Air Cooled VCSEL Applications with Rogers Micro-Channel-Coolers (MCC)

“When air-cooled heat sinks cannot cope with too high power densities, liquid-cooled cold plates are the heat transfer solution of choice.” [1]

Reading this statement got me thinking: How would ROGERS’ Micro-Channel-Coolers (MCCs) perform in air cooling applications? Rogers'MCCs have only been used for liquid cooling; however, customers´ heat management challenges in new VCSEL (vertical-cavity surface-emitting laser) applications are reaching new levels, and several active-cooled approaches are being tested. For our partners, the challenge for moving to liquid cooling is that it is both risky [2], and the cost and maintenance increase while passive/standard air-cooling options might not be able to solve the thermal problem. For that reason, we started testing and evaluating Rogers'MCCs with compressed air as a coolant. As a result, different micro-channel designs have been benchmarked with standard macro-channel heat sinks.

Theses to test:

Rogers'MCCs can achieve a better cooling performance vs. off-the-shelf Macro-Channel cold plates at lower flow rates.

Qua 50 will be the best performing Rogers’ standard MCC structure.

Simulation and conditions

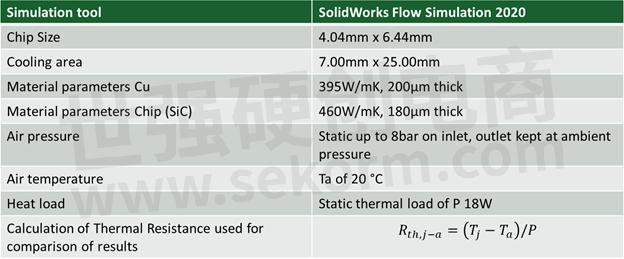

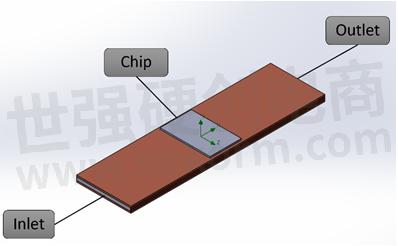

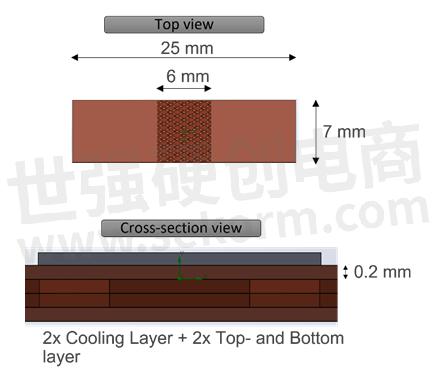

We performed simulations with SolidWorks Flow Simulation 2020 based on the conditions mentioned below, shown in fig. 1. For all thermal CFD simulations of the cooling structure, we applied the inlet and outlet configuration depicted in fig. 2. Unless stated otherwise, we kept the cooler area, as well as the chip position, constant for all simulations and comparisons. The cooler is comprised of four individually structured copper layers with a thickness of 200 µm each. The first layer acts as cover. The following two copper layers form the cooling channel. The last copper layer forms the backside cover, see fig. 3.

Fig 1: Boundary conditions for the test

Fig. 2: Configuration of an inlet, outlet and a chip on cooling structure

Fig. 3: Top and cross-section view of a cooling structure

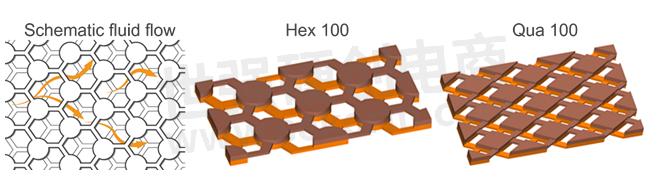

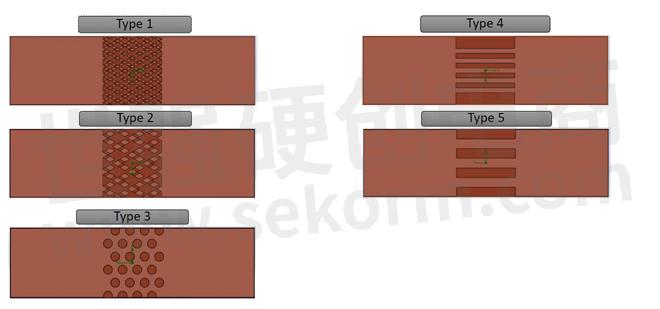

To run the simulations, we used three different cooling structures. Type 1 corresponds to Rogers’ Qua 50 structure and type 2 corresponds to a Qua 100 shown in fig. 4. It should be noted that Qua 50 uses 50% smaller geometries than Qua 100. Compared to these, we used a Hex 50 (type 3) and two standard lamellar coolers with five channels in the size 0.5mm x 0.4mm (type 4) and three channels in the size 1.00mm x 0.4mm (type 5), all shown in fig. 5.

