Why Use Thermal Grease?

Although the heat will dissipate to the surroundings after being generated, most electronic products are not ventilated inside, and the heat is easy to accumulate and cause the temperature to rise, which affects the operation of electronic components. Electronic components are very sensitive to temperature, and high temperatures will cause them to fail. , and the aging speed of the material will be accelerated at high temperatures, so it is necessary to dissipate heat in time.

It is not feasible to only rely on the heat source itself to dissipate heat, and heat dissipation devices, such as cooling fans, heat sinks, and heat pipes, will be used. Relying on the mutual bonding of the two, the excess heat of the heat source is guided into the heat dissipation device, but there is a gap between the heat dissipation device and the heat source, and heat-conducting materials will be used.

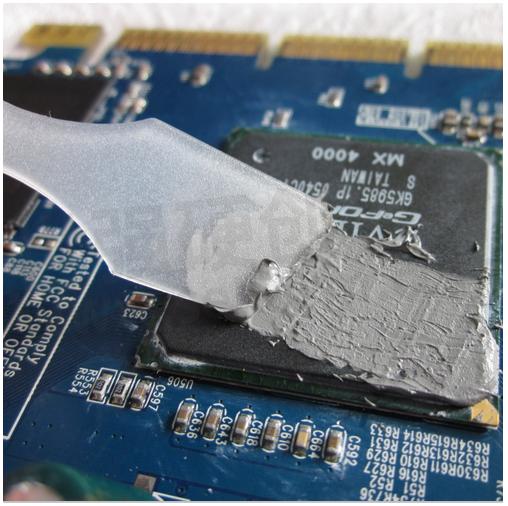

The Thermally conductive material is a general term for a material that is coated between the heating device and the cooling device of the product and reduces the contact thermal resistance between the two. Thermally conductive silicone grease is one of the thermally conductive materials. As one of the most commonly used thermally conductive materials in the market, it has a high reputation. Compared with other heat-conducting materials, the first time many people come into contact with thermal-conducting silicone grease is to install a cooling fan when assembling a computer, apply thermal-conducting silicone grease on the surface of the CPU, and then attach the contact piece of the cooling fan to the surface of the CPU.

thermal grease has high thermal conductivity and low interface thermal resistance. When using it, simply apply a thin layer of thermally conductive silicone grease, and then install the heat dissipation device, which can quickly remove the air in the gap and reduce the interface thermal resistance, so that heat can pass through quickly. Thermally conductive silicone grease is conducted to the heat dissipation device, and thermally conductive silicone grease is easy to operate, can be reworked, and is cost-effective.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由上山打老虎转载自SHEEN News,原文标题为:Why use thermal grease?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

What is a thermally conductive silicone sheet?

A thermally conductive silicone sheet is one of many thermally conductive materials. A thermally conductive silicone sheet is a gap-filling gasket made of silicone oil as the base material and added with heat-conducting, insulating, and temperature-resistant materials.

Thermal Gel vs Thermal Paste: Key Differences Explained

Thermal paste is a viscous material designed for thin-gap applications. Thermal gel is a versatile material available in various formulations, such as single-component silicone gel, dual-component silicone gel, and silicone-free gel. In this article Sheen will explain the key differences of thermal gel and thermal paste.

Thermally Conductive Materials with Ultra-high Thermal Conductivity

The thermally conductive material is a general term for materials that are coated between the heating device and the cooling device of the equipment and reduce the contact thermal resistance between the two.

Parker Chomerics(派克固美丽)热界面材料(热传导性凝胶/在位灌封材料/润滑脂)选型指南

Company Profile Overview of Dispensable Materials Material Selection Equipment Types Technical Parameters Packaging Options

