ATP‘s PCB Assembly Solderability Validation Tests

Overview of ATP’s PCB Assembly Solderability Validation Tests

Soldering is an important process to make sure that components on the printed circuit board assembly (PCBA) are effectively bonded to form reliable mechanical and electrical connections. Part of this process is called “wetting,” where the metal in the solder becomes molten fluid to bond and adhere with the metal components on the PCB. Evaluating solderability is the process of testing how well the solder secures those connections. This crucial process must be done before finalizing the PCB assembly, as poorly soldered parts can affect the PCB functionality, lead to defects, and incur more costs.

ATP PCB Assembly Solderability Validation

ATP performs solderability validation using temperature stress and external forces to validate the robustness of the soldering process.

The tests included in the solder process validation are described in this section.

Visual Inspection

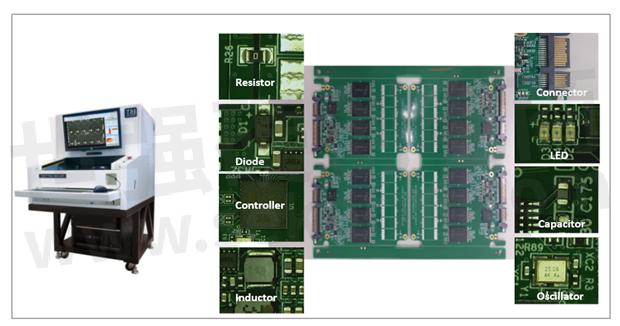

●Automated Optical Inspection (AOI) – Typically performed after the soldering process, AOI is a non-contact method where a camera autonomously scans the PCB for surface defects, soldering flaws, and missing skewed, faulty, or misplaced components.

Pass/Fail Criteria: IPC-610 Specifications

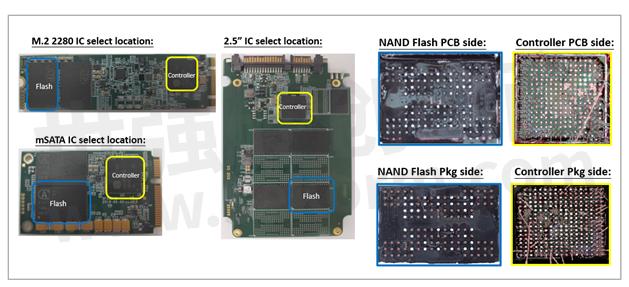

Figure 1. PCB items to be checked.

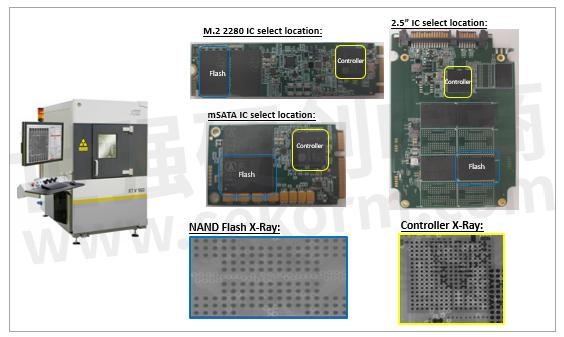

●Automatic X-Ray Inspection. Checks the solder joints are under components, which may not be visible to ordinary optical inspection equipment.

Pass/Fail Criteria: <25% void (IPC J-STD-001), open/short circuit check, component placement, solder ball size/shape check

Figure 2. X-Ray Test Equipment simplifies the complex inspection of multi-layered assemblies.

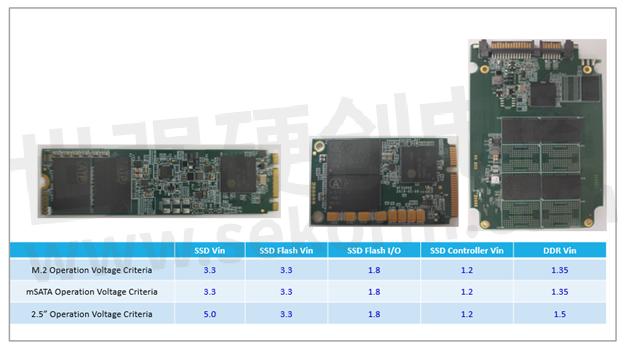

●In-Circuit Test. Accesses the board’s circuit nodes and measures component performance using power parameters such as resistance and capacitance.

