Can Your DRAM Withstand Wide-Temp Operating Conditions?

Whether your systems are installed or deployed in cities or remote locations, constant operation, heavy workloads, space constraints, and rugged environments can pose thermal challenges. Extreme heat or extreme cold can damage components and cause systems to fail, thus leading to breakdowns and costly disruptions.

Memory plays a critical role in any computing system, especially for those that require high reliability and availability while operating under rapid thermal cycling. Such applications require industrial-grade memory modules made with native industrial-grade integrated circuits (ICs) that are rated to operate at the industrial temperature range of -40℃ to 85℃.

Extreme Temp Environments

Applications that typically process huge amounts of data at high speeds encounter heat issues due to their workloads and the environments where they are deployed.

5G DU/CU/MEC, Networking Servers

A 5G Open Radio Access Network (O-RAN) architecture consists of functional components that connect users to the mobile network over radio waves, including distributed unit (DU), centralized unit (CU), and mobile edge computing platform (MEC) servers that require high reliability and low latency. Servers face constant thermal challenges due to numerous and high-performance components packed in a compact chassis.

Challenges:

They run on Intel® Xeon® or AMD central processing units with high core counts. With higher computational power, they also consume more power and generate more heat, especially under heavy workloads, if the airflow is insufficient, and if internal cooling is inefficient.

As more components share the limited space within the chassis, there is less airflow within DIMMs.

They are installed within very limited or constrained spaces without air conditioning, resulting in high humidity levels.

Even with air conditioning, the server cabinet may still have elevated temperatures.

Bus/Truck/Fleet/Public Transportation Gateways

Digital advances are driving today's business transporters and public transportation systems, enabling connected monitoring and management. Passenger and driver experiences are also being enhanced with the delivery of greater comfort, safety, and infotainment by staying connected while on the move. In-vehicle gateways provide high-speed connectivity and real-time data processing to and from various transportation networks as well as functional domains within the vehicle. With more modern business and public transporters using electrical features, gateways enable more efficient in-vehicle control, asset/fleet monitoring, and driver behavior monitoring, and offer connectivity to various hardware devices and other subsystems within the vehicle.

Challenges:

Increasing vehicle electrification is also leading to increasing thermal challenges as high power consumption leads to higher heat flow and component temperature.

Vehicles traversing areas with shifting climates and extreme temperatures need operational reliability to ensure passenger comfort and safety.

Railway Computers

Smart railway infrastructures incorporate high-performance computer systems for passenger information, entertainment, railway controls and management, video surveillance, and other function-critical applications.

Constant operation requires reliable performance even in harsh environments.

Component overheating within the chassis.

Rail track temperatures in extreme conditions.

When a train park at the yard during non-service hours at freezing temperatures, upon resuming operations, the DRAM without wide-temp support will fail at boot-up.

Extreme heat or cold can short out major components, put the train out of service, and cause service delays.

Other Industries Requiring Wide-Temp Solutions

Aside from the above-mentioned industries, other industries that may experience extreme temperatures and harsh environments that could prove detrimental to DRAM modules include aerospace, agriculture, telecom, and more. These applications typically require wide-temp solutions as systems are installed in waterproof, fanless enclosures and operate in environments with limited ventilation.

Is Commercial-Grade Memory Suitable?

While industrial-grade DRAM modules are the preferred memory solutions for systems deployed in harsh environments with extreme temperature shifts, they could be very expensive; hence, many companies resort to using commercial-grade DRAM, which is not suitable and may even prove more detrimental in the long run.

Aside from the actual cost of the modules, technicians may have to travel to remote sites to replace the modules and operations must halt while awaiting replacement. These all translate to huge losses.

