Boosting Your Manufacturing Analytics System with Keysight’s Pathwave Manufacturing Analytics (PMA)

Manufacturing Analytics is not something new. In fact, most manufacturers are either already using commercial Manufacturing Execution Systems (MES) or have their home-grown manufacturing analytics catered to their needs. In some cases, factories may have multiple manufacturing analytics systems in place to meet diverse operational needs.

Most of the existing manufacturing analytics systems focus on operational Key Performance Index (KPI) such as Overall Equipment Efficiency (OEE), throughput, and yield. These KPIs are some of the major performance metrics for manufacturers to increase their revenue and ROIC with better capacity utilization. However, for mission-critical industries such as automotive and cloud server manufacturers, product quality trumps all else when it comes to what matters most in terms of profitability, competitiveness, and growth. If anything 2022 material shortage and the pandemic have taught us, it is that you can use the money to buy capacity where everyone was rushing to secure expensive long lead-time manufacturing equipment, but you can’t use the money to buy quality.

Product quality can be assessed through various means, and one of them is by calculating the Cost of Poor Quality (COPQ), a concept popularized by IBM quality expert H. James Harrington in his 1987 book Poor Quality Costs. The cost of poor quality refers to the total cost incurred by producing defective products or boards. As a defective product should never be shipped to the end customer, it is best to detect any issues internally, either by OEM (Original Equipment Manufacturer) or CM (Contract Manufacturer). Rework, scrap, and re-inspection costs are all examples of internal defect costs incurred due to defects found before the product or board is shipped to the customer. Most significantly, the amount of times the product is being handled directly correlates to field failures resulting from electrostatic discharge, stress, contamination, mix-ups, and general mishandling.

Bridging the Trust Gap: Enhancing Visibility in Manufacturing Analytics

Both rework and scraps can adversely affect productivity, quality, and profitability. While tracking these metrics within the same entity is relatively easy, identifying the root cause of the failure and implementing corrective actions and process improvements can be challenging and time-consuming. This challenge becomes even more significant in the context of the global manufacturing industry, where multiple CMs may produce the same product for an OEM. In such cases, rationalization and clarifications of the reasons for rework and scrap are necessary to build trust between CMs and OEMs. This often leads to wasted time and effort to generate multiple reports and getting on many calls to disposition for scraps. Besides, scraps and rework are just one of the KPIs the OEM tracks.

Moreover, rework and scrap are just two of the many KPIs the OEM tracks, including test coverage, Cpk, board anomalies, and failure rate. The need for multiple report generation on different KPIs is a symptom of a more significant problem: a lack of visibility.

Imagine if there was a way for the OEM to know what is happening on the production floor without waiting on the CMs to respond. At the same time, the CMs could proof-check their observations and results using the same dataset provided to the OEM. Having visibility into the actual manufacturing scene would undoubtedly bridge the trust gap between the CMs and OEMs.

Below are a few examples of how PMA addresses the issues mentioned above:

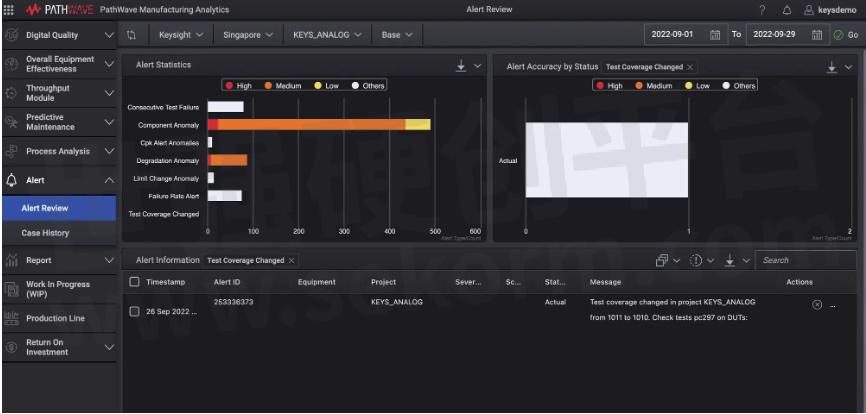

One of them is the Test Coverage Monitor and changed alert. Product quality is the primary and essential requirement in the manufacturing process that cannot be compromised. Test coverage buyoff must be performed prior to releasing products to mass production to ensure that all components and functionality are tested with the proper upper and lower limits of the desired specification. However, manufacturers often face challenges such as incorrect limit changes and skipped tests, which can jeopardize the quality metric.

