The 250kW and 180kW Models of Nidec’s E-Axle Traction Motor System are Officially Adopted for the Car to Commemorate GAC New Energy Automobile’s Production of 20 Millionth Vehicle

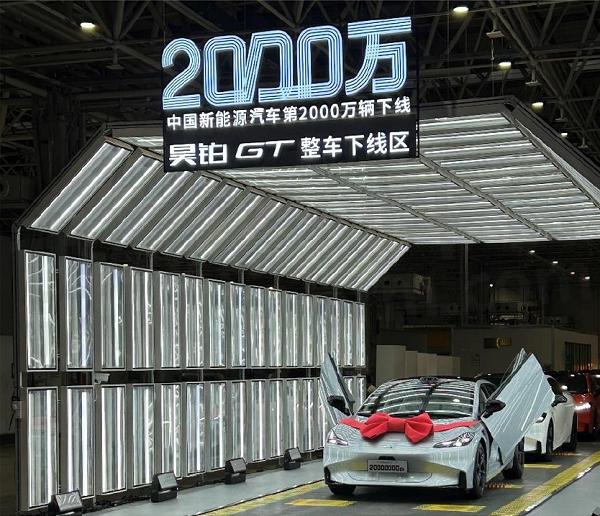

NIDEC Corporation (“Nidec”) announced that AION Hyper GT, each unit equipped with a Nidec-produced E-Axle model, has been selected as the vehicle for AION, the GAC Group’s EV-dedicated brand, to commemorate the production of its 20 millionth new-energy vehicle. AION made this announcement during the ceremony to mark the occasion at its factory in the city of Guangzhou, Guangdong Province, on July 03, 2023.

AION, a brand exclusively for EVs of the GAC Group, is one of the strongest-performing brands in China. AION Hyper GT, the second product that GAC New Energy Automobile launched in June 2023 from the brand’s high-end cars in the Hyper series, is equipped with the AEP 3.0 platform, which the company developed for its EVs and the three-wavelength-tunable LiDAR infrared remote sensing technology. These functions enable the vehicle to predict road conditions and obstacles accurately and run in rain, mist, fugitive dust, and other harsh environments, while the car maintains high levels of cost and power performance and safety with a maximum driving distance of 710km and the 0-100km/h acceleration time of 4.9 seconds (a top-end model).

The 180kW model (mass production started in May 2023) and the 250kW model (mass production to start in August 2023) of Nidec’s E-Axle traction motor system to be installed in Hyper GT are both part of the Company’s new product lineup of second-generation (Gen. 2) models developed based on its first-generation (Gen. 1) model with 150kW. With the use of high-slot-filling wire-winding technology, improved output achieved by a new magnet layout, and improved cooling efficiency achieved by optimizing the oil-cooling system, the Gen. 2 models boast compact sizes, light weights, and a dramatically reduced use of heavy rare-earth magnets.

Compared with the 150kW Gen. 1 product, the 180kW model is 17% smaller in volume, while the 250kW model, which newly uses SiC on its inverter, is capable of handling a high bus voltage of 800V. These features of the new models greatly contribute to improving the power, electric power consumption, and noise and vibration performance of the vehicle, and reducing its weight.

Details of the E-Axle traction motor system models’ specifications

250kW model:

● Peak output: 250kW ● output axis peak torque: 4,630Nm ● weight: 91.6kg ● operating voltage: 690V (nominal) ● external size (mm): 447 x 482 x 327

180kW model:

● Peak output: 180kW ● output axis peak torque: 3,750Nm ● weight: 78.4kg ● operating voltage: 350V (nominal) ● external size (mm): 447 x 482 x 319

As the world’s leading comprehensive motor manufacturer, Nidec stays committed to utilizing its technologies to develop light, thin, short, small, high-efficiency, and highly controllable products, and proposing, at an overwhelming speed, revolutionary solutions that contribute to the evolution of cars.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由玄子转载自NIDEC News,原文标题为:The 250kW and 180kW Models of Nidec’s E-Axle Traction Motor System are Officially Adopted for the Car to Commemorate GAC New Energy Automobile’s Production of 20 Millionth Vehicle,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

