What is the Stacked Battery of iPhone 15, and What is the Difference between the Stacked Battery and the Winding?

Recently, some whistleblowers claimed that the new iPhone will use stacked battery technology, which can increase the energy density of the battery, prolong the battery life of the mobile phone and reduce the problem of overheating and heating of the mobile phone battery.

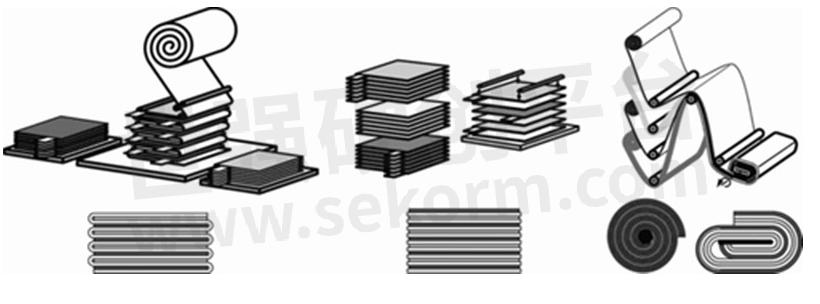

Fig.1

The following Grepow battery will take you to understand in detail what is a stacked battery, why the iPhone 15 uses a stacked battery, and what is the difference between a stacked battery and the existing winding battery.

What is a stacked battery?

A stacked battery also called a stacking battery, refers to a lithium battery produced by the lamination process. Stacked batteries are generally divided into two forms: square shell (hard shell) and soft pack (also pouch cell).

Lithium batteries mostly use two processes of winding and lamination, which have different advantages and disadvantages. The working principle of stacked batteries is the same as that of lithium-ion batteries used in traditional electric vehicles. The interior is mainly composed of positive electrodes, negative electrodes, diaphragms, and electrolytes. The electricity is generated by the movement of lithium ions.

Stacked batteries are widely used in various electronic devices and systems, such as smartphones, laptops, drones, electric vehicles, etc. By using stacked battery technology, manufacturers can deliver higher energy density and greater performance in a relatively small space to meet the demands of modern energy-hungry devices. At the same time, with the continuous development of battery technology, stacked batteries have been continuously optimized and improved to provide more efficient and safer energy solutions.

What is a winding battery?

A wound battery is an energy storage unit in which the positive electrode, the separator, and the negative electrode are combined in a winding manner, and is called a wound battery. A single-wound battery is also called a battery cell, and those in the battery industry call it a "wound cell" or "wound battery."

What is the difference between a stacked battery and a winding battery?

1. The battery's internal resistance

The cells produced by the lamination process have a lower internal resistance, while the winding type has a higher internal resistance. Because the wound-type battery cell is usually a single tab, the stacked battery cell can be regarded as a multi-tab type, which greatly reduces its internal resistance. The difference in internal resistance makes the heat generation of the finished battery different during the charge-discharge cycle and the speed of capacity decay. It is obvious that the capacity decay of the stacked battery is slower.

