What is the packaging technology of soft pack Li Ion battery?

Soft pack lithium-ion batteries are always found in consumer electronics, such as UAV/drone batteries, and the high-performance batteries of RCs, for military, and automotive industries. Grepow(格瑞普) tells What is the packaging technology of soft pack Li Ion battery?

What is a soft pack Lithium-ion battery?

A Lithium-ion battery consists of the positive electrode, a negative electrode, electrolyte, diaphragm, etc., and shell packaging. According to the different shell packaging materials, the overall packaging of lithium-ion battery shell can be divided into steel shell, aluminum shell, and soft-coated aluminum-plastic film. And soft pack lithium-ion batteries (also named pouch cell batteries) are usually rechargeable lithium-ion batteries, typically lithium polymer whose highlights are lightweight, shape customizable, large capacity, etc. the choice of aluminum-plastic composite film (commonly known as aluminum-plastic film).

The soft pack battery structure

This article is talking about what and how the aluminum-plastic film packages Lithium-ion batteries.

The meaning and purpose of packaging

The significance and purpose of soft pack lithium-ion battery packaging are to completely isolate the inside of the cell from the outside using a high barrier flexible packaging material, leaving the inside in a vacuum, oxygen-free and water-free environment.

There are dynamic electrochemical reactions inside lithium-ion batteries, which are sensitive to water and oxygen. If water and oxygen meet the electrolyte, they will react with the lithium salt in the electrolyte to produce a large amount of HF, which will affect the electrochemical performance (such as capacity and cycle life) of the cell.

Note: Hydrofluoric acid (HF) is a contributor to the degradation and shortened life of many energy storage devices that use fluorinated organic electrolytes, such as lithium-ion batteries.

Packaging materials and packaging design

· Aluminum plastic film material and structure

The outer layer: generally nylon layer, its role is to protect the middle layer, reduce scratches and dirt soaking, ensure that the battery has a good appearance, the second is to prevent the penetration of air, especially oxygen, to maintain the internal environment of the battery cell, the third is to ensure that the packaging aluminum foil has good deformation capacity. Sometimes PET is used instead of nylon to have better chemical resistance, but this will lead to a reduction in the depth of the punch pit of the aluminum-plastic film.

The middle layer: with a certain thickness and strength to prevent water vapor penetration and external damage to the core, the most mainstream is made of aluminum foil.

Inner layer: mainly plays the role of encapsulation, insulation, preventing Al layer from contacting with electrolyte, etc., mainly using PP material.

Decorative or special protective layer: In order to improve the luster of battery appearance, sometimes a matte layer is added outside of PET/nylon, but this will lead to a significant increase in the price of aluminum-plastic film.

· What is the principle used for aluminum-plastic film encapsulation?

By and large, it relies on mechanical high temperatures, typically 230°C (446°F), to fuse together. The two PP layers face each other, and by giving a certain amount of heat to the Nylon layer, the heat is transferred to the PP via the Al layer, and the two PP layers fuse together under the combined effect of a certain temperature, pressure, and time.

· Encapsulation process

PP top-sealing: packaging foil is folded & aligned, Tab position is fine-tuned, the core is loaded and aligned, and then heat sealing is performed. The top-sealing process is the most difficult process to control for the whole package, the main difficulties include.

1) Packaging foil alignment (cutting, folding).

2) TAB position control (core width and center distance, edge distance).

3) Core feeding positioning (unsealed area of core)

4) Heat sealing head structure design (head width, Stopper, head recess depth).

5) Optimization of heat sealing process conditions (time, temperature, pressure, etc.).

p Side seal: It is to encapsulate the core after completing the top seal. The process control is mainly for the optimization of core positioning and heat-sealing process conditions.

p Corner sealing: The purpose is to prevent the seal from breaking at the corners of the package foil pair fold. The requirement of corner sealing is just to fuse the two layers of packaging aluminum foil together to prevent the stress concentration caused by bending. Process control is mainly the optimization of core positioning and heat-sealing process conditions.

p Vacuum encapsulation: The purpose is to seal the airbag after liquid injection to prevent electrolyte leakage and the entry of water vapor. The requirement of vacuum encapsulation is only sealing, and the process control is mainly the optimization of core positioning and heat-sealing process conditions.

ppSecondary encapsulation (Degassing): It is the process of venting and sealing the cores after chemical formation. Compared with side sealing, it requires airbag puncture and encapsulation under vacuum conditions.