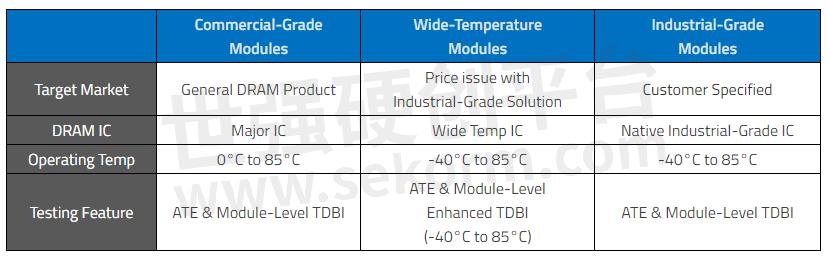

ATP Wide-Temp Solutions vs. Other Industrial Temp DRAM

ATP Electronics understands that businesses need to optimize ownership and operational costs and have come up with the ideal solution: wide-temperature DRAM modules that can operate reliably at -40℃ to 85℃ but at lower costs. Through rigorous testing, ATP is able to offer wide-temp DRAM modules that achieve the best balance between the optimal total cost of ownership (TCO) and long-term reliability.

Compared with other WT DRAMs in the market, ATP uses exclusive IC-level and system-level testing that also provides superior system-wide stability.

ATP Enhanced Module-Level Testing for Wide-Temp DRAM

ATP's stringent testing for its WT DRAM solutions consists of enhanced module-level TDBI and ATE. Through accelerated testing methods, ATP significantly lowers failure rates and extends the product service life by making sure that only robust DRAM chips are on the module. Even just a 0.01% error on a 99.99% effective device can increase the failure rates at the module level and lead to failure in actual usage, TDBI detects and screens out up to 0.01% error to ensure the DRAM modules' reliability.

Test During Burn-In (TDBI) and Automatic Test Equipment (ATE) guarantee that modules meet and even exceed qualifying parameters.

Functional Testing Using Automatic Testing Equipment (ATE).

The ATE detects component defects and structural defects related to the DIMM assembly and screens out marginal timing and signal integrity (SI) sensitivities. The ATE testing system can pinpoint individual defective ICs or DRAM PC boards, thus providing a more efficient failure analysis method for both new product development and mass production stages.

System-Level Failure Detection and Prevention via TDBI.

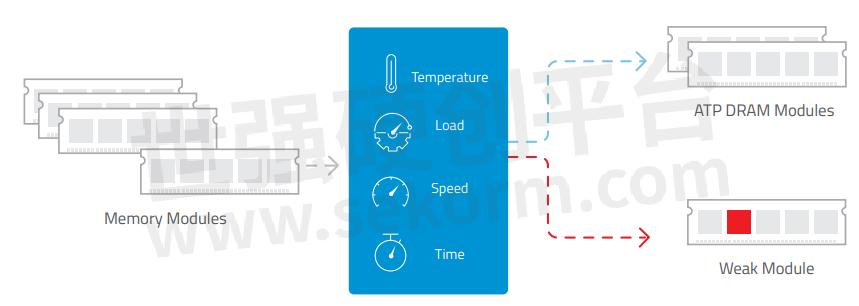

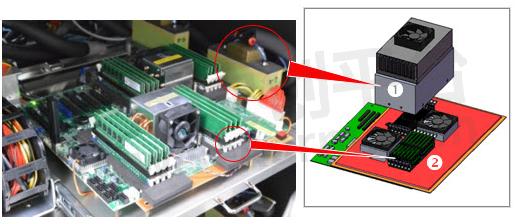

The ATP TDBI system applies extreme high/low temperature, high-low voltage, and pattern testing on DRAM modules. ATP TDBI combines temperature, load, speed, and time to stress test memory modules and expose weak modules. ATP's system-level TDBI can detect and screen out the 0.01% error to ensure the utmost reliability. The system consists of:

1. The miniature chamber, which isolates temperature cycling only to the module being tested so as not to thermally stress the rest of the testing systems. This minimizes the failure of other testing components, such as the motherboards. In conventional large thermal chambers, the failures of non-DRAM-related testing components are constantly given that the whole system is thermally stressed.

2. Module riser adapters from the motherboard, which allow easy module insertions in production-level volumes.

Conclusion: Why You Need ATP's Wide-Temp DRAM Solutions

In operating environments where temperatures could be extremely cold or hot, commercial-grade DRAM solutions may not be enough, and may even prove detrimental in the long run. On the other hand, DRAM modules that are I-Temp operable are ideal but are very expensive. To get the best balance between quality, reliability, and longevity at friendlier price points, ATP's WT DRAM modules offer the optimal solution.

