Grepow Battery was interviewed by Global Sky Media about eVTOL Power

Based in Shenzhen China, Grepow Battery was founded in 1998. The name “Grepow” refers to green power. Grepow entered the lithium battery field and established battery brands Geshi, Gens Ace, and TATTU, which can be found in Uncrewed Aerial Vehicles (UAVs), as well as model aircraft and cars. The company currently has five factories, over 200 engineers and technicians, and more than 2,500 overseas sales outlets. Besides lithium batteries, Grepow researches and develops batteries and charging equipment for a variety of customer power requirements.

Fig.1

What are the differences and difficulties when developing batteries for eVTOLs versus small UAVs?

Compared with small-scale UAVs, eVTOLs have a heavier load and higher battery requirements, with battery voltages over 100 volts and currents up to 100 to 300 amperes. High voltage and current batteries require more series and parallel connections. EVTOLs demand a higher charge/discharge rate and consistency between cells. Assembling modules requires uniform heat control and dissipation, making the manufacture of batteries more difficult. Batteries for eVTOLs should be highly reliable and need a balance between high C-rate, high energy density, and long cycle life.

What are the collaboration strategy for battery development and airworthiness certifications with eVTOL OEMs?

In terms of research and development, Grepow will work together with OEMs to further research the requirements for customized batteries and develop battery standards in line with the development of passenger aircraft. Grepow will also develop and verify our battery technology, thereby improving the reliability and safety of the batteries. Different eVTOL OEMs are designing many types of eVTOLs for different mission profiles, so they have varying battery performance requirements, such as voltage and thermal control during flight, where the voltage demand may vary from 100V to 800V. Some battery packs use a single large module, while others use multiple smaller modules, such as 12 to 24 batteries that have lower voltages. The currents under different flight phases and altitudes are different. Grepow will customize the discharge rate of the cells according to the actual situation and design the power battery to fit the customer’s needs according to the battery charging efficiency, charging speed, and cycle life.

Since no eVTOL OEMs in China have received their airworthiness certifications yet, each OEM is developing its aircraft in its own way. Electric vehicles have a unified industry standard right now, whereas eVTOLs do not. Batteries can be certified independently for airworthiness.

However, because each model performs differently, the requirements for cell type, formula, and discharge performance will vary; hence, there is no unified or general standard for airworthiness certification. Grepow is also waiting to see if there will be minimum battery standards for eVTOLs as there are with Electric Vehicles. The government and the industry are already in communication about this. The industry standards are mainly referencing those in Europe and the United States. China will let companies explore the industry first, then set applicable rules after it reaches scale. Differing from China, the United States, and countries in Europe, which set the standards before developing the industry.

Under different charge/discharge rates, what specific power, specific energy, and cycle life can Grepow batteries reach? How do they compare to other battery manufacturers?

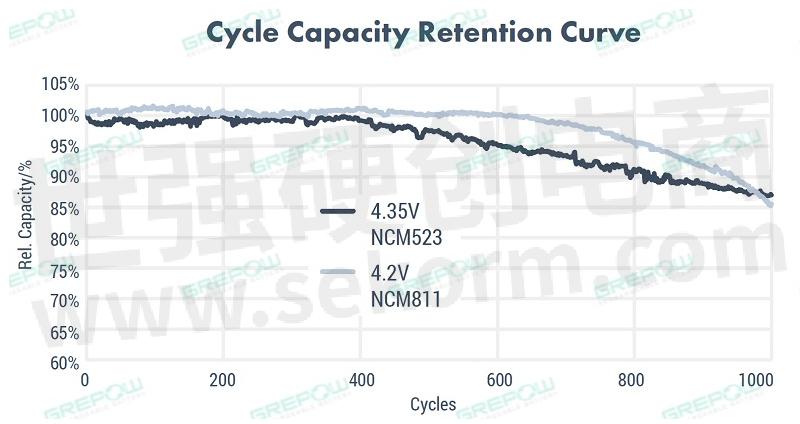

In the eVTOL industry, the 5C charge/discharge rate is a trend and it is one of our strengths. Currently, Grepow has achieved power density up to 1600W/kg, energy density up to 280Wh/kg, and cycle life over 1,000 times under 1C fast charging; a power density up to 1,400W/kg, energy density up to 245Wh/kg, and cycle life over 1,000 times under 5C fast charging.

In the electric vehicle industry, the specific energy of a single cell of an NMC 811 can reach 300 to 350wh/kg. This type of cell has a high energy density but cannot achieve a high discharge rate due to its material properties. Grepow is focussing on developing a high-rate power battery, which can have a 5C fast charging and 10C high discharge rate with 240Wh/kg high energy density.

Fig.2

What are the technical difficulties in improving the charge/discharge multiplier of batteries? How can we improve this? What is the expected battery performance by 2025?

