AI at the IoT Edge Is Disrupting the Industrial Market

Artificial intelligence (AI) at the edge of the network is a cornerstone that will influence the future direction of the technology industry. If AI is an engine of change, then semiconductors are the oil driving the new age that is being defined by machine learning (ML), neural networks, 5G connectivity, and the advent of blockchain, digital twins, and the metaverse.

Despite recent disruptions to the chip industry due to supply chain and more recently, macroeconomic factors, the confluence of AI – and the Internet of Things (IoT) known as AIoT– is poised to shift the world from cloud-centric intelligence to a more distributed intelligence architecture.

It is expected that a staggering 73.1 zettabytes of data are expected to be generated by IoT devices, in 2025 according to IDC Research. As a result, endpoint data will increase at a CAGR of 85% from 2017 to 2025, driving intelligence from the cloud to the endpoint to run AI/ML workloads within tiny machines (TinyML). Some of the applications that are seeing the most disruption include the development of "voice as a user interface" to improve human-to-machine communication, as well as environmental sensing and predictive analytics and maintenance. Major growth segments include wearables, smart homes, smart cities, and intelligent industrial automation.

What are the benefits of embedding intelligence at the endpoint? Many industrial IoT applications operate within environments constrained by memory capacity, limited coMPUting, battery power, and sub-optimal connectivity. Moreover, these applications often require real-time responses that may be mission and system critical. Expecting such devices and applications to operate in a cloud-centric intelligence architecture just does not work.

This is where the power of embedding intelligence at the endpoint is evolving from standard industrial IoT implementations to what RENESAS is calling AIoT for industrial applications.

Transforming data at the source of collection minimizes latency and enables optimized processing for time-critical applications. Because data is not processed and transported over the network, the security concerns related to the transfer and flow of data, are greatly minimized. Another advantage is that data handling can be linked with root-of-trust at the endpoint, making the implementation impervious to attacks. Since data processing is handled at or very near the source, Renesas can fully leverage data gravity and reduce the power consumption associated with turning on radios or moving data through the network.

Renesas' commitment to customers is to lead the industry in endpoint computing technology with the broadest range of MCUs and MPUs. Already this has enabled designers to leverage Renesas' rich ecosystem of IoT and AI/ML building blocks by tapping into a technology ecosystem that features more than 300 building blocks of commercial-grade software provided by Renesas's trusted partners.