Fig. 4: Left to right: Schematic fluid flow through a cooling structure; Detail of a Hex 100 and Qua 100 inner cooling structure

Fig. 5: Top view on cooling structures, five different types are shown

Results and Discussion

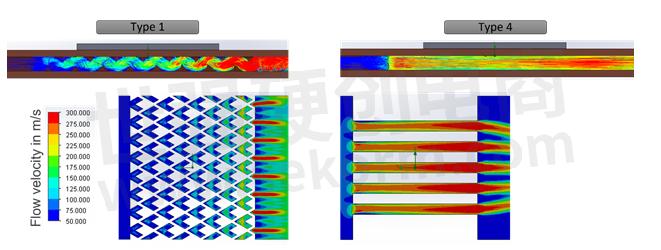

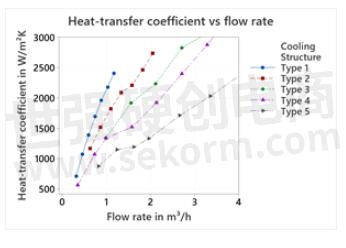

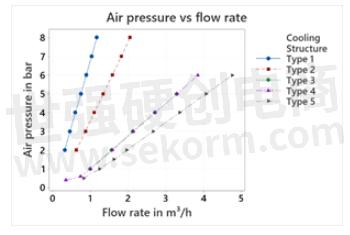

Fig. 6 shows the flow velocity distribution of type 1 and type 4. We can clearly seen that in the channels of type 4, laminar flow is dominate while the cooling structure of type 1 supports a turbulent flow. This, in combination with a larger effective cooling area of type 1, leads to a higher heat transfer coefficient at the same flow rate, depicted in fig. 7. Here, the cooling structure type 1 has the highest heat transfer coefficient at the same flow rate. The smaller cooling structure of type 1, 2 and 3 also leads to a faster increase of the pressure on the inlet compared to type 4 and 5, shown in fig. 8.

Fig. 6: Top view on cooling structures, five different types are shown

Fig. 7: Heat transfer coefficient vs. flow rate

Fig. 8: Air pressure vs. flow rate

Improved performance in comparison with competition comes from a higher specific surface area, as well as a maintained turbulent flow. For certain areas of application, air cooling can be superior to water cooling due to its simple availability, despite the worse thermal performance of air itself. Likewise, liquids are not often used in electronics due to the risk of leaks. Assuming, compressed air up to 90psi is relatively common and available at manufacturing locations, Rogers’ Type 1 micro-channel structure realizes about 50% lower operating costs versus cooler type 4 and 5. Calculating with 7.000 working hours per year times 0,02€ m³/h this accounts for 140€/year less per unit.

Our next steps are to confirm simulation results through tests carried out on our test bench and in customer applications. Another target is to also optimize cooling structures for air cooling use cases to improve performance and cost.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由翊翊所思转载自Rogers,原文标题为:Air Cooled VCSEL Applications with Rogers Micro-Channel-Coolers (MCC),本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

ROGERS层压板/高频板选型表

罗杰斯/ROGERS提供以下技术参数的层压板/高频板选型,超低损耗,低至0.0004(Df) ;超大尺寸:54inchX24inch、52inchX40inch、50.1inchX110inch 等;丰富介电常数:2 -12.85 (Dk);超薄介质,低至1mil

|

产品型号

|

品类

|

产品系列

|

介电常数(Dk)

|

正切角损耗(Df)

|

介质厚度(mm)(mil)

|

导热系数W/(m·K)

|

铜箔类型

|

铜箔1厚度

|

铜箔2厚度

|

尺寸(inch)

|

|

5880LZNS 24X18 H1/H1 R4 0100+-001/DI

|

层压板

|

RT/duroid® 5880LZ

|

2

|

0.0027

|

0.254mm(10mil)

|

0.33

|

电解铜

|

H1

|

H1

|

24X18

|

【经验】如何选择合适介电常数的Rogers高频板材?

