Amphenol New Sensor Technology Offers Robust Early Detection of Thermal Runaway in Lithium Ion Batteries

Challenge

While generally an uncommon event, stressed lithium ion (Li-ion) batteries can undergo failure through a variety of causal factors. This failure can result in an internal reaction that generates heat and chemical decomposition of the battery cell. When this occurs, the cell may vent flammable gases. Under certain conditions, these gases can ignite and spread to other cells within the battery pack, which is known as Thermal Runaway.

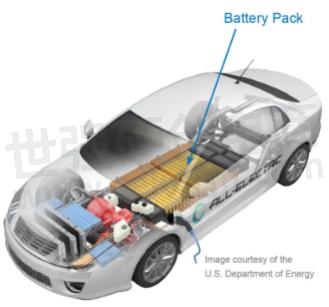

Thermal Runaway can occur in any Li-ion battery pack application, and in any of these applications, it is important to detect Thermal Runaway as soon as it occurs, regardless of cell size, electrochemistry and/or pack design. One of the more common uses of Li-ion batteries is in Electric Vehicles (xEV). In this application, early detection of Thermal Runaway venting is especially important because flammable vent gases in the pack pose an immediate danger to the vehicle and its occupants.

Solution: Robust Early Detection of Thermal Runaway (REDTR) Sensor

Amphenol Advanced Sensors offers a revolutionary new sensor technology for Robust Early Detection of Thermal Runaway (REDTR) to warn of Thermal Runaway by detecting flammable gases vented during Li-ion battery cell failure. Within seconds of initial cell vent, REDTR can identify and qualify whether the event is contained or cascading to adjacent cells by monitoring various physical aspects of the cell ejecta plume within the enclosure. This quick detection provides the Battery Management System (BMS) the opportunity to engage timely countermeasures to protect the occupants.

Features

●Fastest detection of cell venting from a single point within the pack, regardless of cell size, electrochemistry and battery pack configuration

●Demonstrated performance life up to 20 years

●Compact configuration

●Can be used as a standalone device or integrated directly into the Battery Management System (BMS) architecture

●Able to detect Hydrogen (H) and Carbon Dioxide (CO2), as well as monitor internal pack pressure, temperature and Relative Humidity (RH)

- |

- +1 赞 0

- 收藏

- 评论 0

本文由星晴123转载自Amphenol Sensors,原文标题为:Thermal Runaway Detection in Lithium Ion Batteries,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Melexis Unveils MLX91235 Current Sensor and Shrinks Current Sensing Footprint with Coreless Technology

Melexis unveils the MLX91235, a new current sensor that eliminates the need for a ferromagnetic core. The MLX91235 expands Melexis‘ portfolio, enabling the measurement of larger currents flowing through external primary conductors like PCB traces and busbars.

EV Battery Pack Water Detection Sensor from Amphenol Sensors

With the sharp growth of electric vehicles, many OEMs are using a water cooling system for the EV battery system. When water escapes the system and leaks into the battery pack, dangerous conditions are created. Amphenol Advanced Sensors‘ Water Detection Sensor monitors for water leakage by constantly checking resistance values. If a leak is detected in the EV battery pack, this sensor technology provides immediate notification.

Creating Sensor Technology in Healthcare

This article delves into the 7 steps to developing custom sensor technology in healthcare.

Electromagnetic compatibility for Electric Vehicle Sensors

In a sense, cars are now mobile computers. In modern automotive design, there is hardly a system that‘s not monitored or optimized by technology – sensors included. There‘s no vehicle type where this is more apparent than in electric cars.

NPM Pressure Molded Pressure Sensors Adopt“Backside Absolute Pressure“ Technology

NovaSensor NPM Pressure-Molded Pressure Sensor is a silicon-based MEMS device using “Backside Absolute Pressure” Technology designed for harsh media exposure with new edge over-molding pressure sensor technology. This new technology eliminates direct contact of the sensing circuitry with the applied media and provides a small footprint. The device is coupled with an ASIC to provide analog ratiometric and SENT output proportional to the applied pressure. NPM is ASIL B compliant.

Data Center Humidity Control Via Advanced Sensor Technology

In this article, we‘ll dig into one of the most important environmental elements to keep in check in a data center: humidity control.

Optimizing Fast Charging with Electric Vehicle Sensors

Fast-charging technology is making this shift possible as it meets a major concern head-on. Electric vehicle sensors are the unsung hero in making EV charging as uneventful as filling up a gas tank.

