Inductance Optimization for Laminated Busbars

The stray inductance of switching circuits is one of the most critical parameters in the design of power electronics and is becoming even more important for systems using wide-bandgap semiconductors, such as SiC and GaN.

The operating principle of power electronics is based on switches (the semiconductor devices) commutating at frequencies in the order of kHz to create low frequency or DC power. When a switch changes its state, it must deal with the voltage and current in the circuit. For example, in the case of ON to OFF switching, the current flowing in the switch tends to continue flowing which can be regarded as electric inertia or inductance. When this current reaches the closed switch it “crashes” into it like a wave into a breakwater wall, creating a spike in voltage. Thus, the higher the inductance the higher the voltage surge in the semiconductors. In fact, this phenomenon is analog to a water hammer where the speed of liquid flowing in a pipe transforms into an overpressure when we close the tap (that is why any plumber would advise to always close the taps gently).

There are other negative effects linked to the inductance of power circuits, such as EMI (electromagnetic interference). For a given current, a high inductance is a consequence of high unrestrained magnetic flux and can be reduced by correctly routing and shaping the conductors.

Here is where Laminated Busbars come into play: the inductance of a conductor depends on its shape, the proximity of the current paths, and the lowest inductance geometry given by parallel planes: exactly the structure of a busbar. When required to reduce inductance to a minimum, the laminated busbar brings conductors extremely close to each other, in some cases under 100µm.

The inductance of a pair of wires 1 mm apart and 1m in length is around 0.4 mH. It may seem to be a low value but for power electronics, the required inductance is in the range of the nano Henries. The equivalent construction in a busbar of the same section would be 50 nH which is already 88% lower. Additionally, if the distance between conductors is reduced by high-end insulation, for example, 0.2mm, inductance is reduced to below 20 nH.

This was an ideal case to show the potential of busbar construction and the calculations that can be performed using simple formulas. In a real application, the shape of a busbar is much more complex and must comply with many other requirements such as connection points (to semiconductor devices, to capacitors, to power cables, or other busbars), insulation for the required voltage level, adequate thermal dissipation, fixation elements, and of course manufacturability.

