The Advantages of Using GaN-based Inverters Instead of Silicon-based Inverters for Motor Drive Designs

This article discusses the advantages of using GaN-based inverters instead of silicon-based inverters for motor drive designs to operate smoother while reducing size and weight. These advantages are critical for motor drives used in typical applications such as warehousing & logistical robots, servo drives, e-bikes & e-scooters, collaborative and low voltage robots and medical robotics, industrial drones, and automotive motors.

Omdia forecasts that worldwide shipments of warehousing and logistics robots will grow rapidly over the next 5 years from 194,000 units in 2018 to 938,000 units annually by 2022, with the rate of growth slowing after 2021 as many major players will have adopted robotic systems by then. Worldwide revenue for this category will increase from $8.3 billion in 2018 to $30.8 billion in 2022, providing significant opportunities for established participants and emerging players.

GaN Advantages

GaN FETs and GaN ICs switch faster and smoother and have zero reverse recovery compared to equivalently specified silicon MOSFETs. This faster and better switching allows operation at higher switching frequencies in inverter designs to eliminate electrolytic capacitors. Further, GaN can operate at a minimal dead time, which increases the effective torque per ampere obtained from the motor, thus making the motor more efficient. In addition, GaN allows for the integration of the inverter with the motor resulting in an overall reduction in size and weight of the system. Table 1 shows a comparison of EPC GaN FETs vs. MOSFETs with similar RDS(on) ratings.

Table 1:Key parameter comparision of EPC GaN FETs vs. MOSFETs

In a typical motor design, the PWM frequency is between 20 and 40 kHz, with dead times between 100 ns and 500 ns. The input cables can be at least 10 to 20 cm long and become a source of EMI, conducted or radiated. Therefore, in traditional motor drive designs, it is common to add an input EMI LC filter. We will show that this can be eliminated in GaN-based motor drive designs.

Capacitor Selection

When comparing electrolytic with ceramic capacitors, remember that RMS current in the capacitor does not depend on PWM frequency, while the voltage ripple is inversely proportional to PWM frequency and capacitance. Therefore, electrolytic capacitors are sized with RMS current. They are oversized, and their value does not change with PWM frequency. Ceramic caps are sized with voltage ripple and are sized in line with the minimum required capacitance. Their value and size decrease with increasing PWM frequency. 100 kHz operation is a sweet spot for ceramic capacitors ESR. This demonstrates a clear advantage of ceramic capacitors in terms of occupied volume reliability, cost, and EMI.

Dead-Time Effect

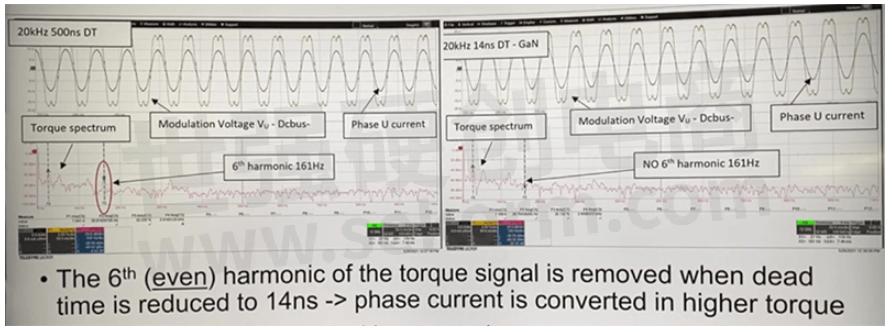

Figure 1

On the left side of Figure 1, the effect of 500 ns dead time on a motor operated at 20 kHz PWM is shown. There are six discontinuities in the current, circled in orange. These discontinuities are responsible for the 6th harmonic in the torque. It is an even harmonic, so it produces only vibration.

On the right side of Figure 1, it is shown that by reducing the dead time to 14 ns, the discontinuities disappear, as does the 6th harmonic.

In Figure 2, the torque signal is obtained with a torque/speed transducer and analyzed with FFT. The 6th (even) harmonic of the torque signal that is present on the left when the dead time is 500 ns is completely absent when dead time is reduced to 14 ns in the setup on the right.

Figure 2

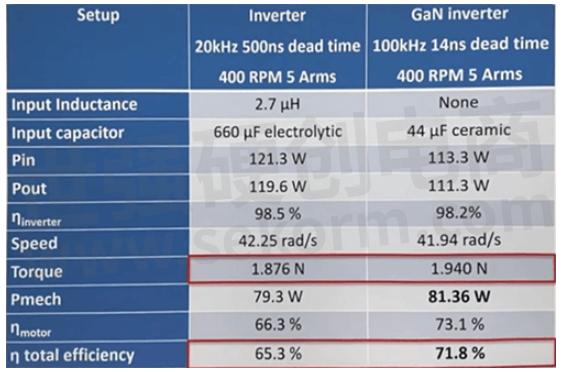

In the EPC Italy Motor Drive lab, an experiment was run to further evaluate these differences. Two systems, both at 36 VDS, 5ARMS, and 400RPM, are compared. Setup 1 uses 2x330µF electrolytic capacitors and 1x2.7µH input inductors, running at 20 kHz with 500 ns dead time, typical of a traditional silicon MOSFET-based motor drive. Setup 2 operates at 100kHz, 14ns dead time, and uses 2x22µF ceramic capacitors and no input inductor, which is something only achievable with GaN.

