Testing LED using PathWave Test Executive for Manufacturing

Light-emitting diodes (LED) gained massive adoption in the past decade, replacing conventional incandescent lighting methods which consume more power. Today, LED is used in a wide range of applications ranging from small optical sensors to large billboard displays on buildings. LED emits light ranging from the invisible spectrum to the visible spectrum. Infra-red sensors or camera systems are some of the applications that use LED on the invisible spectrum, while visible spectrum LED is used primarily for lighting or display purposes.

The automotive industry uses LED for headlights, signaling, dashboard, and cabin lighting. Traditional automotive lighting is controlled by mechanical relays to turn them on or off. However, in today’s automotive environment, a set of headlights doesn’t simply switch between on and off. Lighting sequences and requirements are much more complicated with the increased level of intelligence put into a vehicle. Working together with a range of sensors installed around the car, your car may decide to adjust the level of brightness and color of the headlights as you drive through different environments on the road. This calls for a more sophisticated method of testing to ensure that the automotive lighting assemblies in your car work as expected.

The standard in-circuit test measures each of the LEDs for their values and orientations. While this is sufficient to guarantee that each LED is good, more is needed to ensure the functionality of the product as a whole. With PathWave Test Executive for Manufacturing(PTEM), you can develop customized test sequences that test the actual functionality of the full assembly.

LED Analyzer

PTEM supports the Feasa LED Analyzer module, one of the popular LED test solutions available in the market. PTEM supports the 5 and 20 channels modules so you can mix and match the types of modules to cater to different test channel configurations. To facilitate the assignment of analyzers within a PTEM test plan, PTEM separates the serial COM port definition from the analyzer’s definition. You can have one COM port assigned with multiple analyzers in a daisy-chained setup or one COM port for each analyzer for a standalone setup.

Figure 1: Daisy-chained analyzer modules use one serial COM port for control

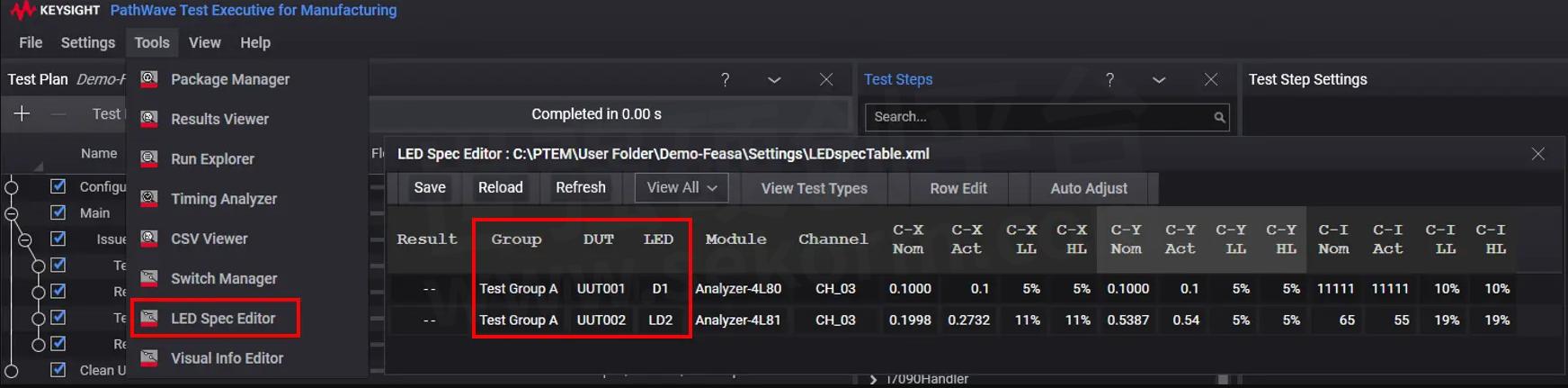

LED Spec Editor

The LED spec editor table holds the details of the LEDs to be tested. This is where you set up a relationship map between the LEDs and their analyzer modules. LEDs can be organized into groups so that you can selectively choose which group of LEDs you want to test. A group is the highest in the test hierarchy. It can have multiple LEDs assigned with different analyzer modules from different boards. When a group is tested, PTEM gets the list of the LED defined under the group and automatically sends the trigger to all the analyzers involved.