在选择板材rogers高频板材时,最关注的指标是介电常数。但也有一部分工程师对介电常数理解的比较片面,在选择rogers高频板材时,会遇到一些问题,通过本文讲解,可以更好的帮助工程师快速准确的选择合适介电常数的板材。介电常数和频率相关,同一种板材的不同厚度有时会有一定差异。rogers板材的范围1.96(RT/duriod 5880LZ)-13(TMM13i)。

诺德新材高频覆铜板选型表

诺德新材提供以下技术参数的高频覆铜板选型:具有不同介电常数(Dk)范围:2.2-3.5,正切角损耗(Df)低至0.0009-0.003,满足高频信号传输需求。介质厚度范围广泛,从0.127mm(5mil)至6.35mm(250mil),导热系数在0.25-0.60W/(m·K)之间,适用于不同散热要求。铜箔类型提供电解铜与反转铜选择,包括E1、EH、S1、SH等规格,满足多样化工艺需求。尺寸涵盖12X18、24X18、48X54英寸,适应多种设计布局。产品适用于5G通信、射频微波、卫星通信等领域,支持高频高速信号处理与高密度电路设计。

|

产品型号

|

品类

|

介电常数(Dk)

|

正切角损耗(Df)

|

介质厚度(mm)(mil)

|

导热系数W/(m·K)

|

铜箔类型

|

铜箔1

|

铜箔2

|

尺寸(inch)

|

|

RHF265 12X18 E1/E1 0200+-0020

|

高频覆铜板

|

2.65

|

0.0015

|

0.508mm(20mil)

|

0.25W/(m·K)

|

电解铜

|

E1

|

E1

|

12X18

|

ROGERS 半固化片选型表

罗杰斯/ROGERS提供以下技术参数的半固化片选型,超低损耗,介电常数(Dk):2.28-10.02,正切角损耗(Df):0.002-11.2,超大尺寸:24inchX36inch 、25.5inchX18inch、48inchX36inch等,超薄介质。

|

产品型号

|

品类

|

产品系列

|

介电常数(Dk)

|

正切角损耗(Df)

|

厚度(mils)(mm)(μm)

|

尺寸(inch)

|

导热系数W/(m·K)

|

|

3003 BOND PLY 25.5X18 005 R3

|

半固化片

|

RO3003

|

3.00±0.04

|

3

|

0.005” (0.13mm)

|

25.5X18

|

0.5

|

Rogers产品变更通知:层压板转换为无砷制造铜箔

Rogers Corporation通知客户,由于REACH法规要求,欧盟铜箔供应商需停止在制造过程中使用砷酸。公司评估后认为,这一变化不影响产品性能。受影响的Rogers系列基板材料将于2022年内完成铜箔转换,包括电极镀铜箔。部分材料名称将进行更改,具体信息见附录。

ROGERS - LAMINATES,层合板,KAPPA® 438,RO4000® SERIES,CLTE®,CLTE® SERIES,RO3003 12X18 HH/HH R3 0100+-0007/DI,92ML™,RT/DUROID™ 5880,ISOCLAD®,RO4000®,AD SERIES®,TC SERIES®,RT/DUROID® 5000,ISOCLAD® SERIES,TMM®,RO3003 12X18 HH/HH R4 0100+-0007/DI,RO3000®,RT/DUROID™ 6006,RT/DUROID™ 6202,RT/DUROID™ 5870,RT/DUROID™ 6002,RO3000® SERIES,MAGTREX® 555,CU4000™,RT/DUROID™ 5880LZ,CUCLAD® SERIES,MAGTREX®555,RT/DUROID®,RT/DUROID® 6000,CUCLAD®,RT/DUROID™ 6202PR,RT/DUROID™ 6010.2LM

Rogers苏州工厂生产的产品的临时交货期延长

Rogers公司宣布,由于近期需求激增,其苏州工厂生产的多个产品将临时延长交货期。预计这种影响将是短期性的,并计划从2024年5月初开始逐步减少交货期。具体产品及其新的交货期已附在邮件中。公司正在评估现有订单的恢复日期,并请求客户提供预测信息以协助决策。

ROGERS - RO4830™,RO4535™,KAPPA® 438,DICLAD880™,RO4533™,RO4000™,DICLAD®,RO3003G2™,RO3035™,RO3003™,RO4003C™,RO4835™,RO3003G2™ PM,TC350™,RO4534™,RO4730G3™ R2,RO4835T™,RO4233™,RO4350B™,RO3006™,AD255™,AD300™,RO3010™,RO3000™,TC350™ PLUS

Rogers(罗杰斯)与世强的代理协议

In January,2023, Rogers Corporation and Sekorm signed a INTERNATIONAL DISTRIBUTION AGREEMENT.

