Wevo Developed Silicones and Polyurethanes with a Lower Hydrogen Permeability Used as Adhesives and Sealants for PEM fuel cells

Hydrogen-based fuel cells achieve high performance and are energy-efficient. They produce no harmful emissions because only water and electrical energy are released when hydrogen reacts with oxygen. The technology, therefore, holds considerable potential for powering electric vehicles in the context of the proposed mobility transition. Since hydrogen is the smallest of all molecules, the adhesives and sealants used for fuel cells must ensure a very tight seal in order to prevent diffusion. Wevo-CHEMIE GmbH has developed silicones and polyurethanes, especially for this purpose, and their low gas permeability has been confirmed by ZBT, the hydrogen and fuel cell center in Duisburg. The products can be used both for fuel cells themselves (“stacks”) and in the surrounding system (“balance of plant”).

The low gas permeability of Wevo’s silicones and polyurethanes has been confirmed in a study by ZBT, the Duisburg hydrogen and fuel cell center.

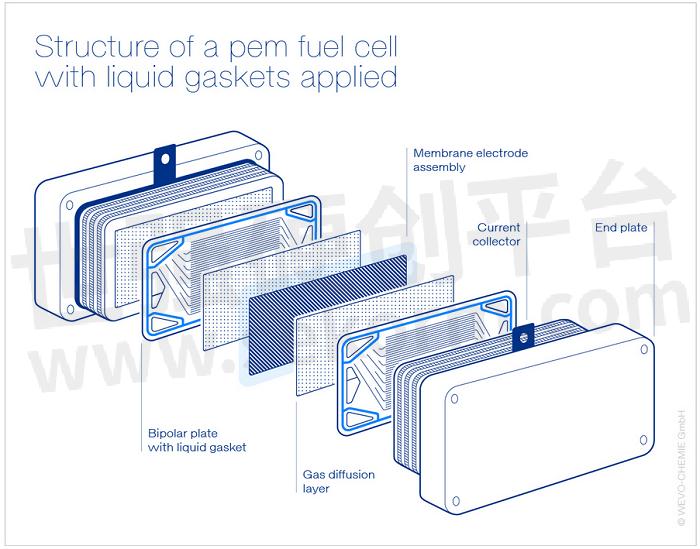

Fuel cells consist of several functional layers that can differ both in terms of the materials and components used as well as in terms of the working principle. One of the most common types, which is currently being widely researched because of its suitability for the automotive sector, is the so-called PEM fuel cells (Proton Exchange Membrane Fuel Cells), which are shown in the figure.

The bipolar plates ensure a steady supply of hydrogen to the cells and simultaneously control the release of electrical energy. Since hydrogen is flammable and can form explosive mixtures (“oxyhydrogen”) in oxygen-containing atmospheres, reliable sealing of the individual cells is essential. The sealing materials must not only be highly impermeable to gas; they must also be resistant to challenging conditions such as continuous high temperatures of up to 120℃ or low pH. Furthermore, if the bipolar plates have tolerances due to manufacturing, this results in uneven pressure distribution on the sealing materials, which has to be compensated – especially while the stacks are being pressed.

Up to now, performed inlay gaskets have been used for this purpose, for example. However, due to the need to insert them manually on both sides of each bipolar plate, they are not suitable for the automated production of high volumes, i.e. for the automotive sector in particular. Furthermore, there is a risk that they will detach the bipolar plate during stacking so that they no longer seal effectively. The commercially available, addition-curing silicone liquid gaskets that are on offer as alternatives likewise have drawbacks, such as their generally high gas permeability and their poor adhesion to the majority of substrates. Wevo therefore developed special, chemically resistant, two-component materials based on polyurethane and silicone for use in proton exchange membrane (PEM) fuel cells. They are applied as liquid formed-in-place gaskets and also have further advantages for the manufacture and operation of fuel cell components.

LOW GAS-PERMEABLE MATERIALS FROM WEVO

The unusually low gas permeability of these materials has been confirmed by ZBT, the Duisburg hydrogen and fuel cell center, which is one of the leading research institutes in Europe in this field. One of the silicone-based products exhibited a very low hydrogen permeation coefficient of about 130 E-8 cm²/s after a measurement time of 16 hours (a figure between 500 and 1000 E-8 cm²/s is typical for addition-curing silicones). Moreover, adhesion to metal surfaces was optimized by Wevo and the compression set was reduced.

