Wevo Materials Make State-of-the-art LED Lighting Systems Possible

Whether it's for automotive headlights, in greenhouses, or for offices and homes, LEDs have gained acceptance in almost all fields of lighting applications. This is because, in addition to their low energy consumption, LEDs are also very versatile. However, this often requires integrating additional electrical and electronic components into the LED luminaires. For this purpose, Wevo-CHEMIE GmbH offers tailor-made potting compounds, gels, adhesives, and sealants that also satisfy additional requirements such as protection against environmental influences, heat, and chemicals.

The demands on lighting are manifold and nowadays go far beyond classical aspects such as safety. Among other things, factors like easy adaptability to ambient conditions, integration into smart applications, or the technical possibilities for further development play an important role. State-of-the-art lighting systems, for example, can precisely create the mood people are looking for – whether they are at home, at work, or in their car. In greenhouses, plant growth is promoted by creating lighting conditions with specific wavelengths ("horticultural lighting"). On the roads, intelligent lighting systems automatically adapt to approaching vehicles or pedestrians.

Technically, this means that LEDs and electronic components need to be integrated into the luminaire and protected against environmental influences in order to guarantee a long service life. In addition, electrical insulation is another important aspect essential to protect users and electricians from hazards and to avoid short circuits and fires. The development of smart and networked systems, as well as new technologies such as Li-Fi (light fidelity), also demands additional components, including sensors, antennas, transformers, drivers, and IoT devices. These are increasingly being integrated directly into the luminaire itself rather than realized as an external component.

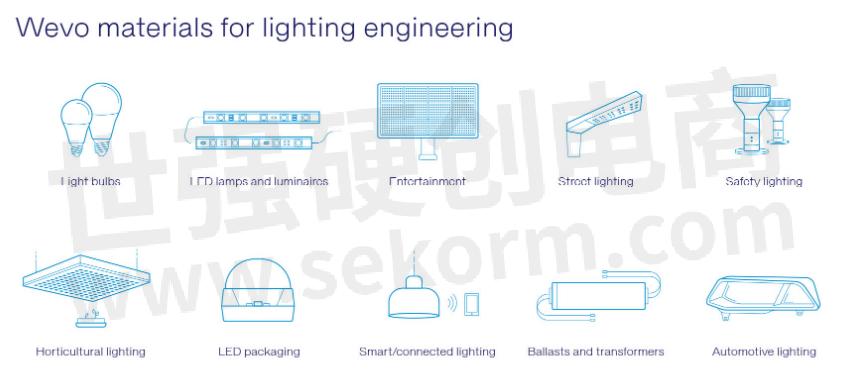

With its tailor-made materials based on polyurethane and silicone, Wevo is actively facilitating these developments in LED lighting systems – and the products can be used in a wide variety of applications (Fig. 1).

Fig. 1: Possible applications of Wevo materials in the lighting industry

Regardless of the application, the use of potting compounds, adhesives, and sealants brings benefits in terms of design, the manufacturing process, and product longevity, and solves among other things the following challenges that arise with respect to lighting engineering.

CHALLENGE: ENVIRONMENTAL CONDITIONS

Potting compounds, gels, adhesives, and sealants from Wevo can be used both indoors and outdoors. Thanks to special ingredients used in their production, LED luminaires (including LED strips) are reliably protected against environmental influences such as ultraviolet light, humidity, dust, or corrosive gases. The materials, which are based on polyurethane and silicone, can be used for interior luminaires as well as for street lamps, architectural lighting, or illuminated advertising systems.

When light sources are used in hazardous or safety-critical environments, such as chemical plants, tunnels, or airports, they are subject to high requirements in terms of resistance to a wide range of environmental conditions. These include, for example, chemicals, explosive gases, salt, weather, or insects. The use of hydrolysis-resistant and hydrophobic polyols with low hygroscopicity and special UV-resistant isocyanates in the hardener component ensures both reliable protection and electrical insulation even in such cases.

CHALLENGE: FOGGING

For use in automotive headlamps and rear lights, Wevo has developed special adhesives and sealants that prevent tension cracks in the housings as well as fogging. To achieve this, the compatibility of the materials with amorphous plastics such as PC and PMMA was adjusted. In addition, they consist of particularly pure and solvent-free raw materials.