Below are some of the reasons why you need ATP's WT DRAM solutions:

Waterproof, no air conditioning, fanless environments.

Even if there is air conditioning, wide-temp DRAMs have a longer life.

Systems running non-stop 24/7 must not fail.

The cost of replacing or fixing an appliance can be more than the cost of wide-temp DRAMs.

For life-critical applications, human life may be at stake if the system fails.

Systems run for over 10 years. ATP WT DRAMs have 5 years + fixed BOM longevity.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Vicky转载自ATP News,原文标题为:Can Your DRAM Withstand Wide-Temp Operating Conditions?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

The ATP Gym and Coach System: Exercising SSDs to Ensure Total Fitness

With the Gym and Coach system, ATP has dramatically improved RDT and the initialization process for functional test details. By making industrial SSDs undergo a lot of “painful” exercises through stringent testing, ATP makes sure that customers have everything to gain by receiving the most robust, reliable and enduring flash storage products for their applications.

ATP Wide-Temp DDR4 RDIMMs with I-Temp Registered Clock Driver Ensure Maximum Reliability in Extreme Temperatures

Like all ATP ELECTRONICS DRAM modules, ATP‘s wide-temp DDR4 modules with I-Temp RCD undergo rigorous 100% module-level testing to ensure maximum reliability.

Alliance Memory’s Featured Products at Electronica 2022: eMMCs/DDR4 SDRAMs/1.8V Serial NOR Flash/DDR3 SDRAMs

Compliant with the JEDEC eMMC v5.1 industry standard, Alliance Memory’s eMMC solutions integrate NAND flash memory with an eMMC controller and flash transition layer (FTL) management software in a single package for solid-state storage in consumer, industrial, and networking applications.

【经验】什么是常见内存错误类型?ECC DIMM如何工作?

损坏的主内存可能会因性能下降或硬件崩溃而中断业务运营,从而导致代价高昂的停机时间。动态随机存取存储器(DRAM)模块通常具有解决存储器错误的内置机制。这篇文章回答了有关计算机内存错误的最常见问题,以帮助您确保关键任务系统中安装的DRAM的高实用性和最大的可靠性。ATP 可提供软错误可纠错的DRAM产品。

工业级模块

描述- SMART公司提供一系列工业级DDR5和DDR4内存模块,这些模块经过100%系统测试,从-40°C的冷启动开始,逐渐升温至+85°C的环境温度。SMART还支持超出工业级温度范围的扩展温度,从-50°C至+105°C。测试时间根据模块的密度而变化。高利用率的定制测试软件确保DRAM中的所有单元在完整的温度循环中完全受压。SMART多年来一直在数百万个DRAM应用组件上进行广泛的DRAM筛选,其严格的测试过程旨在确保这些模块适用于恶劣的、长寿命的计算环境。

