IoT and IIoT: Flash Storage, Sensors and Actuators in Cloud/Edge

Flash Storage in the IoT/IIoT Era

The Internet of Things (IoT) is not merely a buzzword. It is a phenomenon that is already permeating almost every area of our lives, changing the way we live and interact not only with one another but also with everything around us.

Stand-alone objects that were once isolated are now increasingly becoming interconnected in this expansive digital labyrinth. Researches estimate that in less than 2 years, billions of objects will be connected to one another.

IoT Enablers

These important components enable the IoT, allowing objects to connect to one another through networks using various wireless and/or wired technologies.

Figure 1. Sensors, Processors and Actuators allow IoT devices to gather, process and respond to data.

Figure 1. Sensors, Processors and Actuators allow IoT devices to gather, process and respond to data.

Common sensors include those that "sense" or detect temperature, presence/proximity, pressure, sound, water quality, humidity, chemicals, gas and smoke. Data from sensors are then sent to a processor or data center via wired/wireless networks or gateways for analysis and processing. A Processor analyzes the data, and then sends a command to an Actuator. The Actuator receives the command from the Processor and transforms the data into useful output.

Here is a simple example of a parking assistance system showing how these components work together

Ultrasonic sensors detect objects in the front and rear bumpers of your car while you attempt to park. The Processor analyzes and interprets the data (space is not enough or obstruction is present). It then alerts and sends a command to an Actuator. The Actuator then gives off audible warnings with continuous beeps.

Meantime, ground sensors detect which spaces are unoccupied. They send the information to the network where the information is processed, and a real-time map of the parking lot is updated. You may view options using an app on your mobile phone or the IoT-enabled car head unit, and proceed to park in a vacant space.

IoT vs. IIoT

IoT has been increasingly impacting practically everything from common everyday activities to businesses of every size and scale. Everything will be affected by the IoT. The application of IoT technologies in manufacturing and other industries is referred to as Industrial Internet of Things (IIoT) or Industry 4.0. It involves the use of smart machines, sensors, big data technologies and machine-to-machine (M2M) communication to gather, analyze and relay data that can detect inefficiencies as well as process or product defects to improve production methods and save businesses time and money.

Although IoT and IIoT are commonly founded on human-object and object-object interaction, they differ greatly in their requirements. IIoT devices are usually deployed in rough environments with varying ranges of temperature and environmental challenges. Additionally, various usage cases spanning diverse workload scenarios mean that IIoT solutions have to be suited to specific applications, as "one size does not fit all" and faster or bigger is not always better.

In the Cloud or At the Edge?

From self-driving cars to oil rigs, airplanes, factory robots, and medical equipment, IIoT use cases generate a steady stream of data. Asset tracking and monitoring, manufacturing automation, predictive maintenance, road safety, smart homes/buildings, and health care are just among the myriad of applications that capture, store, process and transmit data.

Data collected, analyzed and retrieved are usually of critical importance and can even be worth more than the devices that store them. Data corruption or loss, as well as wrong analysis and inaccessibility can disrupt operations and cause disastrous results. As such, it is crucial that IIoT storage solutions be absolutely reliable, durable and secure.

A few years ago, it was commonly thought that everything was going to the cloud. Today, however, the IIoT revolution is happening, not in the cloud but at the edge.

Cloud storage, in simplest terms, refers to storing and accessing data over the Internet instead of the storage device on your computer. The cloud offers many advantages, such as the ability to retrieve files from any device in any location with available Internet connection. Multiple users can also access the same files at the same time as long as they have the necessary passkey.

IIoT applications that generate hundreds of terabytes and petabytes of data by the hour, however, may be unable to transmit such huge amounts of data over the Internet in real time. It is not only costly, but could cause network congestion and slow the connection due to bandwidth concerns. Some critical applications require real-time processing and retrieval, and relying on the network or the Internet could cause delays that will render the data irrelevant or even result in undue risks to life or property.

Due to the need for faster, real-time processing especially for many IIoT applications, edge computing has become a more viable alternative. Simply put, edge computing is storing, analyzing and processing critical data at or closer to the data source rather than in a centralized or cloud-based location. Edge computing offloads the network, cuts transmission costs, and optimizes the data collected for immediate insight or swift response.

