Crocus TMR Sensors with Higher Sensitivity, Better Linearity and Less Temperature Sensitivity Are Becoming More Popular in EV BDUs

As EV adoption continues to outpace even the most optimistic projections, the focus has been on the range, efficiency – and increasingly, the safety – of batteries. Today’s requirement is 24/7 monitoring of the vehicle’s current, voltage, and temperature – all in a 100% safe design.

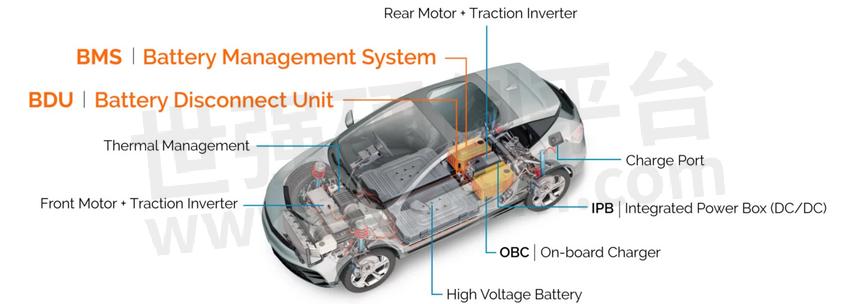

At the core of the safety technology is the Battery Management System which uses a Battery Disconnect Unit (BDU) to connect the battery to the vehicle’s high-voltage powertrain and charging systems.

The BDU identifies overcurrent and short circuits and automatically disconnects the battery, preventing the flow of electricity to damaged components, and reducing the risk of electric shock or fire.

When performing maintenance or repairs on an EV, technicians need to ensure that the high-voltage battery is mechanically disconnected to prevent any risk of electric shock or accidents. The BDU facilitates this disconnection. In addition, in some cases, the BDU acts as an anti-theft feature, making it challenging for potential thieves to start or operate the vehicle.

EV High Voltage Components

The Importance of Current Sensing in BDUs

As electric vehicle technology evolves and safety standards continue to improve, some advanced electric vehicles are incorporating additional safety features, including pyro fuses or other similar devices.

According to Eaton, a BDU Manufacturer, “Current EVs rely on one of three traditional BDU configurations – fuse and contactor, pyro fuse and contactor, or fuse, pyro fuse and contactor – all used together in a single BDU.”

At the core of BDU architectures are current sensors. Current sensors provide real-time monitoring of the electrical current flowing between the battery and the electrical system. By continuously monitoring the current, the BDU can detect abnormal or excessive current. In the event of a short circuit or other electrical malfunction, the current sensor triggers the BDU to disconnect the battery immediately, preventing potential hazards such as fires or electrical shock.

By measuring the current during charging and discharging cycles, the BDU can ensure that the battery operates within safe limits and prevents overcharging or over-discharging. This helps to extend the battery’s lifespan and maintain its performance over time.

In addition, EVs rely on sophisticated energy management systems to maximize their range. Current sensors in the BDU can contribute to this effort by providing data on the battery’s energy consumption and efficiency. The vehicle’s onboard systems use this information to optimize power usage, allowing the vehicle to travel longer distances on a single charge.

Current Sensing Systems

Shunt current sensors have been historically employed in BDUs due to their simplicity, reliability, and cost-effectiveness. They measure current by monitoring the voltage drop across a resistor placed in series with the current path. The voltage drop is directly proportional to the current flowing through the shunt, allowing for accurate current measurements.

However, EV technology is quickly evolving, and manufacturers are exploring new sensor technologies, most notably, Tunnel Magneto-Resistance (TMR) to further enhance safety, efficiency, and overall performance.

There are multiple benefits to TMR sensors in BDUs

Fast Response

TMR sensors quickly detect changes in the magnetic field generated by the current passing through a conductor. This allows the BDU to rapidly respond to sudden increases in current levels, such as those caused by a short circuit or a component failure. The fast response time enables the BDU to initiate battery disconnection promptly.

Enhanced Safety

TMR sensors can be used in combination with a shunt current sensor to achieve high sensitivity and accuracy. The fast response time of TMR sensors, when complemented by the high accuracy of shunt sensors, optimizes for safety. This proactive approach allows the BDU to meet the requirements for achieving high ASIL ratings.

Non-Intrusive

Unlike shunt, TMR sensors do not require a physical connection in the current path. Instead, they measure the magnetic field generated by the current passing through a conductor. This non-contact sensing method simplifies integration into the BDU and reduces potential issues associated with electrical connections and resistive losses.

Reduced Power Consumption

TMR sensors have lower power consumption compared to shunts, important for energy efficiency in vehicle range and battery life.

High Accuracy and Linearity

TMR’s high level of precision is essential for BDUs to accurately detect abnormal currents and trigger disconnection.