Figure 2: LED spec editor maps LED to analyzer's channel number

In Figure 2 above, Test Group A consists of two LEDs from different boards, each assigned to a different analyzer. When a test calls for this group, PTEM will trigger analyzers 4L80 and 4L81 to make the measurement. This makes things a lot easier as you only need to decide which LED to test and not worry about which LED uses which analyzers.

Next in the hierarchy is the board. Similar to the concept of a group, multiple LEDs on a board can also be assigned to different analyzers. During runtime, PTEM automatically sorts out the linkage between the LED and the respective analyzers and triggers them for measurement accordingly.

The lowest level in the hierarchy is the LED part itself. This targets specifically to the LED part name of any board so you can create a test specifically for each LED if needed.

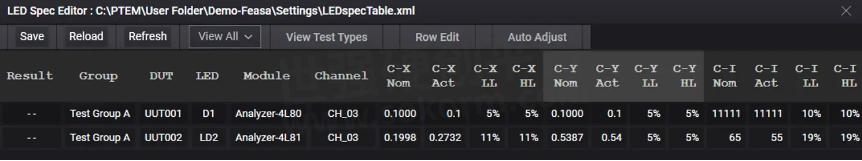

The measurements from the test are updated in the table after each execution so that you can easily monitor the results for troubleshooting. Based on the limits defined in the table for each test, PTEM updates the result column with the pass/fail value. You can use the Retrieve test step to get the result value and perform pass/fail judgment with the limit check test step accordingly.

Test measurement

There are many different ways you can test an LED. Depending on the application of the product, testing methods and criteria vary. LED used for lighting products are tested for brightness, but not necessarily color whereas LED in graphical display applications will test for its color as well.

Chromaticity (CxCy), Hue, Saturation, Intensity (HSI), Red, Green, and Blue components (RGB), and Wavelength (Wavelength) are different types of measurement methods that represent the brightness and color of an LED. Depending on your preference, you can choose which measurement methods to use. Applications with stringent criteria on the LED’s color may choose to do an RGB test as each color component is represented individually. For other applications without strict color requirements, the wavelength test provides a quick measurement of the color. All the tests also report a value to represent intensity, which is the brightness of the LED.

Figure 3: Measurement units for LED test in PTEM

Four test steps are provided in PTEM, each for a type of measurement. You can selectively choose the test that you need and add them to the test plan. The test step allows you to define which group, board or LED you like to test.