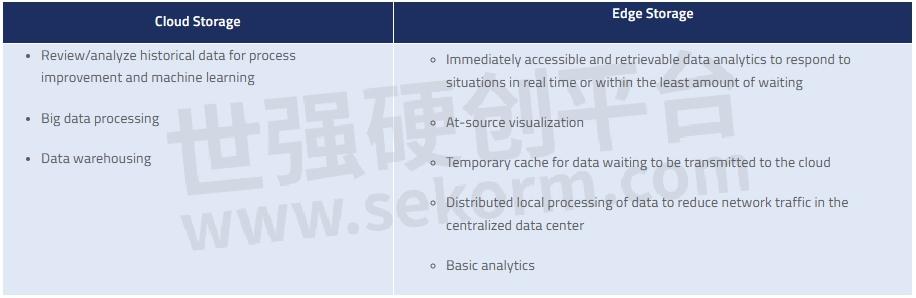

Considering their pros and cons, the table below shows respective ideal use cases for cloud and edge storage:

Table 1. Ideal use cases for cloud and edge storage

Flash Storage Challenges for IoT/IIoT

Flash storage devices are used in cloud and edge computing and industries typically use a combination of both storage solutions. Depending on the types of data being collected, analyzed and processed and the immediacy of analytics needed, systems will have to be designed to respond smartly, whether it is delivering data at the fastest speed or analyzing vast amounts of historical data.

Frequent Writes: Impact on Endurance

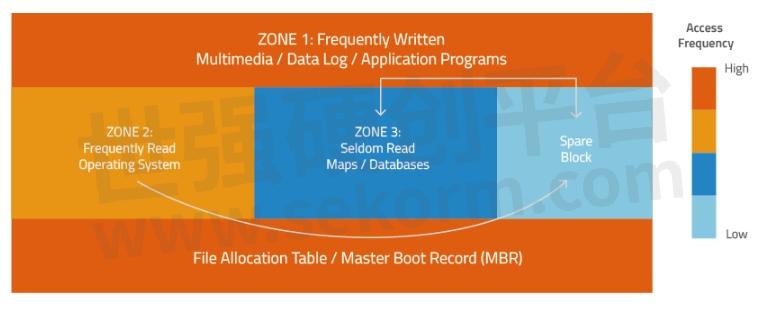

IoT/IIoT-generated data is broadly categorized into two types. Large files like videos and images such as those from surveillance cameras are usually accessed sequentially; meaning, the files are read one after another, from the beginning in the order they were stored. Small files, which are typically in bytes and just less than 1 page in size such as log files captured from sensors or recorders can be very numerous and are typically read/written randomly, or in no particular order.

Considering the nature of flash memory, which requires data to be programmed or written to at the page level and deleted at the block level, frequent and random writing of small data files will result in high write amplification. Since flash memory can be written to for a finite number of times, frequent writes can decrease endurance faster.

ATP Solutions

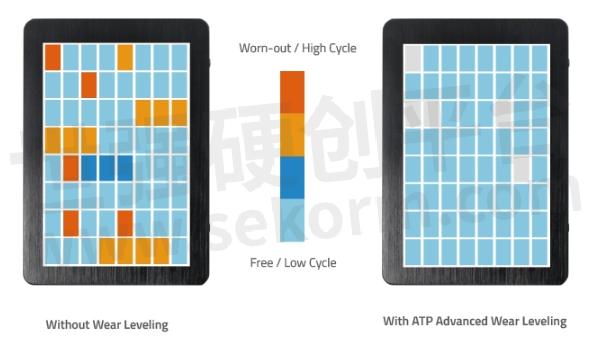

To prevent the fast decline of flash memory endurance resulting from frequent, small-file write applications, ATP Electronics flash products use Advanced Wear Leveling, which evens out the erase count of all blocks to effectively "wear level" the entire flash storage device to extend the life expectancy. The ATP SD Life Monitor / S.M.A.R.T. provides tools for providing early warning to prevent data wear out and spare block exhaustion. Using a friendly interface for monitoring various indicators of drive reliability and other attributes, users can plan way ahead and replace the flash storage device before it wears out, saving data and precious financial resources.

Figure 2. ATP Advanced Wear Leveling manages the reads and writes across blocks to optimize the overall life expectancy of a flash product.

Frequent and Seldom Reads: Read Disturb and Data Retention Issues

Storage for IoT/IIoT is usually pre-loaded with data requiring high reliability under frequent or continuous reading (e.g., operation system) and long-term data retention (e.g., application programs).

A memory block containing data that are frequently read but not overwritten, moved or deleted can cause threshold voltages of unread cells in the same block to shift to different logical states. This phenomenon, called "read disturb error," affects surrounding memory cells that are seldom accessed, and will cause possible data loss if the errors exceed the error correcting code (ECC) threshold.

