How to Distinguish the Advantages and Disadvantages of Water Cold Plates?

YuanYang Thermal Energy specializes in manufacturing water chill plates and heat sink dissipation modules in various fields, and has its own unique views on heat dissipation field, which can provide different solutions for customers. YuanYang Thermal Energy has always put forward the safest process in production based on customers' pursuit of quality, including the mature technology of fiber groove, friction welding and deep-buried copper tubes on aluminum plate, which can be applied to different products for customers to choose from, emphasizing that it can be applied to different production processes in different fields.

Methods/steps:

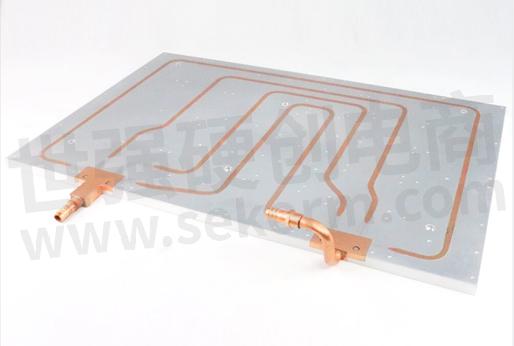

1. Look at the material. Most of the water cooling plates in the market are designed with aluminum plate and copper tube. This kind of water-cooled plate is made of aluminum and copper alloy with high cost performance and relatively low cost. Look at the quality of aluminum and copper, whether there are impurities, that is and thus, look at the advantages and disadvantages of raw materials, which is not difficult for everyone.

2. Look at the craft. The material can be the same but the process is different, but the effect of the radiator is completely different. We should start from two aspects to see the process. On the one hand, whether the production is carried out according to the design drawings, and check the parameters indicated in the drawings with vernier calipers. Normally the error is less than 0.05 mm is qualified, but if you prefer higher accuracy can reach into 0.02 mm.

3. On the other hand, judging from the workmanship of the water cold plate, there will be a problem of adhesion through the process of embedding copper tube inside the aluminum plate. If there is a gap between the two, it will affect the heat dissipation effect and even lead to water leakage. In addition, copper pipes and aluminum plates are connected by the process of burying pipes, and then gradually by the process of grinding or polishing surfaces, so that the whole water-cooled plate forms completely flat in one piece.

4. The quality of a radiator water cooling plate can be roughly judged from several above aspects. If the requirements are higher, the measured data of heat dissipation and thermal simulation test of related products can be requested from YuanYang Thermal Energy, and it is more accurate to judge by the data.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由香菜脆脆鲨转载自YuanYang Thermal Energy,原文标题为:Water cooling plate manufacturer tells you how to distinguish the advantages and disadvantages of water cold plates,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

【经验】利用热仿真软件FlothermXT确定水冷系统散热能力

目前水冷散热器主要分为两部分,冷头将热源产生的热量转移至流体里,流体将热量带到换热器部分通过风冷将热量转移至环境中,实现热传递,达到散热效果。然而对于水冷系统的散热能力却很难经验评估,本文通过热仿真软件FlothermXT研究水冷换热器的换热能力。

设计经验 发布时间 : 2022-12-14

【经验】利用热仿真软件Flotherm进行自然散热齿片设计

对于电子设备而言,自然散热与风冷是最常用的散热方式,相对于自然散热,风冷虽然拥有更好的散热效果,然而其不可避免的噪声问题、可靠性问题等问题,工程师一直在追求更安静、可靠性更高的被动散热。本文介绍如何利用热仿真软件Flotherm进行自然散热齿片设计。

设计经验 发布时间 : 2022-11-02

【经验】设备外壳自然散热对流系数估算经验

散热方式一般分为被动散热与主动散热两种,其中被动散热由于无需额外散热设备,是大多数低功耗设备的首选散热方式。然而,在设计被动散热设备时,由于其散热能力有限,存在极限值,需要在设计之初确定机器的散热量,本文将介绍被动散热量初步估算经验。

设计经验 发布时间 : 2022-12-13

Advantages of Vacuum-brazed Cold Plates

Vacuum brazed cold plate has unparalleled flexibility in design, as it is not limited by the bending radius limitations of pressure tube cold plate. Heat pipes can also be embedded in the plate to improve heat dissipation.

技术探讨 发布时间 : 2023-04-26

研讨会2024热设计服务&导热散热材料研讨会

12月5日直播,世强硬创平台将汇聚国内外顶尖品牌原厂,带来高导热热界面材料、新型散热器、隔热材料、散热风扇、TEC、氟化冷却液等新产品新技术。

活动 发布时间 : 2024-10-24

铲齿/铝挤散热器定制

支持铲齿散热器鳍片最大加工厚度0.1-10mm,最大宽度600mm,铝挤散热器鳍片最小铝挤厚度5mm,最小鳍片间距1cm;定制散热器产品工艺有热管焊接,穿片,打磨,铲齿,铝挤及CNC加工修边飞面等。

服务提供商 - 源阳热能 进入

水冷板在电脑机箱中的应用,具有高效散热、低噪音、美观设计的优势

随着电脑性能的不断提升,计算机内部的热量管理成为了一个关键问题。传统的风冷系统在应对高性能组件的散热需求时逐渐显得力不从心。水冷系统作为一种高效的散热解决方案,越来越受到电脑爱好者和专业用户的青睐。本文将重点探讨水冷系统中的重要组件——水冷板在电脑机箱中的应用。

应用方案 发布时间 : 2024-10-10

炎热的夏季,水冷板能发挥出多大的作用

在炎热的天气里,水冷板发挥着重要作用,为我们的电子设备保持良好的运行状态。水冷板是一种用于散热的设备,通过水循环的方式将设备产生的热量带走,有效降低设备的温度,确保设备的稳定性和性能。

技术探讨 发布时间 : 2024-10-09

【技术】如何辨别水冷散热器的水冷板的优劣?

对于如何选择好的水冷散热器,很多人都很模糊,其中如何辨别好与坏更是难懂,本文源阳热能就为你讲述水冷散热器的水冷板如何辨别优劣。通过几个方面都可以大致判断一块散热器水冷板是的优劣情况,如果要求较高,可以向文轩五金提出索要散热实测数据,通过数据来断定则更加准确。

技术探讨 发布时间 : 2022-09-24

Which Type of Radiator is Generally Used in Computers?

In computers, choosing the right radiator depends on the purpose of the computer, performance requirements and budget. Here are several common types of computer radiators and their applicable scenarios:

技术探讨 发布时间 : 2024-09-27

【技术】为什么会诞生VC均温板散热器?

传统散热片只是最简单的铝挤工艺所产生出的fin片加平面底座,却应用颇为广泛。然而随着电子工业产品的遍地开花,传统散热器显然是无法再跟上先进的步伐,于是在保证尺寸不变的情况下,需要增加散热功率,VC均温板散热器也就演变诞生了。

技术探讨 发布时间 : 2022-01-06

【技术】一文解析散热器的作用

源阳散热器的种类繁多,所散热的方式不同,分别的用途也不一样,那么散热器的作用是什么呢?本文就让源阳热能为您解答一下。

技术探讨 发布时间 : 2023-04-28

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

支持铲齿散热器鳍片最大加工厚度0.1-10mm,最大宽度600mm,铝挤散热器鳍片最小铝挤厚度5mm,最小鳍片间距1cm;定制散热器产品工艺有热管焊接,穿片,打磨,铲齿,铝挤及CNC加工修边飞面等。

最小起订量: 2pcs 提交需求>

登录 | 立即注册

提交评论