SSD End-of-Life Validation Test: Ensuring Reliability, Endurance and Retention From 0% to 100% and Beyond EOL

Solid-state drives (SSDs) can function for a finite period. How long can yours last?

The expected life span of an SSD depends on several factors, such as NAND flash type, the number of times data has been written to and erased from the drive (also referred to as program/erase cycle), workload, and temperature. As an SSD degrades over time, bit errors increase, and its ability to keep reliable data decreases.

At ATP Electronics, we perform end-of-life (EOL) testing to determine the effective use of the SSD over a certain period given the factors mentioned earlier. The goal is to make sure that our SSDs continue to perform reliably and maintain data integrity over the life span (and even beyond) as required.

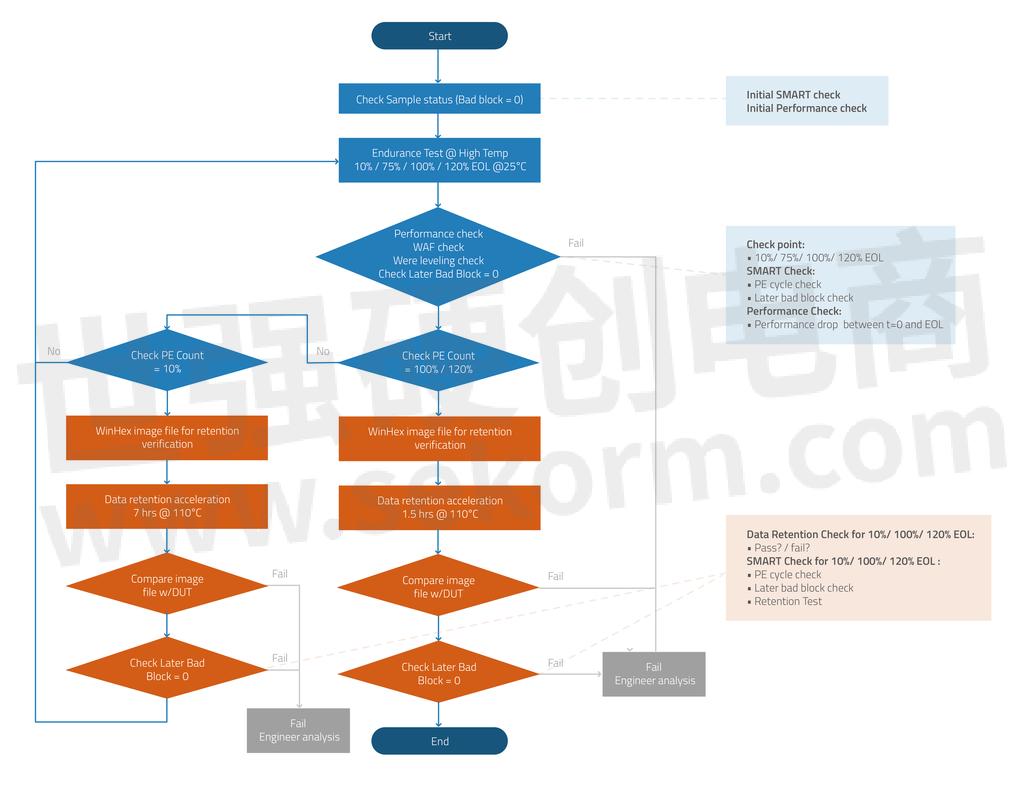

ATP EOL Validation Test Process Flow

ATP uses the Gym & Coach System to perform a series of comprehensive EOL validation tests at the drive level. This entails subjecting the SSD to numerous cycles to ascertain or validate the endurance capability and reliability of the drive.

This test helps predict how long to continue using the SSD and when the SSD will fail based on the target P/E cycle and data retention. Customers can therefore determine when to stop using the drive, and hence develop a transition plan for eventual replacement.

