Why Is Card Edge Connector Called “Goldfinger“?

This is not about the famous 007 movie "Goldfinger", but rather about a card edge connector. It is a method of connecting two PCB cards and is commonly known as "gold finger" because the surface of the PCB terminal is coated with gold or copper, which looks like a finger.

Card edge connectors are widely used and easy to use. Its gold plating layer is generally 0.8μ half gold plating (contacts are gold plated), or full gold plating (the entire terminal including the pins are gold plated). The thicker the gold plating, the better the anti-oxidation ability.

There are several types of card edge power connectors: Standard (SEC), SEC-II, Multi-Beam, and the newer High-Density Card Edge (HDCE).

SEC-II Card Edge Connector

It is a product that replaces the standard SEC and is a high-current printed circuit board power connector with a current rating of 160 amps per linear inch. Compared with the traditional SEC, SEC-II improves the contact design to achieve more efficient current transmission. At the same time, the vented housing design can ensure contact heat dissipation, improve its operational safety and reliability, support continuous long-term operation of the connector, and meet the connection needs of power industry customers.

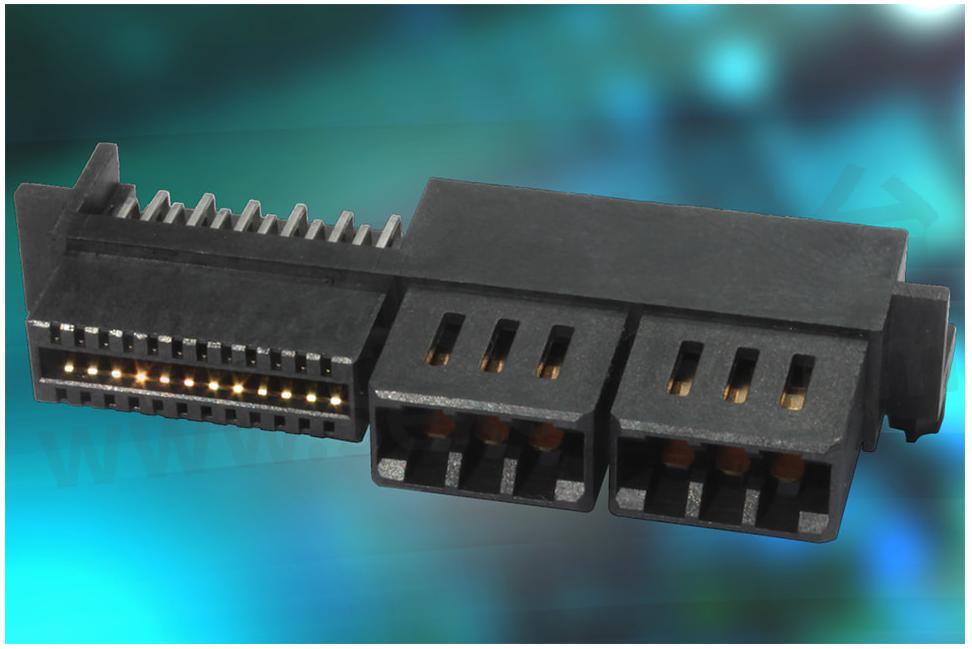

Multi-Beam Power Card Edge Connector

It is a card edge product after SEC-II and can provide good current and signal density for data communication and industrial applications. This owes to the use of 1.00mm signal terminal spacing and 7.26mm power terminal spacing, which respectively save up to 60% and 30% of space compared to existing products, providing higher flexibility for the structure and design of printed circuit board (PCB), and supporting higher power for each terminal, which can be up to 43A.

High-Density Card Edge Connector

It is one of the highest current density power connectors on the market supporting large power applications. This connector can achieve a higher current (25A/terminal) with low resistance and can support 1500-2000W power for data center equipment. The HDCE connector improves the performance of previous generations of card edge connectors, with a maximum operating temperature of up to 130°C and reliable performance in harsh environments. The 1.27mm industry-standard signal spacing enables it to match mainstream circuit board designs on the market. The elasticity of the power/signal pins provides lower insertion and extraction forces.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由上山打老虎转载自Greenconn News,原文标题为:Why is card edge connector called "Goldfinger"?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

What Is a PCB Card Edge Connector?

PCB card edge connector is an important component of modern electronic products, providing a way to connect a printed circuit board to other devices or components.

Wafer Connectors: Compact and Powerful Connectivity Solutions

In the precise world of electronic devices, wafer connectors stand out as expert components enabling efficient electrical connections. Typically composed of metal and plastic parts, they play a critical role on printed circuit boards (PCBs). Thanks to their compact design and high-performance connectivity, wafer connectors are key to realizing complex circuit connections.

