5 Factors That Affect the Lithium Ion Battery Life

Grepow(格瑞普)talks about 5 Factors That Affect the Lithium-ion battery Life.

Firstly, Grepow Introductions to the structure and principle of lithium-ion batteries.

Lithium-ion battery mainly consists of positive and negative electrode materials, electrolyte, diaphragm, fluid collector and battery shell, positive and negative electrode materials consist of two different lithium-ion embedded compounds. When charging, lithium ions are embedded in the negative electrode through the electrolyte via the diaphragm, and vice versa when discharging. During the first charge and discharge of a li-ion battery, a passivation film can be formed at the phase interface between the negative electrode and the electrolyte. It acts as a diaphragm between the electrode and the electrolyte and is an electron insulator but an excellent conductor of lithium ions, which can be freely embedded and disembedded through the passivated layer and has the characteristics of a solid electrolyte. interface, or SEI film for short. The charge/discharge electrode reaction of a Li-ion battery is as follows: take LiCoO2 as an example.

Charge and discharge process of a and LiCoO2 electrodes lithium-ion cell using graphite

The electrolyte is a very important factor

In the impact of the reversible capacity of the battery. The process of electrode material de and embedded lithium-ion is always the process of interaction with electrolyte, and this interaction has an important influence on the interface condition and internal structure change of electrode material. In the process of interaction with the positive and negative electrode materials electrolyte will be lost, in addition to the formation of SEI film and pre-charging in the battery chemistry, which will also consume part of the electrolyte, so the type of electrolyte and the amount of liquid injection also affects the battery life.

The manufacturing process of a lithium-ion battery

The manufacturing process of a li-ion battery mainly includes positive and negative electrode dosing, coating, production, winding, shelling, liquid injection, sealing, and formation. In the battery production process, the requirements for each step of the process are very strict. Any not well-controlled process may affect the battery cycle performance.

The process of positive and negative electrode batching

When batching positive and negative electrodes, attention should be paid to the amount of binder added, stirring speed, the concentration of slurry, temperature, and humidity, and ensuring that the material can be dispersed evenly.

In the coating process

When coating, under the premise of ensuring the high specific energy of the battery, reasonably controlling the amount of positive (negative) electrode coating, and appropriately reduce the electrode thickness to help reduce the decay rate of the battery. After coating, the electrode will be further compacted by roller press. A proper positive electrode compacting density can increase the discharge capacity of the battery, reduce the internal resistance, reduce the polarization loss and extend the cycle life of the battery.

When winding

In the winding process, the rolled cell should be tight and not loose. The tighter the diaphragm and positive and negative electrodes are rolled, the smaller the internal resistance, but when rolled too tightly, it will cause difficulties in wetting the electrode and diaphragm, resulting in a smaller discharge capacity; rolled too loosely will make the electrode over-expand during charging and discharging, increasing the internal resistance, reducing the capacity and shortening the cycle life.

In the battery design process, the selection of materials is the most basic and important factor. The performance characteristics of different materials are also different, and there is a gap in the performance of the battery developed. The cycle life of the battery will be long only if the positive and negative materials are matched with good cycle performance. In terms of ingredients, attention should be paid to the amount of positive and negative materials added. Generally speaking, the design assembly process generally requires the negative electrode capacity relative to the positive electrode in excess of some, if not, the negative electrode will precipitate lithium in the charging process, the formation of lithium dendrites thus affecting safety. If the negative electrode is too much relative to the positive electrode, the positive electrode may be excessively de-lithium, resulting in structural collapse.

The impact of aging and decline of battery materials

Lithium-ion battery charging and discharging cycle is the process of lithium ions through the electrolyte in the positive and negative electrode material back and forth between the process of de-embedding and moving. In the lithium-ion battery cycle process, in addition to the redox reaction in the positive and negative electrodes, there are also a large number of side reactions. If the side reactions of lithium-ion batteries can be reduced to a low level, so that lithium ions can always go back and forth between the positive and negative materials through the electrolyte, the cycle life of lithium-ion batteries can be increased.

The influence of the battery use environment

The use of a lithium-ion battery environment in its cycle life is also very important. Among them, the ambient temperature is a very important factor. The ambient temperature is too low or too high will affect the cycle life of lithium batteries.