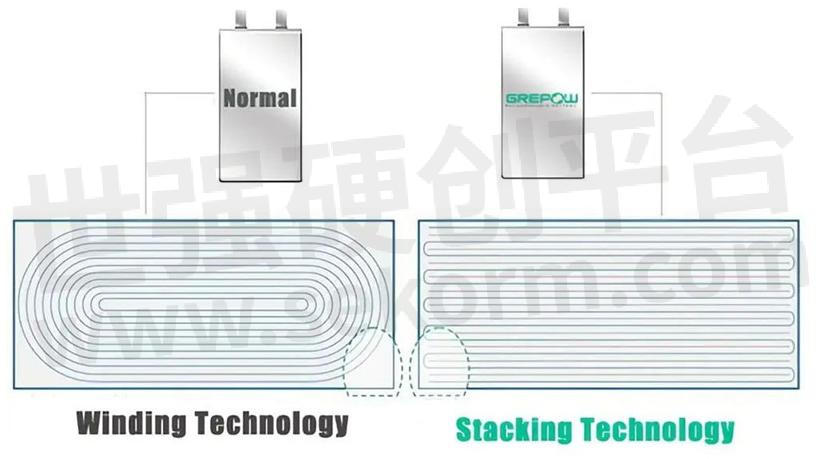

Fig.2

2. Different battery life

As the charge-discharge cycle continues, heat will be generated inside the battery and affect the temperature of the battery. For stacked batteries, the internal temperature distribution is relatively uniform, while for wound batteries, there is only one-way heat transfer between the pole piece and the separator, resulting in a serious temperature gradient distribution phenomenon, with internal high temperature and external low temperature. The uneven temperature distribution leads to the deactivation of the active material (lithium ions) at the high-temperature position first during the charging and discharging process of the battery, which cannot perform the function of deintercalation of lithium ions, which in turn affects the rapid attenuation of other positions and affects the performance of the battery.

3. The stress inside the cell is different

The two manufacturing methods lead to different mechanical characteristics of the cell. The stress-bearing area between the stacked cell pole piece separator is the same, there is no obvious stress concentration point, and the battery will not be damaged sharply in a certain part during use. The edge of the wound battery is where the stress is concentrated. According to previous experience with battery disassembly and analysis, micro-short circuits, electrical breakdowns,s and lithium precipitation are more likely to occur at the end of the pole piece. Stress concentration points are the primary location for battery deactivation, which also leads to reduced cycle life of wound batteries.

4. Different battery rate performance

The stacking process is equivalent to connecting multiple poles in parallel, which makes it easier to complete high-current discharge in a short period of time, which is beneficial to the rate performance of the battery. The winding process is just the opposite, a single tab leads to slightly worse rate performance.

5. Different battery capacity density

The stacked battery has a higher capacity density because its internal space is fully utilized. In contrast to the wound battery, the two sides of the cell are circular and the last two layers of separators occupy a certain thickness, so the capacity density is low.

6. Different security

There are also differences in the safety of the two, which are mainly analyzed from the aspects of internal resistance, stress, and temperature distribution. Winding batteries with uneven temperature and high internal resistance are less safe.

7. The complexity of pole piece production is different

The winding process is simpler and easier to operate, and it is easy to realize industrial automation. Although the stacking process is very cumbersome, it has been adopted by many companies with the continuous improvement of production equipment and technology. At present, battery companies in the market mainly use the winding process and stacking process for cell production.

8. The complexity of cell manufacturing varies

The operation of the winding battery cell is relatively simple, whether it is semi-automatic or fully automatic, it can be completed quickly. The stacking process is highly complex, and manual operation is time-consuming and laborious. However, with the continuous development of automation technology, stacked cells have also achieved fully automated production.

In addition, in terms of the quality control of the battery core, the winding type is easier to control, while the stacked type can achieve good consistency even though the process steps are cumbersome.

Why does the iPhone 15 use stacked batteries? What is the difference between the stacked battery and the winding battery?

According to @RGcloudS, a well-known Android whistleblower, it is known from industry sources that stacked battery technology will be used first in Apple’s iPhone 15 series, which can increase battery density and extend battery life. Samsung will then equip the 2024 Galaxy S24+ and Galaxy S24 Ultra with stacked battery technology.

The stacked battery mainly adopts lamination manufacturing technology, in which the battery pole piece components and separators are folded into zigzag layers, and a separator is used in the middle, while the inside of the traditional battery is designed in a roll, which is likely to cause gaps on the edges.

There is less waste of space in the stacked battery packaging unit, allowing more materials to be placed, higher capacity, and more active materials, thereby increasing the overall battery capacity and making the stacked battery have a higher density than traditional wound batteries.

Fig.3 The traditional wound battery on the left, and the stacked battery produced by Grepow on the right

The use of stacked batteries can also effectively improve the heat. The layered structure allows the battery to operate as a multi-polar battery. The resistance of the battery itself is smaller, and the heat generated during charging and discharging will be less. At the same time, the heat can be evenly distributed to the entire battery, instead of being concentrated in one area like a wound battery, so as to prolong the battery life.