Wevo’s polyurethane sealants, which have similar thermo-mechanical properties to silicones, have even lower hydrogen permeability depending on the Shore hardness setting. Their permeation coefficients vary between about 30 and 70 E-8 cm²/s, also after a 16-hour measurement period. What’s more, these products adhere significantly better than silicones to the different substrates of bipolar plates. This prevents the seal from detaching either in the course of the manufacturing process or during stacking, so that loss of sealing effect is no longer an issue. Last but not least, much faster curing is possible compared to silicones – a major asset when it comes to automated production of high volumes.

ADHESIVES FOR STACKS, BOP COMPONENTS, AND ELECTROLYSERS

Wevo’s polyurethane-based products can additionally be used as adhesives for other applications – both within the fuel cell stack and in the balance of plant (BOP), that is the surrounding system – due to their good adhesion properties. As well as bonding the entire stack together, it is possible, for example, to simultaneously join and seal the bipolar plates’ two half-shells using customized, soft, and elastic Wevo polyurethanes. For metallic bipolar plates, this joining method can be employed as an alternative to laser welding; with plates based on graphite/polymer composites, durable bonding is a must.

Wevo products also allow the sealing and bonding of the humidifier’s components. In particular, their high ion purity and low levels of volatile components (VOC) rule out damage to the sensitive, ion-selective polymer membranes and the associated drop in performance. High hydrolysis resistance at temperatures up to 100℃ is ensured, too, by the special composition of the customized products.

The anode recirculation blower or the air compressor installed in the air circuit are other possible applications in the BOP. In the latter case, Wevo’s epoxy resins and silicones enable potting of the stator for the drive motor. By optimizing the thermal conductivity and crack resistance of the materials, the forces produced during rotation are compensated and the heat generated is removed in a targeted way. Special, thermally conductive, polyurethane potting compounds and silicone gels for the power modules are likewise used for power electronic components such as DC/DC converters, onboard chargers, and control units.

HYDROGEN PRODUCTION WITH WEVO PRODUCTS

Due to their low hydrogen permeation coefficient of only 3 to 4 E-8 cm²/s, Wevo’s customized, tough polyurethane adhesives are also suitable for various components involved in the hydrogen production process. For instance, large stacks for electrolyzers based on polymer membrane technology needed to produce “green hydrogen” can be bonded with the help of.

Alkaline electrolysis plants require adhesive systems with even higher chemical resistance than is afforded by polymer membrane technology because this widely used type of electrolyser works with aqueous potassium hydroxide solution (30–35 percent KOH) at 90 to 95℃ as its electrolyte. The majority of organic adhesive and sealing systems are not able to withstand such conditions permanently. A specially optimized, highly cross-linked, and chemical-resistant Wevo epoxy resin, which in its thixotropic form is suitable for applying adhesive beads, is one of only a few products currently available that are capable of meeting these requirements. Wevo is currently collaborating with various research institutes and industrial partners with a view to offering more solutions in this area in the future.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由玄子转载自Wevo News,原文标题为:Wevo sealants and adhesives for PEM fuel cells,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Wevo’s Potting Compounds and Adhesives Enable Modern Environmental Technologies

WEVO-CHEMIE GmbH’s specially developed potting compounds and adhesives based on polyurethane, epoxy resin, and silicone offer customized solutions for a wide range of requirements and applications.

Wevo Potting Compounds for Fans Facilitate State-of-the-art Ventilation Technology

WEVO-CHEMIE GmbH has developed potting compounds based on polyurethane and epoxy that are specifically tailored to use with fans and ensure individual protection and long service life.

Wevo Products Based on Epoxy Resin and Silicone – are Optimized for Smart Thermal Management in Electric Motors

WEVO has developed highly thermally conductive materials, which are primarily based on epoxy resin and silicone – optimized for, among other things, the short cycle times required in the automotive industry, and they enable the motor to feature a higher power density.

Temperature-resistant and Flame-retardant: Wevo Potting Compounds Materials with High UL Ratings

The polyurethane- and epoxy-based Wevo solutions are therefore suitable for use in electrical and electronic components that are operated continuously at higher temperatures and require flame retardancy.

Certified According to EN 45545-2: Wevo Potting Compounds Products for Rail Vehicles and Railway Infrastructure

Specially designed potting compounds from WEVO-CHEMIE GmbH meet the highest requirements of this standard and can therefore be used for electrical and electronic components in rail vehicles and railway infrastructure.

