Chroma 17010H Battery Reliability Test Solution for Lithium Batteries with Ultra-low DC Internal Resistance, Achieving 200% Pulse Current Output

Internal resistance is a key parameter that determines the power capability, energy efficiency, and heat generation of lithium-ion batteries. It is also an important indicator of the state of health (SoH) of the batteries, which affects the acceleration, fast charging, and cooling system design of electric vehicles (EVs). In addition, in order to avoid battery abuse and improve battery safety and service life, the Battery Management System (BMS) needs to establish an internal resistance model to accurately manage the power capability. Therefore, research on internal resistance and power capability plays an important role in developing next-generation battery cells and optimizing battery systems. However, as it has become a trend for manufacturers to adopt ultra-low DC internal resistance and enlarge single-cell designs as a means to improve the power density of electric vehicles, general equipment is increasingly unable to deliver the required test current of thousands of amperes, which usually leaves test engineers with a limited choice of expensive equipment.

Nowadays, battery internal resistance measurement technology is mainly divided into two types: 1) DC resistance is primarily determined by using pulse (step) current to measure the potential difference, which is then used to calculate the internal resistance value; 2) AC resistance is determined with electrochemical impedance spectroscopy (EIS) using disturbance spectrum technology. Due to the complex electrochemical properties of the battery, the DC resistance cannot be directly compared with the AC impedance. The two measurement techniques are complementary due to the difference in the analyses' time domains and are mostly selected according to the application conditions.

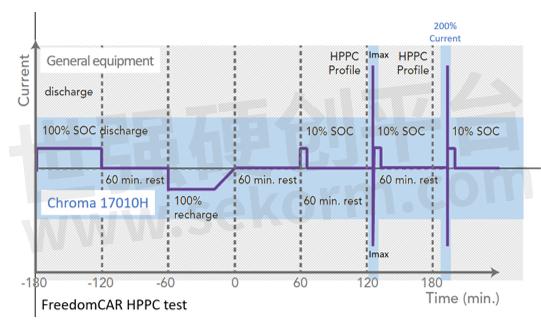

In terms of EV and energy storage system design, pulse current is often used to test DC internal resistance. In addition to the short test time, research has shown that current amplitude also affects the internal resistance of the battery and that the high-current pulse test more closely approximates real load applications. The internationally standard methods for pulse current test are the VDA current step method and the Hybrid Pulse Power Characterization (HPPC) test, with pulse widths between 100mS-30S.

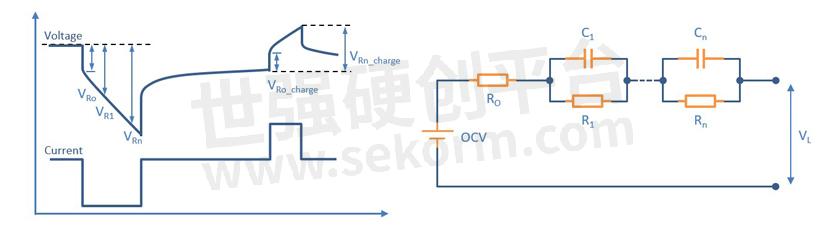

The voltage drops are impacted by various phenomena related to internal resistance, depending on their respective measurement timescales: ohmic resistance of the transient voltage drop, equivalent capacitance, and interface electric charge transfer resistance during the first few seconds of the voltage drop, and polarization resistance of slower response due to ion diffusion (Figure 1). The total resistance is calculated from the results of the pulse test. It should be noted that a greater pulse width may change the state of charge (SOC) and cause additional voltage drops leading to deviations in the internal resistance measurement. Conversely, a pulse amplitude that is too small will lead to a significant increase in measurement uncertainty. Measurement errors may also be caused by current/voltage measurement errors and temperature control errors.

(Figure 1) The relationship between DA pulse test voltage change and battery internal resistance equivalent circuit

During USABC HPPC tests, the internal resistance and power characteristics of the battery are calculated by subjecting battery cells to 10~30S of maximum pulse discharge and 10S of maximum pulse charge under different SOCs with the aim of measuring the change in electric potential. By this principle, if a 60Ah lithium battery cell needed to have its pulse working current (10C-rate) tested 10 times, it used to be necessary to purchase 600A charging and discharging equipment. But not anymore, because now CHROMA provides a 200% pulse current test solution!

The single channel current capacity of Chroma 17010H is 300A, which can be amplified with Super Mode to output 200% current (600A) within 30 seconds, especially suitable for pulse current performance testing. The new design focuses on battery applications and optimizes the power output mode, leading to a 50% reduced footprint and a 30% reduction in price (Figure 1).