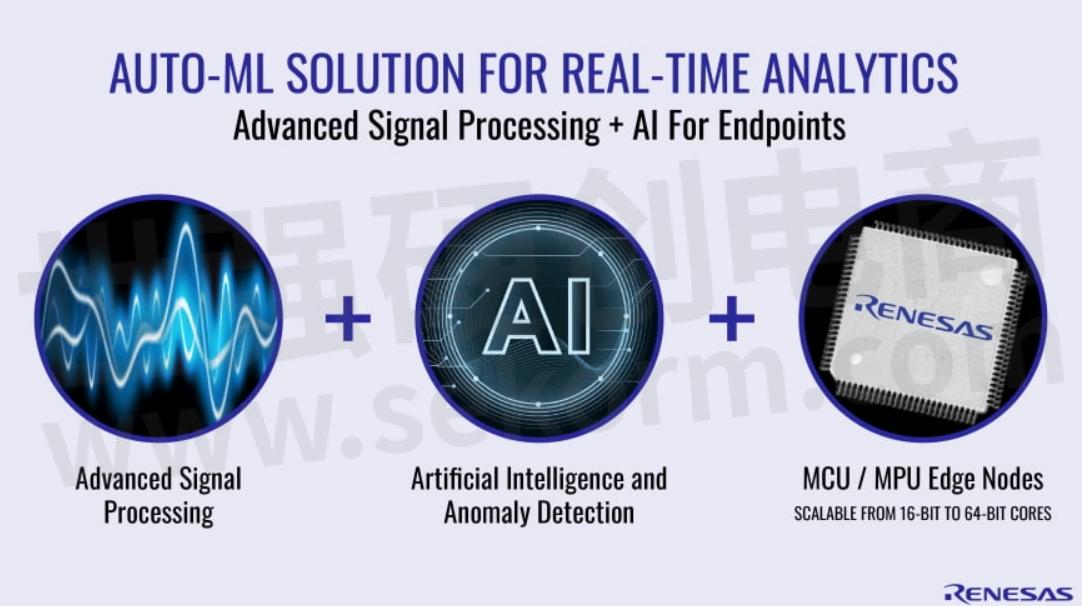

Renesas growing AIoT portfolio also explains Renesas' recent acquisition of Reality AI, a new platform powering edge and endpoint AI in industrial IoT applications using Renesas processors. Reality AI automatically searches a wide range of signal-processing transforms and generates custom machine learning models while retaining traceability in its approach and offering valuable hardware design analytics. The models run on nearly every MCU and MPU core available from Renesas – with new ones added constantly.

This puts an incredibly powerful tool into the hands of designers to help them solve their most difficult problems because the model development is specifically for non-visual sensing use cases and is based on advanced signal processing math and edge deployment. This enables advanced analytics capable of supporting full hardware design and complete frameworks, including data collection, instrumentation, firmware, and ML workflows. Other solutions simply generate algorithms and models that often account for only 5% of typical project costs, while ignoring the other 95% of development expenses.

Renesas' comprehensive approach to AIoT design allows developers to reduce unscheduled equipment downtime, improve production efficiencies and perform sophisticated quality assurance tasks that are costly or difficult to replicate in a current testing environment.

In a real-world use case tested under 51 different environmental and load conditions in a three-ton residential HVAC system, Reality AI was able to achieve a greater than 95% accuracy when detecting and distinguishing single fault conditions. The test also detected indoor and outdoor air-flow blockage and charge faults as small as 5% from OEM specifications in both heating and cooling modes.

The convergence of AI and IoT for industrial applications is a megatrend with significant potential. The acquisition of Reality AI unlocks the potential of combining advanced signal processing with AI at the edge and is supported by Renesas' extensive hardware, software, tools, and ecosystem to provide all the building blocks you need to unleash your creativity.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Vicky转载自Renesas Blogs,原文标题为:Executive Blog: AI at the IoT Edge Is Disrupting the Industrial Market,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Silicon Labs Extends Award-Winning xG22 Platform to Deliver Optimized 32-Bit MCU for IoT Edge Applications

March 3, 2021 – Silicon Labs announced the launch of the EFM32PG22 (PG22) 32-bit microcontroller unit (MCU), a low-cost, high-performance solution with an industry-leading combination of energy efficiency, performance and security. With easy-to-use, cost-efficient analog capabilities, the PG22 MCU is ideally suited for rapid development of consumer and industrial applications with demanding size constraints and low-power operation requirements.“

【经验】解析瑞萨MPU RZ/T1 SPI总线通信功能配置方法

当我们使用瑞萨(Renesas)MPU RZ/T1做项目开发时,基本都会用到SPI总线通信的功能,SPI总线通信速率较快很适合在单片机板级之间进行数据交互,本文将介绍使用瑞萨开发环境配置生成RZ/T1 SPI总线驱动程序的方法。

【经验】瑞萨MPU RZ/T1使用SSC生成EtherCAT CiA402协议栈方法

瑞萨MPU RZ/T1支持EtherCAT网络设计,如何使用协议栈工具生成相对应的EtherCAT从机栈代码呢,本文主要就Beckhoff工具生成EtherCAT CiA402协议栈方法做相关介绍。

瑞萨RX系列MCU实现二级MCU OTA升级:FreeRTOS篇

基于空中下载技术(OTA:Over-The-Air)并通过云服务端实现的MCU固件升级得益于云供应商和设备供应商之间的合作开展,目前已具备了简单且可快速部署的集成环境。瑞萨RX云互联解决方案开发团队开始提供即便在未直接与互联网连接的二级MCU中,也可以利用AWS IoT服务方案进行OTA固件升级的示例代码。

【经验】瑞萨RZ/T2M系列MPU使用IAR开发环境时的调试方法和注意事项

瑞萨RZ/T2M系列MPU可以使用IAR开发环境进行开发,当我们使用IAR开发环境加载一些瑞萨RZ/T2M相关例程项目时,总是会遇到一些编译报错问题,烧写异常问题,此文主要介绍使用IAR开发环境连接调试RZ/T2M系列MPU的方法和一些注意事项。