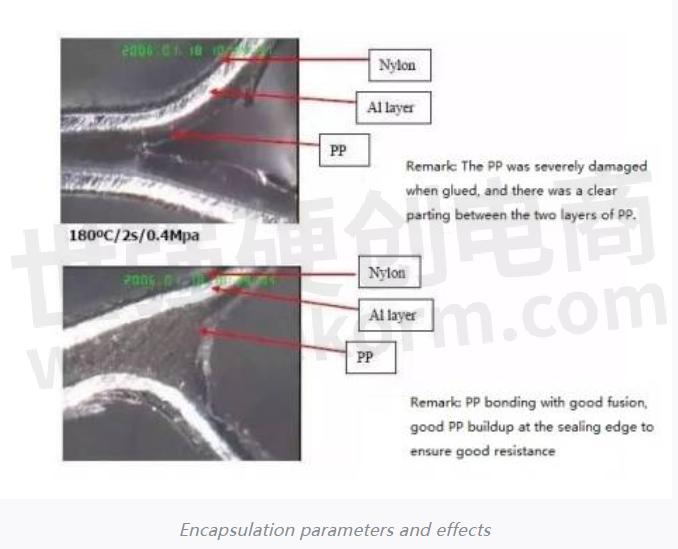

· Encapsulation parameters and effects

1. Temperature (melting point of PP and outer nylon, head structure, and heat dissipation)

2. Time (heat transfer and PP fusion)

3. Pressure (PP lamination, affecting melt and heat transfer)

4. Vacuum degree (mainly vacuum resting and degassing process)

· Effect confirmation

1. Encapsulation parallelism check (on the basis of stopper parallelism ok, encapsulation, tear open the encapsulation surface to observe foil melt glue showing milky white, seamless encapsulation bad place).

2. Tension test (including pole lug position and side seal position) Unsealed area inspection (visual inspection, including the top seal, side seal, and bottom seal of the internal and external unsealed area, check the internal PP situation)

3. Sealant exposed inspection (visual inspection, mainly negative pole lugs)

4. Resistance test (inspection after top and side seal including Al layer between positive and negative pole lugs, negative pole lugs, and Al layer in the pocket bag, an inspection of the negative pole and Al layer in the pocket bag after degassing).

- |

- +1 赞 0

- 收藏

- 评论 0

本文由翊翊所思转载自格瑞普,原文标题为:What is the packaging technology of soft pack Li Ion battery?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

What Is the Beauty Gadget and How to Pick the Built-In Battery

What Are Beauty Gadgets?Beauty gadgets are electronic devices designed to enhance personal care and aesthetic treatments, making professional-grade beauty routines accessible at home. These devices address various needs, such as improving skin texture, reducing wrinkles, cleansing pores, and enhancing hair care.Types of Beauty GadgetsBeauty gadgets cater to specific beauty and skincare needs:● Cleansing Devices: Facial brushes and ultrasonic scrubbers remove dirt, oil, and makeup residue through deep cleansing.

Frequently Asked Questions for UPS Battery Replacement

In fact, it depends. The batteries are the lifeline of the UPS, providing power during electrical outages or fluctuations. By replacing the batteries, you ensure that your UPS continues to function effectively, protecting your connected equipment and preventing data loss. Replace UPS batteries is more cost-effective than buying a new one. But if your UPS has become flaky in some fashion, or it doesn‘t have the features that you want. Then you should buy a new UPS.

What Is LiFePO4 Battery and Why Use It?

LiFePO4 battery becomes more and more popular because of their safety, longevity, and reliability. But what is a LiFePO4 battery, when to choose use it and why it is so expensive? This article will take you into the world of LiFePO4 battery and help you decide whether you should use LiFePO4 batteries.What Is a Lifepo4 Battery?The LiFePO4 battery (lithium iron phosphate) or LFP battery (lithium ferrophosphate) is a specific type of lithium-ion battery known for its robust safety features and impressive cycle life.