Key to the high pulse current capability designed by Chroma is the power circuit's temperature control. First, the 17010H's high-conversion-efficiency energy recovery architecture greatly reduces the heating of components during charging and discharging. Second, it increases the operating current by optimizing power module integration and component selection. Finally, heat flow design is applied to achieve temperature control. As for measurement, a distributed high-precision current transformer structure that ensures current accuracy is supplemented with a cold and hot area circuit layout to reduce temperature drift, together forming an integrated battery test system that achieves 200% pulse current output.

(Figure 2) The benefit of 200% pulse current Mode

The key advantages of the Battery Reliability Test System Chroma 17010H:

High measurement reproducibility helps testers to save considerable time on trend judgment and characteristic analysis.

Zero-crossover and fast current response capabilities provide test results that closely correspond with real applications.

Multiple current range design improves the accuracy of small currents, with a minimum current range of 1:10 and suitable ranges for both high and low-rate performance tests.

Discharge energy recycling efficiency of 75% not only saves on operating power and decreases the waste heat from air conditioning, but also reduces laboratory power distribution requirements.

Independent Level 2 V. Protection function strengthens the safety of high current testing.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由玄子转载自CHROMA News,原文标题为:Are you looking for a test solution for lithium batteries with ultra-low DC internal resistance?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

CHROMA一站式电池芯充放电测试解决方案,为测试安全性加强把关

CHROMA 17010/17010H电池芯充放电测试系统多年来在世界各大知名电芯厂、车厂、储能系统厂中之所以获得采纳与肯定,除了在充放电量测性能上的高精准度、低输出噪声、以及软件和硬件多重安全保护以外,可弹性整合安全型环境箱的控制指令,基于安全管制矩阵构建一站式测试系统,发生测试危害时,让温箱与充放电设备透过讯号交联来即时限缩危害范围,协助客户安全地完成电池测试任务。

【应用】基于致茂锂电池芯17010H的锂电池测试解决方案,体积减小50%,比满功率设计方案直接降本30%

CHROMA锂电池芯17010H单通道电流能力300A,超级模式30秒内能输出电流200% (600A),此项新设计聚焦于电池脉冲电流应用进而优化功率输出模式,具有体积减小50%、相较满功率设计方案直接成本降低30%的优势。

Success Story : Provided Automated Electrical Testing Solution for the Incoming Quality Control of Lithium-ion Batteries for Space Application

Provided customer with a battery electrical test system that complies with NASA JSC EP-WI 37A specifications, has multiple safety protection mechanisms, and can easily switch between manual and automatic test modes.

Chroma携新型电驱动总成测试系统1210等产品重点亮相2024上海汽车测试及质量监控博览会

Chroma推出新型电驱动总成测试系统1210,应用在纯电动乘用或商用车与氢燃料电池混合等车型之动力系统,提供新能源汽车动力系统模拟测试,试验件涵盖电机、电机控制器、变速箱及电力驱动系统等。Chroma携一系列新热产品重点参展2024上海汽车测试及质量监控博览会。

How to Appraise Lithium Batteries for Electric Vehicles?

Chroma 17010 battery reliability test system with the advantages of fast current response, high precision, high efficiency and long-term stability can help testers complete complex test plans rapidly.

电池测试解决方案电池单元/电池模块/电池组

描述- Chroma ATE Inc.作为全球领先的自动化测试设备供应商,提供电池测试解决方案,包括电池单体、模块、包、管理系统(BMS)、车载充电器、直流转换器、电动汽车充电站(EVSE)、无线充电器和电气安全测试。公司提供全面的测试解决方案,涵盖电池生产线的自动化测试系统,包括形成、分级、预充电、OCV/ACIR站、DCIR站等测试设备,以及自动化堆垛起重机、输送带、物流控制系统、分组、分类和返工站等自动化设备。Chroma还提供电池实验室管理系统的解决方案,包括电池测试监控系统(BTMS)和电池实验室管理解决方案。此外,Chroma还提供电池模块/包维护自动化测试系统,以及电池功率HIL测试解决方案。

型号- 8630,19311 SERIES,17216M-6-12,17010H,17020,17040E,17000,17020E,8610,63200A,17040,19055-C,63200E SERIES,17208M-5-12C,63200A SERIES,17000 SERIES,17208M-6-30,17212M-6-100S,A170103,63200E,17216-6-6,A190362,17010,8700,19311,8720,62000D SERIES,62000H,19311-10,62000D,62000E,17091,17216M-10-6,17216-6-12,62000E SERIES,17010H_6-300S,62000H SERIES,11210,17010H_6-300,17010H_6-300U,19032-P,A112100,17208M-6-60,87001,17010H_6-300Z

17010H型电池可靠性测试系统

描述- Chroma 17010H电池可靠性测试系统是一款高精度充电放电测试设备,专为高性能和高电流测试设计。该系统适用于大型锂离子电池单元(LIB)、超级电容器(EDLC)和锂离子电容器的性能评估、寿命周期测试和产品选择。