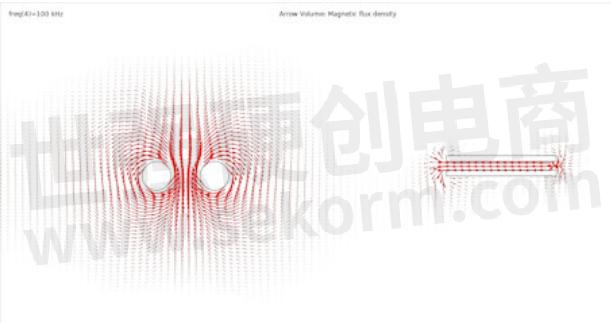

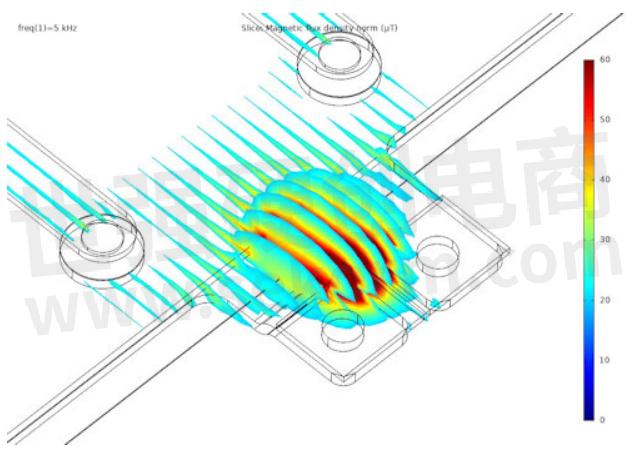

Inductance measurement of real busbars has traditionally been performed by lab or field testing. It requires highly specialized equipment and a delicate setup. Additionally, at least one prototype must be manufactured. The effect of small changes in the geometry of the busbar can have a large impact on the inductance, therefore it is extremely difficult to build a sample that can be modified for testing and optimization. However, Finite Element Method simulations do not require a physical sample and modifications can be easily done in the 3D model of the busbar. This allows a fast-iterative process that translates into a very low inductance solution. Furthermore, other features of the busbar can be evaluated in parallel by FEM simulations such as current distribution and thermal behavior which leads to a highly optimized busbar. When a busbar is simulated to evaluate its inductance a plot of the magnetic field is obtained. As mentioned before, the inductance is proportional to the magnetic field. Besides, a simulation allows a fast sweep along with a wide range of frequencies, reaching up to MHz. This is especially valuable as magnetic flux is highly dependent on the frequency and each system is designed for a particular switching frequency and slope. Consequently, due to the simulation results, it is easy to pinpoint the most critical areas for improvement and act on them.

In the following paragraph, it will be demonstrated how a typical inductance optimization is performed.

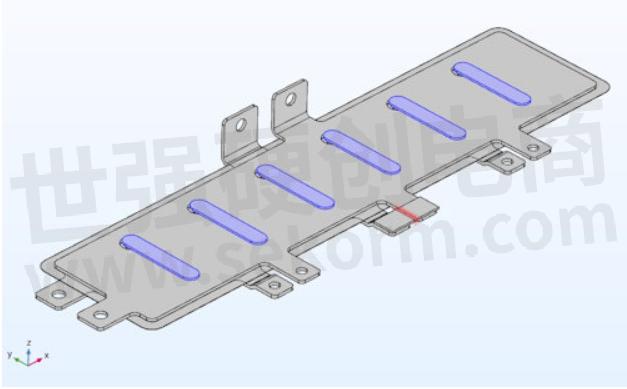

The first step is to 3D model the busbar that shall be simulated. Typically, semiconductor devices and capacitors are not included in the model. The capacitors are substituted by a short-circuit that allows current to flow following the lowest-impedance path. In order to calculate this path simulation software considers all electromagnetic physics constraints, including proximity and skin effect at high frequencies. In the connection of the semiconductor devices, the probe to evaluate the inductance is placed.

The next image shows the 3D model of the first busbar design. The elements highlighted in blue are the short-circuit blocks at the capacitor positions and the red element is the probe which is placed at the connection of the central IGBT in this case.

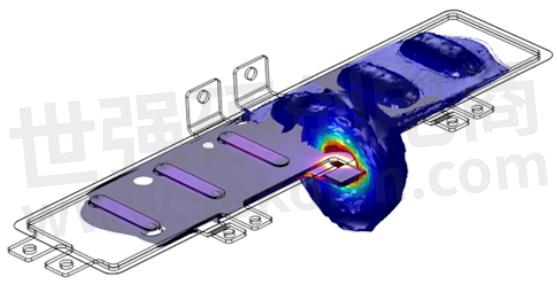

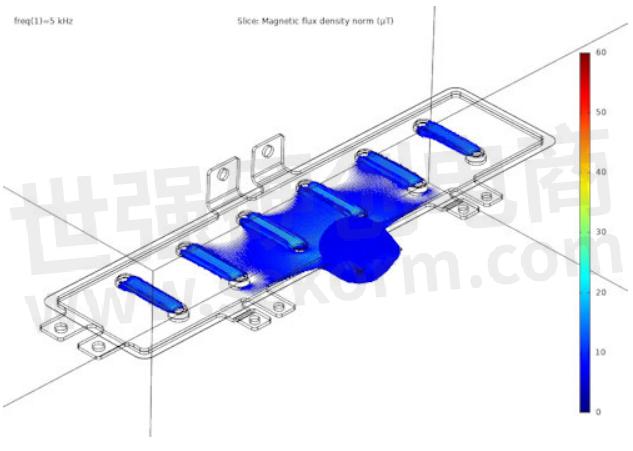

The simulation shows the areas in and around the busbar with a high magnetic flux (values in µT, as probe current, is only 1 A). It can be observed that the highest magnetic flux, thus the largest contribution to the inductance is found in the connection terminal of the IGBT. The second-largest contributors are the capacitor connections.

The total inductance of this system at the simulation frequency of 5kHz is 12.0 nH.