Wevo(威孚)WEVOPOX环氧树脂产品选型指南

Company Profile and CUSTOMISABLE EPOXY SYSTEMS Introduction EPOXY CASTING RESINS

WEVO - 环氧树脂,EPOXY CASTING RESINS,环氧浇铸树脂,EPOXY,A 50,5001,8260 FL/60,5004,34021,34020,1018,2511 FL,34003,BX,2003 FL,32702,958,32703,1003/07,36001 FL,1018/25,VE,263,2513,1005,389,30010,5007,5008,5009

电子移动

WEVO提供针对电动汽车各个方面的解决方案,包括电池、充电站、燃料电池等。其产品如聚氨酯、环氧树脂和硅基灌封化合物、热界面材料和粘合剂,用于保护绝缘敏感组件,确保最佳散热和绝缘,同时提高效率和延长使用寿命。WEVO产品还针对充电连接器、电机的定子、电池冷却系统、车载充电器和墙盒等应用提供定制化解决方案。

WEVO - FLAME-RETARDANT POTTING COMPOUND,CHEMICAL RESISTANT BATTERY ADHESIVE,硅酮,聚氨酯基灌注化合物,SILICONE-BASED POTTING COMPOUNDS,SILICONE,聚氨酯,环氧树脂,THERMALLY CONDUCTIVE ADHESIVE,黏合剂,POTTING COMPOUNDS,耐化学电池粘合剂,结构胶粘剂,导热灌封化合物,POLYURETHANE-BASED POTTING COMPOUNDS,间隙填充剂,ADHESIVES,热界面材料,THERMAL INTERFACE MATERIALS,THERMALLY CONDUCTIVE POTTING COMPOUNDS,导热粘合剂,灌封化合物,阻燃灌封料,环氧树脂基灌封化合物,EPOXY,硅基灌封化合物,POLYURETHANE,GAP FILLER,STRUCTURAL ADHESIVES,EPOXY RESIN-BASED POTTING COMPOUNDS,WEVOSIL 28002,WEVOSIL 28001,WEVOPUR 9251 FL,WEVOSIL 26009 FL,WEVOPUR 60910 FL,WEVOPOX 32702,WEVOSIL 22006 FL,WEVOSIL 26009 FLB,WEVODUR 32702,WEVOSIL 22002 FL,WEVONAT 600,WEVOPOX 2513,WEVOPUR 56003 FL,WEVOSIL 27015 FLB,WEVODUR 5008,WEVOPUR 600,WEVOSIL 27015 FLA,WEVONAT 552 FL,WEVOPUR 56093 FL,WEVOPUR 552 FL,WEVODUR 5001,WEVOPUR 300 RE,WEVOSIL 26010 FL,WEVONAT 56003 FL,WEVOPUR 56002 FL,WEVOSIL 22005 FLA,WEVOSIL 26020 FL,WEVOPUR 60515 FL/40,WEVOPOX 1003/07,WEVOPUR 895,WEVOPUR PD 445,WEVONAT 507 L,WEVODUR 1003/07,WEVOSIL 20201,WEVOSIL 27015 FL,WEVONAT 512 FL,WEVOPUR PD 52,WEVOSIL 26020 FLB,WEVOSIL 26020 FLA,WEVONAT 403 FL,WEVONAT 78901,WEVONAT 507,WEVONAT 7210 FL,WEVONAT PD 79952,WEVONAT 900,WEVOPUR 56005 FL,WEVOPUR 68389 FL,WEVOSIL 22005 FLB,WEVOPOX 5008,WEVOPUR 900,WEVOPUR PD 79952,WEVONAT 56093 FL,WEVONAT 300,WEVOPOX 5001,WEVONAT 385,WEVOPUR 403 FL,WEVOPUR 512 FL,WEVOPUR 300,WEVOPUR 78901,WEVOSIL 22002 FLB,WEVOPUR 385,WEVONAT PD 52,WEVOSIL 22002 FLA,WEVONAT 300 RE,WEVOPOX 36001 FL,WEVODUR 2513,WEVOPUR 56992,WEVONAT 56992,WEVOSIL 22006 FLB,WEVOSIL 22006 FLA,WEVODUR 34020,WEVONAT PD 445,WEVOSIL 28002B,WEVOSIL 28002A,WEVONAT 68389 FL,WEVOSIL 22005 FL,WEVONAT 56005 FL,WEVOPUR 507,WEVOSIL 20201B,WEVOSIL 20201A,WEVOPUR 67210 FL,WEVONAT 67210FL,WEVONAT 895,WEVOPOX 34020,WEVOSIL 26009 FLA,WEVODUR 36001 FL,WEVOPUR 7210 FL,WEVONAT 9251 FL,OBCS,WALLBOXES,ON-BOARD CHARGERS,充电基础设施,FUEL CELL,车载充电器,充电连接器,ELECTRIC CARS,TRANSFORMERS,定子灌封,OBCS,BATTERY TENSION BARS,电池灌封,BATTERY CELLS,BATTERY POTTING,感应充电,MOTOR,卷绕头封装,CHARGING STATION,壁盒,MOTOR POTTING,充电基础设施组件,CONNECTOR,ON-BOARD-CHARGERS,蓄电池张力杆,电池冷却,马达,电机灌封,燃料电池,电池,CHARGER,LINEAR POTTING,CHARGING STATIONS SUPPLY,电力电子,POWER ELECTRONICS,ELECTRIC MOTOR STATOR,INDUCTIVE CHARGING,E-MOBILITY应用,电动汽车,FUEL CELLS,WALLBOX CHARGERS,充电站供电,WALLBOX,充电场站,CHARGING-INFRASTRUCTURE COMPONENTS,CHARGING CONNECTORS,RAPID-CHARGING STATIONS,快速充电站,BATTERY,WINDING HEADS POTTING,BATTERIES,变形金刚,充电器,CHARGING INFRASTRUCTURE,连接器,线性灌封,STATORS,电池单元,壁盒充电器,FAST-CHARGING STATIONS,BATTERY COOLING,电动机定子,E-MOBILITY APPLICATIONS,定子,STATOR POTTING

