PMA‘s DPAT Implementation Safeguards Against Potential Yield Losses

DPAT, also known as Dynamic Part Average Testing, is used by the Automotive industry to control their parts manufacturing. With the advent of Electric vehicles (EVs), there is an increasing number of requests for incorporating DPAT into KEYSIGHT’s PathWave Manufacturing Analytics (PMA) Dashboard for a more precise calculation of what to discard as fails and what to pass and ship out to end user.

The Automotive Electronics Council (AEC) has described DPAT in their AECQ-100 standard as an outlier detection method mostly applied to automotive devices that must be qualified and tested to meet strict requirements. Along with its family of other standards in AECQ-100, DPAT detects outliers using statistical methods to predict items that are likely to fail in the near future but still considered passing within the static upper and lower limits given as the item's specifications.

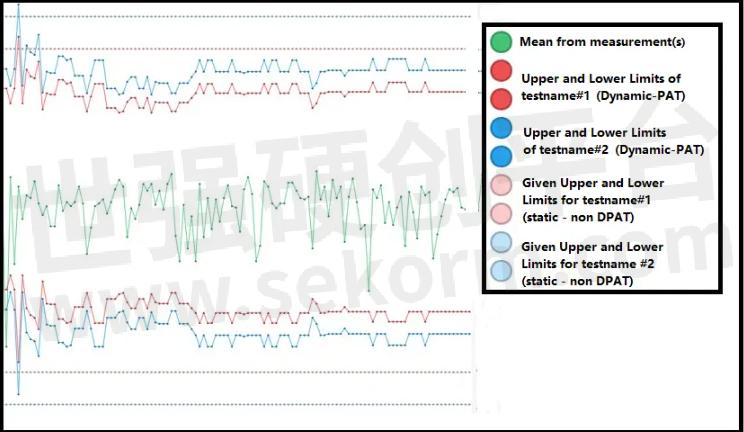

Figure 1. Dynamic PAT in action

Principles of DPAT

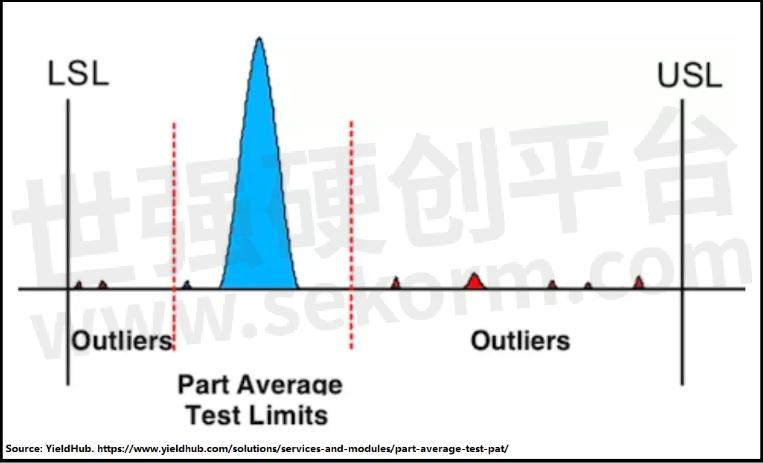

DPAT is derived initially from the idea of its predecessor Part Average Test (PAT). PAT is originally intended to have a stricter quality with a narrower passing range, resulting in higher quality products at the expense of a higher rejection rate. From Figure 2 below, more Device Under Test (DUT)s will fall under the outliers range and be considered as Fails.

Figure 2. Using PAT to increase the quality at the expense of a higher rejection rate

Over time, the automotive industry decided to further improve the quality of their output by introducing DPAT. What DPAT does is that it uses the measurement value to continuously calculate the mean value, resulting in a non-constant mean that makes the upper and lower limits dynamically change according in real-time.

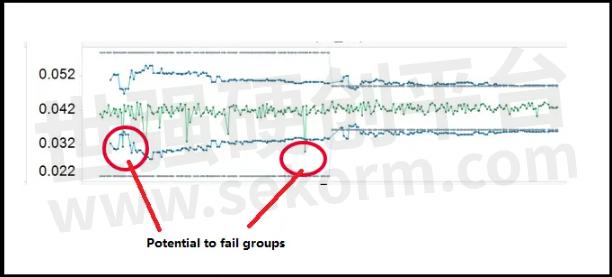

With DPAT coming into the picture, the manufacturer can see from the chart in real-time what falls under the outlier group of items and predict what is likely to fail next, and make adjustments and fixes to increase their yield. Instead of mindlessly rejecting items that fall under the outlier range, the manufacturer can increase their yield by “saving” the potential yield losses by acting toward them.