Table 1. Sample In-Circuit Validation Test results for M.2, mSATA, and 2.5” SSDs

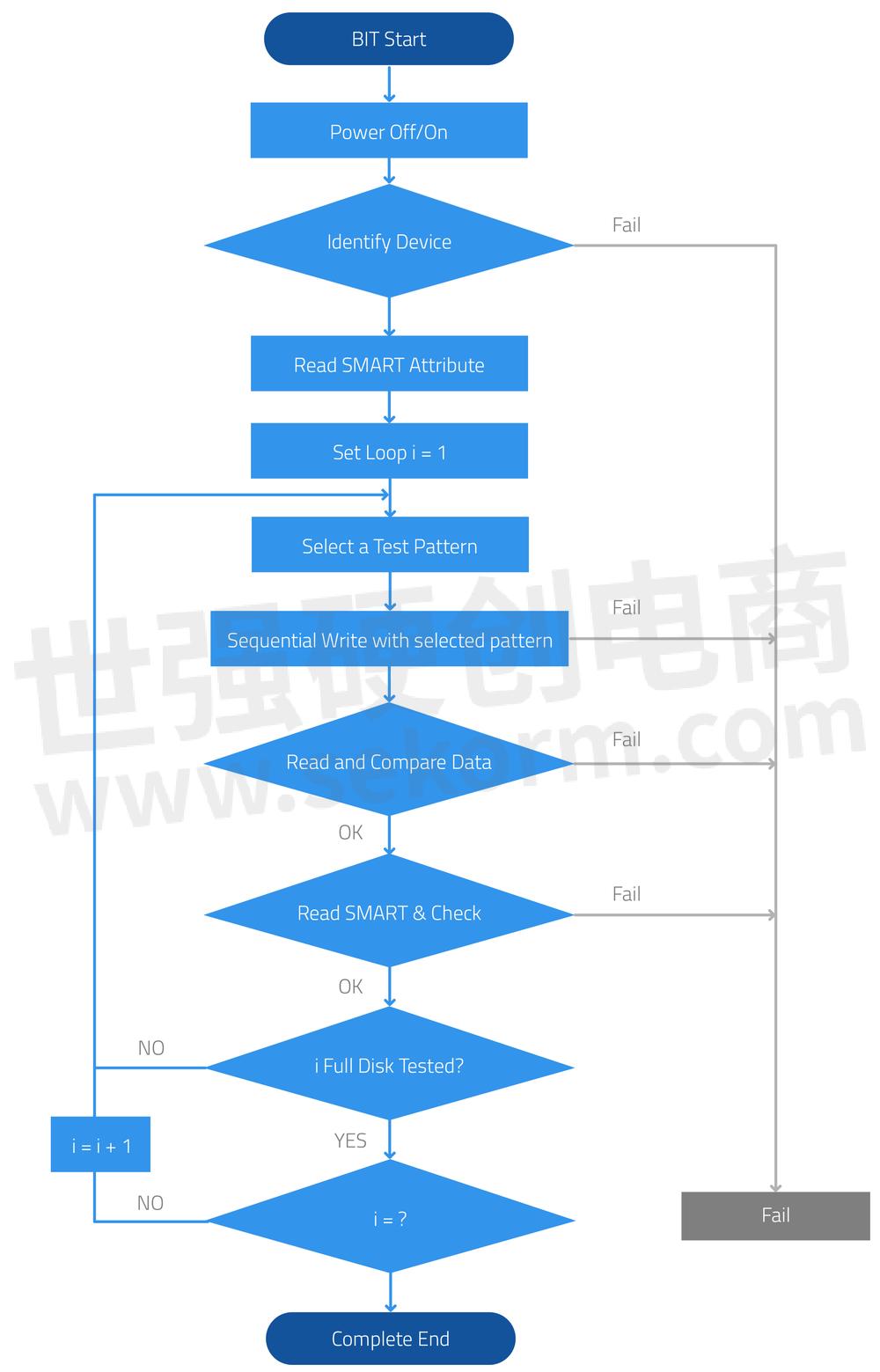

●SSD Functional Test Verification. Uses the ATP Gym & Coach System to verify PCB functionality after burn-in using Read-Write test patterns on SSDs.