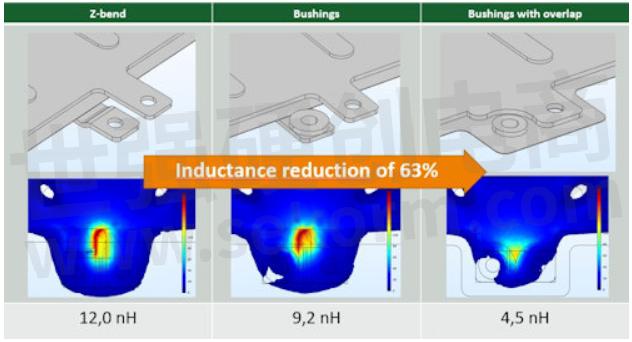

When zooming into the terminal area it is noted that the magnetic flux is created in the open-loop between the terminals. Thus, why it is highly recommended to optimize this part to have a large impact on the inductance reduction.

The first optimization consists of changing the bend terminal from the original design into a flat terminal with connection bushings. This allows to reduce the open gap and decreases the inductance to 9.2 nH.

In a second optimization loop, the overlap between the terminals is increased, which reduces the flux in the area. As a result, the inductance is further reduced to 4.5 nH.

The optimization could continue and tackle other areas of the busbar, but it has been demonstrated that with a fast approach the inductance of the original part has been reduced by 63% to a value below 5 nH. With the right tools, knowledge, and experience FEM simulation is an ideal approach to optimize the inductance of a laminated busbar (which is, by construction, the lowest inductance structure) in order to boost the performance of any power electronics system.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由董慧转载自Rogers,原文标题为:Inductance Optimization for Laminated Busbars,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Busbars for e-Aviation and High Altitude Applications

The evolution to cleaner transportation is pushing the development of e-aircrafts and is already reality in development phase. Operation at high altitude and other demanding specifications creates many challenges, pushing all electrical components a step further in performance. Operating at high altitude with low air density has many implications on the design of laminated busbars. Technical requirements, ambient conditions and physical phenomena are studied case by case at Rogers to deliver the safest and most optimized ROLINX busbar solution.

Rogers Corporation’s Curamik® Ceramic Substrates, Low Inductive ROLINX® Laminated Busbars Power Renewable Energy Sources

The 2024 Paris Summer Olympic Games have captivated audiences worldwide, and part of that excitement has centered around the new and innovative technology applications utilized in this year’s games. Many of these technologies are enabled by materials that Rogers Corporation manufactures, including applications in footwear, 5G wireless infrastructure, renewable energy, and more.

Rogers Corporation Announces Further Actions to Streamline Operations and Drive Margin Improvement

Chandler, Arizona, June 6, 2024: Rogers Corporation (NYSE: ROG) (“Rogers”) announced today plans to drive further operational efficiency and margin improvement. Rogers intends to wind down manufacturing of advanced circuit materials and other related activities at its Evergem, Belgium factory by mid-2025. Rogers will continue to support its advanced circuit materials customers through its existing footprint in China and the United States.

ROGERS层压板/高频板选型表

罗杰斯/ROGERS提供以下技术参数的层压板/高频板选型,超低损耗,低至0.0004(Df) ;超大尺寸:54inchX24inch、52inchX40inch、50.1inchX110inch 等;丰富介电常数:2 -12.85 (Dk);超薄介质,低至1mil

|

产品型号

|

品类

|

产品系列

|

介电常数(Dk)

|

正切角损耗(Df)

|

介质厚度(mm)(mil)

|

导热系数W/(m·K)

|

铜箔类型

|

铜箔1厚度

|

铜箔2厚度

|

尺寸(inch)

|

|

5880LZNS 24X18 H1/H1 R4 0100+-001/DI

|

层压板

|

RT/duroid® 5880LZ

|

2

|

0.0027

|

0.254mm(10mil)

|

0.33

|

电解铜

|

H1

|

H1

|

24X18

|

选型表 - ROGERS 立即选型

ROGERS 半固化片选型表

罗杰斯/ROGERS提供以下技术参数的半固化片选型,超低损耗,介电常数(Dk):2.28-10.02,正切角损耗(Df):0.002-11.2,超大尺寸:24inchX36inch 、25.5inchX18inch、48inchX36inch等,超薄介质。