型号- SRZHG8RD5648-SP,SRHG8RD5645-MD,SR2G7UD5285SBV,SRI4097SO420825-SC,SRI2G7SO5285-SB,STI5126SO451893SG,SR1026SO411625-SC,SPT2046SV310816GB,STI4097UD420825SCU,STT1026MP411625MF,SR4G8RD5285SBV,SR2G6SO5285-SB,SRI5126SO451625-SG,SRI4G7SO5285SB,STB4097SO420825SC,SR3G6SO5385HM,STI2046SO410825MR,SR2G8RD5285-SB,SR1G6UD5165-SB,STI1027RD451825SG,SR4G7SO5285-SB,SRZ4097SO420825-SC,SRHG8RD5648-MD,STT2566MP421625NE,STB2047RD420425-SE,STI4097SO420825MF,STI5127SO451893SG,STI2046UD410825-SE,SR4G8RD5288SBV,SRI4G7UD5288-SP,SR2G7SO5288-SP,SR2G7SO5285SB,SR8G8RD5445-SB,SRI2G7SO5288-SP,SRI4G7UD5285SB,SR4G6SO5285SB,SPI2566SV325838NJ,SRI6G7UD5385HM,SR2G6SO5288-SP,STI1026SO410825-SE,STI4097RD420825MF,SRZ2G8RD5285-SB,SR4097UD420825-SC,SRI2G7UD5285SBV,SR6G7UD5388HMV,SRI2G6UD5285-SB,STB4097RD420425-MR,STT2566MP421625MG,SR3G8RD5388-SP,SR4097RD420825-SC,SR6G7UD5388HM,SR4G7SO5288SB,SR4G7SO5288-SP,SR4G7UD5285-SB,SR4097SO420825-SC,SR6G8RD5648-SP,SRI1G6SO5165-SB,STI1026SO410893-SE,SR6G7UD5385HMV,SR6G6SO5385HM,SRZ8197RD440425-SC,SR5126SO451625-SG,SR4096SO420825-SC,STI2047SO410814MR,STI2046SO410825-SE,SRZ4G8RD5448-SP,SRI2G7SO5285SB,SRZ2047RD410825-SE,SRI4G6UD5285-SB,SR4G7UD5288-SP,SRBG8RD544H-SB,SR5126UD451625-SG,STI2047SO410825SG,SR2G7UD5285SB,STI2047SO420825SC,SRHG8RD5648-SP,SR4G8RD5445-SB,STT4096UD420825MF,STI2046SO410893-SE,SPI5126SV351838NE,SR2G6SO5285SB,STI1026SO410825MR,SR1026UD411625-SC,SRI2G8RD5285-SB,SR4G8RD5288MDV,SRZ4097RD420825-SC,SR4097RD440425-SC,SPI1026SV351838NE,SR2G6UD5285-SB,SR6G7UD5385HM,SR1637LR440425-SD,SR4G8RD5448-SP,SR2G7UD5288-SP,STI5126UD451825SG,SR4G7SO5285SB,STI1027SO410825SG,STT5126MP451625MR,SPI1027SV351816NE,SRZ4G8RD5445-SB,SRI2G7UD5285SB,SR4G8RD5288-SP,SRI4G6SO5285-SB,SRI4G8RD5285-SB,SR2047SO420825-SC,SPI5126SV325838NJ,SR8G8RD5448-MD,SR1G6SO5165-SB,SRI2047RD420425-SE,SR4G6SO5288-SP,SRI4G7SO5288-SP,SR6G7SO5385HM,SRI2G7UD5285-SB,SR2046UD420825-SC,SPI5127SV351816NE,SR4G7UD5285SB,SRB8G8RD5445-SB,STI4097UD420825SC,STI1026SO410825SG,SRI6G7UD5385MB,SR2G8RD5288-MD,SR2G7UD5285-SB,SPI1026UV351838NE,SPI5126UV351838NE,SRZ4097RD440425-SC,SRI4G7UD5285SBV,STZ8G8RD5445-HA,SR4G8RD5285HAV,SRI4097RD420425-SE,SRZ8G8RD5448-SP,SR4G7UD5288SBV,SRI8G8RD5445-SB,SR4G6SO5285-SB,SR1G6SO5168-SP,SR2047RD410825-SE,SRI2G7UD5288-SP,SR4G8RD5448-MD,SRI1G6UD5165-SB,SRI2047SO420825-SC,SR6G6SO5385MB,SRI2047RD410825-SE,STI2046SO410825SG,SRZAG8RD5846-SB,SRI2G6SO5285-SB,STI4096SO420825-HD,STI4097SO420825SC,SR4096UD420825-SC,SR8G8RD5448-SE,SR8G8RD5448-SP,SRI8197RD440425-SC,SR6G7SO5388HM,STI4096SO420825HD,SR4G8RD5285SB,STI2047RD410825SG,SR4G7UD5285SBV,SRZ4G8RD5288-SP,SRB4G8RD5445-SB,SPI2567SO325838NJ,STB4097RD420425-SE,SRI4096SO420825-SC,SR4G7UD5288MDV,SR2047UD420825-SC,SR2046SO420825-SC,SR2G8RD5288-SP,SRZ8G8RD5448-MD,SR4G8RD5285-SB,SR1026UD410825-SE,SR6G7UD5385MB,SRI4G7UD5285-SB,SRAG8RD5848-MB,SRAG8RD5846-SB,SRI4G8RD5445-SB,SRI4097RD420825-SC,SR4G6UD5285-SB,STT4097RD420825MF,SR2G7SO5285-SB