At present, stacked battery technology is also being used in the field of electric vehicle batteries, which can provide high power output and fast charging, as well as batteries with higher energy density. This technology is relatively new to smartphones.

For example, the iPhone 15 can use a new generation of stacked battery technology, which means that the iPhone has faster charging speed, longer battery life, smaller battery temperature rise, and faster heat dissipation.

In addition, the source also said that the new 40W wired and 20W wireless MagSafe protocol and power chip has passed the test, and it is uncertain whether it will be used in the iPhone 15 or iPhone 16 series, which means that the subsequent iPhone wired fast charging will be increased to 40W.

Which battery manufacturer can produce stacked batteries?

Stacked battery manufacturers include Grepow. Grepow, as an early contact with soft-packed stacked lithium battery manufacturers in China, established a lithium battery business department as early as 2007, specializing in the manufacture and development of stacked soft-packed lithium polymer batteries. Up to now, it has become a well-known manufacturer of stacked lithium polymer batteries at home and abroad. The soft-pack stacked batteries produced by Grepow have the following advantages:

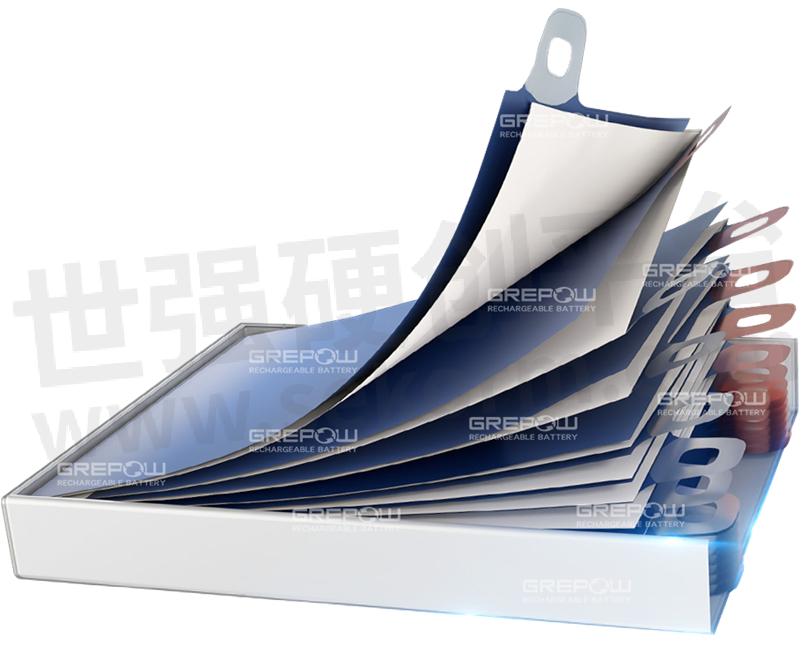

1. Low internal resistance

The internal resistance will affect the cell rate performance and discharge platform to a certain extent. So the lower the internal resistance, the better the battery. Compared with wound batteries, stacked batteries have very low internal resistance, which is equivalent to connecting multiple small pole pieces in parallel to reduce internal resistance.

2. High rate discharge

A high-rate battery can also be called a high-current discharge battery. It is not necessary for conventional battery applications, but for power batteries, high-rate discharge is a necessary part. It is difficult to fully discharge a single tab of a wound battery with a large current. Since the stacked battery is connected in parallel with multiple poles, it is easier to complete high-current discharge in a short time.

Fig.4

3. Discharge platform

Due to the lower internal resistance of the stacked battery, the polarization is also smaller, so the discharge platform will be higher than that of the wound battery and closer to the self-discharge platform of the material. For much electrical equipment with a higher discharge cut-off voltage, stacked batteries with a higher discharge platform are undoubtedly the preferred choice.

4. Capacity density

Due to the stacking process, the stacked battery makes full use of the internal space of the battery, so compared with the winding process, the volume-specific capacity is higher, which also makes the capacity density relatively high.