|

产品型号

|

品类

|

产品系列

|

介电常数(Dk)

|

正切角损耗(Df)

|

厚度(mils)(mm)(μm)

|

尺寸(inch)

|

导热系数W/(m·K)

|

|

3003 BOND PLY 25.5X18 005 R3

|

半固化片

|

RO3003

|

3.00±0.04

|

3

|

0.005” (0.13mm)

|

25.5X18

|

0.5

|

选型表 - ROGERS 立即选型

Temporary Lead Time Extension for Products Made in Rogers Suzhou Factory

型号- RO4830™,RO4535™,KAPPA® 438,DICLAD880™,RO4533™,RO4000™,DICLAD®,RO3003G2™,RO3035™,RO3003™,RO4003C™,RO4835™,RO3003G2™ PM,TC350™,RO4534™,RO4730G3™ R2,RO4835T™,RO4233™,RO4350B™,RO3006™,AD255™,AD300™,RO3010™,RO3000™,TC350™ PLUS

Rogers Expands Capabilities and Services with New Application Laboratory

Rogers Corporation today announced that the new application laboratory was completed, expanding the company‘s assembly, testing and inspection capabilities and services at the curamik® production site in Eschenbach.

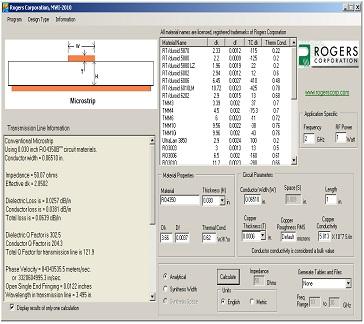

【经验】罗杰斯(Rogers)微波阻抗计算工具使用简介

ROGERS为方便工程师更好的使用高频PCB板材,特推出专门用于微波阻抗计算的工具:微波阻抗计算器(Microwave Impedance Calculator)。其最新的版本为2014版。本文将以MWI-2014为蓝本,来介绍其的具体使用。

【经验】如何选择合适介电常数的Rogers高频板材?

在选择板材rogers高频板材时,最关注的指标是介电常数。但也有一部分工程师对介电常数理解的比较片面,在选择rogers高频板材时,会遇到一些问题,通过本文讲解,可以更好的帮助工程师快速准确的选择合适介电常数的板材。介电常数和频率相关,同一种板材的不同厚度有时会有一定差异。rogers板材的范围1.96(RT/duriod 5880LZ)-13(TMM13i)。

Rogers高频板RO4350B板材在24GHz时介电常数和损耗因子

Rogers高频板RO4350B达到了成本和高频性能的最优化,是最具性价比的低损耗高频板材。为了更好的实现设计要求,笔者在设计微带阵列天线时研究了基于Rogers高频板RO4350B板材的微带传输线在24GHz的插入损耗。

电子商城

品牌:ROGERS

品类:Circuit Materials

价格:¥2,479.9453

现货: 1,409

品牌:ROGERS

品类:High Frequency Circuit Materials

价格:¥547.1207

现货: 1,031

品牌:ROGERS

品类:Antenna Grade Laminates

价格:¥2,989.4355

现货: 429

品牌:ROGERS

品类:Liquid Crystalline Polymer Circuit Material

价格:¥1,485.0299

现货: 253

品牌:ROGERS

品类:Antenna Grade Laminates

价格:¥2,571.9097

现货: 250

品牌:ROGERS

品类:High Frequency Circuit Materials

价格:¥2,669.6313

现货: 250

品牌:ROGERS

品类:PTFE/Woven Fiberglass Laminates

价格:¥16,030.1502

现货: 201

品牌:ROGERS

品类:High Frequency Circuit Materials

价格:¥4,679.1859

现货: 180

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

可加工PCB层数:1-30层;板材类型:FR4板/铝基板/铜基板/刚扰结合板/FPC板/高精密板/Rogers高频板;成品尺寸:5*5mm~53*84cm;板厚:0.1~5.0mm。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论