【应用】超柔导热垫片THERM-A-GAP™MCS30解决服务器大面积散热问题

服务器(SERVER)是网络中的重要设备,要接受少至几十人、多至成千上万人的访问,因此对服务器具有大数据量的快速吞吐、超强的稳定性、长时间运行等严格要求。CPU是计算机的“大脑”,是衡量服务器性能的首要指标。依可靠统计,温度每升高10度,计算机的可靠性能就下降25%,使用寿命将减少50%,因而热管理在服务器中的应用至关重要。

散热设计当中常用的方法有:使用主动散热和被动散热(散热器,冷却风扇),TIM截面材料,高导PCB等,导热材料实际应用中要针对客户实际需求,给出最佳最合理的方案,将以上几种方式应用到实处中。

下面介绍一下导热垫片在Server中的一种应用方式:

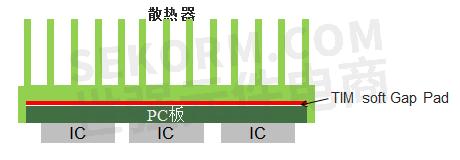

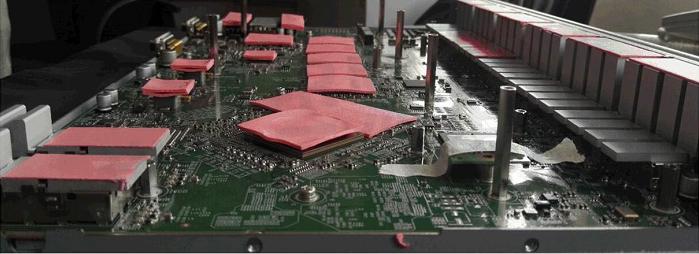

在服务器中,需要散热芯片很多,一般将导热垫片安装放置在需要散热的芯片对应的PCB板底部和外壳之间(如图一),但其pcb背端,温度也是很高,同时需要解决散热,这时,可使用大面积软性导热垫片(如图二),可以充分利用其良好的填充效果,压缩性能,以及良好的截面浸润性能带来导热效能,同时材料本身有优越的电气绝缘效果以及减震效果,区别于其他的导热介面材料。同时柔性导热硅胶片的使用便利,不易损耗,可重复使用,便于安装,为客户设计验证批产节省人力物力。

图一(PCB背端散热模型)

图二(PCB背端使用整张超软垫片)

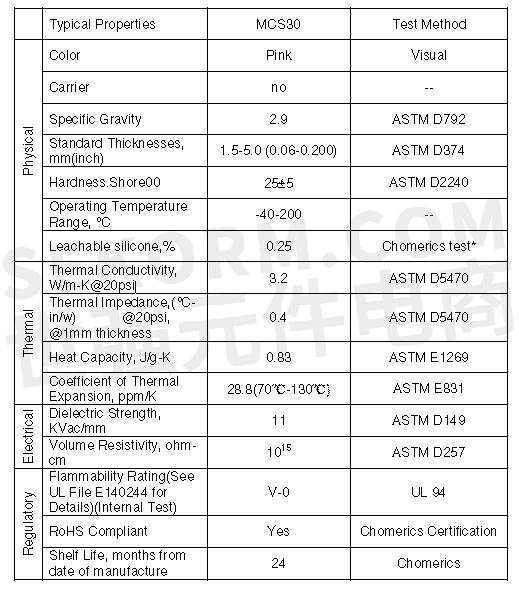

大面积Pcb板散热对导热垫片的要求是:

1、 硬度小,回弹性好;

2、 压变应力小,力学强度高,耐磨损;

3、 绝缘强度在8KVac/mm以上;