Electric Vehicle Hvac System Optimization With Sensor Technology

Amphenol Sensors Smart sensor technology integrated into an EV’s HVAC system’s design ensures the vehicle lives up to expectations and runs as intended with minimum waste energy and intelligence that allows the driver to focus on the road.

Melexis Makes a Splash with New Triphibian™ Pressure Sensor MLX90833 Featuring LIN Interface, Which Measuring Pressures Up to 70 Bar

Melexis introduces the MLX90833, a new pressure sensor with Triphibian™ technology, enabling robust measurement of both gas and liquid media from 2 to 70 bar, all within a compact SO16 package.

Amphenol Sensors Electric Car Battery Packs-A New Power Source

Amphenol Sensors‘ Electric car battery packs paired with the appropriate sensor technology, electric vehicles open new doors to remote and emergency power supply that’s efficient, safe, and long-lasting.

Application of Sensors in Healthcare: Catheters

Regardless of their intended application, a catheter is much like any other medical device that takes measurements – it‘s only as good as the sensor technology behind it.

NPB 102数字输出绝对压力传感器

NPB 102是一款数字输出的绝对压力传感器,适用于低成本应用。它具有标准4x4毫米QFN封装,适合汽车(AECQ-100认证)、便携式电子设备和空间受限的应用。该传感器采用MEMS压力传感器和信号调理IC,提供从26kPa到200kPa的压力测量精度。

AMPHENOL SENSORS - 数字输出绝对压力传感器,ABSOLUTE PRESSURE SENSOR,绝对压力传感器,DIGITAL OUTPUT ABSOLUTE PRESSURE SENSOR,NPB-102I-0126A,NPB-102I-0200A,NPB 102,NPB-102X-XXXX,OUTDOOR NAVIGATION,TABLETS,智能手表,ENHANCED GPS NAVIGATION,气象站设备,CONSUMER DRONES,HDD,休闲,硬盘驱动器,SMART WATCHES,PORTABLE DEVICES,消费型无人机,户外导航,THERMAL RUNAWAY DETECTION,便携式设备,INDOOR NAVIGATION,智能手机,ALTIMETER AND BAROMETER,天气预报,SPORTS,增强型GPS导航,AUTOMOBILE APPLICATIONS,平板,信息娱乐,汽车应用,室内导航,HARD DISK DRIVE,移动设备,热失控检测,INFOTAINMENT,WEATHER STATION EQUIPMENT,LEISURE,高度计和气压计,体育,WEATHER FORECAST,MOBILE DEVICES,SMART PHONES

Sensor Technology Helps Electric Vehicle HVAC Systems Meet Air Quality Standards

In electric vehicles, recirculating air presents a bigger challenge, as many EVs use an HVAC system’s recirculation function to maintain efficiency and conserve energy. It takes less energy to heat or cool recirculated air than it does to heat or cool “fresh” outside air using an HVAC system, but those power savings come at a cost to health.

锂离子电池热失控检测应用热点

本文介绍了锂离子电池热失控检测的重要性,以及Amphenol Advanced Sensors提供的REDTR(热失控早期检测)技术。该技术能够快速检测电池单元泄漏,并通过监测电池单元喷射物中的物理特性,判断事件是否被控制或正在蔓延。REDTR技术适用于各种电池包配置,能够检测氢气和二氧化碳,并监控电池包内部的压力、温度和相对湿度。

AMPHENOL ADVANCED SENSORS - THERMAL RUNAWAY DETECTOR,热失控探测器,锂离子电池组应用,LI-ION BATTERY PACK APPLICATION

HVAC System Upgrades and Optimization Via Sensors + 2 Checklists

Remote Monitoring and Control: In a certain respect, HVAC control system optimization strategies are no different than what we‘re seeing with other building management systems – you no longer need to be in the same room or even continent to control the system. Thanks to IoT (Internet of Things) technology, HVAC system managers can give the system attention no matter where they are.

电子商城

现货市场

服务

可定制板装式压力传感器支持产品量程从5inch水柱到100 psi气压;数字输出压力传感器压力范围0.5~60inH2O,温度补偿范围-20~85ºС;模拟和数字低压传感器可以直接与微控制器通信,具备多种小型SIP和DIP封装可选择。

提交需求>

可定制温度范围-230℃~1150℃、精度可达±0.1°C;支持NTC传感器、PTC传感器、数字式温度传感器、热电堆温度传感器的额定量程和输出/外形尺寸/工作温度范围等参数定制。

提交需求>

登录 | 立即注册

提交评论