RZ/G MPU G2L、LC、UL组

型号- RZ/G3YYY,RZ/G2L,RZ/G2M,RZ/G2LC,RZ/G2UL,RZ/G1M,RZ/G2N,RZ/G1N,RZ/G,RZ/G1C,RZ/G2E,RZ/G1E,RZ/G2H,RZ/G1H,RZ/G3YY,RZ/G3XX,RZ/G3ZZ,RZ/G4X,RZ/G3X,RZ/G3Y,RZ/G4XX,RZ/G3Z

【经验】瑞萨MPU RZ/T1使用code generator生成SCI的初始代码方法

工程师初次使用瑞萨(Renesas)RZ/T1系列MPU时,可能不知道SCI该如何配置波特率,中断入口,中断标志位等。本文将介绍RZ/T1系列MPU利用code generator生产SCI的配置方法。

【经验】瑞萨MPU RZ/T1使用中断方式DMA传输的方法介绍

瑞萨(Renesas)MPU RZ/T1系列可以用于工业通信,伺服等领域项目中,这些领域往往需要主控与外设进行大量数据的交互,当我们使用RZ/T1的DMA中断传输功能接收大量数据时,在程序及配置中具体我们该怎么操作呢,本文主要介绍中断方式操作DMA传输的方法。

RZ/G MPU G2H,M,N,N组

型号- RZ/G3YYY,RZ/G2L,RZ/G2M,RZ/G2LC,RZ/G2UL,RZ/G1M,RZ/G2N,RZ/G1N,RZ/G1C,RZ/G2E,RZ/G1E,RZ/G2H,RZ/G1H,RZ/G3XX,RZ/G3YY,RZ/G3ZZ,RZ/G4X,RZ/G3X,RZ/G3Y,RZ/G4XX,RZ/G3Z

【经验】解析瑞萨MPU RZ/T1在e2 studio环境下的双核仿真步骤方法

瑞萨(Renesas)RZ/T1为基于32位和64位Arm的高端MPU,广泛应用工业控制领域,本文主要介绍使用瑞萨RZ/T1的双核CR4和CM3在e2 studio下的双核仿真步骤方法,帮助大家快速的进阶RZ/T1项目开发。

【经验】基于瑞萨RH850/F1K的MCU 15833 CAN通信中断接收实现注意点

最近有客户在调试基于RH850/F1K的MCU CAN通信功能程序时,一直无法进入中断接收程序;经过查验总结问题所在点,步骤如下:1.在boot.asm文件,如果使用eiint作为表引用方法,启用下一行的宏。

【经验】瑞萨MPU RZ/T1使用双寄存器切换开启DMA传输的方法介绍

在项目中使用瑞萨(Renesas)MPU RZ/T1做从机接收大量数据时,为了传输和接收数据效率,我们会启用DMA传输的功能,有时候项目中需要传输的是两块数据,这时候我们可以使用双寄存器切换的方式来完成,本文主要介绍启用双寄存器切换启用DMA传输的方法。

【经验】RZ/T1系列MPU批量生产两种烧录程序方式:在线烧录&直接FLASH烧录

瑞萨的RZ/T1系列的MPU没有内置的FLASH,程序一般是保存在外部SPI接口的FLASH中,在产品的批量生产时可以使用两种烧录程序的方式,一种是在线烧录,一种是直接FLASH烧录。

电子商城

现货市场

服务

可定制显示屏的尺寸0.96”~15.6”,分辨率80*160~3840*2160,TN/IPS视角,支持RGB、MCU、SPI、MIPI、LVDS、HDMI接口,配套定制玻璃、背光、FPCA/PCBA。

最小起订量: 1000 提交需求>

可烧录IC封装SOP/MSOP/SSOP/TSOP/TSSOP/PLCC/QFP/QFN/MLP/MLF/BGA/CSP/SOT/DFN;IC包装Tray/Tube/Tape;IC厂商不限,交期1-3天。支持IC测试(FT/SLT),管装、托盘装、卷带装包装转换,IC打印标记加工。

最小起订量: 1pcs 提交需求>

登录 | 立即注册

提交评论