4、 导热系数为3.0W/mK左右。

派克固美丽THERM-A-GAP™MCS30系列导热垫片,导热系数为3.0W/mK。其特点是超柔特性,标准硬度shore 00为25,可大张使用,紧密贴合在pcb背端表面与散热机壳之间的界面,对板端压变应力小,截面接触好,从而达到高导热效率。其柔顺性使其压缩率可达到50%及以上,而且绝缘强度达到11KVac/mm以上,同时MCS30有带玻纤、绝缘膜等版本,力学强度高,且具有一定的耐摩擦性,可以使用不同行业应用。

- |

- +1 赞 0

- 收藏

- 评论 8

本文由DRIFT提供,版权归世强硬创平台所有,非经授权,任何媒体、网站或个人不得转载,授权转载时须注明“来源:世强硬创平台”。

评论

全部评论(8)

-

![]()

![]() maomao Lv8. 研究员 2020-04-05不错的资料

maomao Lv8. 研究员 2020-04-05不错的资料 -

![]()

![]() zwjiang Lv9. 科学家 2020-03-21学习学习

zwjiang Lv9. 科学家 2020-03-21学习学习 -

![]()

![]() Keil Lv7. 资深专家 2020-03-14学习了

Keil Lv7. 资深专家 2020-03-14学习了 -

![]()

![]() 天冷要下雪 Lv7. 资深专家 2020-02-18学习

天冷要下雪 Lv7. 资深专家 2020-02-18学习 -

![]()

![]() lizzy Lv5. 技术专家 2020-02-18谢谢分享

lizzy Lv5. 技术专家 2020-02-18谢谢分享 -

![]()

![]() 桃梅 Lv7. 资深专家 2020-02-13学习了

桃梅 Lv7. 资深专家 2020-02-13学习了 -

![]()

![]() Mary Lv5. 技术专家 2020-01-30学习

Mary Lv5. 技术专家 2020-01-30学习 -

![]()

![]() terrydl Lv9. 科学家 2020-01-23学习了

terrydl Lv9. 科学家 2020-01-23学习了

相关推荐

【应用】T500导热绝缘垫片助力新能源汽车中IGBT散热,具有绝缘强度高、导热效果好等优势

电动汽车IGBT模块对导热绝缘垫片的要求是绝缘强度高,导热效果好,力学强度大抗撕裂和穿刺等。因此本文推荐使用派克固美丽推出的一款导热绝缘垫片T500,采用玻璃纤维布,拉伸强度,抵抗撕扯、剪切和穿刺效果好,其厚度仅为0.25mm,但绝缘强度达到4000Vac;热阻仅为0.19°C-in2/W @ 300 psi,散热效果优秀。

【应用】导热垫片THERM-A-GAP™MCS30为车载仪表盘提供散热解决方案,可以在高达200°C下连续工作

随着汽车行业的电子化和智能化的发展,汽车仪表的功能做的也越来越多,大大丰富了仪表盘的功能,提高了用户的视觉体验。但仪表盘经常会出现发烫现象,主要原因是仪表后面的LED光源和散热件,简单来说就是散热问题,那如何解决仪表盘产品小空间中的散热问题呢? 这里可推荐Parker Chomerics导热垫片THERM-A-GAP™MCS30系列产品,与传统的高模量热垫相比,可提供优异的性能和长期热稳定性。

【应用】导热垫片MCS30结合热仿真软件smart CFD为T-BOX提供散热解决方案

parker chomerics,其热界面材料导热垫片MCS30可以很好填充芯片与散热器之间的界面,其理想的柔软度能有效的减少接触热阻,提高导热效率,满足车载核心T-BOX散热需求。

Therm-A-Gap™Pad 80 8.3 W/M-K导热高性能填隙垫片

描述- THERM-A-GAP™ PAD 80是一种高性能热导率间隙填充垫,具有8.3 W/m-K的热导率。它适用于电子设备中散热片与发热组件之间的有效热界面材料,可在不同厚度下提供优异的热传递性能,同时保持低压缩力和良好的贴合性。