5. Energy density

Since the discharge platform and volume-specific capacity are higher than those of winding batteries, the energy density of common stacked batteries is correspondingly higher.

6. Thickness

The internal structure of the battery cell is consistent, and the thickness of each part of the battery is also consistent, so the thickness of the stacking process is easy to control. Also because the internal structure of the battery is unified and the reaction rate is relatively consistent, it is not easy to deform even if the thickness is large.

7. Battery shape

Due to the flexible size of the stacked battery, it can be made into any shape according to the remaining space of the actual application.

8. Fields of application

Due to the better rate performance of the stacking process and more choices of appearance and shape, the scope of application is also wider than that of wound batteries. It can be more suitable for high-rate batteries, special-shaped batteries, and power batteries.

The above is an introduction to what is a stacked battery, why the iPhone 15 uses a stacked battery, and what is the difference between a stacked battery and the existing winding battery. I believe that through the above introduction, everyone knows that stacked batteries are a new type of battery technology that can effectively increase the energy density of batteries. It stacks multiple battery cells to increase the electrode area and capacity, thereby achieving higher current output. As a well-known stacked lithium battery manufacturer at home and abroad, Grepow's stacked lithium batteries are widely used in drones, RC models, agricultural plant protection, sports cars, auto parts, medical, outdoor, maritime, special, industrial, wearable devices, AR/VR and consumer electronics and other fields.

It is believed that with the rapid development of science and technology, the technology of stacked batteries will become more and more mature. Stacked batteries will be widely used in more fields in the future, bringing more convenience and innovation to people's lives. Let us expect this technology to provide more efficient, reliable, and sustainable solutions for our energy consumption.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由三年不鸣转载自Grepow News,原文标题为:What is the stacked battery of iPhone 15, and what is the difference between the stacked battery and the winding?,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

【技术】格瑞普解析刀片电池的特点和优势

关于刀片电池相信各位一定有所耳闻,那么什么是刀片电池?它有什么特点和优势呢?本文格瑞普将为您进行介绍。

【技术】格瑞普解析无人机电池循环次数是多少及如何计算?

近年来随着短视频的兴起,无人机也越来越流行了,但很多朋友都对无人机电池使用寿命短而感到苦恼,因此很多小伙伴都关心无人机电池循环次数,想了解无人机电池循环次数是多少及怎么样计算无人机电池循环次数?本文格瑞普将为你详细介绍。

电池pack厂格瑞普的pack原则

pack通过柔性(热缩膜或胶带),壳体或支架,辅以胶水,螺丝,卡扣或超声焊接等工艺,选配合适的保护板(BMS),做好绝缘与散热来实现电芯的多串并方案,由此满足终端客户的电气性能,寿命与环境使用要求。Pack是电芯实现使用价值的手段。今天就来看一下电池pack厂格瑞普的pack部分原则

Grepow Battery was interviewed by Global Sky Media about eVTOL Power

Grepow‘s products are mainly high-rate batteries. We will continue to develop high rate and high energy density power batteries with an energy density between 300 to 350Wh/kg while meeting a 5C to 10C fast charging and long cycle life of more than 1000 times.

格瑞普电池选型表

格瑞普锂电池,磷酸铁锂电池,高压锂电池,镍氢电池,低温锂电池,快充电池,三元锂电池选型表。倍率(C):1~50C,容量(mAh):48~40000mAh,电压:1.2V~4.35V

|

产品型号

|

品类

|

倍率Rate(C)

|

Thickness(mm)

|

Width(mm)

|

Length(mm)

|

容量(mAh、mA)

|

Voltage(V)

|

|

CP6431122-R1A

|

三元锂电池

|

1C

|

6.4mm

|

31mm

|

122mm

|

3000mAh

|

3.7V

|

选型表 - 格瑞普 立即选型

SAIC Anji Logistics Halves Inventory Time with Silion‘s RAIN RDIF and Drones

SAIC Anji Logistics, a subsidiary of China‘s largest car manufacturer, uses RAIN RFID-powered drones to conduct inventory checks of finished vehicles. By placing UHF RFID tags on each vehicle, drones can fly over and collect data accurately, reducing inventory input time by 50% and increasing accuracy. This solution saves human labor for more impactful tasks.

