Increasing Thermal Challenges: Boyd and Innovative Cooling Technologies Enable the Development of Advanced Electronic Devices

Rising Trend: Miniaturized Semiconductor Components

As semiconductor geometries continue to shrink, advances in microelectronics are driving the development of powerful, smart, and sophisticated devices. This ongoing miniaturization trend propels semiconductor innovation, enabling the scale-down of intricate patterns on wafers essential to produce advanced semiconductor devices.![]()

Advanced Chipmaking Technologies: Pushing the Limits of Moore’s Law

Advancements in fabrication techniques, especially extreme ultraviolet (EUV) and deep ultraviolet (DUV) lithography, are revolutionizing the semiconductor manufacturing process, enabling increasingly miniaturized and efficient semiconductor components with significant improvements in transistor density, performance, and energy efficiency.

Extreme ultraviolet (EUV) lithography is a cutting-edge semiconductor fabrication technique that employs very short wavelengths of 13.5 nm, which is 14 times smaller than the other advanced lithography technique, deep ultraviolet (DUV) lithography with wavelengths of 193 nm. Such short wavelengths enable microchip circuit and transistor production at extremely small nodes, such as 7nm and 5nm, achieving unprecedented precision and resolution levels in semiconductor manufacturing.

Short wavelengths enable more transistors in a given chip size

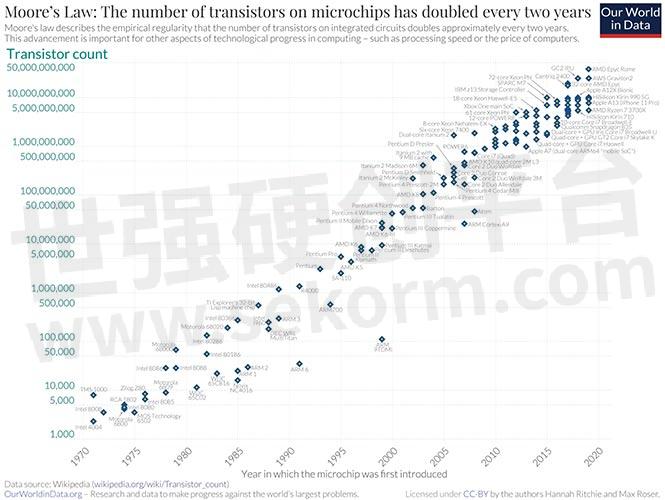

By pushing the limits of possibilities in miniaturization and performance, these advanced techniques have pushed the boundaries of Moore’s Law. Moore’s Law predicted in 1965 that the number of transistors in an integrated circuit (IC) will double every two years until the technology reaches its miniaturization and performance limits.

Increasing Thermal Challenges: Need for Innovative Cooling Solutions

Extreme ultraviolet (EUV) and deep ultraviolet (DUV) lithography adoption has led to higher power densities which creates more heat in electronic components. Thermal management is a barrier to semiconductor innovation. More powerful, energy-efficient performance requires advanced cooling innovation.

More transistors in a smaller footprint means higher concentrations of heat

Semiconductor manufacturers continuously explore innovative cooling solutions such as liquid cooling, heat pipes, heat sinks, and advanced materials to dissipate growing heat levels from densely packed electronic components. Sustainable cooling innovation is required to unlock semiconductor technology’s fullest potential and enable continued advanced electronic device development.

Innovative thermal solutions enable the development of advanced electronic devices

BOYD and Innovative Cooling Technologies

Boyd has decades of experience and expertise innovating and manufacturing cooling solutions for semiconductors. Their customer-first service with market-leading speed and responsiveness combined with decades of semiconductor design expertise and robust, proprietary modeling tools enable us to iterate designs quickly and accelerate speed to market.

Boyd’s overlapping thermal technology portfolio enables liquid, two-phase, and air-cooling innovation to co-exist. Leverage their highly efficient, reliable, and sustainable liquid cooling systems to decrease test times, maximize temperature forcing range, or decrease chip operating temperature for faster processing and better uptimes.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由洛希转载自BOYD News,原文标题为:Rising Trend: Miniaturized Semiconductor Components,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

Boyd anticipates exponential semiconductor power growth and continually develops innovative cooling solutions

The semiconductor industry continues to drive Moore’s Law and push the boundaries of semiconductor chip power and performance. Higher performance, more powerful and complex chips generate more heat with higher power densities. Thermal technology innovators like Boyd are developing new methods to cool exponentially rising chip power and performance.