Recycling and Regeneration of Lithium Batteries

Under the pursuit of economic and environmental protection, the production and demand of lithium batteries have grown in recent years. Decommissioned lithium batteries are known as high-grade mines, coupled with the price and mining of raw materials, so the recycling value is obvious.

What is the Impact of Long Coldness on Agriculture Spraying UAVs Batteries and How to Deal with it

Agricultural drones are not only used for spraying and applying medicine, but also for spreading fertilizer, seeds, and feeds to meet the diversified needs of farmers and improve production efficiency.

Thin Film Lithium-ion Battery Vs Lithium-ion Battery: What’s the Difference?

In the rapidly evolving world of battery technology, thin film lithium-ion batteries have emerged as a promising alternative to traditional lithium-ion batteries. These batteries, with their ultra-thin structure and solid-state electrolyte, offer distinct advantages in flexibility, safety, and application potential. This article delves into the fundamental differences between thin film lithium-ion battery and conventional lithium-ion battery, exploring their respective structures, manufacturing processes, and applications across various industries.

Can Lipo Battery Cells Be Shipped by Air?

With the widespread use of electronic products, batteries nowadays have become household items that we can see everywhere. The most commonly encountered type of battery is the lithium-ion battery.

NMC vs NCA Battery Cell: What’s the Difference?

Choosing between NMC and NCA battery cells depends on the specific requirements of the application. NMC cells offer a versatile and cost-effective solution with balanced energy and power characteristics, making them ideal for a wide range of uses from EVs to power tools. On the other hand, NCA cells provide higher energy density and longer cycle life, making them suitable for high-performance EVs, consumer electronics, and aerospace applications.

What are the Best Intelligent Lithium Battery Manufacturers in Shenzhen?- Grepow Battery

At one time, a survey by the Japan Economic Research Institute showed that Chinese battery manufacturers accounted for more than 60% of the global automotive lithium-ion battery market.

What Caused The Lithium Battery to Explode?

With over 20 years of customer service experience, Grepow has developed a very complete service system, specifically tailored for Grepow customers, which helps Grepow in better understanding your needs in the first step of our communication, in a highly time-efficient way.

Steel-Shell vs. Soft Pack Coin Cell Batteries for TWS Earbuds: Which is Better ?

The mainstream TWs headset battery types currently on the market are steel-cased button batteries and soft pack button batteries. The two have differences in the amount of charge, shape, and many other aspects, so TWS headphones with Steel-Shell or Soft Pack Coin Cell Batteries cells are good.

Lithium-ion Battery Cycle Life VS. Calendar Life VS. Shelf Life

Lithium-ion batteries have become an integral part of our daily lives, powering everything from smartphones to electric vehicles. As these batteries play a crucial role in various applications, understanding their life expectancy is essential. In this article, we will explore the concepts of cycle life, calendar life, and shelf life of lithium-ion batteries, shedding light on their individual characteristics and implications.

5 Factors That Affect the Lithium Ion Battery Life

Grepow talks about 5 Factors That Affect the Lithium-Ion Battery Life.

What Is an Ultra Thin LiPo Battery?

The Lithium-ion battery (LIB) has revolutionized our lives and is widespread from small-scale devices such as mobile phone to emergency distributed power supply, electric vehicle, etc. Lithium-ion batteries are evolving even now. Many current types of research for LIB focus on life extension, energy density, safety, cost reduction, and charging speed. Thin film LIB is one of the forms of LIB, it has attracted much interest for use as power sources of smart cards, implantable medical devices, micro-sensors, and soon.

What Is a NMC Battery?

NMC batteries are a type of lithium-ion battery that has gained popularity in various industries due to their high energy density and long lifespan. These batteries use a combination of nickel, manganese, and cobalt in the cathode, which allows them to store a large amount of energy in a relatively small and lightweight package. NMC batteries are used in a wide range of applications, including electric vehicles, portable electronics, and renewable energy systems.

电子商城

现货市场

服务

可自由定制电池形状,锂离子聚合物/磷酸铁锂成分,放电倍率Max. 50C (持续放电倍率) / 150C (脉冲放电倍率),充电倍率:Max. 5,厚度可达0.5mm。

最小起订量: 5000 提交需求>

登录 | 立即注册

提交评论