Table 2 is a summary of the overall impact of the two setups. By running at 100 kHz, the GaN inverter allows the usage of ceramic capacitors in place of bulky electrolytic capacitors. By reducing the dead time it is possible to get more torque per ampere, making the motor more efficient and thus making the overall system more efficient. The higher frequency setup increases the overall system efficiency from 65.3% to 71.8%.

Table 2: Summary of two motor drive setups

Conclusion

The faster and better switching performance of GaN FETs and ICs allows inverter operation at higher switching frequencies to eliminate electrolytic capacitors. Further, GaN can operate at a minimal dead time. This reduction in dead time increases the effective torque per ampere obtained from the motor, making the motor more efficient and allowing for the integration of the inverter with the motor, further reducing overall system size and weight. These advantages are critical for the motor drives used in eMobility solutions, robotics, and drones.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由董慧转载自EPC,原文标题为:Motor Drives Showdown – GaN vs. Silicon,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

How to Design a 2kW 48V/12V Bi-Directional Power Module with GaN FETs for 48V Mild Hybrid Electric Vehicles

This artical tells how to Design a 2kW 48V/12V Bi-Directional Power Module with GaN FETs for 48V Mild Hybrid Electric Vehicles. A new reference design demo board, EPC EPC9165, is available to help jump start the design of a 2 kW bi-directional converter.

How to Design a 2 kW 48 V/12 V Bi-Directional Power Module with packaged eGaN® FETs

This application note introduces a bi-directional high-power EPC9165 converter for mild-hybrid cars and battery power backup units using four EPC EPC2302 packaged eGaN FETs. When converting between 48V and 14.3V, the efficiency exceeds 96% with a 500kHz switching frequency.

How To Use An EPC Development Board to Evaluate The Performance of A Given GaN FET or IC in Common Applications?

This article have shown that an EPC development board can easily be utilized to evaluate the performance of a given GaN FET or IC in common applications with very little setup effort.

EPC(宜普)eGaN® 氮化镓晶体管(GaN FET)和集成电路及开发板/演示板/评估套件选型指南

目录- eGaN FETs and ICs eGaN® Integrated Circuits Half-Bridge Development Boards DrGaN DC-DC Conversion Lidar/Motor Drive AC/DC Conversion

型号- EPC2212,EPC2214,EPC2059,EPC2216,EPC2215,EPC2218,EPC2016C,EPC2050,EPC2052,EPC2051,EPC2054,EPC2053,EPC2055,EPC9086,EPC2218A,EPC90153,EPC9087,EPC90154,EPC2069,EPC2102,EPC2101,EPC2104,EPC2103,EPC2106,EPC2105,EPC2107,EPC9018,EPC2065,EPC90151,EPC90152,EPC21702,EPC2100,EPC2067,EPC2221,EPC21701,EPC2066,EPC90150,EPC9097,EPC90145,EPC90142,EPC9098,EPC90143,EPC9099,EPC9092,EPC90148,EPC90149,EPC90146,EPC9094,EPC90147,EPC2219,EPC9091,EPC2619,EPC2036,EPC2035,EPC2038,EPC2037,EPC2014C,EPC2039,EPC9507,EPC2030,EPC9067,EPC2032,EPC2031,EPC9068,EPC2152,EPC2033,EPC9063,EPC9186,EPC9066,EPC8010,EPC9180,EPC2204A,EPC9181,EPC9061,EPC2308,EPC2307,EPC9005C,UP1966E,EPC2203,EPC9004C,EPC2202,EPC2204,EPC2015C,EPC2207,EPC2206,EPC2040,EPC2045,EPC2044,EPC9194,EPC2012C,EPC2019,EPC9049,EPC9203,EPC9204,EPC9205,EPC2252,EPC9166,EPC9167,EPC9047,EPC9201,EPC9041,EPC9162,EPC9163,EPC9165,EPC7020,EPC9160,EPC9040,EPC2024,EPC8009,EPC2302,EPC2001C,EPC2029,EPC2304,EPC2306,EPC2305,EPC8002,EPC2021,EPC9177,EPC2020,EPC9057,EPC9167HC,EPC2023,EPC9179,EPC9058,EPC8004,EPC2022,EPC9059,EPC9173,EPC9174,EPC9055,EPC9176,EPC9170,EPC9050,EPC9171,EPC9172,EPC2010C,EPC2034C,EPC7007,EPC7002,EPC9148,EPC2071,EPC7001,EPC23101,EPC23102,EPC23103,EPC9144,EPC90140,EPC23104,EPC2111,EPC7004,EPC2110,EPC7003,EPC90133,EPC90132,EPC9022,EPC9143,EPC90137,EPC90138,EPC90135,EPC90139,EPC7019,EPC7018,EPC9038,EPC9159,EPC9039,EPC2007C,EPC21603,EPC9156,EPC9036,EPC9157,EPC9037,EPC2088,EPC7014,EPC21601,EPC9158,EPC90122,EPC9151,EPC9031,EPC90123,EPC90120,EPC9153,EPC9033,EPC90121,EPC9154,EPC90124,EPC9150,EPC90128