What Role Do Industrial Connectors Play and What Characteristics Do They Have?

The main function of industrial connectors is to transmit and control electrical signals and power connections between electronics and electrical equipment. In this article Greenconn will introduce the role and characteristics of industrial connectors.

Production Process of Board-to-Board Connectors

The production process of board-to-board connectors can be roughly divided into four steps: stamping, electroplating, injection molding and assembly.

Greenconn GB03 Series Wafer Connectors Complied with LV214 Standards: Engineered for Reliability and Space Efficiency

Greenconn’s GB03 Series Wire-to-Board Connectors comply with LV214 standards, ensuring high reliability for automotive applications. Featuring a compact design, exceptional performance, and robust durability, these connectors deliver optimized space utilization, efficient assembly, and dependable connectivity for a wide range of applications.

Greenconn GC04 Series Floating Connectors: Unleashing Superior Performance with 6A Current and 8Gbps Data Transfer

Greenconn has developed a range of floating connectors with pitches of 0.5mm, 0.635mm, and 0.8mm, and stacking heights ranging from 6.3mm to 30mm. These connectors are widely employed in high vibration environments, such as automatic assembly, automobiles, and industrial applications. Its double contact design enables flexible error tolerance for connector displacement during vibration.

What You Need to Know About PCB Card Edge Connectors

In this article, Greenconn will explore the fundamentals of PCB card edge connectors, their importance, and the key features you should consider when choosing the right connectors for your projects.

Nextron D38999 Series Connectors: Rugged and Reliable Connectivity Solutions for Aerospace and Industrial Applications

Whether you need standard models or customized solutions, investing in D38999 series connectors is a prudent decision for aerospace or industrial applications. They deliver long-lasting performance and quality, proving themselves as dependable and resilient components.

Applications of Terminal Block Connectors

Terminal block connectors have a broad range of applications, spanning from industrial and building systems to transportation, energy, communication, and more. Their reliability, durability, and ease of maintenance make them indispensable components in electrical systems.

Greenconn’s GB Series Wafer Connectors: Secure, Reliable, and Easy to Install

With their compact design, durable materials, and flexible configuration options, Greencon‘s GB series Wafer connectors excel in providing efficient and reliable connection solutions across multiple industries such as consumer electronics, automotive applications, industrial automation, and medical equipment.

Greenconn’s GT Series Waterproof Connectors with a Single Contact Current up to 13A

Greenconn’s GT series waterproof connectors are equipped with a lock-lock anti-loosening design in the shell. Upon insertion, they emit a reassuring “click“ sound to guarantee a secure and dependable fit. The connectors boast built-in cable and connection seals, ensuring waterproof compliance with IP67 standards and making them suitable for use in harsh environments. Additionally, the crimp terminal‘s individual contact can handle a current of up to 13A, making it an exceptionally reliable and robust connection solution.

Advantages and Technological Trends of Terminal Block Connectors

Terminal block connectors play an irreplaceable role in the electrical connection field due to their unique advantages and continue to evolve with technological advancements, providing safer, more convenient, and efficient electrical connection solutions for industrial automation, power systems, transportation, and construction sectors.

LINK-PP‘s Magnetic RJ45 Connectors Empowers Industrial Automation

This paper mainly introduces the application characteristics and advantages of LINK-PP RJ45 connector products in industrial automation

What is the Role of Industrial Connectors? What Types of Industrial Connectors Can Be Divided into?

Wanlian technology (valnk) knows the main forms of industrial connectors based on many years of production and manufacturing experience. So what is the role of industrial connectors? What other connection forms can be divided into? Keep looking down on these questions!

What are the Three Common Connectors?

Connectors are essential components in various electronic systems, enabling the transfer of power, data, and signals between different devices. Whether in consumer electronics, industrial machinery, or automotive applications, connectors ensure reliable connections and efficient system operation. In this article, we will explore the three most common types of connectors used in electronics: USB connectors, HDMI connectors, and SMA connectors.

电子商城

现货市场

服务

可定制连接器单PIN电流最大不超过10A;环境温度:-45度~+125度;寿命/拔插次数:不超过5000次。

最小起订量: 5000 提交需求>

可定制排针排母间距:0.8~2.54mm,排数:1~3,电流:最大不超过10A;环境温度:-45度~+125度;寿命/拔插次数:不超过5000次。

最小起订量: 5000 提交需求>

登录 | 立即注册

提交评论