Energy density and the charge/discharge multiplier are generally constrained by each other. If Grepow were to enhance the charge/discharge rate, the energy density will decrease. It is necessary to develop materials with a higher specific capacity, highly compacted, and better performance under high rates, such as high voltage high nickel ternary cathode materials, silicon carbon cathode materials, and so on, to improve charge/discharge rate under a sufficient energy density. As for the performance improvement of power batteries in 2025, Grepow believes that the high-rate battery will increase in energy density, ideally reaching 280 to 300wh/kg. It depends on the development of raw materials.

Maintaining battery life at a high charge/discharge rate is one of the problems that eVTOL batteries face. What technologies and methods could extend battery life?

Batteries that are under high temperature and high voltage, and during the charging and discharging process, the unbalanced temperature distribution of the battery cells will reduce the life of the battery. In terms of battery packaging, cell-to-cell consistency (capacity difference, voltage difference, and internal resistance difference) is also one of the critical factors that cause a decrease in battery life. There are different ways to improve battery life. Grepow can optimize the design of the single cell, such as improving the multiplier performance and optimizing the cell size to reduce the temperature rise of the battery during charging and discharging. Grepow can also optimize the module structure design to improve the heat dissipation and soaking, reducing the battery from heating and ensuring the consistency of the temperature distribution.

The battery packaging technology is closely related to the aircraft's design structure by the OEMs. Grepow will develop a corresponding battery module structure to fit the OEM’s structural design and adopt technologies and concepts of CTP and CTC battery packaging. In the past two years, Grepow continued to improve the capacity of single cells, introduced laser welding technology, and adopted lightweight assembly materials to improve the energy density of the whole battery pack.

Fig.3

What are your thoughts on the development of solid-state batteries and their application to eVTOLs?

The development direction of power batteries is mainly to improve energy density, reliability, and safety, and solid-state batteries have advantages in terms of safety. If possible, the main development direction is to develop and achieve the mass production of more stabilized batteries with a breakthrough in high-rate charging and discharging technology. But the problem is that solid-state batteries are difficult to mass produce in the short term. This situation is similar to graphene batteries where production on a large scale is difficult. Optimistically, Grepow can expect solid-state batteries to reach mass production in the next three to five years.

Grepow is still focusing on developing a semi-solid-state battery for now, which can achieve an energy density of 275 to 300wh/kg, and expects to bring it into mass production in 2023. The all-solid-state battery cannot meet the requirements of a high charge/discharge rate at this stage due to its low electrolyte conductivity, so it is hard to apply it to the aerial vehicle market in the short term. Grepow will continue to follow up on the development of solid-state batteries.

Fig.4

Are there any other development directions for battery technology besides solid-state batteries in the future? What is Grepow's development plan for batteries?

Besides solid-state batteries, hydrogen and sodium batteries also show good development momentum. The industry has been seeking a high energy density to enhance the range of EVs. However, the social concern about battery safety has risen in recent years as there is more media coverage in this regard, so the development of batteries will also focus more on this area. Hydrogen energy is a good development direction. Japan and South Korea are vigorously developing hydrogen energy. Due to safety issues, building hydrogen energy plants in China is difficult. Hydrogen storage is dangerous, and the government has not relaxed the corresponding safety standards. Sodium batteries are stable, but the energy density is low, so the probability of using them is not very high in their current state.

Grepow's products are mainly high-rate batteries. Grepow will continue to develop high rate and high energy density power batteries with an energy density between 300 to 350Wh/kg while meeting a 5C to 10C fast charging and long cycle life of more than 1000 times.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由三年不鸣转载自Grepow News,原文标题为:Grepow Battery was interviewed by Global Sky Media about eVTOL Power,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Top Lithium Polymer Battery Manufacturer Internationally Grepow Lithium Polymer battery manufacturer

Grepow‘s new generation of polymer lithium-ion batteries can be thinned in shape (lithium polymer batteries up to 0.5 mm thinner, relative to the thickness of a card), arbitrarily area and arbitrarily shaped, greatly improved The flexibility battery design. Therefore, it can be made into a battery of any shape and capacity in accordance with product requirements. Provides application designers with a high degree of design flexibility and adaptability in power solutions to maximize the performance of their products.

What Battery Does a Smart Sports Bracelet Take?

Smart bracelets are usually powered by high-performance polymer batteries to ensure the continuous, efficient and stable operation of the product. The Grepow shaped battery is officially a good choice for you to achieve your creativity.

Grepow Patented Button Cells Outstanding to Power TWS

Grepow Battery Co., Ltd. (Abbr. Grepow) patented the button battery has a wide range of application scenarios due to the stacking tech, lightweight and performance advantages.

NMC vs NCA Battery Cell: What’s the Difference?