The following items are validated in the ATP EOL validation test:

•Program/Erase (P/E) Cycle Check. One of the main causes of flash wear out is the number of P/E cycles performed. During this test, P/E cycles are performed on the SSD until its rated end of life to check for degradation and retention capabilities. This test validates if our quality can meet the TBW rating on the datasheet. Sample devices under test are checked at 10%, 75%, 100%, and even 120% EOL, which is beyond the rated usable life span of the SSD.

•Later Bad Block Check. NAND flash blocks can wear out from use, which can make them unreliable or unusable. This test checks for bad blocks at different stages of the SSD’s life span: 10%/ 100%/ 120% EOL.

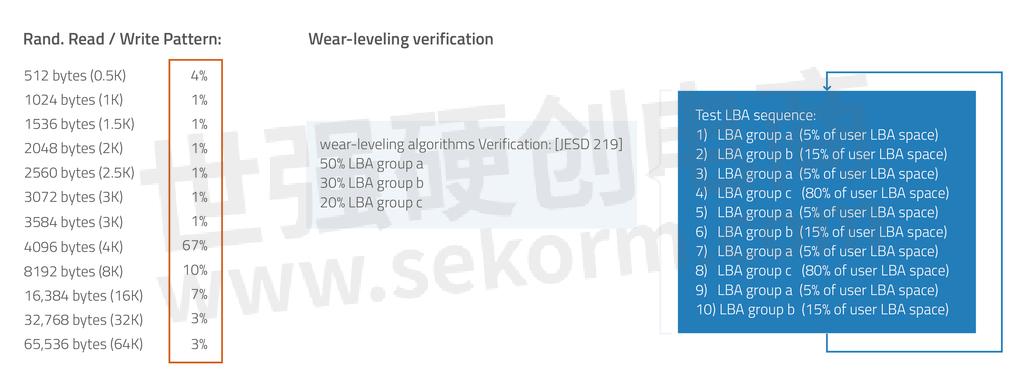

•P/E Count Distribution (Wear Leveling) ATP’s wear-leveling test process follows JEDEC’s JESD219 standard for the Enterprise application class. During the P/E aging process, each writer should be followed by a read (i.e., W/R = 1), and all errors are recorded. Reading solely at the SSD’s end of life is not acceptable.

The Enterprise Endurance Workload according to JESD219 consists of random data distributed across the SSD. The following figure shows the payload size distribution.

Figure 1. JESD 219 Enterprise Endurance Workload payload size distribution

•Retention Test after 120% EOL P/E Cycle. This test checks if the SSD can retain or hold data at different stages of its lifespan (10%/ 100%/ 120% EOL).

The following figure shows the ATP EOL Validation Test Process Flow.