型号- PAD 80,6W-XX-1015-ZZZZZZZ,THERM-A-GAP™ PAD 80

【经验】有机硅导热垫片渗油及挥发问题分析及解决方案

本文主要分析了导热垫片的渗油及挥发问题产生的原因,危害及解决方法,希望大家尽量选择国际大品牌,同时需要参考导热垫片数据手册里的Leachable silicone, %和Outgassing, % TML这两个参数。

【选型】Parker Chomerics(派克固美丽)热管理材料选型指南

目录- 产品简介 热传递基础 填缝材料 THERM-A-GAP™569,570,579,580,热垫片 THERM-A-GAP™974,G974,976,高性能热垫片 THERM-A-GAP™T63X系列,可涂布填缝材料 THERM-A-GAP™TP575NS,无硅热垫片 THERM-A-GAP™174,274,574,热垫片 THERMFLOW®相变垫片 HERMATTACH®热粘合带 THERM-A-FORM™可现场固化的灌注和底部填充材料 导热脂和导热胶 绝缘垫片 CHO-THERM®商用热绝缘垫片 CHO-THERM®高能热绝缘垫片 T-WING®和C-WING™薄型散热器 热管理词汇表 安全指南

型号- 65-00-T6XX-0030,WW-XX-5442-ZZZZ,WW-XX-D426-ZZZZ,T500,69-XX-20684-ZZZZ,WW-XX-D387-ZZZZ,69-12-XXXXX-A274,WW-XX-D390-ZZZZ,WW-XX-4659-ZZZZ,61 - 07 - 0909 - G570,69-XX-20698-ZZZZ,6WWXXYYYYZZZZ,T630,WW-XX-D409-ZZZZ,WW-XX-YYYY-ZZZZ,WW-XX-D6875-ZZZZ,WW-XX-D375-ZZZZ,WW-XX-D410-ZZZZ,69-XX-20686-ZZZZ,WW-XX-D424-ZZZZ,THERM-A-FORM™ T64X,69-11-25177-T630,65-00-T6XX - 0030,65-00-T670-3790,WW-XX-D399-ZZZZ,T63X,T404,T647,60-12-20264-TW10,69-11-24419-T630,T405,T646,T766,T644,T642,WW-XX-D385-ZZZZ,62-20-23116-T274,69-11-27155-575NS,69-12-22745-CW10,69 - 12 - XXXXX - A569,WW-XX-D414-ZZZZ,65-00-YYYY-ZZZZ,T650,T636,T635,WW-XX-D389-ZZZZ,65-00-T6XX - 0010,575-NS,WW-XX-D407-ZZZZ,62-16-23115-A274,WW-XX-8531-ZZZZ,WW-XX-D392-ZZZZ,WW-XX-D373-ZZZZ,69-11-27156-575NS,65-00-1642-0000,60-12-20267-TW10,T64X,69-11-27157-575NS,WW-XX-D379-ZZZZ,62-13-23114-T274,WW-XX-D396-ZZZZ,WW-XX-D382-ZZZZ,WW-XX-D418-ZZZZ,WW-XX-D403-ZZZZ,60-XX-YYYY-ZZZZ,274,WW-XX-4306-ZZZZ,62-04-23111-A274,65-00-1641-0000,65-00-T644-0045,WW-XX-402-ZZZZ,62-16-23115-T274,69-XX-20675-ZZZZ,WW-XX-4353-ZZZZ,WW-XX-D397-ZZZZ,T670,WW-XX-D417-ZZZZ,WW-XX-D378-ZZZZ,T405-R,T418,WW-XX-D419-ZZZZ,T777,T413,T414,WW-XX-D380-ZZZZ,T411,T412,69-12-22849-CW10,60-12-20269-TW10,65-00-T6