Insensitivity to Thermal Effects

Shunt current sensors can be affected by self-heating or ambient temperature variations. TMR’s reduced thermal influence ensures more consistent and reliable current measurements.

Design Flexibility

TMR sensors are available in multiple form factors and configurations, allowing for design flexibility in the BDU. They can be tailored to specific space constraints and environmental considerations, making them suitable for a wide range of EV applications.

Crocus TMR Sensors

For all of these reasons, TMR sensors are superior performers in EV BDUs. Nowhere is this superiority more evident than in the Crocus TMR CT45x contactless sensor family and the new CT405x, with a total output error of less than ±1.0% full-scale (%FS) over the full temperature range. CT45x features a 300ns response time, so it quickly responds to changes in current. Finally, both sensor families have ultra-low noise of 9.0 mARMS and low power consumption of <10mA.

Suncall Corporation, an auto parts manufacturer, is releasing a new lineup of electric vehicle products based on a magnetic sensor built around an integrated sensor from Crocus. This new current sensor achieves a high accuracy of 1.0% or less over the entire temperature range and a low power consumption of 6mA or less, making it more efficient than conventional products.

There’s a reason carmakers are increasingly turning to Crocus TMR sensors for BDUs. This combination of higher sensitivity, better linearity, less temperature sensitivity, and lower power consumption is unbeatable, especially when you consider they are isolated, small, lightweight, and less expensive than legacy current sensors.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由玄子转载自Crocus Technology News,原文标题为:Keeping EVs Safe,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Crocus’ XtremeSense® TMR CT81xx Sensors: a Combination of High Sensitivity, Low Power and Small Footprint for Medical Wearables Applications

Crocus’ XtremeSense® TMR CT81xx series of sensors are ideal for battery-operated medical wearable devices. The high sensitivity of the XtremeSense® TMR sensor enables the use of smaller or lower-cost magnetics while drawing very low supply current (as low as 110 nA). XtremeSense® TMR delivers this sensitivity in a small footprint and at the lowest power consumption on the market.

Crocus Technology‘s CT430 TMR isolated current sensor Reference Design with Digital Output Simplifies Implementation

Crocus Technology announced the release of a high accuracy energy metering solution with isolated current sensing and digital output. The key to precise power measurements is the CT430 current sensor which provides better than 1% current measurement accuracy over the -40℃ to +125℃ operating range.

Crocus TMR Sensors Offer High Magnetic Sensitivity and Low Power Consumption for Smart Lock Systems

Today, smart lock systems are moving to TMR sensors, which have the decided advantage of offering both extremely high magnetic sensitivity and less susceptibility to temperature change. Smart locks employ Crocus TMR sensors, with high sensitivity, longer battery life, and low power consumption.

Suncall Corporation Taps Crocus Technologies TMR Sensor Technology to Develop Advanced Sensors for EV Industry

Suncall’s collaboration with Crocus is a significant milestone in the development of the magnetic current sensor. By implementing TMR for current detection applications in devices with high currents, Suncall is breaking new ground in the industry, paving the way for further innovation and growth.

Only TMR Current Sensors Can Enable Efficient Industrial and Automotive Applications

Today, a wide variety of industrial and automotive applications are demanding higher efficiency which impacts many design decisions including the current sensing requirements. The demands are so dramatic that it may be that existing magnetic-based solutions will be obsolete by 2030. These applications demand wide band gap (WBG) power devices pushing the performance requirements for current sensing.

电流传感器–CH1S01xB规格书

描述- 该资料主要介绍了CH1S01xB电流传感器在电动汽车(EV)中的应用及其优势。该传感器利用开环霍尔效应技术,提供双通道输出信号,具有高精度、低热漂移和隔离特性,适用于电池管理系统、混合动力车、电动汽车和商用车辆等领域。

型号- CH1S01XB

MVA封装中的MLX91209霍尔电流传感器IC

描述- MLX91209是一款基于平面霍尔技术的单片可编程霍尔传感器IC,适用于电流测量。该产品具有高速度、可编程线性传输特性,广泛应用于逆变器应用中的HEV和EV BLDC电机电流监测。其主要特点包括:可编程高速电流传感器、可选模拟比率输出、宽频带(直流至200kHz)、短响应时间、过流检测电路、无铅组件、符合RoHS标准、汽车级认证。

型号- MLX91209LVA-CAA-003,MLX91209,MLX91209LVA-CAA-001-RE,MLX91209LVA-CAA-002-RE,MLX91209LVA-CAA-000-RE,MLX91209LVA-CAA-003-RE