CHALLENGE: OPERATING TEMPERATURES

Another challenge is high operating temperatures, as in the case of high-power LED spotlights for theatre stages and closely packed LED luminaires for greenhouse lighting. In these cases, the special heat-conducting potting compounds and gap fillers provide reliable protection for the components and LEDs. Effective heat dissipation from the LED modules to the heat sink and ultimately to the ambient air is ensured by the use of special thermally conductive fillers in the potting compound or thermally conductive paste.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由Vicky转载自Wevo News,原文标题为:Wevo materials make state-of-the-art LED lighting systems possible,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Wevo’s Potting Compounds and Adhesives Enable Modern Environmental Technologies

WEVO-CHEMIE GmbH’s specially developed potting compounds and adhesives based on polyurethane, epoxy resin, and silicone offer customized solutions for a wide range of requirements and applications.

Wevo Customized Potting Compounds, Adhesives, and Sealants Are Facilitating Smart Cities and Power Grids

Adapted to the respective requirements, customized potting compounds, adhesives, and sealants from WEVO-CHEMIE GmbH protect such components from challenging environmental conditions, heat generated during operation, or tampering – and play their part in enabling these new technologies to be implemented.

Wevo Developed Silicones and Polyurethanes with a Lower Hydrogen Permeability Used as Adhesives and Sealants for PEM fuel cells

Wevo’s polyurethane sealants, which have similar thermo-mechanical properties to silicones, have even lower hydrogen permeability depending on the Shore hardness setting. Their permeation coefficients vary between about 30 and 70 E-8 cm²/s, also after a 16-hour measurement period.

THERMAL INTERFACE SOLUTIONS

型号- TPLI™ 200,7000,TPUTTY™ 607,TGARD™ 500,P100,TFLEX™ HD80000,P300,TGARD™ 220,210B,TPUTTY™ 403,TFLEX™ HD7.5,TGREASE™ 300X,230,SF10,2500,910,TFLEX™ CR607,TFLEX™ P100,TPUTTY™ 910,TFLEX™ 300,TFLEX™ CR900,TGARD™ 230,TFLEX™ P300,TGARD™ 210B,B200,TPCM™ 7000,SF600,200,TNC-4,TGARD™ TNC-4,600,TFLEX™ SF10,SF800,403,CR607,TFLEX™ B200,607,SLIM TIM™ 10000,TPUTTY™ 508,5000,TPUTTY™ 502,HP34,HD80000,TFLEX™ HD700,TFLEX™ CR350,TGREASE™ 2500,300X,HD7.5,TFLEX™ HD300,TPCM™ 780,TPCM™ 580,208B,TFLEX™ HR600,TGARD™ 208B,HD300,TFLEX™ 600,CR350,TFLEX™ SF800,UT20000,HD700,TPCM™ 5000,580,TGARD™ K52-3,TFLEX™ SF600,780,HR600,220,TFLEX™ HP34,TGARD™ K52-2,300,TGARD™ K52-1,K52-2,K52-1,500,502,TFLEX™ UT20000,K52-3,10000,CR900,508,TGARD™ 5000

E-MOBILITY

型号- WEVOSIL 28002,WEVOSIL 28001,WEVOPUR 9251 FL,WEVOSIL 26009 FL,WEVOPUR 60910 FL,WEVOPOX 32702,WEVOSIL 22006 FL,WEVOSIL 26009 FLB,WEVODUR 32702,WEVOSIL 22002 FL,WEVONAT 600,WEVOPOX 2513,WEVOPUR 56003 FL,WEVOSIL 27015 FLB,WEVODUR 5008,WEVOPUR 600,WEVOSIL 27015 FLA,WEVONAT 552 FL,WEVOPUR 56093 FL,WEVOPUR 552 FL,WEVODUR 5001,WEVOPUR 300 RE,WEVOSIL 26010 FL,WEVONAT 56003 FL,WEVOPUR 56002 FL,WEVOSIL 22005 FLA,WEVOSIL 26020 FL,WEVOPUR 60515 FL/40,WEVOPOX 1003/07,WEVOPUR 895,WEVOPUR PD 445,WEVONAT 507 L,WEVODUR 1003/07,WEVOSIL 20201,WEVOSIL 27015 FL,WEVONAT 512 FL,WEVOPUR PD 52,WEVOSIL 26020 FLB,WEVOSIL 26020 FLA,WEVONAT 403 FL,WEVONAT 78901,WEVONAT 507,WEVONAT 7210 FL,WEVONAT PD 79952,WEVONAT 900,WEVOPUR 56005 FL,WEVOPUR 68389 FL,WEVOSIL 22005 FLB,WEVOPOX 5008,WEVOPUR 900,WEVOPUR PD 79952,WEVONAT 56093 FL,WEVONAT 300,WEVOPOX 5001,WEVONAT 385,WEVOPUR 403 FL,WEVOPUR 512 FL,WEVOPUR 300,WEVOPUR 78901,WEVOSIL 22002 FLB,WEVOPUR 385,WEVONAT PD 52,WEVOSIL 22002 FLA,WEVONAT 300 RE,WEVOPOX 36001 FL,WEVODUR 2513,WEVOPUR 56992,WEVONAT 56992,WEVOSIL 22006 FLB,WEVOSIL 22006 FLA,WEVODUR 34020,WEVONAT PD 445,WEVOSIL 28002B,WEVOSIL 28002A,WEVONAT 68389 FL,WEVOSIL 22005 FL,WEVONAT 56005 FL,WEVOPUR 507,WEVOSIL 20201B,WEVOSIL 20201A,WEVOPUR 67210 FL,WEVONAT 67210FL,WEVONAT 895,WEVOPOX 34020,WEVOSIL 26009 FLA,WEVODUR 36001 FL,WEVOPUR 7210 FL,WEVONAT 9251 FL