广汽集团埃安Aion新能源汽车采用尼得科第二代驱动电机系统E-Axle,提高冷却效率并减轻车辆重量

中国新能源汽车第 2000 万辆下线仪式车辆采用尼得科驱动电机系统 “E-Axle”(250kW 与 180kW)。180kW 驱动电机系统的体积比第一代 150kW 的小 17%。此外,250kW 驱动电机系统的逆变器中新采用了碳化硅,支持母线电压为 800V 的高电压。

Nidec’s Traction Motor System, E-Axle 200kW Model, Drives the First Model of Geely Automobile Group’s Premium EV Brand, Zeekr

Nidec announced that Ni200Ex, the Company’s 200kW, E-Axle traction motor system, has made its way into ZEEKR 001, an electric vehicle newly released by Chinese auto giant Geely Automobile Group, under its premium brand, “Zeekr.”

尼得科EV用驱动电机系统“E-Axle” 旗舰工厂签约浙江平湖!满负荷年产能预计可达100万台

面对纯电动汽车日益增长的市场需求,尼得科(NIDEC)将在中国浙江省平湖市建设EV用驱动电机系统“E-Axle”的旗舰工厂。此次拟建的新工厂占地面积为72800平方米,人员规模在满负荷生产时预计达2500人,将成为尼得科在中国的第五家驱动电机业务工厂、第四家E-Axle装配工厂。

日本电产集团综合产品目录(Nidec Group Products Catalog)

型号- PM4系列,H300,D SERIES,NRFEIS-5060,DFS,GATS-2000 SERIES,TPI SERIES,GATS-7800 SERIES,R-6100,TVX,GATS-6300,GATS-8600,SX-20,RWI SERIES,ZI20A,GATS-7500系列,LSR-3230,BP100,RSH,GATS-7700 SERIES,K-MC1000,P2H系列,E300,GATS-2000系列,GATS-6300系列,NVM-6060GCP,VL-H系列,GATS-7500,MH3NCV,VL SERIES,GATS-7800系列,SS-SV,DEWE3-A4,TPI,TVX SERIES,RGA20,NRTES-1000 SERIES,FCPL,ΜV1,RSH系列,ZG SERIES,ID300,FMD,TPI系列,GATS-8600系列,S-CART,GATS-6300 SERIES,KS,CM,R-580,SS-SV SERIES,ANEX SERIES,LD SERIES,VP600GC,GE15FR PLUS,MD2,ANEX系列,NRTES-1000,P2H SERIES,FFB,VL系列,LS,RSH SERIES,RVL,VL-H SERIES,RVP,F600,SS-SV系列,S-FLAG,GATS-7500 SERIES,REC-92FT,DEWE3-PA8,ECO-KA,KCV1000-5AX,S-CART-V1000-LFT,RVL SERIES,RVP SERIES,R-700 SERIES,P2H,ZE16C,CPLS,S-CART-V500,HM500S,VM53RⅡ,GATS-7700,ANEX,NRTES-1000系列,HM-X6100,RWI,TVX系列,KA SERIES,S-CART-MINI,GATS-2000,PM4,VL-H,GATS-7700系列,CBZ,GH,GATS-8600 SERIES,R-700,R-5920系列,NRFEIS-3570,DFS SERIES,MVR-HX,MAF130EⅡ,BL-V20,ECO-KA SERIES,SERIES S-FLAG,RWI系列,HE,GATS-7800,R-5920

数字孪生赋能电动化出行:尼得科E-Transport! Simulator实现xEV装置各组件的合理化

NIDEC新开发的“E-Transport Simulator”集成化模拟工具,不仅可实现各个组件的数字孪生化,还可对电动车整体进行数字孪生化和合理化设计。从开发的初期阶段到详细评估,在电动车的所有开发阶段都可使用本工具,可以大幅缩短开发周期,压缩试制成本,以支援*xEV(电动车)的设计和解析。

【软件】尼得科精密检测科技开发出xEV建模模拟器“E-Transport Simulator”