Figure 2. ATP EOL Validation Test Process Flow

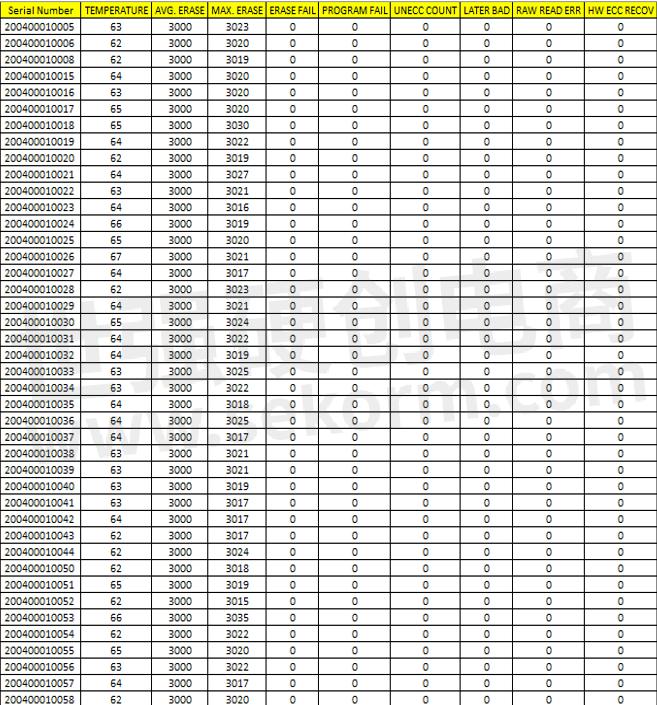

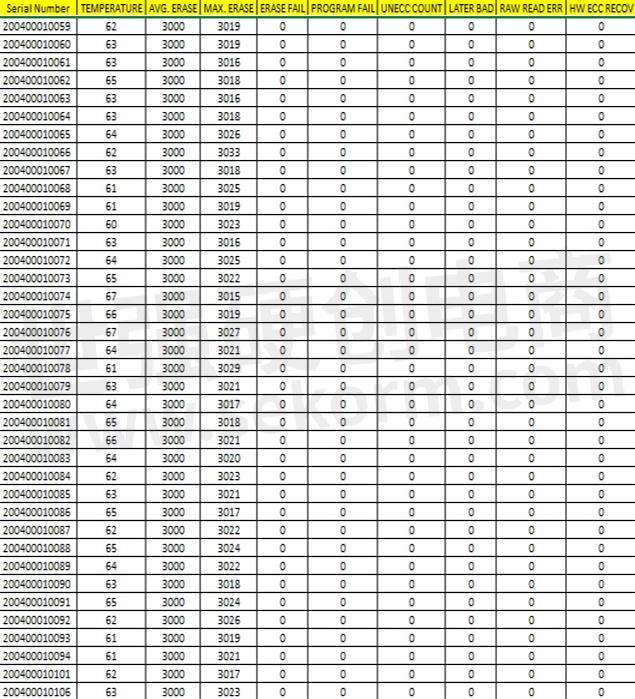

SSD EOL Validation Results

•All sample SSDs tested completed the 100% EOL Test successfully.

•From 0% to beyond EOL, there were…

No program errors

No erase errors

No uncorrectable error correction code (UECC) errors

No later bad blocks

•The cumulative TBW for all SSDs demonstrates UBER to be less than 1 Uncorrectable Read Error in 1017 bits read on SSD drive level

•Retention test results would meet:

1-year minimum data retention requirement at the start of the drive’s life, in an environment with up to 40°C at 10% PE cycle

3 months minimum data retention requirement at the end of the drive’s life in an environment with up to 40°C

Figure 3. Sample EOL Validation Test successfully performed for an ATP Customer.

Key Takeaways

ATP performs EOL Validation Test at the drive level to validate SSD endurance and reliability within and even beyond its rated life span. P/E cycles, later bad blocks, wear leveling, and retention tests at different stages of the SSD life span (from 10%, 100%, and up to 120% EOL) are among the key items checked. All ATP SSDs tested completely this test successfully with no program/erase errors, UECC errors or later bad blocks, and UBER less than 1 Uncorrectable Read Error in 1017 bits read, demonstrating ATP SSDs’ exceptional reliability for mission-critical applications during its rated service life and even beyond EOL.

ATP’s EOL Validation Test is just one of the many reliability and endurance tests developed and performed by ATP to ensure strict compliance to the highest standards of quality. ATP is committed to delivering high-performance and high-endurance NAND flashes storage products to ensure the best value for a total cost of ownership (TCO).

- |

- +1 赞 0

- 收藏

- 评论 0

本文由深蓝的鱼转载自ATP,原文标题为:SSD End-of-Life Validation Test: Ensuring Reliability, Endurance and Retention From 0% to 100% and Beyond EOL,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关推荐

【应用】为SSD类闪存特制的数据清除SecurWipe解决方案可以帮助用户安全而永久地擦除闪存

诸如存储卡和固态驱动器(SSD)之类的闪存非常适合存储和处理大量数据。但是,确保敏感数据被永久安全地擦除是一个挑战,尤其是在处置NAND介质的储存器时。如果未经授权的人可以恢复检索这些数据,则可能造成严重的后果。 擦除闪存设备上的数据并不像看起来那样容易从存储设备中删除那么容易,因此本文介绍ATP专门针对SSD数据清除的SecurWipe解决方案。