ATP(华腾国际)DRAM存储模块和NAND闪存产品选型指南(英文)

目录- Company Profile Segment Challenges and Solutions Thermal Solutions Endurance Solutions Security Solutions CFexpress & USB 3.0 Value Line SSDs DDR5 DRAM SOLUTIONS FLASH SOLUTIONS Flash Products Naming Rule Solutions & Technologies Flash Technology Overview table Complete Flash Spec Overview & Product Dimensions

型号- A750PI,E650SC SERIES,S600SC,B800PI,S750 SERIES,S600SI,S600SCA,E750PC SERIES,B600SC,N700PC,S700SC,E650SC,A750 SERIES,E600VC,S800PI,A750PI SERIES,I800PI,A600VC,A650SI,A650SC,N700 SERIES,S650SI,N750,N750PI,A800PI,A700PI,N700SI,N650 SERIES,E600SAA,N700SC,A750,N600SC,A600VC SERIES,E600SA,E650SI,E650SI SERIES,N750 SERIES,E700PIA,TR-03153,N600SI,S650,S650SC,E700PAA,N650SIA,E600SI,B600SC SERIES,S750SC,S600SIA,I700SC,N650SI,N600VI,E600SIA,E750PI,N650SC,N750PI SERIES,N600VC,I600SC,E750PC,S700PI,A650 SERIES,N650,N600 SERIES,N600VC SERIES,S650 SERIES,A650,AES-256,E700PI,A600SI,E750PI SERIES,N700PI,E700PA,S750,S750PI,E700PC,A600SC

【经验】DRAM的可靠性受什么因素影响?ATP DRAM为何具备高可靠性?

ATP的DRAM模块经过两个级别的测试,以确保最大的可靠性:1、先进的IC级集成电路测试;2、增强的模块水平测试:老化测试(TDBI)和自动测试设备(ATE)确保模块达到甚至超过合格参数。同时具有工业额定温度,采用密封涂层,使用使用抗硫电阻器(基于项目)和厚度为30µm的金手指镀层。

特殊DIMM类型产品线

描述- SMART Modular提供多种特殊类型DRAM内存模块,包括VLP、ULP、mini-DIMM、MIP、LRDIMM、XRDIMM和NVDIMM,以满足不同应用需求。这些模块适用于计算、网络、通信、存储、移动和工业市场。产品特点包括高可靠性、低功耗和优化系统性能。SMART Modular还提供Zefr技术,以提升内存可靠性。

ATP(华腾国际)DRAM存储模块和NAND闪存产品选型指南(中文)

目录- 公司简介 细分市场挑战和解决方案 热管理解决方案 TSE闪存解决方案 DRAM解决方案 闪存解决方案 闪存解决方案-固态驱动器和模块 闪存解决方案-存储卡 闪存解决方案-托管NAND 闪存产品命名规则 闪存规范概述和产品尺寸

型号- A750PI,S600SC,N750PI系列,B800PI,S750 SERIES,S600SI,S600SCA,B600SC,N700PC,S700SC,N600,E650SC,E750,E750PC系列,E600VC,S800PI,I800PI,E750 SERIES,A600VC,A650SI,N600系列,A650SC,N700 SERIES,S650SI,N750,N750PI,A800PI,A700PI,N700SI,E600SAA,N700SC,A750,N600SC,A600VC SERIES,E600SA,E650SI,E700PIA,N600SI,S650,S650SC,E700PAA,N600VC系列,N650系列,N650SIA,N750系列,E600SI,S750系列,E650,N700,S750SC,S600SIA,I700SC,N650SI,N600VI,E650SI系列,E600SIA,E650SC系列,E750PI,N650SC,S650系列,N600VC,I600SC,E750PC,A600VC系列,A650系列,S700PI,N700系列,N650,N600 SERIES,N600VC SERIES,A750PI系列,S650 SERIES,A650,E700PI,E750PI系列,A600SI,N700PI,A750系列,E700PA,E650 SERIES,S750,S750PI,E700PC,A600SC