Choosing between NMC and NCA battery cells depends on the specific requirements of the application. NMC cells offer a versatile and cost-effective solution with balanced energy and power characteristics, making them ideal for a wide range of uses from EVs to power tools. On the other hand, NCA cells provide higher energy density and longer cycle life, making them suitable for high-performance EVs, consumer electronics, and aerospace applications.

What is Al Translator Earphone and What Battery Powering it?

The space left for the battery will become less and less, or more and more demanding, which determines the AI translation headset can’t use the square battery if the square battery does not make good use of the product‘s internal space.

What Is a 6S LiPo Battery?

Lithium Polymer (LiPo) batteries are widely used in drones, RC vehicles, and various other applications due to their lightweight, high energy density, and power delivery. Among these, 6S LiPo batteries are particularly popular. This guide explores their specifications, types, and applications.

5 differences between capacity lithium battery and the power one

Grepow tells about the following 5 levels(composition materials, current size, discharge rate , voltage level, applied products) in order to be clearer about their battery categories and select the right power supply device for them.

Round LiPo Battery: A Comprehensive Guide

Round LiPo batteries offer a versatile and efficient power solution for a wide range of applications. With their compact design, high energy density, and customizable features, they are an excellent choice for modern electronic devices and specialized equipment. Grepow‘s innovative solutions further enhance the potential of round LiPo batteries, making them a reliable option for various industries.What is a Round LiPo Battery?A round LiPo battery, or round lithium polymer battery, is a type of rechargeable battery with a circular shape.

An In-Depth Guide to Drone Motors

Drone motors come in a variety of types and configurations, each with unique advantages. Understanding how each motor type functions, along with key specifications like KV rating, thrust, and ESC compatibility, is essential in selecting the right motor. As drone technology continues to evolve, motor advancements will likely play a pivotal role in achieving higher efficiency, greater power, and more specialized functionality across a wide range of drone applications.

Lithium-ion Battery Cycle Life VS. Calendar Life VS. Shelf Life

Lithium-ion batteries have become an integral part of our daily lives, powering everything from smartphones to electric vehicles. As these batteries play a crucial role in various applications, understanding their life expectancy is essential. In this article, we will explore the concepts of cycle life, calendar life, and shelf life of lithium-ion batteries, shedding light on their individual characteristics and implications.

Grepow Custom Lipo Battery Pack Solutions for Consumer Electronics, Drones, UAVs, EVs and So on

Grepow‘s custom Lipo Battery Pack solutions offer unmatched flexibility, performance, and safety for a wide range of applications. By leveraging advanced technology and extensive customization options, Grepow ensures that each battery pack is tailored to meet the specific needs of its customers. Whether for consumer electronics, drones, electric vehicles, or industrial equipment, Grepow‘s LiPo battery packs provide reliable, high-performance power solutions.

How Drone Light Shows are Created and Key Battery Power Requirements

This paper mainly introduces the application of Grepow‘s battery products in Drone Light Shows, and introduces the battery requirements for the application of drone light shows.

How to Choose Solar System and Deep Cycle Batteries?

Solar panel systems are a little expensive in some cases but are a worthy, long-term investment. Whether it‘s wanted to produce day-to-day energy to our home, vehicle, boat or any other device, or simply to have a sunlight-charged energy backup. Every year more and more people switch to solar power energy, and they have a point. With the increasing concerns of climate change, plus gaining independency in terms of energy supply as in the cases of recreational vehicles. Using solar panels as our source for electricity, looks to be the smart decision to make these days.

RFID Tags Battery Guide

As the world becomes increasingly interconnected through the Internet of Things (IoT), the demand for efficient and reliable tracking systems has never been higher. Radio Frequency Identification (RFID) tags, particularly those powered by batteries, play a crucial role in this landscape. From tracking merchandise to monitoring livestock and even safeguarding patients, RFID technology offers unparalleled advantages in various applications.

NMC Battery vs. LCO Battery: What’s the Difference?

When it comes to lithium-ion batteries, two of the most commonly discussed chemistries are NMC (Nickel Manganese Cobalt) and LCO (Lithium Cobalt Oxide). Both are widely used in a variety of applications, from electric vehicles to consumer electronics, but they differ significantly in terms of chemical composition, energy density, cycle life, and cost. Understanding the key differences between NMC and LCO batteries is essential for choosing the right battery for specific applications, whether you‘re powering a smartphone or an electric vehicle.

电子商城

服务

可自由定制电池形状,锂离子聚合物/磷酸铁锂成分,放电倍率Max. 50C (持续放电倍率) / 150C (脉冲放电倍率),充电倍率:Max. 5,厚度可达0.5mm。

最小起订量: 5000 提交需求>

登录 | 立即注册

提交评论