EPC eGaN®FET/晶体管选型表

EPC提供增强型氮化镓半桥功率晶体管/增强型功率晶体管/功率晶体管的选型:配置:Dual Common Source、Dual with Sync Boot、Half Bridge、Half Bridge Driver IC、HS FET + Driver + Level Shift、Single、Single - AEC Q101、Single – Rad Hard、Single with Gate Diode、Single with Gate Diode – AEC-Q101、Dual Common Source - AEC Q101,VDS最大值(V):15~350V;VGS最大值(V):5.75~7V

|

产品型号

|

品类

|

Configuration

|

VDSmax(V)

|

VGSmax(V)

|

Max RDS(on) (mΩ)

@ 5 VGS

|

QG typ(nC)

|

QGS typ (nC)

|

QGD typ (nC)

|

QOSS typ (nC)

|

QRR(nC)

|

CISS (pF)

|

COSS (pF)

|

CRSS (pF)

|

ID(A)

|

Pulsed ID (A)

|

Max TJ (°C)

|

Package(mm)

|

Launch Date

|

|

EPC2040

|

Enhancement Mode Power Transistor

|

Single

|

15

|

6

|

30

|

0.745

|

0.23

|

0.14

|

0.42

|

0

|

86

|

67

|

20

|

3.4

|

28

|

150

|

BGA 0.85 x 1.2

|

Apr, 2017

|

选型表 - EPC 立即选型

Advancements in USB Power Delivery: GaN Technology for Efficiency and High-Power Density

型号- EPC9195,EPC2619,LTC7891

【IC】EPC推出新型80V、40A eToF™激光驱动器GaN IC,实现更高功率密度激光雷达系统

宜普电源转换公司(EPC)推出新型氮化镓集成电路EPC21701,这是一款80V激光驱动器IC,可提供15A脉冲电流,适用于飞行时间激光雷达应用(ToF激光雷达应用),包括真空吸尘器、机器人、3D安全摄像头和3D传感器。

【元件】EPC新推80V氮化镓晶体管EPC2204A/EPC2218A,具有较低的栅极电荷,可用于自动驾驶激光雷达

EPC推出了两颗新的80V AEC-Q101认证的氮化镓晶体管(GaN FETs),为设计者提供了比硅MOSFET更小、更高效的解决方案,可用于汽车48V-12V DC-DC转换、信息娱乐和自动驾驶的激光雷达。

【视频】EPC发挥其GaN技术优势,将帮助实现高效能电机驱动应用和DC/DC转换器

型号- EPC9173,EPC2302,EPC2304,EPC2306,EPC2305,EPC2308,EPC2307,EPC23102

【应用】基于GaN(氮化镓)的D类音频放大器,实现高质量、低成本的音质

现在,氮化镓FET和IC的出现正在迎来高质量、低成本D类音频放大器的时代。基于GaN的FET和IC更优异的开关和热性能产生的波形比硅MOSFET所能达到的波形更接近所需的理想波形。采用GaN技术的高级音频D类放大器提供高于A类放大器设计的音质。

BRC Solar Selects EPC 100V eGaN FETs for Next Generation Solar Optimizer

Designing EPC‘s EPC2218 100V FETs into BRC Solar GmbH‘s next generation M500/14 power optimizer has enabled a higher current density due to the low power dissipation and the small size of the GaN FET making the critical load circuit more compact.

EPC to Showcase Advanced GaN Power Solutions at PCIM Asia 2024

EPC’s GaN Experts will be available during PCIM Asia, showcasing the latest generation of GaN FETs and ICs in a wide variety of real-world applications including AI servers, robotics, and more.

电子商城

现货市场

服务

世强深圳实验室提供Robei EDA软件免费使用服务,与VCS、NC-Verilog、Modelsim等EDA工具无缝衔接,将IC设计高度抽象化,并精简到三个基本元素:模块、引脚、连接线,自动生成代码。点击预约,支持到场/视频直播使用,资深专家全程指导。

实验室地址: 深圳 提交需求>

拥有IC烧录机20余款,100余台设备,可以烧录各种封装的IC;可烧录MCU、FLASH、EMMC、NAND FLASH、EPROM等各类型芯片,支持WIFI/BT模组PCBA烧录、测试。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论