The real-time automated Test Coverage Monitor detects any changes in test coverage for testing the quality of the products or device-under-test (DUT). Rather than relying on manual data entry by operators for checking solutions, KEYSIGHT's PMA has developed an automated learning process within the Test Coverage Monitor. This system learns in real time as it analyzes data, enabling it to improve its accuracy and effectiveness continuously.

Test Coverage changed alert (Figure 1) will be triggered when the number of test execution registered for a passing board exceeds the baseline reference. With that, the user can immediately track down this board via its serial number, investigate the test names in differences, and reroute the affected boards back to ensure the execution of all necessary tests for passing quality purposes.

Figure 1. Test Coverage Changed Alert

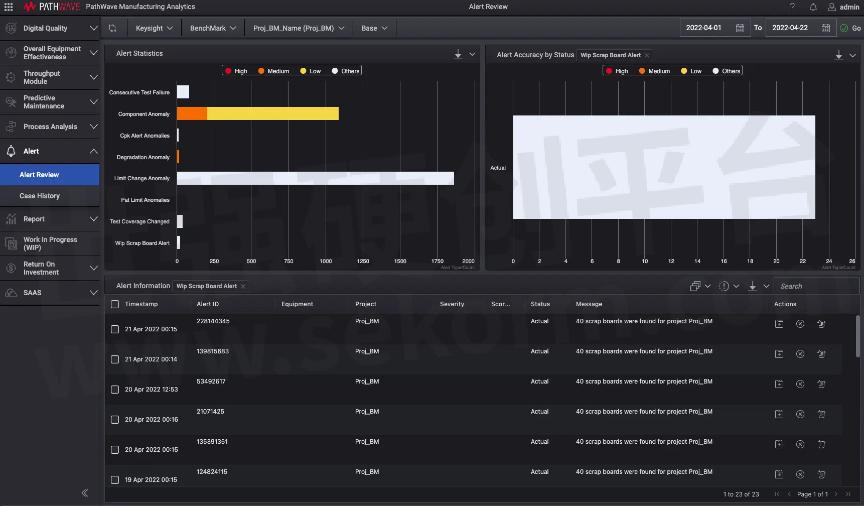

Another useful feature is the Scrap Board alert, which triggers a notification when a scrap board hits the predetermined scrap threshold, as shown in Figure 2. This feature enables users to make informed decisions on cost and investigate the root cause of the scrap.

Alternatively, users can easily get the Scrap Board information by accessing the Work In Progress (WIP) module, as shown in Figure 3. This gives you an overview of the Scrap board performances of the particular site and project.

To dive deeper into the details of the scrap board, the user can click on one of the horizontal bars on the Failure Pareto by Scrap Board chart in Figure 4. By selecting p3v3_aux_gnd, for example, a Test Result Dialog box will appear, as shown in Figure 4. The user can quickly identify the scrap board(s) by looking at the blue-coded points in the Test Result chart, as shown in Figure 4. Hovering the mouse over the blue-coded points will provide historical information about the scrap board(s).

With this, users can make better decisions regarding cost and find out the root cause of scraps without halting the production line to conduct a root cause analysis.

Figure 2. Alert Review – Scrap Board Alert

Figure 3. Scrap Board information in WIP (Work-In-Progress) dashboard.

Figure 4. Test Result - p3v3_aux_gnd

Boosting your manufacturing analytics system with Keysight’s PathWave Manufacturing Analytics (PMA)

Keysight has been in the manufacturing industry for more than 30 years, and PathWave Manufacturing Analytics (PMA) has been an instrumental addition to all existing manufacturing analytics platforms. With the recently launched feature that tracks all rework and scraps, PMA has helped manufacturers globally by working alongside their existing manufacturing systems to improve their cost of poor quality and leading towards lowering the defects of the test boards.