型号- 17010H,17010H-6-300Z,MODEL 17010H,17010H-6-300,17010H-6-300S,17010H-6-300U

Chroma携创新电池测试解决方案亮相2024年CIBF展会

2024年CIBF展会(4/27~29)即将在美丽的山城——重庆盛大开幕!汇聚2200家行业内知名企业,交流行业信息,探讨电池技术发展方向。Chroma深耕电池行业多年,将携最新的电池测试相关解决方案参与此次盛会,愿与广大行业内先进一起学习交流。

8610 Battery Pack Integrated Testbed for Testing New Energy Vehicle Battery Systems and Subparts | Chroma

Chroma ATE launches the 8610 Battery Pack Integrated Testbed. The 8610 system integrated with Chroma’s 17040 Regenerative Battery Pack Test System can simulate the charging and discharging of battery pack using the power system under various driving conditions to increase the test reliability when testing a whole vehicle.On the part of communication, the 8610 testbed supports the common CAN, CAN FD, and LIN interfaces and is capable of loading CAN communication DBC files.

MODEL 17010 电池信赖性测试系统

描述- Chroma 17010电池可靠性测试系统是一款专为锂离子电池、电化学双电层电容和锂离子超级电容器设计的专业充电放电测试设备,适用于产品开发、性能评估、寿命验证与产品选型等用途。该系统具备高精度测量、快速电流响应、高效充放电、低发热等特点,支持多种国际测试标准。

型号- MODEL 17010,17216M-6-12,17010,17208M-5-12C,11805-20-10,17208M-6-30,17216M-10-6,17216-6-12,A172013,17212M-6-100S,A172014,A170103,17208M-6-60,A170105,17216-6-6,11805-10-20

【产品】Chroma新推可达4800A的电池芯倍率电流测试解决方案17010H,提升能源回收效率达75%

电池在储能应用方面肩负电力调节任务,大容量与倍率电流能力同样被要求,但大容量且高电流倍率的电池芯常受限于设备而无法进行完整的测试,Chroma推出全新的17010H电池信赖性测试系统,为您提供200%的脉冲输出能力与信道并联功能满足4800A以下的电池芯测试需求。

电池测试解决方案 电池芯/电池模组/电池包

描述- Chroma ATE Inc. 提供全面的电池测试解决方案,涵盖电池芯、电池模组、电池包等各个阶段。公司提供包括电池芯化成、分容、预充等测试系统,以及电池模组和电池包的充放电测试系统。此外,Chroma还提供电池管理系统(BMS)功能性测试系统、电池包生产线测试方案、电池模组和电池包维护保养测试系统等。公司产品广泛应用于电动汽车、储能系统等领域。

型号- 17040E,17000,17020E,8610,63200A,17040,17010系列,17212M-6-100S,62000H 系列,63200E,62000D 系列,17216-6-6,17010,8700,19311,62000H,62000D,62000E,17091,17216M-10-6,17010H_6-300S,17010H_6-300,17010H_6-300U,17010H_6-300Z,8630,17010H,17020,17216M-6-12,19055-C,17208M-5-12C,17208M-6-30,32S,96S,A170103,A190362,8720,19311-10,19311系列,17000系列,63200A系列,63200E 系列,17216-6-12,11210,62000E 系列,19032-P,87001,A112100,17208M-6-60,A112101

17010型电池可靠性测试系统

型号- MODEL 17010,17208M-6-30,17216M-10-6,17216-6-12,17216M-6-12,17010,17212M-6-100S,17208M-6-60,17208M-5-12C,17216-6-6

MODEL 17010H 电池信赖性测试系统 BATTERY RELIABILITY TEST SYSTEM

描述- Chroma 17010H电池芯信赖性测试系统是一款专为高电流/高功率性能测试设计的专业充电放电测试设备,适用于大型锂离子电池芯(LIB Cells)、电气二重层电容器(EDLCs)和大量产热的控制电路。该系统具备高测量精度、高供通道并联功能、快速电流响应、放电能量回收等功能,旨在提高电池芯实验的电容量测试精确度和性能参数验证。

型号- 17010H,17010H-6-300Z,MODEL 17010H,17010H-6-300,17010H-6-300S,17010H-6-300U

電池信賴性測試系統 BATTERY RELIABILITY TEST SYSTEM MODEL 17010H

描述- Chroma 17010H电池芯信赖性测试系统是一款专为高电流/高功率性能测试设计的专业充放电测试设备,适用于大型锂离子电池芯(LIB Cells)、电气二重层电容器(EDLCs)和大量产热的控制电路。该系统具备高测量精度、高供通道并联功能、快速电流响应、放电能源回收等功能,旨在提高实验室内电池芯试验的电容量测试精确度和性能参数辨别。

型号- 17010H,17010H-6-300Z,MODEL 17010H,17010H-6-300,17010H-6-300S,17010H-6-300U

电子商城

登录 | 立即注册

提交评论