笔记本需要更换大容量硬盘,求推荐性价比更的SSD固态硬盘。

您好,推荐ATP(华腾国际)的SSD固态硬盘,M.2 NVMe接口最高容量可达1TB,M.2 2280接口最高容量1TB,SATA接口最高容量1TB,具体可参考【选型】ATP(华腾国际)内存及存储产品选型指南

PCIe® Gen 3 NVMe M.2 2280 / 2242 / 2230 SSD The Global Leader in Specialized Storage and Memory Solutions

型号- FT960GP38AG8BPC,N750PI,FT480GP38ANDBFC,FT120GP38AG8BPC,FT480GP38AG8BPC,FT480GP34ANDBFC,FT960GP38AG8BPI,FT240GP38AG8BPC,FT120GP38ANDBFC,N700PC,FT240GP38AG8BPI,FT120GP38AG8BPI,N600SC,N650SI,N600VI,FT960GP34ANDBFC,N700PI,FT240GP38ANDBFC,N600SI,FT120GP34ANDBFC,N650SC,FT240GP34ANDBFC,N600VC,FT480GP38AG8BPI

ATP AcuCurrent: Innovative Signal Integrity Optimization Technology

ATP‘s AcuCurrent Technology is an innovative signal optimization technology, enabling dynamic, real-time temperature-responsive drive setting adjustments across a wide operating range, up to 125℃. AcuCurrent Technology is temperature-responsive, dynamically adjusting settings in real time to ensure that the SSD operates at great efficiency across various scenarios, effectively minimizing unnecessary read-retry cycles, and substantially reducing error rates.

ATP NVMe BGA pSLC SSD安全保护及加密功能特点

硬件写保护* 写保护功能将ATP NVMe BGA SSD置于“只读”模式,以防止数据写入设备,并保护重要数据不被意外删除、移动或修改。通过在控制器印电路板(PCB)上的通用输入/输出(GPIO)信号引脚的特定引脚上放置跳线,在存储设备上启用写保护。硬件快速擦除*对于特定应用,主机可以使用GPIO连接器触发“擦除数据”行动。

【经验】什么是SSD的M.2标准?M.2 SSD和mSATA SSD之间又具体有哪些差异?

近年来发布的固态驱动器(SSD)变得更快,并且能够处理大量数据。但是,它们的全部功能受到与其连接的接口的阻碍或限制。Mini-SATA(mSATA)接口虽然专为提供最小的SSD尺寸而设计,但受到SATA 6 Gb / s的限制。M.2标准是内部安装的计算机附加卡的规范,旨在解决mSATA的局限性,并为小型卡(包括不同大小和容量的SSD)提供更多选择。

PCIe® Gen 3 NVMe M.2 2280 / 2242 / 2230 SSD

型号- FT960GP38AG8BPC,N750PI,FT480GP38ANDBFC,FT120GP38AG8BPC,FT480GP38AG8BPC,FT480GP34ANDBFC,FT960GP38AG8BPI,FT240GP38AG8BPC,FT120GP38ANDBFC,N700PC,FT240GP38AG8BPI,FT120GP38AG8BPI,N600SC,N650SI,N600VI,FT960GP34ANDBFC,N700PI,FT240GP38ANDBFC,N600SI,FT120GP34ANDBFC,N650SC,FT240GP34ANDBFC,N600VC,FT480GP38AG8BPI

ATP对所有SSD进行数千小时RDT测试,确保产品严格遵守最高质量标准

可靠性验证试验(RDT)是对ATP固态驱动器(SSD)进行的一项长期严格测试,旨在证明每个SSD符合最严格的质量要求。ATP在较长时间内对其 SSD执行完整的实际驱动器级别测试,以验证额定MTBF值,而不是依赖可靠性预测系统。

