How to Master EV Charging Components Testing - Chroma Can Help!

Shortening the battery charging time while improving its safety has become one of the most important topics in the industry. During AC charging, the on-board charger (OBC) plays a key role and, currently, OBC power range varies with each new vehicle model. For example, the power range of a plug-in hybrid electric vehicle (PHEV) and a battery electric vehicle (BEV) is within 3.3kW and 6.6kW respectively with maximum 350V~700V output voltage. In the meantime, the development of new technology is focused on increasing OBC power density, integrating the DC-DC converter, and adding new inverter functions (V2G/V2L/V2V). While 6.6kW is limited to single-phase AC power, we are seeing new products with power increased to 20kW three-phase.

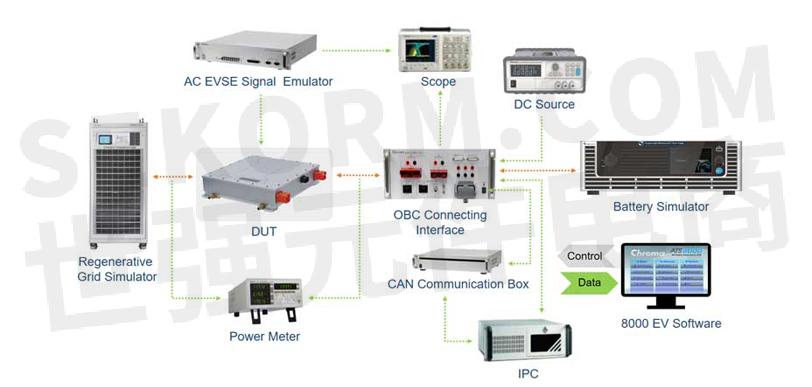

For the basic required test items such as calibration test, performance test and protection function in the OBC production line, CHROMA's automated test platform can simulate the limit conditions testing of voltage/current/CP signals or other failure conditions. Main features include:

1.Simulating AC EVSE output signal or power grid abnormal

2.Simulating EV CANBUS signal and battery pack charging status

3.Providing bidirectional OBC (BOBC) test requirements

4.Supporting 2-in-1 model (OBC+DCDC) integration test

5.Programmable open source software platform for users to program test items as desired and upload test reports to MES automatically.

With built-in test items conforming to QC/T895 and GB/T 24347 standards, on-board charger and DC/DC converter test solutions by Chroma have been widely used in the EV industry to meet diverse testing needs. More than 40 types of test items are provided to verify the product performance, environmental adaptability and reliability for the quality inspection required by government and third-party laboratories. They can be applied to car manufacturers and parts suppliers as well for product specification validation or incoming quality control of material. Chroma's test solution is able to be customized and is equipped with BOBC test platform capabilities. BOBC is one of the essential components for electric vehicles to feed power back to the grid (V2G). V2G technology not only alleviates the power pressure of grid spikes, but also helps the distribution of microgrid power in remote areas. According to industry reports, standardized communication interfaces and good testing environment are the keys to the future success of V2G.

▲Structure of Chroma Onboard Charger Test System

Chroma provides significant comprehensive test solutions to the EV industry for R&D, incoming inspection, mass production, and the entire vehicle's upstream and downstream processing.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由赚钱养太阳转载自Chroma,原文标题为:How to Master EV Charging Components Testing - Chroma Can Help!,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

印度光伏检测需求增,Chroma 8000光伏逆变器助力指标实验室测试能量

据市调公司数据,2019年有超过1100万台光伏逆变器出货至世界各地,衍生测试商机需求庞大,认证权威机构德国莱茵TÜV于全球各大光伏测试中心,已陆续采用Chroma太阳能阵列模拟电源及交流电源(电网模拟器)等设备建置测试实验室,其中位于印度光伏检测实验室为开展光伏逆变器及电力转换装置强制性注册(CRS)检测,进一步采用Chroma 8000光伏逆变器自动测试系统。

Chroma电动车无线充电测试方案拥多国专利,获得日韩国际车厂与中国大陆指标实验室青睐

车辆电力化、联网化与智慧化,已成为全球汽车产业的重要指标,其中兼具安全与便利性的无线充电与全自动驾驶在许多车联网场景上的要求不谋而合,能够让电动车无线充电的便利性得到充分发挥。电动车无线充电(EV WPT)近来有突破性的发展,今年5月中国大陆正式发布GB/T 38775,7月安规认证大厂宣布『UL2750电动车无线电力传输设备的评估大纲』,预估2021年将有标配无线充电系统电动车问市;技术方面日系

Chroma CCS EV充电测试系统获美系电动车大厂采用

Chroma发展CCS充电测试系统,整合电网仿真器与电池仿真器再搭配CCS接口仿真器,可满足客户于研发、测试验证及生产使用需求,依循国际试验标准:ISO15118、DIN70121/122及SAE-J1772…等,提供电气参数标准测试项目与测试用例,其开放式软硬件平台可依据使用者需求提供客制化服务,协助客户快速解决测试相关问题。凭借上述优异性能,已获某美系电动车大厂采用,建置于产线端做充电功能检测

【选型】OBC用SiC MOS推荐WM2A075120L, 漏源极电压高达1200V,连续漏极电流33A

11KW的OBC项目需要一款SiC MOS,1200V电压、内阻60mΩ~80mΩ、TO247四角封装。推荐中电国基南方WM2A075120L,漏源极电压1200V,高阻压,适合高压复杂情况;连续漏极电流33A,驱动简单。

【仪器】IEEE 1547.1-2020并网逆变器测试要求,Chroma 8000自动化测试系统助您轻松应对!