In the world of manufacturing analytics, there is no perfect solution that provides end-to-end insights with actionable results. Each analytics provider operates in their specific area of expertise. By combining test measurement science with data science in PMA, we strive to provide our customers with visibility into their own manufacturing lines and, most importantly, to build trust between CMs and OEMs.

Figure 5. Digital Quality Dashboard in PathWave Manufacturing Analytics.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由翊翊所思转载自Keysight Blogs,原文标题为:A Boost to Your Existing Manufacturing Analytic Approach,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

Root Cause Analysis on Return Merchandise Authorization (RMA) Boards

Sometimes early failure boards are returned to the factory for diagnostics,Keysight is going to talk about Root Cause Analysis on Return Merchandise Authorization (RMA) Boards.

【经验】是德科技的PathWave制造分析软件(PMA)使用实例:更快地进行半导体召回诊断

在是德科技(Keysight)推出的PathWave制造分析应用程序中,其中有一个RMA模块,该模块让用户可以检索电路板及其批次的完整测试历史记录。RMA模块专门设计用于帮助OEM和CM执行更快的根本原因分析。

【经验】退货商品授权(RMA)板的根本原因分析

人们普遍认为,只有在生产线上通过的电路板才能从工厂运往市场。然而,在一些罕见的情况下,产品或电路板出现故障的时间比市场预期的要早。在某应用程序中,有一个RMA模块,让用户能够根据板子的序列号回顾测试历史记录。本文Keysight呈现退货商品授权(RMA)板的根本原因分析。

Littelfuse(力特)保护继电器和控制装置选型指南

描述- Littelfuse is a diversified industrial technology manufacturing company empowering a sustainable, connected, and safer world. Across more than 20 countries, and with approximately 17,000 global associates, Littelfuse partners with customers to design and deliver innovative, reliable solutions.