Momentum DRAM系列:DDR4专业存储和内存解决方案的全球领导者

描述- 该资料介绍了ATP电子公司的Momentum DDR4内存模块系列。这些模块提供8GB至32GB的密度,最大带宽为3200MT/s(DDR4),采用1.2V电压标准,具有低功耗和高数据传输速率的特点。它们符合JEDEC标准,并利用高级DRAM芯片提供高可靠性和兼容性。适用于网络存储系统、嵌入式系统、边缘人工智能、工业个人电脑和零售与数字标牌等领域。

型号- R48G00SD328ACSC,R416G0SD3282CSC,R416G0UD328BCSC,R432G0SD3282ASC,R48G00UD328ACSC,R432G0UD328BASC

DDR4-3200 DRAM Solutions Deliver Memory Boost to AMD EPYC™ and 2nd Gen Intel® Xeon® Scal | ATP

Taipei, Taiwan (March 2020) – ATP Electronics announces the release of fast, low-power DDR4-3200 solutions to take full advantage of the latest AMD EPYC™ Family and 2nd Generation Intel® Xeon® Scalable Processors (formerly codenamed Rome and Cascade Lake, respectively). ATP’s DDR4-3200 modules ensure a big boost in performance, compute density and productivity with their fast 3200 MT/s data rate to optimize the power of AMD’s eight-memory channel and Intel’s six-memory channel architectures.

提供I-TEMP/C-TEMP可操作型号的无DRAM超值系列固态硬盘

描述- 该资料介绍了ATP Electronics的Value Line固态硬盘(SSD)系列,包括N600Vi/Vc和A600Vi/Vc两款产品。这些SSD专为工业/嵌入式应用设计,提供可靠的性能、多种容量选项和长期供应承诺。它们采用无DRAM配置,以降低功耗和热量产生。产品适用于读密集型或读写混合型应用,如网络服务器、盒式PC、自助服务亭/销售点系统(POS)和其他需要可靠性和低成本投资的工业/嵌入式启动驱动器。

型号- A600VC SERIES,N600VI,A600VI,A600VI SERIES,A600VC,N600VC SERIES,N600VC,N600VI SERIES

DDR5: What is On-Die ECC?

As dynamic random access memory (DRAM) capacity increases with each generation and wafer lithography shrinks to achieve higher speeds and better economies of scale, bit errors are also expected to increase. On-die ECC is an important feature of DDR5. It provides additional protection by correcting bit errors within the DRAM chip before sending data to the central processing unit (CPU).

ATP(华腾国际)固态硬盘选型指南

描述- Since 1991, we have consistently distinguished ourselves as one of the world’s leading original equipment manufacturers (OEM) of high-performance, high-quality and high-endurance NAND flash products and DRAM modules.

型号- A750PI,S600SC,B800PI,S750 SERIES,S600SI,B600SC,N700PC,A750 SERIES,E650SC,N601,N651SI,A600VI,S800PI,E600VC,I800PI,A600VC,A650SI,A650SC,N651SC,N750,S650SI,A600VI SERIES,N750PI,N651SIE,A800PI,N601 SERIES,A700PI,N651SIA,N650 SERIES,E600SAA,A750,A600VC SERIES,N600SC,E600SA,E650SI,N750 SERIES,E700PIA,N600SI,S650,S650SC,N651SI SERIES,E700PAA,B600SC SERIES,E600SI,N600VI SERIES,I700SC,N600VI,N650SI,E600SIA,N650SC,E750PI,N600VC,I600SC,E750PC,N651,S700PI,A650 SERIES,N650,N751PI,S700PC,N600VC SERIES,N651 SERIES,S650 SERIES,A650,N601SC,S750PC,E700PI,A600SI,N700PI,E700PA,S750,S750PI,E700PC,N651SCE,A600SC

电子商城

现货市场

登录 | 立即注册

提交评论