XX-0180,WW-XX-D421-ZZZZ,WW-XX-4997-ZZZZ,WW-XX-D377-ZZZZ,T660,WW-XX-4305-ZZZZ,69-XX-27083-ZZZZ,69-12-23802-CW10,67-XX-YYYY-ZZZZ,69-11-27159-575NS,T444,65-01-1641-0000,WW-XX-4511-ZZZZ,174,TP575NS,65-00-T646-0200,WW-XX-D428-ZZZZ,WW-XX-5791-ZZZZ,WW-XX-8302-ZZZZ,WW-XX-D371-ZZZZ,WW-XX-D422-ZZZZ,974,976,65-00-T647-0200,WW-XX-6956-ZZZZ,T558,T557,WW-XX-4996-ZZZZ,61-07-0909-G174,62 - 20 - 0909 - A579,69-XX-20685-ZZZZ,60-12-20268-TW10,T441,62 - 20 - 0909 - A574,WW-XX-D381-ZZZZ,WW-XX-D412-ZZZZ,G974,65-00-T6XX - 0300,WW-XX-D411-ZZZZ,WW-XX-D374-ZZZZ,61 - 07 - 0909 - G174,WW-XX-4661-ZZZZ,WW-XX-D391-ZZZZ,PC07DS-7,WW-XX-D425-ZZZZ,WW-XX-D386-ZZZZ,6W-XX-YYYY-ZZZZ,WW-XX-D372-ZZZZ,WW-XX-D430-ZZZZ,65-00-T6XX-0300,WW-XX-D427-ZZZZ,WW-XX-D408-ZZZZ,WW-XX-D413-ZZZZ,69-11-27158-575NS,THERM-A-FORM™ 164X,WW-XX-D388-ZZZZ,69-XX-27072-ZZZZ,WW-XX-D423-ZZZZ,WW-XX-D376-ZZZZ,WW-XX-5792-ZZZZ,69-XX-20687-ZZZZ,WW-XX-D429-ZZZZ,WW-XX-D398-ZZZZ,T630G,6-6W-XX-YYYY-ZZZZ,69-XX-27070-ZZZZ,62-07-23112-A274,WW-XX-5527-ZZZZ,69-XX-27082-ZZZZ,62-10-23113-A274,WW-XX-D395-ZZZZ,1642,1641,WW-XX-4969-ZZZZ,65-00-T650-0003,WW-XX-4374-ZZZZ,WW-XX-D370-ZZZZ,WW-XX-D401-ZZZZ,62-20-23116-A274,WW-XX-D404-ZZZZ,WW-XX-D420-ZZZZ,C-WING,62-13-23114-A274,62-04-23111-T274,69-11-27154-575NS,65-00-T6XX - 0180,62-10-23113-T274,65-00-T644-0200,65-00-T642-0035,WW-XX-D383-ZZZZ,WW-XX-D405-ZZZZ,1671,60-12-20266-TW10,69 - 12 - XXXXX - A274,WW-XX-D416-ZZZZ,62-07-23112-T274,569,WW-XX-D065-ZZZZ,164X,T725,69-XX-YYYY-ZZZZ,65-00-T6XX-0010,65-00-T642-0250,65-00-T646-0045,WW-XX-D393-ZZZZ,THERM-A-GAP™ T63X,T609,570,WW-XX-D400-ZZZZ,69-XX-21259-ZZZZ,1678,574,1674,579,WW-XX-D406-ZZZZ,69-XX-20672-ZZZZ,65-00-T647-0045,WW-XX-D394-ZZZZ,69-XX-20991-ZZZZ,T710,580,WW-XX-D384-ZZZZ,WW-XX-D415-ZZZZ,60-12-20265-TW10,T-WING