型号- TDR4B23,EL3100,RK-325,TDR4B22,SCR,CT-0050-F10,TDI120AL,ECSL4HBH,DLMU,TDML110DL,SD12-PC,KSPSN21B,LLC42B15A,RK-332,SE-TA6ASF-WL,PC-200-LLC-CZ,THDS410.25SA,ZSCT30-31,TSU2000 SERIES,RK-325I,P1004-XX-(X),ORB120A25,P1004-12-X,SE-FLASH,PSC11,TDM24DL,LLC6210F10M,SB6000,FS146RC,SIO-RTD-02-00,LLP-24,FS165-30T,ARPX1S SERIES,233P,RK-105I,NDS-11,50R40029,MPS-RTD,460-15-100-SLD,ESDR423A4,ECSL4HAC,RM1000 NEMA 4,ASXX SERIES,KRDI2110S,ESDR423A3,KRPDA2129RXE,TDB120AL,LLC54AF10,455 SERIES,KRDM223,KRDM220,KRDM221,ORS120A150SD,PGC-31FC,PGM-8325,460-XXX-SP,FS126-45,CT-0800-F30,CT-0400-D20,TSB634,LLC26A1F25C,PLR240A,ECSW3LABT,TSB632,TDUH SERIES,TSDS SERIES,WVM811AH,TDM24AL,LPSM003Z,HRDM SERIES,235P,FA155-2,KSDB315SP,601,SB6100-01X-0,102A,KRPD215S190SMB,601 SERIES,EL731-03-X0,PC-200-LLC-GM,SIR,MPU-32-X69X SERIES,ORS230A150SD,KSD3120A,FPS,ECSW6MBHT,MSM20.15W9,FB9L,HRDR331A1,TSD6 SERIES,TS22120,201575-AU,201-100-SP-DPDT,FS300 SERIES,ECSH31F.08D,FS126-60,TDS SERIES,KRDI220,MSM130W9,KSD2 SERIES,FS500,102A SERIES,201-XXX-SP SERIES,LLC52BA,A0220 SERIES,460-200-SP,ALT230-S-SW,HRDR121A4R,LLC52AA,ORB120A160,P0400-82,TDI SERIES,PC-XXXLLC-CZ SERIES,P0400-83,DCSA5,PC-XXX-LLC-GM,P0400-86,SLR,INFORMER-MS,HRDB321,CT-0150-D10,PGC-4064,HRDB324,KSDB SERIES,FS512,ECSW4MBHT,TSDR612.5SA4.5S,TMV8000 SERIES,TSD2411S,ECSW4MBGT,FS524,CT-XXXX-DXX,KSDR SERIES,RS SERIES,P1004-XX,MPU-32-X69X–XXX00,WVM,SLR1610A,KSD1320,ASQU SERIES,TS1424,TS1423,TS1422,TS1421,HRDR330A0R,TSB222,77C SERIES,T10,CT-1200-F15,NGR SERIES,NGR1080,TS1416,NGR1081,TS1415,HRISW21FT,TS1412,KRPS913MB,HLMUDNAAN,202-575-RP,CT-0300-F10,TSD7621,LSRU-115-OR-2,DCSA50,HLMU,EL731-23-X0,NGR1077,NGR1078,NGRM-ENC-230-00,TRDU24A1,NGR1079,TRDU24A2,AF0100-10,TRDU24A3,SB6100-21X-0,NGR1070,NGR1071,NGR1072,NGR1073,NGR1074,ESDR450A1,NGR1075,NGR1076,ECS40AC,TVM460A75S2M,PMA-16-RTDB,PGR-3200-120,SE-703-0U-0X,ESDR123B4P,FS SERIES,NGR1066,NGR1067,D1100,PLR SERIES,NGR1068,AF0100-00,NGR1069,202,KSDB120P,KRPSD25S,TRM24D1X2,777-HRG-P2,ECS40BC,TRDU120A3,TRDU120A1,TRDU120A2,ERDM4130S,TDS120ALD,LLC14B60AX,ISS-102 SERIES,TDIH SERIES,NGR1050,NGR1051,NGR1052,NGR1053,TVW6510S0.4S,FB230A,CT-0300-F20,KSD3432A,PGE-05KV,DCSA20,LLC2,LLC1,LLC6,NGR1045,LLC5,ALT-XXX-1-SW,LLC4,SE-330AU-XX-0X,TVM230A101S1S,LLC8,SC4 SERIES,T10120,NGR1041,KSPSN13MI,VTP0E,PGE-35KV,FS100,TDB12D,T10S400,TSDR4412SA1,LLC842F103M,TDSL SERIES,KRD92115MB,FPU-32-00-00,201-200-SP-DPDT,KRD92115MA,ECSH4HAD,SE-GRM250,PGR-4300 SERIES,NGR1036,PMA-23,NGR1038,PMA-24,PMA-21,ERDM429,ERDM425,KRDB