PARKER CHOMERICS - 现场固化灌封化合物,GELS,ELECTRONIC APPLICATION,UNDERFILL MATERIALS,导热凝胶,DISPENSABLE, VERY LOW COMPRESSION FORCE, THERMAL GAP FILLERS,THERMAL GREASES,THERM-A-GAP™ GELS,CURE-IN-PLACE POTTING COMPOUNDS,热接口材料,热润滑脂,TIM,THERMALLY CONDUCTIVE GELS,THERMAL INTERFACE MATERIAL,POTTING MATERIALS,T636,T647,T635,T646,CIP 35,GEL 30,T642,TC 50,GEL 25NS,1642,1641,GEL 8010,T630,GEL 75,T650,GEL 45,T660,T670,GEL 37,HIGH-VOLUME AUTOMATED DISPENSING SYSTEMS,配药设备,制动控制,CONSUMER ELECTRONICS,消费电子,POWER DRIVERS,MEMORY MODULES,功率半导体,TELEVISIONS,移动服务器,DC/DC CONVERTERS,DC/DC转换器,LED模块,欧洲货币单位,MICROPROCESSORS,电信基站,不间断电源,TELECOM BASE STATION,POWER CONVERSION EQUIPMENT,TELECOM BASE STATIONS,AUTOMOTIVE ELECTRONIC CONTROL UNIT,DISPENSING EQUIPMENT,ENGINE,AUTOMOTIVE ELECTRONIC CONTROL UNITS,MOBILE SERVERS,微处理器,POWER SUPPLIES,BRAKING CONTROLS,MOSFET ARRAYS,发动机,牵引力控制,UNINTERRUPTABLE POWER SUPPLIES,功率转换设备,TRACTION CONTROLS,电视和电子产品,金属氧化物半导体场效应晶体管阵列,功率驱动器,POWER SEMICONDUCTORS,汽车电子控制单元,DESKTOPS,电源,ECU,高容量自动分配系统,TELEVISIONS ELECTRONICS,内存模块,台式机,LED MODULES

What Are the Characteristics of a Phase Change Thermal Pad?

The phase change thermal pad is a member of the thermally conductive material. , is also a very characteristic of a new type of thermal conductivity material. In this article, Sheen will introduce the characteristics of a phase change thermal pad.

An Introduction and Comprehensive Guide to Thermal Interface Materials

This article is mainly SHEEN‘s comprehensive guide to what is a thermal interface material, introduces a number of thermal interface materials, and introduces a number of SHEEN applications.

Why Does Thermal Resistance Affect the Thermal Conductivity of Thermal Silicone Pad?

Thermal silicone pad is a kind of gap-filling thermal pad made of silicone resin as the base material and added with temperature-resistant and thermally conductive materials. It has the characteristics of high thermal conductivity, low thermal resistance, insulation, compression, etc.

Why Look for A Thermally Conductive Material with Low Thermal Resistance?

A thermally conductive material is a general term for materials that are coated between heat-generating devices and heat-dissipating devices and reduce the contact thermal resistance between the two.

Thermal Interface Material Supplier Offers High-Quality TIM Solutions

When it comes to thermal management solutions, choosing a reliable thermal interface material (TIM) manufacturer is essential. Sheen Technology is a leading provider of high-quality TIMs, offering innovative solutions to meet the diverse needs of industries such as automotive, electronics, and telecommunications.

Heat Dissipation Requirements of Electronic Components and Application of Thermally Conductive Materials

After using the thermally conductive material, the gap between the two can be effectively filled and the air in the gap can be removed, thereby improving the operating environment of the electronic components.

Why Thermal Gel Become More and More Popular?

The thermal gel is one kind silicone two-component paste-like thermal conductive filling material. It mainly meets the requirements of low pressure and high compressive modulus during use. It can realize automatic production. It has the properties of excellent contact with electronic products, low contact heat resistance and excellent electrical insulation. This material has the advantages of thermal pad and thermal grease, while at the same time better compensating for the shortcomings of above two materials.

What is Thermal Putty?

Thermal putty, also known as thermal gel, is a highly versatile thermal interface material (TIM) designed to efficiently transfer heat between electronic components and their cooling solutions.

Heat Dissipation Application of Thermal Materials in Outdoor Communication Cabinets

By filling the gap between the heat dissipation device and the heat source, Thermally conductive materials air between the interfaces is eliminated. This reduces the contact thermal resistance between the two, thereby improving the heat dissipation effect of the cabinet.

Introduction of Thermal Gel and Its Application

The Thermal Gel series is a two-component preformed thermal grease product that meets the requirements of low pressure. In this article Sheen will introduce thermal gel and its application.

A Brief Description of Thermally Conductive Gap Filler Material-Silicon-free Thermal Pad

Power consumption electronic components are the main body of heat generation in electronic equipment. The higher the power of electronic components, the more heat they will generate. However, the development trend of science and technology in today‘s society is based on high performance, high integration and light weight. Mainly, the performance of electronic components is getting stronger and stronger, which also means that their power is also rising, so the heat dissipation must keep up with the pace.

电子商城

品牌:VINCOTECH

品类:IGBT POWER MODULE

价格:¥545.9490

现货: 192

品牌:VINCOTECH

品类:IGBT POWER MODULE

价格:¥392.2850

现货: 186

品牌:VINCOTECH

品类:IGBT POWER MODULE

价格:¥500.3350

现货: 181

品牌:VINCOTECH

品类:IGBT POWER MODULE

价格:¥296.0670

现货: 77

登录 | 立即注册

提交评论