加速发展。降低风险。用于生命科学设备的电磁干扰(EMI)屏蔽和热接口材料解决方案

型号- PREMIER™ A240-FRHF,WIN-SHIELD™ P,SOFT-SHIELD® 4850,CHO-SEAL® 1285,PREMIER™ PEI 140,THERM-A-GAP™ GEL 30,CHOFORM® 5528,CHO-SHIELD® 2040,PREMIER™ A220-HT,THERM-A-GAP™ 974,CHO-SHIELD® 2044,CHO-SEAL® 6370,THERM-A-GAP™ 976,THERM-A-GAP™ 579,WIN-SHIELD™ G,THERM-A-GAP™ GEL 8010,THERM-A-GAP™ HCS10,CHO-SEAL® S6305,DURALAN™ P,CHO-SEAL® 1298,CHO-SEAL® 6502,THERM-A-GAP™ GEL 45,THERM-A-GAP™ G974,THERM-A-FORM™ T646,CHOFORM® 5513,CHO-SHIELD® 2056,THERM-A-FORM™ T647,CHO-SEAL® 6503,PREMIER™ A240-ST,THERM-A-GAP™ TC50,THERM-A-GAP™ 569,PREMIER™ PBT-225,SOFT-SHIELD® 3500,THERM-A-FORM™ 1641,SOFT-SHIELD® 3700

【选型】如何选择一款合适的导热垫片?

导热垫片占了导热界面材料一半的市场份额,应用非常广泛,所以导热垫片选择成为很多工程师的难点,导热垫片有几个非常重要的参数:导热系数,厚度,硬度,基体等,本文从这几个方面分析了导热垫片如何选择。

笔记本cpu用导热硅脂还是导热硅胶片导热效果好?

常规笔记本电脑CPU会选用导热硅脂来进行散热,长时间使用会存在老化掉粉的风险。导热垫片就不会。可推荐Parker Chomerics 导热垫片MCS30,导热系数3.5W/mk,性价比高,数据手册可见:THERM-A-GAP™ GEL 8010 & GEL30 High Performance Fully Cured Dispensable GELS 数据手册