电动汽车充电解决方案电动汽车基础设施

型号- SE-704,SCR,L75QS,TMOV,59045,WPB,SPF,LVR,EV1K,WPC,L50QS,RCM01-02,DSB,DSA,SE-CS30,DLAXX,RCM14-03,SP1026,CPC1981Y,RCM14-04,DST,HCD,HCC,RCM20-01,SFPJ,PSR,DCNXX,XGD10402,526,606,IX4351NE,607,PXXX0FNL,RCM14-01,N-SERIES,DSEPXX,DHG,LSIC,59060,LVSP,PPG,SM712,CG3,CG2,LOC110ST,CPC1006NTR,DSEI,215,IXD_6XX,DMA,SPD TYPE 2,CPC1390GRTR,SSA,HE3600,L5QQS,JLLN,SMPD,443E,JLLS,SM24CANX,SE-CS3Q,CPC1017,USW,AQ24CAN,505,LPSM,828,DSIXX

CH1S01xB电流传感器规格书

描述- 该资料为Littelfuse公司生产的CH1S01xB系列电流传感器的预览数据手册。该传感器采用开环霍尔效应技术,提供双通道、比例输出信号,与内部C型磁芯集中器产生的磁通密度成正比。资料详细介绍了产品的特性、应用领域、机械和电气特性,以及性能参数。

型号- CH1S01XB-D0105A-Q,CH1S01XB,CH1B01XB-D0108A-Q,CH1B01XB-D0110A-Q,CH1B01XB-D0111A-Q,CH1S011B,CH1S01XB-SXXYYA-Q,CH1S010B

Melexis Launches the MLX91230 Current Sensors Which Brings 0.5% Accuracy in a Compact Design

Melexis launched the MLX91230, the first product of its third generation of current sensors. This digital solution brings 0.5% accuracy at an affordable price in a compact design. The MLX91230 is perfect for EV battery management and power distribution systems.

EV/HV感应元件

描述- PREMO公司提供创新的感应元件,专注于混合动力和电动汽车领域。产品包括3D功率、OBC变压器、隔离DCDC、Mild-Hybrid DCDC逆变器、辅助和信号变压器等。产品特点包括高功率密度、低损耗、宽工作温度范围和符合AEC-Q200标准。此外,公司还提供多种型号的共模电感、谐振电感和NPT系列电感。

型号- WC-RX-002-90K,NPT SERIES,PLC-001,DCDC214-002,3DP-3KWHVHV-002,CS35A,3DP-3KWHVHV-001,HPC SERIES,PFC SERIES,GDAU-001,GDAU-003,GDAU-002

电动汽车的位置、速度和电流传感器

描述- 本文介绍了多种传感器解决方案,包括电机的转子位置传感器、电流传感器和用于传动系统的位置传感器。这些传感器适用于电动汽车、电池管理系统和逆变器等领域。文中详细描述了不同类型传感器的技术特点、应用场景和性能优势,如高精度、快速响应、抗干扰能力强等。

Melexis Newly Produced MLX91230 and the MLX91231 Hall Sensors for EV battery current sensing

“The new MLX91230/MLX91231 current sensor family is meeting customers’ demands for a versatile modular BMS development strategy. It allows them to achieve much more with fewer engineering resources,” states Bruno Boury, product line manager at Melexis. “

适用于电动汽车充电应用的SafeBlue®系列剩余电流传感器

型号- SB200,MB-67X,SB300,SB300 SERIES,SB200 SERIES,MB-67X SERIES,SAFEBLUE® SERIES

MLX91209 Hall Current Sensor IC in VA package

描述- MLX91209是一款基于平面霍尔技术的单芯片可编程霍尔传感器IC,适用于电流测量。该产品具有高速度、可编程线性传输特性,广泛应用于逆变器应用中的HEV和EV BLDC电机电流监测。

型号- MLX91209LVA-CAA-003,MLX91209,MLX91209LVA-CAA-001-RE,MLX91209LVA-CAA-002-RE,MLX91209LVA-CAA-000-RE,MLX91209LVA-CAA-003-RE

电子商城

品牌:MELEXIS

品类:Integrated Current Sensor IC

价格:¥15.3811

现货: 50,898

品牌:MELEXIS

品类:Integrated Current Sensor IC

价格:¥14.2165

现货: 24,580

品牌:MELEXIS

品类:Integrated Current Sensor IC

价格:¥15.3811

现货: 10,200

品牌:MELEXIS

品类:High Speed Current Sensor IC

价格:¥13.9577

现货: 3,822

品牌:MELEXIS

品类:Integrated Current Sensor IC

价格:¥15.3811

现货: 2,995

品牌:MELEXIS

品类:Integrated Current Sensor IC

价格:¥15.3811

现货: 2,927

现货市场

服务

可定制烧结NdFeB磁铁的剩磁最高1.45T,易加工成各种尺寸。充磁方向:径向充磁、轴向充磁、辐射充磁等;镀层:Zn、Sn、Ni、电泳等,最高工作温度220℃。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论