SERIES,ERDM427,FS590,NGRM-ENC-431-21,ER-72KV,777-MV-P2,240,460-MR,PCR SERIES,TDBL120AL,TS1211.5,EL731-11-X0,CT30S1,LLC4 SERIES,KSDS230,PGC-3140,3506002,FS126,FS127,TSD2434,DSQU SERIE,TDB24DL,T2D120A15M SERIES,TDUSH3001A,ALTXXX-X SERIES,THD7421A,TDUIL3001A,ERDM423,ECS6HAH,ERDM422,TDSH120AL,RS4B12,FPS SERIES,TS13115,PMA-18,HRPSD12HI,PMA-16,KSDU SERIES,PMA-17,LLC825F5M,LSRU-115-AL-3,PMA-14,PMA-15,PMA-12,LSRU-115-AL-2,PMA-13,PMA-10,TSDS421,SE-105,MPS-CTU-01-00,ORM24D13.5,TH1 SERIES,TDUIL3002A,MSM450W6,SE-107,DLMUBLAAA,FS143,TSU2000,FS146,RS1A11,KSPU SERIES,SB5060-20X-0,LLC44B4A,TCR9C,MSM42W6,50R-100-2,TDUB SERIES,THDB SERIES,FS152,777-HP-P2,PGR-8800-00-CC,LSR-XXX,LLC14B15AX,TS441165,PGR-4300,TSD24145S,ASXX,LSRU-115-OU-1.5,KSD2221,ORB,FS162,TA24A5,KRDR424A4,KSDR40A0,TA24A3,HRDR321A4R,TRM24A8Y5,KRDR424A0,TH1C415,TSDR6412SA1,ORM,RK-310X-0Y,SIR1A20A4,ALT115-S-SW,ORS,VMPS,TDIL SERIES,LLC44B2A,VMPU,FPS-CTU-03-00,ORB24A25,BZ1,777-ACCUPOWER,HRPS SERIES,PHST-38QTN,TS2412,LSRX-C,350200,HLMUDRAAA,LLC44B1A,KSD2413M,TRDU SERIES,TSS SERIES,SIR1A1A4,KRPSA24M,TL230A5,ECS2HBC,TS2421,PC-100-LLC-CZ,TS2422,TS2423,PGA-LS20,777-575-HRG-P2,IR KIT-12,TSDR6110SA30S,1N5339B,AC700-SMK,KRDB21180S,KRPSA22B,ER-15KV,PGA-LS30,TDB120ALD,LLC44B5F100,TSS421,ISS-102A-LC,202-200-SP,MPS-469X,TVM480A100.5S3S,KRDM121,ARP43,ARP41,777-KW-P2 SERIES,HRDR431A1R,MPU-32-X69X,TSS424,TSS422,TSD6310.8SN,THDS SERIES,KRPD SERIES,601575,ASTU SERIES,TS121150,PGA-LS10,VTP5N,460L-OEM,TCSA50,LLC44B5A,TDUIL,ELCT,SE-CS40,TDUIH,SE-502,TDR2A23,VTP4B,TSDR215SB18M,VTP4F,NGRUS003,VTP4J,P0200-20,PC-100-LLC-GM,P0200-19,SE-CS30,NGRM-ENC,PCR11,PCR10,TDUL SERIES,PMA-60,WVM611AL,PLS480A,PRLM423,VTP3B,ECSW,PGR-8800-00,PCR13,PCR12,PLM6502,ESDR120A0P,SB5032-21X-0,ESDR424A1,WVM611AH,ERDI436,VTP2C,VTP2A,TDUSL3000A,VTP2F,TCS,VTP2E,ORB SERIES,VTP2J,202-200-SP SERIES,KSPSA21FT,MPS-469X–XX000,SCR490D,THC421C,ELCT30-88,IR KIT-36,VTP2P,TDB,P1004-9,202 SERIES,SE-CS10,TDI,KRDR420A3,ECSL31A,KRDB415S,TDM,TSD7611S,VTP1B,TDS,SERIES,TS141180,TDR,TDU,VTP1D,VTP1C,MSM11W6,MSM210P3,TDB24AL,MPS-RTD-01-00,PGR-6100,PMA-55,PGR-6101,ARP23S,50R200,PLS120A,PGR-6100 SERIES,KSDB330N,KRDB,777-575-TS,FA155,KRDI,ALT115-X,KVM4,KRDM,ALT115-S,ECSH34F.08C,KRDB1120M,TDML120AL,KRDS,EFCT SERIES,KRDR,KVM6,TDUIL SERIES,EL731-04-X0,MPS-469X-PMA24,PGR-2601,THD1B410.5S,201-100-DPDT,AF0500 SERIES,ECS40A,SE-TA6A SERIES,TDM12DL,NGRM-ENC-231-01,TSDR442MA2,ELCT5,77C-KW SERIES,KRD3,FS219-45,ISS-102AA-DCS,TH1,A0220.0040,KRD9,KSDB1115SP,TDR4A23,MPU-32-X69X-PMA16,KVM,KRDM1110S,EFCT-26,111P,FS126RC-45,THC,T