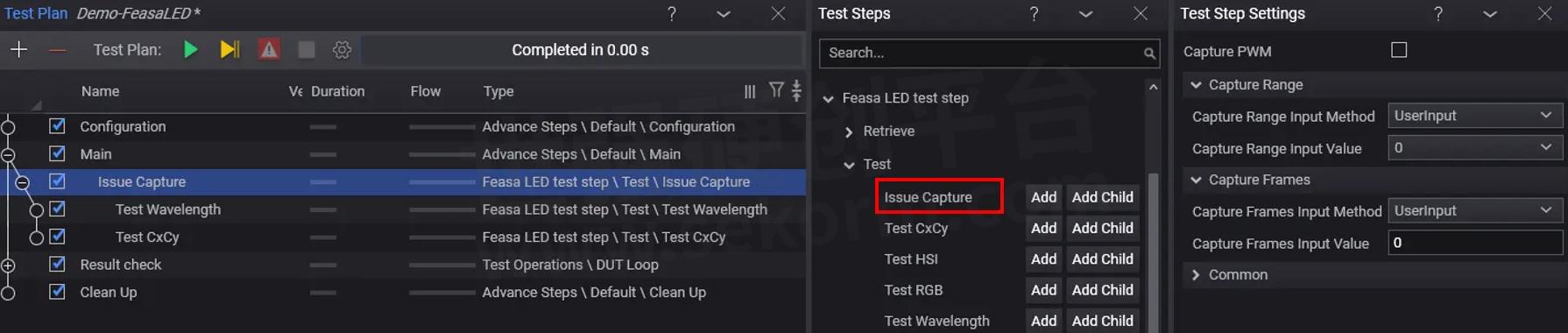

Issue Capture

Ideally, you want to light up all LEDs at once and test them together. This reduces test time significantly compared to lighting and testing them sequentially. Once the LEDs are lighted up, you execute the Issue Capture test step to capture the measurements with the analyzers. Some applications may only allow you to light up some LEDs at the same time because of circuit restrictions or proximity between LEDs which may lead to light interference in the measurement. In cases like these, you separate the LEDs into different groups and test each group sequentially under its own Issue Capture test step.

When PTEM executes the test, it consolidates the list of selected LEDs from the child steps structured under the Issue Capture step. In Figure 4 below, the Issue Capture step contains two child steps which are Test Wavelength and Test CxCy. Based on the LED selected in these test steps, PTEM sends the trigger to the respective analyzers concurrently to make the measurements.

Figure 4: Issue Capture step triggers analyzers to capture measurements

Measured values are updated in the LED spec editor table after each Issue Capture step execution. PTEM tests the measured value against the limits set in the table and places the result into the Result column. There are multiple values for each type of test, and as long as one of the values goes beyond the limits, that LED will be considered to fail. In Figure 5 below, the chromaticity test contains a total of 3 values, namely C-X and C-Y for color, and C-I for intensity. All these values must stay within the limits for the test to pass.

Figure 5: Measurement is updated into the LED spec editor table after each capture

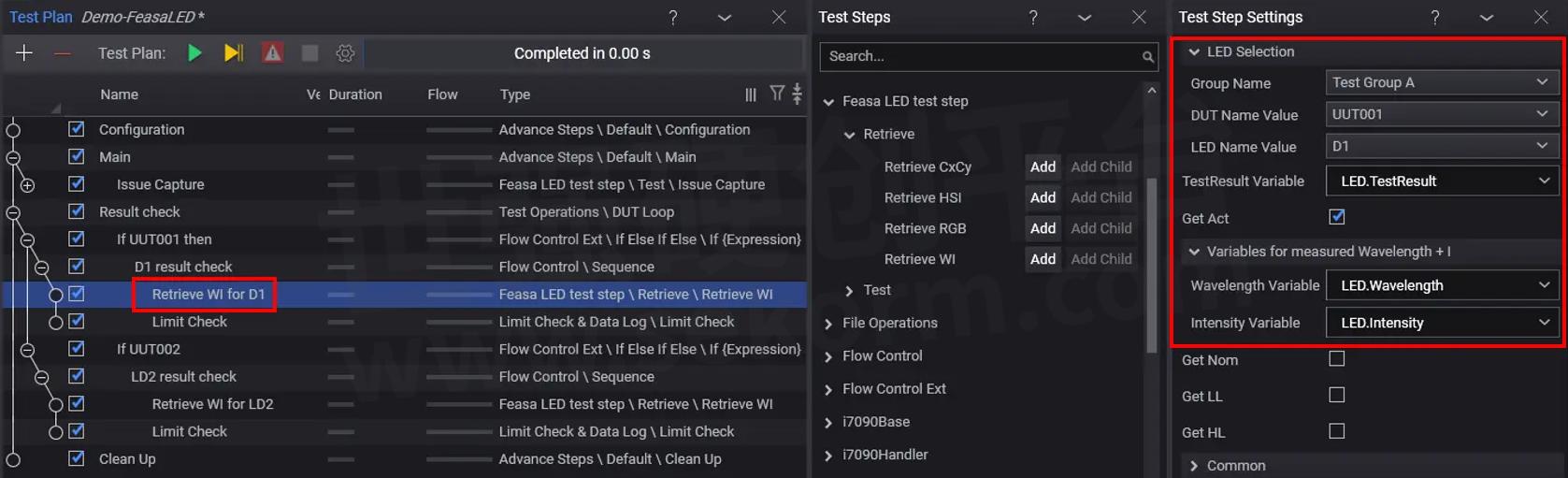

Retrieve

Retrieve test steps allow you to read individual LED test result and process it at the test plan to determine the final pass/fail of the board that the LED belongs to. Other than the test result value, you can also get the measured value of color and intensity as well. This is useful when you want to use the values for further decision-making in the test plan.