Test Benchmark: ATP Gym & Coach System

Test Condition: 10 full SSD capacity loops

Figure 3. SSD Functional Test Process Flow

●Thermal Cycling Test. This test is used to determine the PCB’s resistance to extreme temperatures. By thermally stressing the PCB solder balls, flaws such as solder joint cracks, warps, lead damage, and other defects can be detected.

ATP performs the thermal cycling test between 0°C to 100 °C for 1000 cycles, with an interim check performed on the 500th cycle. The temperature is ramped up at 14°C per minute, with the PCB dwelling at each extreme temperature level for 10 minutes.

●Shock and Vibration Tests. In many embedded and industrial applications, PCBs are subjected to severe conditions, such as shock and vibration, that can damage the boards themselves or the components on them, compromising the physical, mechanical and electrical integrity of the PCB.

ATP performs these shock and vibration tests to make sure that the PCBs can endure such conditions.

●Non-Operational Random Vibration

●Non-Operational Half-Sine Shock

●Non-Operational Square Wave Shock

●Dye & Pry. This test is used to detect any defects on the solder ball and ball-to-pad interfaces. A dye is infused on the PCB, forcing the dye to penetrate cracks in the solder joints or on the PCB. The PCB is then dried in an oven to prevent the dye from smearing. The board is then mechanically pried to check for the presence of the dye in solder joints/balls or under the solder pads.

Pass/Fail Criteria: Follow IPC-A-610 specifications

Figure 4. Dye and Pry's results on sample SSDs tested to show that there are no cracks (red dye penetration) on the solder joint and soldering ball.

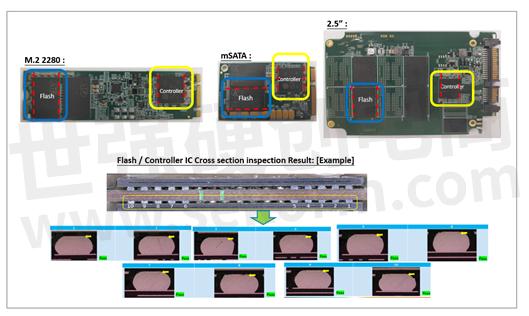

●Cross-Section Check. Also called micro-section analysis, the cross-section test inspects the internal quality of the PCB and provides an interconnection defect analysis. It helps detect internal failures, such as those related to soldering and plating, as well as the thickness of the board layers.

Pass/Fail Criteria: Intermetallic Compound (IMC) layer, soldering status check (Examples: no wetting, cold soldering, dewetting, and others)

Key Takeaways

Soldering defects can affect the functionality of the PCB assembly. This is why ATP takes great care in making sure that all PCB components are effectively bonded through the soldering process. ATP evaluates solderability through rigorous tests, such as visual inspection, thermal cycling, shock and vibration, dye and pry, and cross-section check.

ATP’s PCB assembly validation tests are part of the many reliability and endurance tests developed and performed by ATP to ensure strict compliance to the highest standards of quality. ATP is committed to delivering high-performance and high-endurance NAND flashes storage products to ensure the best value for the total cost of ownership (TCO).

- |

- +1 赞 0

- 收藏

- 评论 0

本文由深蓝的鱼转载自ATP,原文标题为:SSD PCB Assembly Solderability Validation Tests,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

ATP NVMe BGA pSLC SSD安全保护及加密功能特点

硬件写保护* 写保护功能将ATP NVMe BGA SSD置于“只读”模式,以防止数据写入设备,并保护重要数据不被意外删除、移动或修改。通过在控制器印电路板(PCB)上的通用输入/输出(GPIO)信号引脚的特定引脚上放置跳线,在存储设备上启用写保护。硬件快速擦除*对于特定应用,主机可以使用GPIO连接器触发“擦除数据”行动。

世强有关于PCIE接品的存储产品的方案介绍吗,要能做到16TB/32TB容量的,满足PCIE4。0标准。另外,这个PCB板材是否用常规的FR4即可还是说要用高频板材?请大神指点

新增工业级SSD存储、DRAM模块、NAND闪存,世强代理ATP Electronics【选型】ATP(华腾国际)内存及存储产品选型指南;【应用】ATP闪存用于IOT/IIOT中数据云存储/存储储存应用,满足严苛耐用性、保留性和可靠性要求; 高频特种多层线路PCB板打样加工服务,可提供FR4/ROGERS/ARLON/Taconic等多种板材FR-4升级替代首选Kappa™438板材,完全兼容FR-4加工工艺,兼具低成本和低损耗【选型】比传统FR-4材料高6-8倍导热系数的92ML板材,助力解决高端通信电源、工业电源的散热问题