Constant operation under wide temperature ranges can affect the ability of a memory cell to hold charge, resulting in data retention concerns that could affect the integrity of stored data and the operation of applications.

ATP Solutions

To address read disturbance and data retention concerns, ATP flash storage products feature advanced NAND flash controller mechanisms like AutoRefresh and Dynamic Data Refresh. The flash controller counts the number of reads to a block since the last erase. If the memory cells have been read for a certain number of times and the read count has reached the predefined threshold value (the maximum number of errors that can be corrected by the ECC), ATP AutoRefresh automatically backs up data to new blocks to prevent data loss and corruption. For seldom-accessed areas, ATP Dynamic Data Refresh runs automatically in the background, sequentially scanning the user area flag record without affecting the read/write operation to reduce the risk of read disturbance and sustain data integrity.

Figure 3. ATP AutoRefresh moves data to a healthy block before the error bits in a block reach or exceed the preset threshold value. This prevents the controller from reading blocks with too many error bits to avert read disturb and data corruption.

Extreme Temperatures and Harsh Operating Environments: Reliability and Durability Concerns

IoT hardware in industrial applications typically operates in harsh conditions including, but not limited to extreme temperatures, humidity, pressure, vibration, shock, ambient radiation, dust, sand, power supply instability, and long-term reliability across all such conditions is highly critical.

ATP Solutions

To ensure extended reliability in harsh operating conditions, ATP conducts comprehensive, in-depth testing from the NAND IC level through the mass production level. Rigorous power cycling tests ensure data integrity under real-world power supply conditions. Industrial temperature-rated NAND flash products undergo testing within wide temperature operating ranges from -40°C to 85°C to make sure they can withstand and perform reliably under extreme temperatures. Select flash products feature temperature sensors and dynamic thermal throttling mechanism to maintain cool operation without drastic drops in performance.

Conclusion

For data in the cloud or at the edge, ATP offers industrial-grade flash storage solutions that meet stringent endurance, retention and reliability requirements of IoT/IIoT. As a member of the Intel® Internet of Things Solutions Alliance, ATP is a qualified IoT/IIoT hardware manufacturer offering memory and storage solutions designed to meet the growing needs and challenges of a connected world. For more information on IoT/IIoT-ready ATP products, visit the ATP website or contact an ATP Distributor/Representative in your area.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由涂抹转载自ATP Blogs,原文标题为:IoT and IIoT: Flash Storage, Sensors and Actuators in Cloud/Edge,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

【经验】什么是NAND闪存的检错校正,LDPC,BCH,Reed-Solomon算法?

本文介绍了NAND闪存存储设备中坏块以及ATP NAND闪存设备采用先进的错误检测和纠正技术。

【经验】过度配置如何提高基于NAND的ATP SSD的耐用性和性能介绍

过度配置(overprovisioning, OP)为固态硬盘(SSD)的垃圾收集过程提供了额外的空间,有助于提高性能,并增加其耐久性,从而有助于延长驱动器寿命。本文ATP ELECTRONICS深入介绍OP及其大小如何影响写入(TBW),以及SSD的随机写入性能。

How Over-provisioning Improves NAND-based ATP SSDs’Endurance and Performance

Over-provisioning (OP) provides additional space for garbage collection process of solid-state drives (SSDs), aids in improving the performance, and increases their endurance, hence contributing to extended drive life. This article ATP provides an in-depth view of OP and how its size affects the terabytes written (TBW), along with random write performance of SSDs.

ATP e.MMC集成数据刷新技术,确保数据在使用寿命期间的可靠性和准确性,对2D NAND e.MMC提供长期供货支持

ATP Electronics的e.MMC解决方案集成了数据刷新技术,专为空间受限的系统而设计和制造,可确保数据在整个使用寿命期间的可靠性和准确性。为了满足对基于2D NAND闪存的e.MMC的持续需求,ATP Electronics致力于长期向客户提供低容量e.MMC,产品容量包括MLC 8GB/16GB,pSLC模式的4GB/8GB。

SMART(世迈科技)DuraFlash™闪存产品选型指南

目录- Company Portfolio/Products Applications Flash Storage Product Introduction 2.5” SATA M.2 SATA mSATA Slim SATA M.2 PCIe NVMe U.2 PCIe NVMe EDSFF / U.2 PCIe NVMe (Enterprise and Data Center SSDs) BGA eMMC 5.1 Memory Cards CF Cards/CFast Cards eUSB Flash Drives/USB Flash Drives RUGGED SSD LINE-UP