Figure 6: Retrieve step returns the test values of LED from the LED spec editor

In Figure 6 above, the Retrieve step for device D1 of UUT001 returns the test results along with the actual measured value of wavelength and intensity to the test plan. Nominal (Nom), low limits (LL), and high limits (HL) values are not selected in the example. The Limit Check test step below the Retrieve step checks the test result value and sets the pass/fail flag of UUT001 in the test plan.

Overall, the integration of Feasa’s LED analyzer into PTEM is simple and easy with the low-level commands of the analyzers built into PTEM’s test steps. Creating test steps for individual LEDs is tedious and time-consuming. The LED spec editor lets you set up the mapping between the LED, board, and analyzers easily so that you can simply select groups or individual LEDs to test in the test plan.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由翊翊所思转载自Keysight News,原文标题为:Testing LED using PathWave Test Executive for Manufacturing,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

Keysight i7090 with PathWave Test Executive for Manufacturing

Keysigt’s FlexiCore Parallel ICT system and i7090 Massively Parallel ICT system are automated inline handler systems designed specifically for high throughput automated inline test applications.

Datalogging for Functional Test Using PathWave Test Executive for Manufacturing

PTEM uses a flexible approach to allow you to customize your data log. Instead of a standard “log everything” feature, PTEM lets you choose the necessary information to include in the data log. This reduces the overall file size of the data log as it does not have unnecessary data.

【经验】如何利用PTEM开发FlexiCore在线并行的ICT系统测试计划

本文为读者介绍PTEM,这是一种开源的解决方案,它有着对用户友好的接口和内置的测试步骤。文章介绍了PTEM的一些优势,同时在一个初次使用者的视角介绍如何利用PTEM开发一个FlexiCore在线并行的ICT系统测试计划。

Keysight i7090 with PTEM – System Initialization

Automated inline handler systems for in-circuit testers rely on numerous sensors fitted around the system to detect and control mechanical operations. The programmable logic controller (PLC) runs a set of complex algorithms that supervise all handler operations and maintain control of safeguards. This ensures consistent and safe operation of the system. To prevent any external interruption to its operation, the PLC does not allow any user intervention to its process once it starts the automated operation.

Keysight i7090 with PTEM – Auto Mode Operation

An automated inline handler system minimizes human involvement in the handling of the product through a manufacturing production line. This improves efficiency and guarantees consistency in the quality of the product as it removes the ambiguity of human judgments and prejudice. Balancing the beat rate of different systems in a production line decides how efficient the manufacturing process will be. The key is to distribute the workload among the different machines or testers along the production line such that all of them work at the same beat rate.

Keysight Lidar Target Simulator is A Benchtop Solution to Test Lidar Devices in The Design Verification and Manufacturing Stages

The solution is designed to reduce the test cost by significantly reducing the floor space as it can simulate target distances from 3 to 300 meters and surface reflectivity from 10% to 94% while supporting volume production and accelerating the testing with full automation and analytics software.

Keysight Announces RF Calibration and Verification Testing Support for Autotalks Safety Connectivity Vehicle Chipsets

Keysight announces that its PathWave Test Executive for Manufacturing Developer Version now supports automated RF calibration and verification testing for the Autotalks cellular vehicle-to-everything (LTE V2X) and dedicated short-range communications (DSRC) chipsets.