Wevo(威孚)WEVOPUR透明聚氨酯产品选型指南

WEVO - TRANSPARENT POLYURETHANE,透明浇铸树脂,TRANSPARENT CASTING RESINS,透明聚氨酯,356,1223,1211,1222,50001,1230,1240,1250,360,BUILT-IN MOTION SENSORS,LED LUMINAIRES,LED LUMINAIRE,LEDS,SENSORS,内置运动传感器,LED灯具,发光二极管,LED条,LED BAR,传感器,LED STRIP,LED灯带

WEVO浇注树脂环氧

WEVO公司提供定制化的环氧树脂系统,广泛应用于电子、汽车、航空航天等领域。产品具有高热导率、高耐化学性、耐高温、机械强度高、电气性能优良等特点。公司提供全面的技术支持和物流服务,确保产品满足客户需求。

WEVO - 环氧树脂,CASTING RESINS,SILICONE,EPOXY,硅酮,POLYURETHANE,浇铸树脂,聚氨酯,A 50,5001,8260 FL/60,5004,34021,34020,1018,2511 FL,34003,BX,2003 FL,958,32702,32703,1003/07,36001 FL,1018/25,VE,263,2513,1005,389,30010,5007,5008,5009,ELECTRICAL APPLICATIONS,电气应用

定制的硅胶解决方案

Wevo公司提供定制化的硅酮解决方案,包括硅酮、聚氨酯和环氧树脂等,广泛应用于电气和电子领域。这些产品具有高弹性、耐高温、阻燃和良好的电气性能,适用于机械要求高的应用。Wevo的产品包括凝胶、粘合剂、封装材料和热导填料等,满足不同应用的需求。公司提供从产品设计到系列生产的全程支持,并确保产品质量符合国际标准。