导电弹性体工程手册:产品和定制集成解决方案

型号- 19-04-12901-XXXX,10-06-A778-XXXX,19-04-M394-XXXX,10-04-4180-XXXX-40,19-04-22951-XXXX**,10-00-0028-XXXXX,10-00-1846-XXXXX,19-09-LH10-1298,10-04-3076-XXXX-40,M83528/007Y005,M83528/007Y004,M83528/007Y003,M83528/007Y002,20-01-5060-1239**,M83528/007Y001,CHO-SEAL V6433,10-05-4542-XXXX,10-00-2029-XXXXX,10-02-1492-XXXXX,19-07-22989-XXXX,20-01-5115-1239**,M83528/007Y007,19-09-28855-XXXX,M83528/007Y006,10-00-0010-XXXXX,19-05-12375-XXXX,19-07-12959-XXXX,19-08-12844-XXXX,19-08-C929-XXXX,10-04-3560-XXXX-40,19-09-E053-XXXX,40-TA-1010-1350,19-04-21194-XXXX,20-02-6565-1212,30-02-2051-XXXXX,19-04-25964-XXXX,19-09-L524-XXXX,19-09-14831-XXXX,19-09-LE24-XXXX,19-06-11223-XXXX,19-09-14645-XXXX,20-01-5055-1239,30-02-2043-XXXXX,19-08-12885-XXXX,40-T0-1020-6307,19-04-16104-XXXX,40-TA-1020-6460,19-04-26610-XXXX,19-04-14349-XXXX,10-01-6515-XXXXX,10-00-3550-XXXXX,10-00-1782-XXXXX,19-06-22037-XXXX,40-TA-1010-1310,19-04-13759-XXXX,19-04-14964-XXXX,19-04-22324-XXXX,10-07-4272-XXXX,19-04-21493-XXXX,10-05-1364-XXXX,19-07-26620-XXXX,10-07-3225-XXXX-40,19-04-28067-XXXX**,30-02-2056-XXXXX,19-04-11875-XXXX,19-04-25051-XXXX,19-04-27546-XXXX**,19-09-11540-XXXX,40-TA-1015-S6305,20-01-5005-1239,19-04-16162-XXXX,19-07-27622-XXXX,19-04-12908-XXXX,19-06-M412-XXXX,19-08-17623-XXXX,19-09-11434-XXXX,40-TA-1015-1298,19-04-24444-XXXX,19-04-22253-XXXX,40-TA-1015-6503,40-TA-1015-6502,CHO-SEAL 6371,19-04-22371-XXXX**,CHO-SEAL 6370,10-00-0044-XXXXX,19-05-21166-XXXX,19-07-21339-XXXX,10-05-10648-XXXX,10-00-2231-XXXXX,19-26-5575-0240,10-00-2536-XXXXX,10-04-5514-XXXX,20-01-5225-1239**,19-04-11228-XXXX,19-09-W321-XXXX,10-01-1375-XXXXX,19-05-Z586-XXXX-40,10-05-3369-XXXX,10-06-8560-XXXX,19-06-Z731-XXXX,10-04-2862-XXXX,30-03-2071-XXXXX,40-TA-1015-1273,10-00-2070-XXXXX,10-00-2040-XXXXX,19-04-26424-XXXX,19-04-23836-XXXX,19-04-16390-XXXX,19-05-15343-XXXX,19-04-23158-XXXX,10-06-2750-XXXX-40,19-07-12951-XXXX,19-09-L453-XXXX,10-07-B447-XXXX,10-00-2227-XXXXX,40-TA-1015-1285,10-00-2777-XXXXX,40-TA-1015-1287,19-04-F371-XXXX-40,19-26-1800-0345,10-00-2228-XXXXX,19-04-22049-XXXX,20-02-6515-1212,30-02-2048-XXXXX,19-04-12910-XXXX,19-09-19925-XXXX,10-01-1240-XXXXX,19-07-W391-XXXX,10-00-0052-XXXXX,19-07-21881-XXXX,19-09-C032-XXXX,10-05-1363-XXXX-40,19-07-15804-XXXX,10-00-2320-XXXXX,CHO-SEAL 