是德科技宣布为Autotalks安全连接车辆芯片组的射频校准和验证提供测试支持,加快产品上市

2023年6月19日,是德科技日前宣布,其 PathWave Test Executive for Manufacturing Developer 版本开始支持 Autotalks 蜂窝车联网(LTE V2X)芯片组和专用短程通信(DSRC)芯片组的自动射频校准和验证测试。这些芯片组通常用于远程信息处理控制单元(TCU)。

KEYSIGHT示波器选型表

KEYSIGHT示波器选型,高清晰度示波器、混合信号示波器、手持式示波器等,最大存储器深度120kpts-2Gpts。

|

产品型号

|

品类

|

描述

|

宽带(MHz、GHz、GBd)

|

最大存储器深度(kpts、Mpts、Gpts)

|

最大采样率(GSa/s、KHz)

|

操作系统

|

类型

|

|

DSAZ504A

|

示波器

|

Infiniium 示波器:50 GHz

|

50 GHz

|

2 Gpts

|

160 GSa/s

|

Windows 10

|

Real-Time

|

选型表 - KEYSIGHT 立即选型

KEYSIGHT数字万用表选型表

KEYSIGHT数字万用表选型,手持式数字万用表、USB 模块化数字万用表、手持式钳形表等,基本 1 年 DCV 精度0.00%-0.5%。

|

产品型号

|

品类

|

描述

|

Digits of Resolution

|

基本 1 年 DCV 精度

|

连通性

|

测量功能

|

|

34470A

|

数字万用表

|

数字万用表,七位半,Truevolt DMM

|

7 ½

|

0.0016%

|

LAN,USB,GPIB (optional)

|

DCV and ACV,DCI and ACI,2- and 4-wire Resistance,Frequency,Capacitance,Diode test,Continuity test,Temperature

|

选型表 - KEYSIGHT 立即选型

如何把KEYSIGHT示波器连接到matlab上?

怎么把KEYSIGHT示波器连接到matlab上呢?本文将讲解详细步骤。

Keysight解决方案选择矩阵完全支持您的Keysight解决方案

描述- KeysightCare解决方案提供全面支持,旨在帮助用户解决技术难题,优化工作流程。服务包括硬件和软件的集成支持,旨在提高市场投放速度,减少计划外停机和项目延误。服务分为基本和高级两个层次,提供快速响应、现场技术支持、软件更新和预防性维护等。

Keysight i3070 09.20pc软件修补程序

描述- Keysight Technologies发布了一款针对i3070测试系统的软件补丁,版本号为09.20pc,发布日期为2018年11月。该补丁适用于装有i3070 09.20p软件的测试系统或工作站,支持Windows 7或Windows 10操作系统。补丁主要解决了多个变更请求,包括改进故障显示、电容补偿、用户界面布局、IPG功能、错误消息、安全性和其他功能增强。安装补丁时需以管理员身份登录,并遵循屏幕上的安装说明。安装后,用户可以通过Korn Shell窗口检查软件版本。

Keysight Enables Microamp Solutions to Accelerate Development of mmWave Radio Units for Private 5G Networks

Keysight Technologies announced that Microamp Solutions has selected Keysight Open Radio Architect (KORA) solutions to meet increasing demand for mmWave radio units in private 5G networks.

圣罗莎的Keysight

描述- Keysight Technologies在Santa Rosa设有其智力中心,专注于高性能电子和通信测试产品及其相关技术。Santa Rosa位于旧金山北部55英里,太平洋海岸线东部30英里处,是一个艺术、文化和美食的交汇地。该校区拥有1300名员工,占地面积195英亩,提供户外工作区、步行道、运动场、健身设施、食堂和咖啡吧等。此外,Santa Rosa提供丰富的休闲活动,包括骑行、皮划艇、远足、滑雪等,以及世界级的葡萄酒产区。Keysight Technologies是一家平等机会雇主,欢迎有志之士加入。

现货市场

服务

提供是德(Keysight),罗德(R&S)测试测量仪器租赁服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器租赁服务;租赁费用按月计算,租赁价格按仪器配置而定。

提交需求>

朗能泛亚提供是德(Keysight),罗德(R&S)等品牌的测试测量仪器维修服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器维修,支持一台仪器即可维修。

提交需求>

登录 | 立即注册

提交评论