DDR2专业存储和内存解决方案的全球领导者

描述- 本资料介绍了ATP Electronics生产的DDR2内存模块。这些模块具有多种密度选项(从256MB到4GB),支持Chipkill技术,并采用更低的电压以减少能耗。它们适用于不同的系统形式因素,包括240针全尺寸UDIMM和200针SO-DIMM,但不与DDR、DDR3或DDR4兼容。资料还提供了关于速度、PCB高度和工作温度的技术规格。

PCNE21092701000:A600S系列TLC SSD产品设计变更通知

描述- ATP发布产品设计变更通知,涉及ATP Superior Line SSD A600S系列TLC SSD,包括2.5” SSD、M.2 2242、M.2 2280和mSATA。由于Novatek突然停止其电源管理IC(PMIC)相关产品线,ATP的SATA III TLC SSD受到影响。需要调整PCB设计以适应新的PMIC。受影响的产品编号和替代方案已列出,建议进行最小重新认证。

型号- AF960GSTIC-7BAXP,AF120GSTIC-7BAXP,A600S SERIES,AF120GSTIC-7BEXP,AF640GSACJ-7BCIP,AF480GSTIC-7BFXP,AF1T92STCJ-7BBXP,AF240GSTIA-7BAXP,AF240GSTCJ-7BBXP,AF1T92STCJ-7BFXP,AF960GSTIC-7BEXP,AF240GSTIA-7BEXP,AF240GSTCJ-7BFXP,AF960GSTIC-7BBIP,AF120GSTIC-7BBIP,AF240GSTIC-7BEIP,AF120GSTIA-7BFXP,AF80GSACJ-7BAIP,AF240GSTHI-7BAIP,AF240GSTIC-7BAIP,AF120GSTIC-7BFIP,AF120GSTIA-7BBXP,AF240GSTHI-7BEIP,AF240GSTIA-7BBIP,AF120GSTHI-7BFXP,AF960GSTIC-7BFIP,AF80GSAIC-7BCIP,AF240GSTIA-7BFIP,AF120GSTHI-7BBXP,AF240GSTHI-7BAXP,AF240GSTHI-7BEXP,AF480GSTCJ-7BAIP,AF160GSAHI-7BCIP,AF480GSTCJ-7BEIP,AF80GSAHI-7BCIP,AF480GSTIC-7BBXP,AF160GSAIA-7BCIP,AF120GSTIC-7BBXP,AF240GSTIC-7BEXP,AF960GSTIC-7BBXP,AF240GSTIC-7BAXP,AF120GSTIC-7BFXP,AF120GSTIA-7BFIP,AF120GSTCJ-7BEIP,AF480GSTIC-7BEXP,AF320GSACJ-7BAIP,AF120GSTIA-7BBIP,AF80GSAIA-7BCIP,AF120GSTCJ-7BAIP,AF960GSTCJ-7BAIP,AF120GSTCJ-7BFXP,AF960GSTCJ-7BEIP,AF960GSTIC-7BFXP,AF160GSACJ-7BAIP,AF240GSTIC-7BFIP,AF240GSTHI-7BBIP,AF480GSTIA-7BAIP,AF240GSTIC-7BBIP,AF240GSTIA-7BAIP,AF120GSTIA-7BEXP,AF240GSTHI-7BFIP,AF480GSTIA-7BEIP,AF480GSTHI-7BBIP,AF120GSTIA-7BAXP,AF240GSTIA-7BEIP,AF480GSTHI-7BFIP,AF240GSTHI-7BBXP,AF480GSTHI-7BFXP,AF240GSTHI-7BFXP,AF160GSAIC-7BCIP,AF480GSTIC-7BBIP,AF480GSTHI-7BBXP,AF120GSTCJ-7BEXP,AF480GSTIC-7BFIP,AF320GSAIC-7BCIP,AF960GSTCJ-7BAXP,AF120GSTCJ-7BAXP,AF480GSTIC-7BAXP,AF960GSTCJ-7BEXP,AF240GSTIC-7BFXP,AF480GSTIA-7BAXP,AF480GSTCJ-7BBXP,AF240GSTIC-7BBXP,AF120GSTIA-7BEIP,AF480GSTIA-7BEXP,AF120GSTCJ-7BFIP,AF480GSTCJ-7BFXP,AF960GSTCJ-7BBIP,AF120GSTIA-7BAIP,AF120GSTCJ-7BBIP,AF960GSTCJ-7BFIP,AF80GSACJ-7BCIP,AF480GSTIA-7BBIP,AF480GSTIA-7BFIP,AF480GSTHI-7BAIP,AF80GSAIC-7BAIP,AF480GSTHI-7BEIP,AF480GSTHI-7BAXP,AF480GSTIC-7BEIP,AF120GSTHI-7BEIP,AF480GSTHI-7BEXP,AF480GSTIC-7BAIP,AF120GSTHI-7BAIP,AF160GSAIA-7BAIP,A600S,AF240GSTCJ-7BAIP,AF80GSAHI-7BAIP,AF160GSAHI-7BAIP,AF120GSTCJ-7BBXP,AF960GSTCJ-7BBXP,AF240GSTCJ-7BEIP,AF1T92STCJ-7BAIP,AF960GSTCJ-7BFXP,AF1T92STCJ-7BEIP,AF480GSTIA-7BBXP,AF480GSTCJ-7BAXP,AF240GSTCJ-7BAXP,AF320GSACJ-7BCIP,AF480GSTIA-7BFXP,AF480GSTCJ-7BEXP,AF1T92STCJ-7BAXP,AF240GSTCJ-7BEXP,AF240GSTIA-7BBXP,AF80GSAIA-7BAIP,AF1T92STCJ-7BEXP,AF240GSTIA-7BFXP,AF960GSTIC-7BAIP,AF120GSTIC-7BAIP,AF120GSTIC-7BEIP,AF120GSTHI-7BEXP,AF960GSTIC-7BEIP,AF160GSACJ-7BCIP,AF120GSTHI-7BAXP,AF160GSAIC-7BAIP,AF120GSTHI-7BFIP,AF120GSTHI-7BBIP,AF320GSAIC-7BAIP,AF480GSTCJ-7BBIP,AF240GSTCJ-7BBIP,AF480GSTCJ-7BFIP,AF1T92STCJ-7BBIP,AF240GSTCJ-7BFIP,AF640GSACJ-7BAIP,AF1T92STCJ-7BFIP