【经验】格瑞普解析MSD及MSD电池系统的作用

MSD电池系统作为一种高能量密度、长寿命、环境友好的新型电池系统,在电子设备领域具有广泛的应用前景。它的独特优势使得电子设备可以更长时间地保持高效工作,给用户带来更好的使用体验。同时,它的环保性能也符合当今社会对绿色可持续发展的要求。

2024无人机竞速联赛柯桥站,格瑞普R-LINE 5.0系列TATTU电池大放异彩,成为众多飞手信赖的选择

格瑞普研发生产的多款TATTU电池大放异彩,尤其是R-LINE 5.0系列的1550mAh、1480mAh及1400mAh型号,成为众多飞手信赖的选择。资格赛中,Minjae、王淼等一众顶尖飞手凭借卓越技术和装备优势,纷纷展现出非凡实力。

【技术】格瑞普解析导致锂电池电芯低容的原因有哪些

容量是电池的第一属性,锂电池电芯低容也是样品、量产中经常遇到的问题,在遇到低容问题后要怎么立刻分析出原因呢,本文格瑞普就来给大家介绍一下导致锂电池电芯低容的原因有哪些。材料的匹配特别是负极与电解液的匹配对电芯容量的影响尤为重大。

揭秘格瑞普电芯:从电池原料到成品的制作工艺

格瑞普作为电池领域的先锋品牌,其技术部汇聚了超过200位资深工程师与技术精英,致力于电池技术的尖端研发与创新。公司配备了全面的电池产品测试与验证设备,确保每一款产品的卓越性能,更在产品研发、生产制造及技术创新上不断突破,为市场带来了一系列高性能、高安全性的电池产品。在生产层面,格瑞普坐拥四大现代化厂区,依托先进设备,能够灵活生产及定制包括镍氢电池、聚合物锂电池。

格瑞普负40度还能正常工作的磷酸铁锂电池,尺寸灵活,可进行专业化定制

深圳市格瑞普电池有限公司研发出了负40度还能正常工作的磷酸铁锂电池,一举打破了市场上的空缺,值得一提的是这负40度跟市场上大部分低温电池(可定制)产品不一样,格瑞普低温电池是实打实的低温。

【经验】格瑞普解析锂电池出现鼓包的原因

锂电池的安全性有时候会得不到保证,另外如果使用不当或者是制作水平有限的话还是有一定的安全隐患的,就比如锂电池鼓包,那么锂电池为什么会出现鼓包现象呢?今天格瑞普来为大家讲解。

【元件】格瑞普钢壳异形电池全新上市,为未来智能产品创新提供助力

格瑞普带着全球领先的钢壳异形电池产品和服务再次来到大众的视野!随着科技的进步,智能可穿戴设备愈发增多,且对产品空间的需求更加严格;因此,深圳市格瑞普特推出全新的,钢壳异形电池,为新时代的AI产品增加助力!

格瑞普推出磷酸铁锂电池,循环寿命可达2000+次,电压、形状及容量可按需定制

磷酸铁锂电池厂家格瑞普的创新技术很好的实现了磷酸铁锂电池的高功率性能,也延长了电池的使用寿命。格瑞普提供磷酸铁锂电池电芯定制+电池管理系统(BMS)+结构设计的一体化电池系统定制服务,使用专有的电池原料配方,耐温性能高,高能量密度比。

【技术】格瑞普科普18650锂电池的分类

在很多领域都能够看到18650锂电池的影子,因为这种电池相比其他的电池,优势非常的明显,并且安全性也相对来讲比较好,甚至已经被用在了大型设备上,但是大家不知道的是18650锂电池也是可以分类的,那18650锂电池怎么分类呢?本文格瑞普将为您进行介绍。

电子商城

登录 | 立即注册

提交评论