ROGERS - 粘合膜,BONDING FILM,材料,MATERIALS,BONDPLY,PREPREG,ELECTRODEPOSITED COPPER FOIL,电解铜箔,LAMINATES,半固化片,层合板,粘结片,AD SERIES™,ML92 SERIES,RO3000,CLTE,RT/DUROID,XT/DUROID®,DICLAD®,CU4000 LOPRO®,ISOCLAD®,RO4000®,CU4000 LOPRO,2929,CUCLAD,ML92,TMM®,DICLAD,CLTE SERIES,TC SERIES™,ML92 SERIES™,XT/DUROID,RO4000,RO3000®,AD SERIES,CLTE SERIES™,DICLAD® SERIES,ISOCLAD,CU4000™,CU4000,TMM,TC SERIES,RT/DUROID®,CUCLAD®

Rogers苏州工厂碳足迹减排项目的计划停工时间

Rogers苏州工厂计划于2024年3月11日至3月16日进行升级改造,期间将暂停生产,影响交货期。此次停工旨在实施碳减排项目,符合公司全球ESG目标。改造完成后,预计交货期将恢复至项目前水平。公司正努力提前完成订单,并请求客户提前下单。

ROGERS

ROGERS 粘结片选型表

ROGERS提供粘结片选型:介电常数(Dk):2.94-2.97,正切角损耗(Df):0.03-0.0012,厚度(mm):0.038-0.102,导热系数W/(m·K):0.4-0.5。

|

产品型号

|

品类

|

产品系列

|

介电常数(Dk)

|

正切角损耗(Df)

|

厚度(mm)

|

尺寸(mm)

|

绝缘强度(V/mil)

|

热变化率(ppm/℃)

|

导热系数W/(m·K)

|

吸湿率

|

|

2929 BOND PLY 12X18 0015+-10%

|

粘结片

|

2929

|

2.94±0.05

|

0.003

|

0.0015” (0.038mm) +/- 10%

|

12”X18” (305mm X457mm)

|

2500

|

-6

|

0.4

|

0.10%

|

ROGERS 粘结膜选型表

ROGERS 粘结膜选型:介电常数(Dk):2.32-2.35,正切角损耗(Df):0.0013-0.0025,Lengths(ft):30ft-150ft,熔化温度(℃):397°F (203°C),多种尺寸:12X18/24X18/24X30等。

|

产品型号

|

品类

|

产品系列

|

介电常数(Dk)

|

正切角损耗(Df)

|

Lengths(ft)

|

熔化温度(℃)

|

尺寸(inch)

|

厚度(mm)

|

|

6700 2.35 24X30LFX0.003

|

粘结膜

|

CuClad 6700

|

2.35

|

0.0025

|

30ft

|

397°F (203°C)

|

24X30

|

0.0030" (0.08mm)

|

Rogers AD1000™产品停产(EOL)通知

Rogers Corporation宣布其AD1000™品牌高Dk层压板的停产通知。由于原材料问题,生产持续受阻,导致公司决定结束该产品线的生产。公司对可能给客户带来的不便表示歉意,并提供替代产品建议。现有订单将由客户服务代表处理。

ROGERS - 高DK层压板,HIGH DK LAMINATES,AD1000™,AD1000™ FAMILY

Sekorm Became an Authorized Distributor of Rogers

Rogers is a global leader in engineered materials to power, protect and connect our world. As one of the oldest listed companies in USA, Rogers has a fine tradition of innovation and working with customers to solve problems.

Rogers RT6010LM, DK是否有=11.2的材料

ROGERS的RT6010系列高频板材曾经有三个型号,6010.2LM、6010.5LM以及6010.8LM但是后两者陆续停产,现在推荐使用6010.2LM,该型号没有DK为11,2的,具体资料见:Rogers(罗杰斯) RT/duroid 6006/6010LM 高性能板材数据手册

Rogers6250/0.0381mm

Rogers6250/0.0381mm的具体型号是6250 2.32 24X30LFX0.0015,规格书请参考CuClad® 6250 and 6700 Bonding Films

电子商城

品牌:ROGERS

品类:High Frequency Laminates

价格:¥2,617.4106

现货: 3,621

品牌:ROGERS

品类:Antenna Grade Laminates

价格:¥2,989.4355

现货: 429

品牌:ROGERS

品类:High Frequency Laminates

价格:¥6,925.1976

现货: 376

品牌:ROGERS

品类:Circuit Materials

价格:¥2,479.9453

现货: 338

品牌:ROGERS

品类:Liquid Crystalline Polymer Circuit Material

价格:¥2,925.3526

现货: 253

品牌:ROGERS

品类:Antenna Grade Laminates

价格:¥2,571.9097

现货: 250

品牌:ROGERS

品类:PTFE/Woven Fiberglass Laminates

价格:¥31,150.9849

现货: 201

品牌:ROGERS

品类:High Frequency Circuit Materials

价格:¥3,332.3918

现货: 200

现货市场

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论