ATP推出工业宽温企业级SSD系列产品N651Sie,包含U.2,M.2,E1.S三种接口类型

ATP推出工业宽温企业级SSD系列产品N651Sie,结合了工业级固态硬盘和企业解决方案的优点,专为在不受控制的恶劣环境中处理企业级工作负载而设计。

ATP Industrial Enterprise SSD Series: The Best of Both Worlds, Engineered for Uncontrolled Environments at the Edge

ATP offers the best of both of industrial and enterprise worlds: THE NEW INDUSTRIAL ENTERPRISE Series, which leverage NVMe PCIe Gen4x 4 and are available as M.2, U.2, and E1.S. They combine the best of enterprise and industrial features, making them excellent as boot drives, data storage drives, or mixed-use drives.

【电气】ATP推出业界最佳工业级宽温8TB E1.S固态硬盘N651Si系列,专为1U边缘服务器设计

ATP推出N651Si系列工业级宽温E1.S固态硬盘,支持工业温度工作范围(-40°C至85°C)以及硬件断电保护,在恶劣环境中提供最高级别的可靠性和总拥有成本价值,使其特别适用于在极端温度下运行的关键任务应用,如汽车、数据记录仪、数据中心和国防/航空航天,为要求最苛刻的应用提供一流的性能、耐用性和数据保持能力。

PCIe® Gen 4 NVMe M.2 2280 SSD The Global Leader in Specialized Storage and Memory Solutions

型号- FT3T84P48APHBFC,FT1T92P48APHBYC,FT240GP48APHBPC,FT240GP48APHBPI,FT960GP48APHBYI,N651SI,AF960GSTJA-HBAXX,FT1T92P48APHBPI,N601VI,FT480GP48APHBFI,FT3T84P48APHBFI,FT1T92P48APHBPC,FT480GP48APHBFC,FT960GP48APHBYC,N651SC,N601VC,FT960GP48APHBFC,FT240GP48APHBSC,FT960GP48APHBFI,FT480GP48APHBYI,FT240GP48APHBSI,AF240GSTJA-HBBXX,AF1T92STJA-HBBXX,AF480GSTJA-HBBXX,FT1T92P48APHBYI,FT480GP48APHBPI,FT480GP48APHBPC,FT1T92P48APHBFC,FT960GP48APHBSI,FT1T92P48APHBFI,FT960GP48APHBSC,FT3T84P48APHBYC,FT240GP48APHBFC,FT480GP48APHBYC,AF960GSTJA-HBBXX,FT240GP48APHBFI,FT240GP48APHBYC,FT240GP48APHBYI,FT480GP48APHBSI,N751PI,FT480GP48APHBSC,FT3T84P48APHBYI,FT960GP48APHBPI,N601SC,FT1T92P48APHBSI,AF1T92STJA-HBAXX,AF240GSTJA-HBAXX,FT960GP48APHBPC,AF480GSTJA-HBAXX,FT1T92P48APHBSC

ATP‘s Power Loss Protection Just Got Smarter with MCU-based SSD Design

ATP customers want constant assurance that power loss events will not cause massive downtime or lost data that could affect business operations and lead to higher operating costs. The MCU intelligently monitors sudden power failure conditions from a glitch to a surge or a complete outage...

The ATP Gym and Coach System: Exercising SSDs to Ensure Total Fitness

With the Gym and Coach system, ATP has dramatically improved RDT and the initialization process for functional test details. By making industrial SSDs undergo a lot of “painful” exercises through stringent testing, ATP makes sure that customers have everything to gain by receiving the most robust, reliable and enduring flash storage products for their applications.

电子商城

服务

可定制ATP TE Cooler的冷却功率:40~200W;运行电压:12/24/48V(DC);控温精度:≤±0.1℃; 尺寸:冷面:20*20~500*300;热面:60*60~540*400 (长*宽;单位mm)。

最小起订量: 1 提交需求>

登录 | 立即注册

提交评论