Firstohm(第一电阻)电阻产品选型指南(英文)

目录- Company Profile MELF Resistor

型号- SCP,MM(P),HVR,MVM,FM,MVR,WA,SLC,SRM204T,MMP(V),EFP,SRM,C3,EFR,PPR,C3M100,HFT,SFP101V,ISC,SL,SM,CSM,SFP,SWA,IG,ESM,MSD,SFP(V),MM,MO,CSR,MP,FGE,PMA,SWM,CM,ISW,SWMT,SWAT,MMP,SSR,MM102,MM(V),ZMM,HVM,SGS

适用于移动设备的汽车兼容单放大器多模无线电源

描述- 本文介绍了一种基于eGaN® FET的单放大器多模式无线充电解决方案,适用于移动设备,包括汽车应用。该方案通过简单修改放大器电路,使其能够在低频(Qi & PMA标准)和高频(A4WP标准)下均能高效运行。实验验证了该方案在不同无线充电标准下的性能,并展示了其在汽车应用中的可靠性。

将数据导入到是德科技PathWave Manufacturing Analytics软件,优化制造工艺和效率

PathWave Manufacturing Analytics(PMA)由Keysight团队提供支持,可以帮助实现从您的制造测试设备和软件中导入数据进行分析和演示的目标,帮助获得必要的可操作的视图,这些视图可以用于从生产线上的操作员到业务组织的最高高级管理层。

Reducing Retest Improves First Pass Yield (FPY) with PathWave Manufacturing Analytics

PathWave Manufacturing Analytics (PMA) provides a big data platform for performing time-series analytics on all kinds of test equipment in a manufacturing environment. In this customer success story, the contract manufacturer is utilizing Keysight‘s Cloud platform for hosting the analytics to speed deployment and reduce the upfront server infrastructure investment costs and maintenance.

是德科技与您相约NEPCON Asia深圳,将带来涵盖SMT产线的系统化电子制造测试解决方案,推动工业4.0

Keysight的系统化电子制造测试解决方案涵盖SMT产线,包括ICT、功能测试和开创性的PathWave制造数据分析(PMA)软件-旨在推动您的工厂步入工业4.0时代,是推动运营改进的重要力量。PMA从设计到制造在各个层面提供全面支持,实现问题的主动检测和优化。

PMA‘s DPAT Implementation Safeguards Against Potential Yield Losses

With the advent of Electric vehicles (EVs), there is an increasing number of requests for incorporating DPAT into Keysight’s Pathwave Manufacturing Analytics (PMA) Dashboard for a more precise calculation of what to discard as fails and what to pass and ship out to end user.

是德科技即将亮相NEPCON China 2023,提供系统化电子制造测试解决方案

NEPCON China 2023将于7月19日-21日在上海世博展览馆隆重开幕。Keysight的系统化电子制造测试解决方案涵盖SMT产线,包括ICT、功能测试和开创性的PathWave制造数据分析(PMA)软件-旨在推动您的工厂步入工业4.0时代,是推动运营改进的重要力量。

PathWave设计和测试软件目录

描述- 该资料介绍了Keysight Technologies的PathWave设计测试软件系列,旨在提高设计测试效率。软件涵盖设计仿真、信号分析生成、组件和合规测试、测试自动化以及数据分析等方面,支持远程工作,并提供多种应用软件和工具,如PathWave Advanced Design System (ADS)、PathWave Signal Generation、PathWave Vector Signal Analysis (89600 VSA)、PathWave Oscilloscope Software、PathWave Network Analyzer Software、PathWave BenchVue、PathWave Test Automation、PathWave Waveform Analytics、PathWave Manufacturing Analytics和PathWave Measurement Analytics等。

型号- X-SERIES,89600

【应用】是德科技PMA可帮助全球汽车零部件制造商把RCA过程从6个月减少到5分钟,还能对治具运行状况进行日常监控

使用Keysight PathWave制造分析,可以一目了然地查看适量的测试设备测量数据,用户还可以轻松捕获和报告数据,从而有助于加快调查过程并减少生产中的停机时间。因此,使用该分析软件,生产线可以重回正轨,甚至可以提高其能力。

Loading data into PathWave Manufacturing Analytics

PathWave Manufacturing Analytics (PMA) is a backed by an experienced team of people at Keysight, who can help you achieve the goal of bringing in data from your manufacturing test equipment and software, for analysis and presentation, to help you to gain the necessary actionable insights that can be used from an operator on the line to the highest senior management levels of the business organization. PMA includes a scalable architecture that can grow with your business.

电子商城

现货市场

服务

提供是德(Keysight),罗德(R&S)测试测量仪器租赁服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器租赁服务;租赁费用按月计算,租赁价格按仪器配置而定。

提交需求>

朗能泛亚提供是德(Keysight),罗德(R&S)等品牌的测试测量仪器维修服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器维修,支持一台仪器即可维修。

提交需求>

登录 | 立即注册

提交评论