适用于高强度工作负载的DDR3高强度性能

描述- ATP DDR3模块提供1GB至32GB的密度,支持Chipkill,并具备高带宽性能,最高可达1866 MT/s。这些模块在1.5V(正常)和1.35V(低电压)下运行,功耗低于DDR2内存。ATP DDR3模块与Intel Core i7系列、AMD AM3 Phenom处理器和最新的AMD嵌入式企业芯片组兼容。产品线包括SO-DIMM和Mini-DIMM,具有低、超低和超超低轮廓选项。此外,ATP提供防尘、化学物质、极端温度和腐蚀的防护涂层,金手指镀层厚度为30µ",确保更好的耐用性和信号传输质量。产品规格包括不同类型的DIMM、密度、速度、PCB高度和操作温度。

型号- AQ12P64A8BLK0M,AQ24P64B8BLK0M,AW24P64F8BLK0M,AW12P6438BLK0M

ATP为SSD的PCB组装进行严格可焊性验证测试,确保可靠性和耐久性

ATP 通过严格的测试来评估可焊性,例如目视检查、热循环、冲击和振动、染色以及截面检查。本文描述了焊接工艺验证中包含的测试项及其验证标准。

ATP DDR4 DRAM Solutions

描述- 该资料介绍了ATP DDR4 DRAM解决方案,重点在于其高性能和适用于高强度工作负载的特点。它提供了从2GB到128GB的不同容量选项,支持高达3200 MT/s的数据传输速率,并采用低电压设计以降低功耗。这些内存模块旨在提高可靠性和服务性(RAS),同时优化用于工业温度应用的性能。

【经验】DRAM的可靠性受什么因素影响?ATP DRAM为何具备高可靠性?