6330,10-07-3226-XXXX,19-07-25333-XXXX,19-09-16336-XXXX,10-04-9769-XXXX,10-04-8817-XXXX-40,19-04-11204-XXXX,19-06-L064-XXXX,10-00-5983-XXXXX,10-07-E263-XXXX,19-09-11225-XXXX,10-00-1406-XXXXX,10-03-1859-XXXXX,10-04-8363-XXXX-40,19-06-15899-XXXX,10-04-6386-XXXX**,19-09-30385-XXXX,20-01-5225-1239,19-07-27623-XXXX,10-05-6394-XXXX,19-08-23568-XXXX,19-09-11408-XXXX,19-04-20951-XXXX,19-07-12200-XXXX,10-07-4483-XXXX-40,10-00-4452-XXXXX,10-08-3872-XXXX,10-00-2230-XXXXX,10-04-8363-XXXX,19-07-25114-XXXX,19-09-18963-XXXX,30-03-2068-XXXXX,19-04-21162-XXXX,19-09-23709-XXXX,19-04-W049-XXXX,19-09-24684-XXXX,19-05-B254-XXXX,19-04-14261-XXXX,19-09-32174-XXXX,19-05-12883-XXXX,10-04-8133-XXXX-40,20-03-3731-1212,19-04-20982-XXXX,19-04-22066-XXXX,10-05-4542-XXXX-40,40-TA-1015-6371,10-00-0032-XXXXX,19-04-22129-XXXX,30-03-8800-XXXXX,19-04-12902-XXXX,10-00-1342-XXXXX,10-00-1407-XXXXX,19-09-10843-XXXX,10-06-6175-XXXX,20-01-5135-1239,30-03-2076-XXXXX,30-03-1981-XXXXX,10-05-1363-XXXX,10-06-C716-XXXX,19-05-12066-XXXX,19-09-X962-XXXX,10-05-4318-XXXX-40,19-09-19880-XXXX,20-01-5120-1239,30-02-2042-XXXXX,19-07-F463-XXXX,19-05-19354-XXXX,19-04-X787-XXXX,10-04-4254-XXXX,40-TA-2020-6371,19-05-F173-XXXX-40,40-TO-1020-V6433,10-08-4315-XXXX-40,10-00-1845-XXXXX,19-04-12909-XXXX,10-05-3224-XXXX,10-04-4148-XXXX,19-08-22217-XXXX,19-07-11294-XXXX,19-04-14632-XXXX,10-07-4217-XXXX-40,20-11-5020-1239,10-06-3599-XXXX-40,19-06-C442-XXXX,10-05-1362-XXXX-40,10-01-6565-XXXXX,20-01-5145-1239**,20-01-5140-1239**,10-00-4123-XXXXX,19-04-26087-XXXX,CHO-SEAL 6308,30-03-2075-XXXXX,CHO-SEAL 6307,20-01-5145-1239,10-05-6394-XXXX-40,20-02-6531-1212,10-04-1720-XXXX,19-07-L463-XXXX,40-TA-1015-6330,19-26-5541-0650,19-04-23086-XXXX,19-05-C128-XXXX,20-11-5035-1239,10-02-2736-XXXXX,30-02-2052-XXXX,19-09-28323-XXXX,46-TA-1020-90XX,19-09-22539-XXXX,19-07-12877-XXXX,20-03-6645-1212,10-07-4523-XXXX,19-04-11651-XXXX,19-09-24030-XXXX,19-05-L547-XXXX,19-04-14537-XXXX,19-09-25853-XXXX,10-04-1687-6503,10-00-1360-XXXXX,20-03-6685-1212*,40-T0-1015-V6433,20-03-3561-1212,19-04-20072-XXXX,19-07-M327-XXXX,10-00-2071-XXXXX,19-26-5538-0650,20-01-5055-1239**,20-02-6530-1212,19-08-E622-XXXX,19-09-F676-XXXX,10-04-W267-XXXX,19-09-19022-XXXX,19-04-22533-XXXX,20-03-L767-1212,19-09-24063-XXXX,19-09-17428-XXXX,10-05-1499-XXXX-40,10-04-3560-XXXX,30-02-2057-XXXXX,19-04-13564-XXXX,19-09-M942-XXXX,19-04-12792-XXXX,20-11-1683-1239,19-05-14960-XXXX,19-09-14377-XXXX,10-05-8635-XXXX,40-TA-1010-6460,30-02-ZZZZ-XXXXX,40-T0-1010-V6433,CHO-SEAL S6305,10-04-W293-XXXX,19-04-25875-XXXX**,10-00-1770-XXXXX,19-04-22230-XXXX,30-02-2050-XXXXX,19-07-F627-XXXX,10-05-2618-XXXX-40,10-05-6419-XXXX,19-04-15443-XXXX,20-02-6510-1212,10-04-2561-XXXX,30-03-2066-XXXXX,30-02-2055-XXXXX,10-01-1264-XXXXX,20-01-5135-1239**,

【经验】导热垫片老化变硬问题怎么解决?

导热垫片使用广泛,是最常用的导热界面材料,但导热垫片也存在一些问题,其中老化变硬问题比较突出,本文讲解了老化变硬问题产生的原因,危害及解决方法,给使用和开发导热垫片提供思路,并推荐固美丽的导热垫片,如MCS30、TPS55、TPS60。

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

提供稳态、瞬态、热传导、对流散热、热辐射、热接触、和液冷等热仿真分析,通过FloTHERM软件帮助工程师在产品设计初期创建虚拟模型,对多种系统设计方案进行评估,识别潜在散热风险。

实验室地址: 深圳 提交需求>

登录 | 立即注册

提交评论