Low temperature

The constant voltage charging time increases at low temperatures, and the charging performance also deteriorates significantly.

High temperature

With high temperature charging and discharging, the negative electrode performance will gradually deteriorate eventually leading to battery failure.

Strong vibration or shock

Under strong vibration or shock, the pole lugs, external connecting wires, terminals, solder joints, etc. of lithium-ion batteries may break or fall off, and the active material on the battery pole pieces may also be peeled off, which will affect the life of the battery or even produce dangerous situations.

The impact of the charge and discharge system during the cycle

The use of lithium-ion batteries is the process of charging and discharging cycle, the size of the charge and discharge current, the choice of charge and discharge cut-off voltage, and the use of what charge and discharge system on the cycle life of lithium-ion batteries also has a very important impact. Any blind increase in the working current of the battery, increase in the charging cut-off voltage, lower in the discharging cut-off voltage, etc. will degrade the performance of the battery.

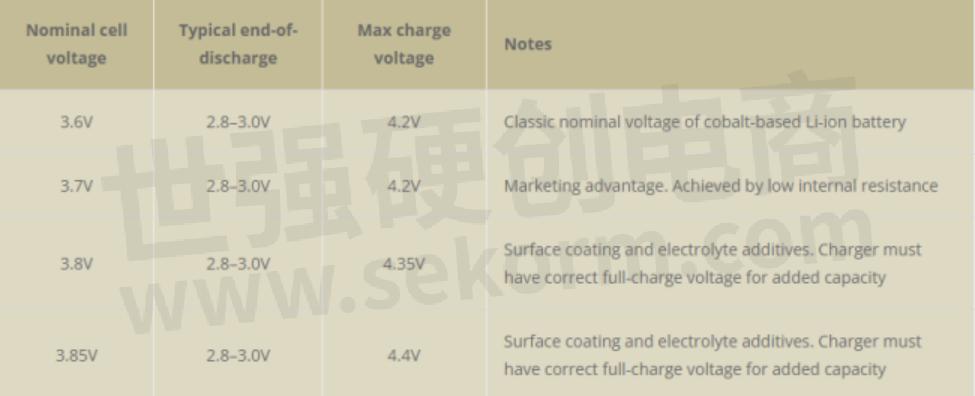

Different electrochemical systems of lithium-ion batteries have different charge and discharge cut-off voltages.

Source: Battery University

As the battery needs to discharge a large capacity in a relatively short period of time when discharging at a high current, the electrode reaction is rapid and violent, and some lithium ions are too late to deem or cross the negative electrode material discharge process is over. In addition, the battery lugs may melt under high current conditions, and equipment components may be damaged.

Conclusion

Whether in design and manufacture or in use, there are multiple factors that affect the cycle life of rechargeable lithium-ion batteries.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由翊翊所思转载自格瑞普,原文标题为:5 Factors That Affect the Lithium Ion Battery Life,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

Grepow Battery will exhibit at 2022 Summer Asia Smart Wearable Exhibition

The bi-annual Asia Smart Wearable Exhibition (ASWE) will be held from July 18 to July 20 at Shenzhen International Convention and Exhibition Center. Grepow will bring its smart wear accessories shaped lithium-ion batteries and button batteries present, booth number: C24 in Hall 4.

Steel-Shell vs. Soft Pack Coin Cell Batteries for TWS Earbuds: Which is Better ?

The mainstream TWs headset battery types currently on the market are steel-cased button batteries and soft pack button batteries. The two have differences in the amount of charge, shape, and many other aspects, so TWS headphones with Steel-Shell or Soft Pack Coin Cell Batteries cells are good.

What are the Best Intelligent Lithium Battery Manufacturers in Shenzhen?- Grepow Battery

At one time, a survey by the Japan Economic Research Institute showed that Chinese battery manufacturers accounted for more than 60% of the global automotive lithium-ion battery market.

Recycling and Regeneration of Lithium Batteries

Under the pursuit of economic and environmental protection, the production and demand of lithium batteries have grown in recent years. Decommissioned lithium batteries are known as high-grade mines, coupled with the price and mining of raw materials, so the recycling value is obvious.