型号- N200,R800,RU350,SP2800,S5E,RU150,T5E,M4,R800V,BGAE440,S1800,BGAE240,RD130M,ME2,M1HC,H9 CF,M1400,HU250E,M4P,T5EN,T5PFL,RU150E,N200V,T5PF,RD230M,MDC7000,XL+,RD230

Alliance Memory Expands Serial NOR Flash Portfolio With New High-Density Devices, Offering Increased Storage and Performance for a Wide Range of Applications

Alliance Memory today announced the expansion of its Serial NOR Flash product line with the introduction of three new 3.3V families with density of 128Mb, 256Mb, and 512Mb. The devices are now available for embedded applications that require reliable, high-performance code storage and execution.

复旦微电子(FMSH)MCU/RFID读写器/读卡器IC/串行EEPROM芯片/SPI NOR Flash/SPI NAND Flash闪存选型指南(英文)

描述- Founded in July 1998, Shanghai Fudan Microelectronics Group Co., Ltd (hereinafter:FMSH) was jointly initiated by Fudan University's State Key Laboratory of Application-Specific Integrated Circuits and Systems and Shanghai Commercial Investment Corporation.

型号- FM3312,FM33LC045N,FM3313,FM25LG,FM33LC025N,FM3316,FM15160,FM25FXX SERIES,FM25LQ,FM33LG0XX SERIES,FM25FXX,FM25Q SERIES,FM25LG SERIES,FM33LC046N,FM33LC026N,FM33L015,FM33L013,FM33G042,FM33L012,FM33G043,FM24CXX,FM38025T,FM33LG023,FM17XX,FM33LG022,FM15XX,FM33LG028,FM3312T,FM33LG025,FM25QXX,FM17XX SERIES,FM33LG026,FM33G0XX,FM33G045,FM25Q,FM33G046,FM33L016,FM33G048,FM33A068,FM33L022,FM33LC023N,FM25F,FM17520,FM33L026,FM33L025,FM33LC043N,FM33L023,FM17522,FM3316 SERIES,FM33A0XX SERIES,FM3313 SERIES,FM3312 SERIES,FM33LC046U,FM33A0410,FM33A0610,FM15XX SERIES,FM151M,FM25F SERIES,FM24CXX SERIES,FM320X,FM17550,FM33LG043,FM33LG042,FM33LG045,FM33LG0XX,FM33A045,FM33A042,FM320X SERIES,FM33LG046,FM25QXX SERIES,FM33LC0XX,FM33G0XX SERIES,FM33LG048,FM33LC0XX SERIES,FM33G022,FM33G023,FM33G025,FM33G026,FM33A048,FM33G028,FM33LC043U

ATP Unveils Industry’s Highest-Endurance Industrial SSD with 125℃ Operating Temperature Range

ATP Electronics proudly announces the launch of the N751Pi PCIe®Gen4 NVMe M.2 2280 SSDs, which set a new industry standard with unmatched endurance among industrial solid state drives (SSDs) configured with pseudo single-level cell (pSLC) NAND.

ATP推出业界最高擦写寿命的工业级固态硬盘(SSD),具有出色的耐久性和在极端温度下工作的能力

ATP推出N751Pi系列PCIe Gen4 NVMe M.2 2280 SSD,该SSD在配置了pSLC NAND的工业级固态硬盘(SSD)中具有出色的耐久性和在极端温度下工作的能力,是恶劣环境、恶劣条件和高负荷工作负载下关键任务和写入密集型应用的理想选择。

NVMe固态硬盘外形标准介绍

10 年前推出的NVMe规范将NAND闪存存储的速度和性能提升到了前所未有的水平,与串行ATA 6 Gbps(也称为 SATA III)相比,吞吐量提高了6倍,延迟却降低了7倍。支持NVMe协议的NAND闪存有几种形式,使用不同的接口,ATP将在本文中讨论。

ATP(华腾国际)DRAM存储模块和NAND闪存产品选型指南(英文)

目录- Company Profile Segment Challenges and Solutions Thermal Solutions Endurance Solutions Security Solutions CFexpress & USB 3.0 Value Line SSDs DDR5 DRAM SOLUTIONS FLASH SOLUTIONS Flash Products Naming Rule Solutions & Technologies Flash Technology Overview table Complete Flash Spec Overview & Product Dimensions

