A,最大脉冲电流17A;漏源电阻仅80mΩ,可有效降低系统损耗等。

应用方案 发布时间 : 2022-12-21

EPC Showcases Cutting-Edge Power Electronics Solutions for Automotive, Robotics, Power Tools, Solar, and More at PCIM Europe 2024

EPC, the world’s leader in enhancement-mode gallium nitride (GaN) FETs and ICs, is proud to announce its participation in PCIM Europe, the international leading exhibition and conference for Power Electronics, Intelligent Motion, Renewable Energy, and Energy Management. The event, held from 11 June to 13 June in Nuremburg, Germany, brings together industry experts and thought leaders to explore the latest advancements in power electronics and motion control.

原厂动态 发布时间 : 2024-05-30

电子商城

现货市场

服务

满足150W内适配器、PD快充、氮化镓快充等主流产品测试需要;并可查看被测开关电源支持协议,诱导多种充电协议输出,结合电子负载和示波器进行高精度测试。测试浪涌电流最大40A。支持到场/视频直播测试,资深专家全程指导。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论