Grepow Rechargeable Li-lon Button Cells Solutions for High-tech Applications

Grepow has provided dedicated energy solutions for high-tech applications in bluetooth headsets for smart phones, notebook bridging function, body shaping and training sensors, medical and health care equipment, wireless sensor and network infrastructure and many more. For all these applications, Grepow offers a range of Lithium-Ion button cells and battery assemblies in diameters from 7.8 - 24 mm with 6.5 mAh to 210 mAh.

What is a High Energy Density Battery?

In this article, we explore what makes a battery high-energy, identify the current leaders in the field, and discuss the science behind their high performance, focusing on the materials and technologies that enable such impressive energy storage capabilities.

What is the Impact of Long Coldness on Agriculture Spraying UAVs Batteries and How to Deal with it

Agricultural drones are not only used for spraying and applying medicine, but also for spreading fertilizer, seeds, and feeds to meet the diversified needs of farmers and improve production efficiency.

Can Lipo Battery Cells Be Shipped by Air?

With the widespread use of electronic products, batteries nowadays have become household items that we can see everywhere. The most commonly encountered type of battery is the lithium-ion battery.

NMC Battery vs. LCO Battery: What’s the Difference?

When it comes to lithium-ion batteries, two of the most commonly discussed chemistries are NMC (Nickel Manganese Cobalt) and LCO (Lithium Cobalt Oxide). Both are widely used in a variety of applications, from electric vehicles to consumer electronics, but they differ significantly in terms of chemical composition, energy density, cycle life, and cost. Understanding the key differences between NMC and LCO batteries is essential for choosing the right battery for specific applications, whether you‘re powering a smartphone or an electric vehicle.

NMC vs NCA Battery Cell: What’s the Difference?

Choosing between NMC and NCA battery cells depends on the specific requirements of the application. NMC cells offer a versatile and cost-effective solution with balanced energy and power characteristics, making them ideal for a wide range of uses from EVs to power tools. On the other hand, NCA cells provide higher energy density and longer cycle life, making them suitable for high-performance EVs, consumer electronics, and aerospace applications.

How Are Smart Rings Powered?

Smart rings are powered by efficient, rechargeable batteries and designed with energy-saving technologies, they provide a balance of performance and convenience. As a global leading lipo battery manufacturer, Grepow can provide extremely narrow smart ring batteries, as thin as 1.4mm and as narrow as 4.5mm, to meet the design requirements of various innovative smart rings.

How to Solve the Imbalance between Li-ion Battery Pack Cells and the usual maintenance of Lithium-ion batteries

Grepow tells how to Solve the Imbalance between Li-ion Battery Pack Cells and the usual maintenance of Lithium-ion batteries? and then Grepow shares with you some of the usual maintenance of lithium-ion batteries

What Caused The Lithium Battery to Explode?

With over 20 years of customer service experience, Grepow has developed a very complete service system, specifically tailored for Grepow customers, which helps Grepow in better understanding your needs in the first step of our communication, in a highly time-efficient way.

AUV vs. UUV: What’s the Difference?

Underwater exploration, research, and military operations often require the use of specialized vehicles that can operate autonomously or be remotely controlled. Two key types of underwater vehicles are AUVs (Autonomous Underwater Vehicles) and UUVs (Unmanned Underwater Vehicles). Though they share similarities, these systems have distinct roles, capabilities, and applications. In this article, we’ll explore what these terms mean, their differences, and the advantages and disadvantages of each type of vehicle.

Prescription vs OTC Hearing Aids: What‘s the Difference?

If you value convenience, long-term savings, and eco-friendliness, rechargeable hearing aids could be the better choice. However, if you prefer a lower upfront cost and the simplicity of changing batteries without worrying about charging, disposable battery models might be more suitable. Both options are available in prescription and OTC hearing aids, so you can make a choice that best suits your lifestyle and hearing needs.

电子商城

品牌:至诚微

品类:Highly integrated synchronous boost charger IC

价格:¥1.9200

现货: 10,000

品牌:至诚微

品类:Highly integrated synchronous boost charger IC

价格:¥1.2941

现货: 10,000

现货市场

登录 | 立即注册

提交评论