一般而言,据统计手动完成IEEE 1547.1-2020所有测试要求,最少需要数周的时间,对测试工程师而言,是相当耗时沉重负担。CHROMA 8000自动化测试系统具备全面的测试覆盖率,通过定制的测试程序可快速有效的验证逆变器产品是否符合IEEE 1547.1-2020标准的要求,大幅减少测试时间,避免人为错误和随机测试造成漏测,提高测试可靠度,降低产品开发与上市时间,提升市场竞争优势。

Chroma携手运算智能全球领导者Altair和创奕能源,展开先进的动态电池充放电测试合作

Chroma携手运算智能全球领导者Altair和创奕能源,展开了一项先进的动态电池充放电测试合作,旨在透过先进设备和精密模拟技术,验证并提升电池使用性能寿命。此次测试计划结合了Chroma Battery Pack Power HIL系统、Altair车辆动态与电池精准模型以及创奕电动巴士的实际运行数据,在实验室台架中模拟创奕电巴的行驶工况,进行多次动态充放电与循环测试。

【元件】产品升级!Chroma双向直流电源62000D系列进阶提升37%输出电流能力

Chroma致茂电子不断精进产品技术水平,我们很高兴地宣布,双向直流电源供应器62000D系列中的型号62120D-1200、62180D-1200和62180D-1800,现已实现了操作范围能力的重要提升!我们将操作电流能力,从40A提升至55A,大幅进阶37%!这次升级,伴随着输出功率的相应提升,供给使用者拥有5倍的宽范围操作以应对测试需求。

【仪器】Chroma 17000E高压直流定容一体机上市,减少连接线材成本并提升转换效率,从系统设计面实现降本增效

Chroma 17000E定容水冷一体机采用高压直流入电模块,整合电源功率模块以及量测与控制回路在同一单板,并配置于电池芯接触库位中减少连接线材成本并提升转换效率。相较传统独立电源柜的架构,整体投入充放电系统整合成本大幅下降,并提升充放电效率,从系统设计面实现降本增效。

EV Heat Pumps & Enhanced Battery Life

One such component contributing to improved battery efficiency is EV heat pumps. Considered a new tool for increased battery life, EV heat pumps are providing the alternate route for improved efficiency and range.

为了双向车载充电器生产达到节能减碳以利能源使用,CHROMA推出体积小、具能源回收及一机多用途的测试仪器产品

在此双向车载充电器输出功率不断从3.3kW/6.6kW提升至11kW/22kW设计及V2X应用趋势,为了让生产达到节能减碳以利能源使用,致茂(CHROMA)电子也因应推出体积小、具能源回收及一机多用途的测试仪器产品。包括在四象限交流源与双象限直流电源。另外也搭配多功能的软件平台,整合为自动测试系统。

Chroma ATE Showcases Advanced Test Technology to Propel the AI Revolution at SEMICON Taiwan 2023

Chroma ATE Inc., a leading provider of automated test equipment, is participating in SEMICON Taiwan 2023. The company will exhibit a series of innovative test solutions with a focus on artificial intelligence (AI), high-performance computing (HPC), automotive, and AIoT applications, aiming to meet the ever-evolving needs of semiconductor testing.

EV SERIES MICRO SWITCH

型号- EV163102,EV163112,EV163122,EV163132,EV163142,EV163152,EV163162,EV-11,EV-21,EV21,EV11,EVXXXXXXXX,EV SERIES,EV-16,EV16

Chroma的电池测试软件BatteryPro可实时接收BMS信息监测电池的温度和电压,提供准确的容量测量

电池容量测试(Capacity Test)是评价电池充放电能力的关键测试。一般的充放电机只能使用定流充电(CC),或是定流转定压(CC-CV)的方式做测试,但是实际的电池使用状况是电池管理系统(BMS)会依据当下温度、安全状态而去动态调整输出,因此为了让电池测试能更符合情况,电池测试期间依据BMS 讯息动态更改测试条件变得十分重要。Chroma的电池测试软件BatteryPro可以帮助解决此问题。

EV部件整合再进化,Chroma自主研发的ATS 8000平台助力X-in-1动力总成测试新挑战

Chroma在电动车测试领域有着深厚的专业经验,透过自主研发的ATS 8000平台及各类电源测试设备,已协助众多车厂及Tier 1客户完成三电自动测试系统。致茂电子拥有40年精密量测仪器领域的丰富经验,是自动测试系统的领导者,专注于各种电力电子相关测试应用。随着新能源产业的蓬勃发展,我们积极参与电动汽车、储能系统以及燃料电池等领域的测试工作。

【元件】铭普光磁新品OBC四合一磁性功率转换器:应用、结构集成与技术深度解析

铭普光磁推出OBC四合一高度集成的组合磁性功率变换器,具备功率密度高、效率高、成本低等优势、采用轻量化材料和优化的结构设计,做到了电能双向传输的充放电效果,是一款比较前沿的OBC变换器磁组件。

电子商城

登录 | 立即注册

提交评论