Generative AI and EV Batteries: Why Liquid Cooling?

Advancing technologies like high-performance AI and EV batteries use more power. More power generates more waste heat, so much so that generative AI and EV battery innovators are shifting to liquid cooling. We‘ll explore why liquid cooling is a fundamental part of this conversation.

Boyd is Selected by COOLERCHIPS Program - Advanced Cooling System for Data Centers

A $5 Million grant from the U.S. Department of Energy (DOE) supports NVIDIA and seven partners, including Boyd, to build an advanced liquid cooling system that enables a future class of efficient power-dense data centers.

爱美达(AAVID)5G综合热管理解决方案——世强硬创沙龙2019

描述- Thermal Management Critical to Products that Keep the World Running

专为工业大功率设计,爱美达(Aavid)提供综合热管理解决方案——世强硬创沙龙2019

描述- Thermal Management Critical to Products that Keep the World Running

Boyd’s Chiller Provided Precise Temperature Control for Renewable Energy Storage Solution

As renewable energy generation continues to grow in popularity and Battery Energy Storage Systems become more commonplace across the world, many leading energy storage companies and battery producers rely on Boyd’s extensive thermal expertise to keep them cool and performing optimally.

热交换器、冷却器和冷却剂分配装置(CDU)

型号- RC045,6000 SERIES,6000,5000,4000,5000 SERIES,ES SERIES,4000 SERIES,ASPEN,ASPEN SERIES,RC011,RC022,RC030

Aavid‘s Modular Liquid Cooling Systems: Build a semi-custom system with high performance compatible components

Modular Liquid Cooling Systems are a cost-effective and reliable option where precise temperature control and cooling below ambient temperature are not required. These systems consist of a high performance heat exchanger integrated with a fan, pump, and tank in a durable metal chassis. Aavid‘s Modular Cooling Systems have cooling capacities up to 3.5 kW.

Renewable Battery Energy Storage

Innovative battery sealing and cooling solutions are instrumental in preserving battery integrity and performance while enabling efficient and safe energy storage from renewable sources. Liquid cooling systems coupled with robust sealing mechanisms maintain batteries at optimal operating temperatures, preventing overheating and mitigating thermal runaway. This integrated approach enhances battery efficiency, boosts safety measures, and extends the operational life of the energy storage system.

Coolant Distribution Units - Improve Cooling and Performance of Cloud, Enterprise & 5G Applications

OverviewBoyd Corporation has been the leading innovator in Enterprise cooling and engineered material solutions since data centers first started to emerge and evolve. Boyd utilizes these decades of expertise to develop advanced thermal solutions and systems to stay ahead of rapidly rising processing power, thermal density, and heat loads. This includes forward thinking liquid cooling innovation and system components such as Coolant Distribution Units (CDUs). This article covers CDU technology for improved liquid cooling systems and integrated solutions that help OEMs increase compute density i

Aavid‘s Liquid Cooling Systems: Modular or fully customized liquid cooling optimized for improved heat dissipation in condensed volumes

Liquids have a high capacity for heat transfer and can remove and dissipate heat quickly and effectively. This enables Liquid Cooling Systems (LCSs) that utilize liquid and optimized system components, such as pumps, compressors, or cold plates, to cool high power density devices more efficiently than air cooled systems of the same volume. Aavid, Thermal Division of Boyd Corporation, specializes in engineering and the production of liquid systems as well as fully optimized individual thermal and sealing components.

Data Center Installations: In-Rack Cooling or In-Row Cooling?

New artificial intelligence (AI) applications push rapid data center growth, leaving data center architects to quickly determine if in-rack cooling or in-row cooling is right for their installation. Consumer demands for convenience, flexibility, speed, mobility, and responsiveness drive immense processing. With, extreme data loads and more powerful processors come additional heat generation, where system designers rely on innovative cooling solutions like in-rack cooling and in-row cooling to meet this data explosion.

电子商城

服务

可定制均温板VC最薄0.4mm,有效导热系数超5,000 W / m·K(纯铜(401 W/m·K ,石墨烯1,200 W/m·K)。工作温度范围同时满足低于-250℃和高于2000℃的应用,定制最低要求,项目年采购额大于10万人民币,或采购台套数大于2000套。

提交需求>

可定制商用热管尺寸最高15.88mm,环路热管的热量传递范围为50mm到1000mm以上,同时满足低于-250℃和高于2000℃的应用。定制最低要求,项目年采购额大于10万人民币,或采购台套数大于2000套。

提交需求>

登录 | 立即注册

提交评论