ATP的DRAM模块经过两个级别的测试,以确保最大的可靠性:1、先进的IC级集成电路测试;2、增强的模块水平测试:老化测试(TDBI)和自动测试设备(ATE)确保模块达到甚至超过合格参数。同时具有工业额定温度,采用密封涂层,使用使用抗硫电阻器(基于项目)和厚度为30µm的金手指镀层。

ATP SSDs选型表

ATP推出SSDs(固态硬盘),Capacity(存储容量)120G-7680G,Operating Temperature(工作温度)-40℃~85℃

|

产品型号

|

品类

|

Product Line

|

Capacity(GB)

|

Operating Temperature(℃)

|

Power Loss Protection

|

|

FT240GP48APHBPI

|

固态硬盘

|

N651Si

|

240GB

|

-40℃~85℃

|

Hardware + Firmware Based

|

选型表 - ATP 立即选型

ATP DRAM模块选型表

ATP提供如下DRAM模块的技术选型,Technology:DDR3/DDR4/DDR5;SPEED:1600MHz~5600MHz;Capacity:4GB~16GB。

|

产品型号

|

品类

|

Technology

|

DIMM Type

|

SPEED

|

ECC

|

SIZE

|

CHIP

|

PCB Height

|

DIMM Rank

|

Pin

|

Grade

|

Operating temperature

|

|

D516G0RD568DPSC

|

DRAM MODULE

|

DDR5

|

RDIMM

|

5600MHz

|

ECC

|

16GB

|

2GX8

|

1.23"

|

1

|

288

|

CT

|

0℃~+85℃

|

选型表 - ATP 立即选型

The ATP Gym and Coach System: Exercising SSDs to Ensure Total Fitness

With the Gym and Coach system, ATP has dramatically improved RDT and the initialization process for functional test details. By making industrial SSDs undergo a lot of “painful” exercises through stringent testing, ATP makes sure that customers have everything to gain by receiving the most robust, reliable and enduring flash storage products for their applications.

ATP SecurStor microSD

描述- 该资料介绍了ATP SecurStor microSD存储卡的安全特性。它提供了多层权限控制和数据加密功能,以保护数据免受未经授权的访问。这些卡片具有多级认证、硬件AES-256 XTS加密、安全擦除等功能,符合US Air Force System Security Instruction (AFSSI) 5020标准。

ATP UHS-I MicroSDXC,A1,U3存储卡规格

描述- 本资料详细介绍了ATP UHS-I microSDXC, A1, U3存储卡的规格和特性。资料涵盖了产品规格、特性、环境规格、可靠性、电气特性、IOPS、顺序最大读写性能、写/擦除耐久性、额外功能和证书等方面。

型号- FT256GUD4APEBFI-SEK1,FT64G0UD4APEBFC-SEK1,FT512GUD4APEBFI- SEK1,FT128GUD4APEBFI- SEK1,FT128GUD4APEBFI-SEK1,FT512GUD4APEBFI-SEK1,FT512GUD4APEBFC-SEK1,FT64G0UD4APEBFI-SEK1,FT64G0UD4APEBFI- SEK1,FT128GUD4APEBFC-SEK1,FT256GUD4APEBFC-SEK1,FT256GUD4APEBFI- SEK1

ATP e.MMC v5.1嵌入式闪存存储解决方案

描述- 该资料介绍了ATP e.MMC v5.1嵌入式闪存解决方案,强调其在工业级性能、极端耐用性和可靠性方面的特点。它符合AEC-Q100 Grade 2和Grade 3标准,具有高耐久性,支持JEDEC e.MMC v5.1标准,并采用153球FBGA封装。ATP e.MMC集成了NAND闪存、复杂的闪存控制器和快速的多媒体卡(MMC)接口,适用于空间受限但需在恶劣环境中保持可靠性的嵌入式系统。

型号- E600SI,E650SC,E600SAA,E700PI,E600SA,E650SI,E600VC,E700PIA,E600SIA,E700PA,E750PI,E700PAA,E750PC,E700PC

电子商城

现货市场

服务

可定制UV胶的粘度范围:150~25000cps,粘接材料:金属,塑料PCB,玻璃,陶瓷等;固化方式:UV固化;双固化,产品通过ISO9001:2008及ISO14000等认证。

最小起订量: 1支 提交需求>

可定制插座连接器的间距1.25mm~2.54mm;列数:单列/双列/三列/四列;端子类型:直焊针、直角焊针、表面贴装式、无焊柔性针压接、绕接、载体.;镀层、车针长度/直径、连接针长度等参数可按需定制。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论