Wevo Potting and Sealing Compounds Pass the Endurance Test, Protected Redox Flow Batteries From the Corrosive Electrolyte

Redox flow batteries are elaborately constructed wet-cell batteries in which electrolytes, often based on vanadium, are circulated by means of pumps. The technology is seen as having great potential as a storage system for renewable energy from solar photovoltaic and wind farms or rooftop systems. However, the design of the battery stacks has been a real challenge so far as the aggressive electrolytes may cause stress on the materials.

Wevo(威孚)WEVOPUR透明聚氨酯产品选型指南

描述- Wevo are a leading specialist in custom casting/potting solutions as well as adhesives and sealants based on polyurethane, epoxy and silicone. More than 75 years of experience in development and applications go into each and every one of our products. The outcome: optimum solutions for reliable and safe components.

型号- 356,1223,1211,1222,50001,1230,1240,1250,360

HYDROGEN TECHNOLOGY

型号- WEVOSIL 28002,WEVOSIL 28001,WEVOSIL 26009 FL,WEVOPUR 78901/40,WEVOPOX 32702,WEVONAT 507,WEVOSIL 22006 FL,WEVOPUR VP 408,WEVOSIL 22002 FL,WEVONAT 900,WEVONAT 600,WEVOPUR 56005 FL,WEVOPUR 68389 FL,WEVOPOX 2513,WEVODUR 5007,WEVODUR 5008,WEVONAT 9015,WEVONAT 385,WEVOPUR 512 FL,WEVODUR 5001,WEVONAT 300 RE,WEVOPOX 36001 FL,WEVOPUR 60416 FL,WEVOSIL 26010 FL,WEVOSIL 22005 FL,WEVOPUR 79954/15,WEVOPOX 30010,WEVOPUR 67210 FL,WEVOPOX 34020,WEVOPUR 79086 T,WEVOPUR 895,WEVODUR 1003/07,WEVOPUR 79086,WEVOSIL 27015 FL

CUSTOMISED SILICONE SOLUTIONS

型号- WEVOSIL 28002,WEVOSIL 20201/60,WEVOSIL 20202/60,WEVOSIL 28001,WEVOSIL 26010 FL,WEVOSIL 22007 FL,WEVOSIL 26001 FL,WEVOSIL 22006 FL,WEVOSIL 22005 FL,WEVOSIL 27001 FL,WEVOSIL 22002 FL,WEVOSIL 26020 FL,WEVOSIL 20405,WEVOSIL 22008 FL,20405 FL,WEVOSIL 22102 FL,WEVOSIL 20001,WEVOSIL 22004,WEVOSIL 20200,WEVOSIL 20002,WEVOSIL 27015 FL

Wevo Develops Liquid Battery Adhesive Systems for High-performance EVs

WEVO-CHEMIE GmbH has therefore developed liquid adhesive systems that offer better surface wetting and can also be used as structural adhesives. In addition to optimized heat dissipation, these customizable polyurethanes also open up new possibilities in the design process.

电子商城

登录 | 立即注册

提交评论