WEVO - 硅酮,ENCAPSULANTS,SILICONE,EPOXIES,灌封材料,封装材料,聚氨酯,环氧树脂,GENERAL-PURPOSE ENCAPSULANTS,定制的硅树脂,通用密封剂,黏合剂,导热填隙料,THERMALLY CONDUCTIVE GAP FILLERS,THERMALLY CONDUCTIVE ENCAPSULANTS,TAILORMADE GELS,阻燃的,特制凝胶,TAILOR-MADE SILICONES,GELS,导热密封剂,POTTING MATERIALS,热界面材料,THERMAL INTERFACE MATERIALS,POLYURETHANES,ADHESIVES,透明灌封化合物,凝胶,FLAME RETARDANT,TRANSPARENT POTTING COMPOUNDS,WEVOSIL 28002,WEVOSIL 20201/60,WEVOSIL 20202/60,WEVOSIL 28001,WEVOSIL 26010 FL,WEVOSIL 22007 FL,WEVOSIL 26001 FL,WEVOSIL 22006 FL,WEVOSIL 22005 FL,WEVOSIL 27001 FL,WEVOSIL 22002 FL,WEVOSIL 26020 FL,WEVOSIL 20405,WEVOSIL 22008 FL,20405 FL,WEVOSIL 22102 FL,WEVOSIL 20001,WEVOSIL 22004,WEVOSIL 20200,WEVOSIL 20002,WEVOSIL 27015 FL,光学透明,医学,工业电池,汽车,器具,RESIDENTIAL BATTERIES,MOBILITY,照明,AUTOMOTIVE,FIXTURES,INDUSTRY,住宅电池,CONSUMER,电动汽车电池,高压电池,SECONDARY OPTICS,基础设施,HOMES,ELECTRIC MOTORS,太阳能逆变器,ELECTRIC VEHICLE BATTERIES,LUMINAIRES,保健,LENSES,电气部件,能源,流动性,电子应用,电子元件,BATTERY CELL,INDUSTRIAL BATTERIES,家,MEDICAL,电气应用,ELECTRONIC COMPONENTS,二次光学,电动机,APPLIANCES,AUTOMOTIVE BATTERIES,汽车动力系统,SOLAR POWER INVERTERS,AUTOMOTIVE POWER TRAINS,镜头,LEDS,HEALTHCARE,ENERGY,LIGHTING,INFRASTRUCTURE,消费者,AGRICULTURE,SAFETY,ELECTRICAL COMPONENTS,固定装置,HOME,工业,HEALTH,灯具,ELECTRONIC APPLICATIONS,ELECTRICAL APPLICATIONS,汽车电池,电池单元,发光二极管,安全,农业,HIGH VOLTAGE BATTERIES,健康,家园,OPTICALLY CLEAR

Reliable and Durable Charging Infrastructure with Wevo Products

In order to protect sensitive electrical and electronic components, WEVO-CHEMIE GmbH has developed potting compounds and adhesives that can withstand high operating temperatures and physical stresses.

Wevo(威孚)WEVOPUR聚氨酯(PU)产品选型指南

WEVO - 聚氨酯浇铸树脂,POLYURETHANE,POLYURETHANE CASTING RESINS,聚氨酯,300 RE,300 M,9251 FL,390,801 G,PD 52,895,139,PD 445,923 M,552 FL,512 FL,PD 4,3050,385,300,500 MT/40,403 FL/33,600,403,930 M,801,900,507,7210 FL

伤口护理用硅凝胶

本文探讨了高级伤口敷料中使用的硅凝胶粘合剂的应用。文章介绍了硅凝胶粘合剂在伤口护理中的应用,包括减少疼痛、延长敷料使用时间以及适用于其他医疗设备。文章重点介绍了Wacker公司的高粘度硅凝胶产品Silpuran 2114,该产品具有高粘附力、低表面能和良好的柔韧性,能够在不损伤皮肤的情况下轻松去除敷料,且不留残留物。研究结果表明,Silpuran 2114在提高粘附力的同时,不会影响其柔韧性和可重新定位性,适用于慢性伤口护理和其他敏感皮肤的医疗粘合剂应用。

WACKER - 高粘附性硅凝胶,SKIN ADHESIVES,硅凝胶,SILICONE GELS,皮肤粘合剂,HIGH-ADHESION SILICONE GELS,MEDICAL APPLICATIONS,ATRAUMATIC WOUND DRESSINGS,伤口护理,SENSITIVE ADHESIVE PLASTERS,医疗器件,MEDICAL DEVICES,敏感胶布,医学应用,无创伤伤口敷料,WOUND CARE

Wevo基于聚氨酯、环氧树脂和有机硅专门开发的灌封化合物可用于废物管理,防止水分以及腐蚀性分解气体和冷凝物进入

空气质量控制、水处理和废物分离是现代环境技术的关键所在。WEVO-CHEMIE GmbH基于聚氨酯、环氧树脂和有机硅专门开发的灌封化合物和粘合剂可为各种要求和应用提供定制解决方案。

电子商城

品牌:EXXELIA

品类:POLYPROPYLENE CAPACITORS

价格:¥236.5290

现货: 0

登录 | 立即注册

提交评论