Rogers‘ Micro Channel Coolers (MCC) in High Performance Computing (HPC) Applications

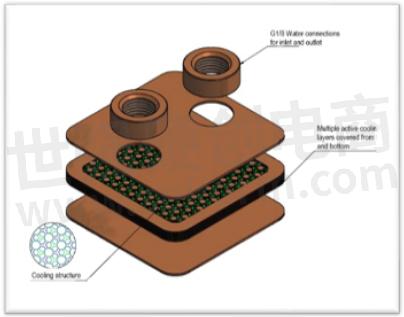

In 2004, and even sometime before the global PC gaming boom started, curamik® engineers from the field of high power laser cooler applications came up with the idea to use our unique Direct Bonded Copper (DBC) technology and developed special microchannel cold plates for CPU cooling. As a result, the curamik® PolarXstream PC-Cooler was born. G1/8 standard connectors for cooling liquid makes it easy for them to adapt to new systems. With multiple active cooling layers, the design can be adjusted to customers' specific needs and purposes based on their performance requirements. Standard and proven cooling structures secure lifetime and efficiency. Even though CPU thermal management is a very interesting application, in today's blog we want to talk about HPC cooling and its needs.

ROGERS PCK 1/1 cooler structure

High-Performance Computing

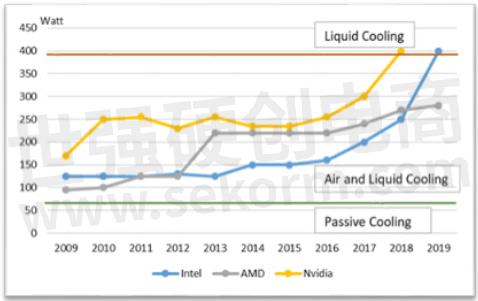

Currently, available cooling solutions have reached their limit in edge and high-performance computing. However, direct chip cooling offers a solution to keep the chip temperatures at an optimum operating temperature. According to forecasts by MarketsandMarkets Inc., the global market for liquid cooling in data centers will grow from $1.2 billion (2019) to $3.2 billion by 2024. This is due to the increasing demand for energy-efficient and compact cooling solutions at lower operating costs and requirements for higher performance from edge to HPC. Conventional rack and room cooling solutions are reaching their limits. One resolution is to use direct chip cooling solutions and Rogers Corporation's microchannel cold plates in order to support your system through the next advancement. Market experts are already testing and/or are using our cold plates.

Own Illustration of HPC chip power development in the perspective of possible cooling options.

Customers

Numerous international HPC providers are among our customer base and driven by COVID 19 impacts, last month's demand for HPC and data centers steadily increased. However, also specialized companies such as MEGWARE are interested in Rogers MCC to fulfill and secure their company goals. “We believe that it is essential to use the available resources sustainably and economically. We develop solutions that significantly cut energy consumption, reduce emissions and thereby actively help protect the environment. Our HPC systems, servers, and workstations are designed for both high performance and energy efficiency.”(MEGWARE, 2021) As HPC systems are usually running 24/7 they can use the heat from the chip to climate buildings and facilities in the surroundings. This saves money for their customers and helps to protect our environment.

©MEGWARE SlideSX®-LC compute platform

Why are Rogers micro-channel cold plates better than others?

Rogers curamik Cooling Solutions offer a wide range of advanced liquid cooling solutions powered by the state-of-the-art curamik bonding process. The layers are hermetically combined without any additional soldering or adhesive. These innovative liquid coolers feature copper foil channel structures (<250-micrometer channel width) that are bonded into a tight block using the curamik process. Compared to standard solutions, Rogers' coolers are up to four times more efficient than traditional liquid cooling module structures. Furthermore, their narrow channels provide a larger highly conductive copper surface area to the cooling medium than many other solutions. This is the secret of Rogers' MCC high performance. If necessary, coolers are integrated with ceramic substrates, enabling direct component assembly and electrical isolation from the cooling circuit.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由董慧转载自Rogers,原文标题为:Rogers' Micro Channel Coolers (MCC) in High Performance Computing (HPC) Applications,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Rogers Corporation Announces Further Actions to Streamline Operations and Drive Margin Improvement

Chandler, Arizona, June 6, 2024: Rogers Corporation (NYSE: ROG) (“Rogers”) announced today plans to drive further operational efficiency and margin improvement. Rogers intends to wind down manufacturing of advanced circuit materials and other related activities at its Evergem, Belgium factory by mid-2025. Rogers will continue to support its advanced circuit materials customers through its existing footprint in China and the United States.

原厂动态 发布时间 : 2024-06-20

Rogers Announces Termination of Merger Agreement with DuPont

Rogers announced the termination of its definitive merger agreement with DuPont de Nemours, Inc. (“DuPont”). In connection with the termination of the merger agreement, Rogers has received a regulatory termination fee of $162.5 million from DuPont.