尼得科精密检测科技株式会社(NIDEC)开发出了名为“E-Transport Simulator”的集成化模拟工具,以支援*xEV(电动车)的设计和解析。本工具对xEV开发时集车载驱动电机、减速机、电机、逆变器等于一体的“E-Axle”的各种特性以及电动车整车进行模拟,提供与车体条件、行驶环境相匹配的电机、组件等解决方案,通过详细计算,缩短电机试验时间,提高与实测值之间的差异解析的效率。

各行有“尼”丨汽车篇,尼得科的汽车业务领域,探索尼得科如何助力汽车产业发展,为实现碳中和目标而努力

我们将聚焦尼得科的汽车业务领域,探索尼得科如何助力汽车产业发展,为实现碳中和目标而努力。

尼得科推出驱动电机E-Axle,高度方向相比竞品缩小20%,同时功率密度远远超过竞争对手产品

驱动电机是电动汽车的核心,它负责为电动汽车提供驱动力。尼得科的“E-Axle”驱动电机,将以非常规的小巧尺寸挑战电动汽车的时代。尼得科E-Axle的特点之一就是小巧,尤其是在高度方向上与其他公司的驱动电机相比缩小了20%。同时它的功率密度远远超过了竞争对手的产品。

尼得科首次亮相COP28,旨在向世界展示其电机技术实力,为削减用电量贡献一份力量

全球气候变化问题的日益严峻以及电力需求的快速增长,导致全球能源短缺加剧,使脱碳化进程明显加快。在此背景下,《联合国气候变化框架公约》第28次缔约方会议(COP28)于今年11月30日-12月12日在阿联酋迪拜举行。

【电机】尼得科EV用驱动电机系统E-Axle Gen.2,进一步提升轻量化和静音性,强势“铸”力新能源汽车

NIDEC的EV用驱动电机系统“E-Axle”将电机、逆变器、减速机集于一体,随着技术的不断精进,“E-Axle Gen.2”顺利落地,进一步提升了产品的性能、轻量化和静音性。尼得科靠过硬的技术在新能源汽车领域赢得了口碑。

Nidec驱动马达系统E-Axle累积销售逾数十万台,可支持50kW~400kW功率

日本电产(Nidec)的E-Axle是集马达、逆变器、减速机为一体的单元系统,体积小、重量轻其一大特点。日本电产作为一级供应商研发了全球首次量产的Ni150Ex等五款机型,可支持50kW~400kW功率,预计覆盖全球98%的汽车市场细分。

【电机】尼得科研发用于冷却电动汽车驱动电机系统“E-Axle”的新型电动油泵,较过往实现质量减轻50%

NIDEC开发出了用于冷却电动汽车驱动电机系统“E-Axle”的电动油泵的新产品,通过大幅减少零件数量、机械零件紧固以及电气连接的简化、采用尼得科株式会社的紧凑型高输出功率无刷直流电机,与目前的量产产品相比,实现了质量减轻50%。

吉利汽车新款新能源汽车几何C采用日本电产(Nidec)的驱动马达系统E-Axle

2020年5月吉利汽车发布的新款新能源汽车“几何 C”中采用的是日本电产(Nidec)的驱动马达系统“E-Axle”的150kW款“Ni150Ex”。轻、薄、短、小的马达结构是日本电产运用在研发主力产品精密小型马达中所积累的优良磁路设计专有技术、永磁体及自主开发的马达油冷结构所研制而成,该马达结构与第二代逆变器十分有助于该车动力性能、电费性能、音振动性能的提升以及车重的降低。

Nidec Power Train Systems Develops New EOP to Cool EV Traction Motor System E-Axle

As a smaller and lighter traction motor, which is the “heart” of the EV, and uses less heavy rare-earth magnets, the traction motor is required to have better cooling efficiency, and the business of the oil-cooling system that can directly cool the motor, the source of heat, continues to expand.

电子商城

服务

使用FloTHERM和Smart CFD软件,提供前期热仿真模拟、结构设计调整建议、中期样品测试和后期生产供应的一站式服务,热仿真技术团队专业指导。

实验室地址: 深圳 提交需求>

可定制风扇尺寸范围:17mm*17mm*05mm~172mm*172mm*51mm。支持轴流风扇、离心风扇、涡流风扇、横流风扇等等产品的个性化定制。

最小起订量: 50000 提交需求>

登录 | 立即注册

提交评论