型号- A750PI,E650SC SERIES,S600SC,B800PI,S750 SERIES,S600SI,S600SCA,E750PC SERIES,B600SC,N700PC,S700SC,E650SC,A750 SERIES,E600VC,S800PI,A750PI SERIES,I800PI,A600VC,A650SI,A650SC,N700 SERIES,S650SI,N750,N750PI,A800PI,A700PI,N700SI,N650 SERIES,E600SAA,N700SC,A750,N600SC,A600VC SERIES,E600SA,E650SI,E650SI SERIES,N750 SERIES,E700PIA,TR-03153,N600SI,S650,S650SC,E700PAA,N650SIA,E600SI,B600SC SERIES,S750SC,S600SIA,I700SC,N650SI,N600VI,E600SIA,E750PI,N650SC,N750PI SERIES,N600VC,I600SC,E750PC,S700PI,A650 SERIES,N650,N600 SERIES,N600VC SERIES,S650 SERIES,A650,AES-256,E700PI,A600SI,E750PI SERIES,N700PI,E700PA,S750,S750PI,E700PC,A600SC

ATP(华腾国际)固态硬盘选型指南

描述- Since 1991, we have consistently distinguished ourselves as one of the world’s leading original equipment manufacturers (OEM) of high-performance, high-quality and high-endurance NAND flash products and DRAM modules.

型号- A750PI,S600SC,B800PI,S750 SERIES,S600SI,B600SC,N700PC,A750 SERIES,E650SC,N601,N651SI,A600VI,S800PI,E600VC,I800PI,A600VC,A650SI,A650SC,N651SC,N750,S650SI,A600VI SERIES,N750PI,N651SIE,A800PI,N601 SERIES,A700PI,N651SIA,N650 SERIES,E600SAA,A750,A600VC SERIES,N600SC,E600SA,E650SI,N750 SERIES,E700PIA,N600SI,S650,S650SC,N651SI SERIES,E700PAA,B600SC SERIES,E600SI,N600VI SERIES,I700SC,N600VI,N650SI,E600SIA,N650SC,E750PI,N600VC,I600SC,E750PC,N651,S700PI,A650 SERIES,N650,N751PI,S700PC,N600VC SERIES,N651 SERIES,S650 SERIES,A650,N601SC,S750PC,E700PI,A600SI,N700PI,E700PA,S750,S750PI,E700PC,N651SCE,A600SC

ATP(华腾国际)DRAM存储模块和NAND闪存产品选型指南(中文)

目录- 公司简介 细分市场挑战和解决方案 热管理解决方案 TSE闪存解决方案 DRAM解决方案 闪存解决方案 闪存解决方案-固态驱动器和模块 闪存解决方案-存储卡 闪存解决方案-托管NAND 闪存产品命名规则 闪存规范概述和产品尺寸

型号- A750PI,S600SC,N750PI系列,B800PI,S750 SERIES,S600SI,S600SCA,B600SC,N700PC,S700SC,N600,E650SC,E750,E750PC系列,E600VC,S800PI,I800PI,E750 SERIES,A600VC,A650SI,N600系列,A650SC,N700 SERIES,S650SI,N750,N750PI,A800PI,A700PI,N700SI,E600SAA,N700SC,A750,N600SC,A600VC SERIES,E600SA,E650SI,E700PIA,N600SI,S650,S650SC,E700PAA,N600VC系列,N650系列,N650SIA,N750系列,E600SI,S750系列,E650,N700,S750SC,S600SIA,I700SC,N650SI,N600VI,E650SI系列,E600SIA,E650SC系列,E750PI,N650SC,S650系列,N600VC,I600SC,E750PC,A600VC系列,A650系列,S700PI,N700系列,N650,N600 SERIES,N600VC SERIES,A750PI系列,S650 SERIES,A650,E700PI,E750PI系列,A600SI,N700PI,A750系列,E700PA,E650 SERIES,S750,S750PI,E700PC,A600SC

电子商城

现货市场

服务

可烧录MCU/MPU,EPROM,EEPROM,FLASH,Nand Flash, PLD/CPLD,SD Card,TF Card, CF Card,eMMC Card,eMMC,MoviNand, OneNand等各类型IC,IC封装:DIP/SDIP/SOP/MSOP/QSOP/SSOP/TSOP/TSSOP/PLCC/QFP/QFN/MLP/MLF/BGA/CSP/SOT/DFN.

最小起订量: 1 提交需求>

拥有IC烧录机20余款,100余台设备,可以烧录各种封装的IC;可烧录MCU、FLASH、EMMC、NAND FLASH、EPROM等各类型芯片,支持WIFI/BT模组PCBA烧录、测试。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论