原厂动态 发布时间 : 2022-11-08

【技术】解析采用Rogers微通道冷却器的空冷VCSEL应用

罗杰斯MCC一直仅用于液冷应用,但客户在新VCSEL应用中面临的热管理挑战达到新水平。转向液冷所面临的挑战是虽然被动/标准空冷方案可能不能解决散热问题,但是液冷是有风险的,同时成本和维护都会增加。故本文开始将压缩空气作为冷却剂,检测和评估了罗杰斯MCC。

技术探讨 发布时间 : 2022-03-08

【应用】罗杰斯微通道冷却器(MCC)用于高性能计算(HPC),效率是传统液体冷却模块结构的四倍

传统的机架和机房冷却解决方案即将无法满足市场需求,一种解决方案是采用芯片直冷技术和罗杰斯公司的微通道冷却器,效率是传统液体冷却模块结构的四倍。此外,相较于许多其他解决方案,罗杰斯冷却器采用的狭窄通道设计为冷却介质提供了更大的高导热的铜表面积。

应用方案 发布时间 : 2021-07-14

Air Cooled VCSEL Applications with Rogers Micro-Channel-Coolers (MCC)

When air-cooled heat sinks cannot cope with too high power densities, liquid-cooled cold plates are the heat transfer solution of choice.How would Rogers‘Micro-Channel-Coolers (MCCs) perform in air cooling applications?

应用方案 发布时间 : 2022-02-08

【应用】Rogers微通道冷却板在高性能计算器中的冷却应用,比传统液体冷却模块结构的效率高出四倍

Rogers curamik 冷却解决方案提供一系列先进的液体冷却解决方案,由最先进的 curamik 粘合工艺提供支持。各层密封结合,无需任何额外的焊接或粘合剂。 这些创新的液体冷却器采用铜箔通道结构(<250 微米通道宽度),使用 curamik 工艺将其粘合成一个紧密的块体。

应用方案 发布时间 : 2021-07-21

【应用方案】罗杰斯微通道冷板MCC用于LED照明,散热效率比传统液冷模块结构高四倍

罗杰斯(ROGERS)的curamik® 散热解决方案各层材料之间以密闭的方式结合在一起,无需使用任何额外焊接或粘结剂。这些新颖的液体冷却器采用铜箔微通道结构(通道宽度最小可达250μm),通过curamik工艺将这些铜箔通道与一个紧密的封盖结合在一起。

应用方案 发布时间 : 2021-10-13

【应用】Rogers微通道冷却器 (MCC) 在高性能计算、LED阵列冷却、聚光光伏和大功率激光市场的应用

本文将介绍Rogers微通道致冷器 (MCC) 在高性能计算、LED阵列冷却、聚光光伏和大功率激光市场的应用。

应用方案 发布时间 : 2021-08-24

Temporary Lead Time Extension for Products Made in Rogers Suzhou Factory

型号- RO4830™,RO4535™,KAPPA® 438,DICLAD880™,RO4533™,RO4000™,DICLAD®,RO3003G2™,RO3035™,RO3003™,RO4003C™,RO4835™,RO3003G2™ PM,TC350™,RO4534™,RO4730G3™ R2,RO4835T™,RO4233™,RO4350B™,RO3006™,AD255™,AD300™,RO3010™,RO3000™,TC350™ PLUS

Rogers Corporation RO3000® PTFE dispersion supplier change RO3206™ Update with data comparison

型号- RO3006™,RO3210™,RO3206™,RO3035™,RO3003™,RO3000®,RO3203™,RO3010™

【经验】如何选择合适介电常数的Rogers高频板材?

在选择板材rogers高频板材时,最关注的指标是介电常数。但也有一部分工程师对介电常数理解的比较片面,在选择rogers高频板材时,会遇到一些问题,通过本文讲解,可以更好的帮助工程师快速准确的选择合适介电常数的板材。介电常数和频率相关,同一种板材的不同厚度有时会有一定差异。rogers板材的范围1.96(RT/duriod 5880LZ)-13(TMM13i)。

设计经验 发布时间 : 2018-08-19

Rogers Corporation Proactively Risk Reducing the Supply Chain for our RO3000® Product Line

型号- RO3006™,RO3003G2™,RO3210™,RO3206™,RO3035™,RO3003™,RO3000®,RO3203™,RO3010™

Rogers Corporation RO3000® PTFE dispersion supplier change RO3010™ Update with data comparison

型号- RO3006™,RO3210™,RO3206™,RO3035™,RO3003™,RO3000®,RO3203™,RO3010™

Rogers高频板RO4350B板材在24GHz时介电常数和损耗因子

Rogers高频板RO4350B达到了成本和高频性能的最优化,是最具性价比的低损耗高频板材。为了更好的实现设计要求,笔者在设计微带阵列天线时研究了基于Rogers高频板RO4350B板材的微带传输线在24GHz的插入损耗。

设计经验 发布时间 : 2024-04-29

电子商城

品牌:ROGERS

品类:Circuit Materials

价格:¥2,479.9453

现货: 1,679

品牌:ROGERS

品类:High Frequency Circuit Materials

价格:¥547.1207

现货: 1,531

品牌:ROGERS

品类:Antenna Grade Laminates

价格:¥2,989.4355

现货: 429

品牌:ROGERS

品类:Liquid Crystalline Polymer Circuit Material

价格:¥1,485.0299

现货: 253

品牌:ROGERS

品类:Antenna Grade Laminates

价格:¥2,571.9097

现货: 250

现货市场

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

可加工PCB层数:1-30层;板材类型:FR4板/铝基板/铜基板/刚扰结合板/FPC板/高精密板/Rogers高频板;成品尺寸:5*5mm~53*84cm;板厚:0.1~5.0mm。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论