In Figure 3, notice the PAT (blue lines) calculated dynamically. The outliers group (in red circles) no longer sits static and waits to be rejected; instead, it is used as a prediction indicator for failed items for the upcoming DUTs.

Figure 3. DPAT introduces its dynamic PAT limits (in blue) and makes the outliers as future predictions for failures.

Applications of DPAT in PMA

PMA has helped one of its automotive manufacturer users to increase the yield of their sensor product by using the DPAT module. The logs provide live measurement to PMA, and it uses it to calculate the PAT dynamically and feed it back to its testers in real-time. This customer has been using PMA to improve their production for over 2 years and will continue using Keysight’s PMA in the future.

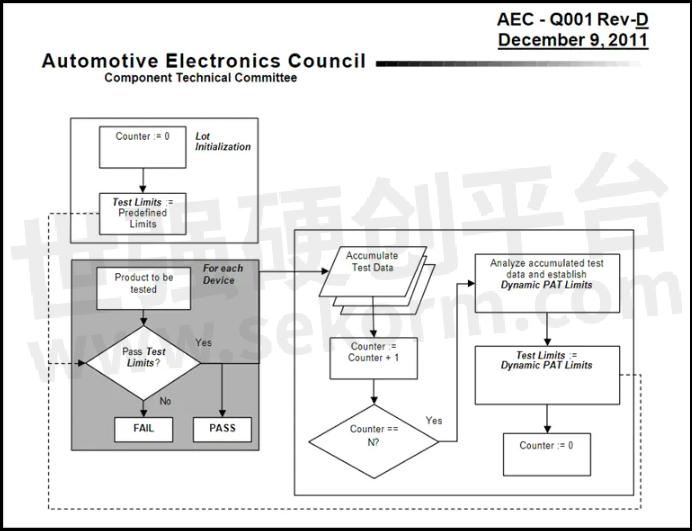

Below is the flowchart of how the limits are calculated and how PMA gathers this feedback into the system. Keysight follows the standards recommended by AEC-Q001, 2001 (in addition to our additional algorithm). Refer to Figure 4 below:

Figure 4. Standards of DPAT being calculated in PMA and feedback live to the system (following AEC-Q001, 2001 standards)

Conclusions

In conclusion, the implementation of DPAT in PMA offers manufacturers a valuable advantage in optimizing their production process. By utilizing real-time data and analyzing charts to identify outlier items, manufacturers can proactively predict potential failures and take necessary actions to enhance yield and save potential yield losses by making targeted adjustments and fixes.

About PMA

PathWave Manufacturing Analytics (PMA) is backed by an experienced team of people at Keysight, who can help you achieve the goal of bringing in data from your manufacturing test equipment and software for analysis and presentation to help you gain the necessary actionable insights that can be used from an operator on the line to the highest senior management levels of the business organization. PMA includes a scalable architecture that can grow with your business. It comes with regular software updates that will allow you to manage the changing business or production requirements in your environment. PMA will free up engineering and development teams to work on the software and tools that are valuable to your manufacturing lines and business, as well as save time on the production floor with its actionable insights.

- |

- +1 赞 0

- 收藏

- 评论 0

本文由翊翊所思转载自Keysight blogs,原文标题为:PMA's DPAT Implementation Safeguards Against Potential Yield Losses,本站所有转载文章系出于传递更多信息之目的,且明确注明来源,不希望被转载的媒体或个人可与我们联系,我们将立即进行删除处理。

相关研发服务和供应服务

相关推荐

将数据导入到是德科技PathWave Manufacturing Analytics软件,优化制造工艺和效率

PathWave Manufacturing Analytics(PMA)由Keysight团队提供支持,可以帮助实现从您的制造测试设备和软件中导入数据进行分析和演示的目标,帮助获得必要的可操作的视图,这些视图可以用于从生产线上的操作员到业务组织的最高高级管理层。

Reducing Retest Improves First Pass Yield (FPY) with PathWave Manufacturing Analytics

PathWave Manufacturing Analytics (PMA) provides a big data platform for performing time-series analytics on all kinds of test equipment in a manufacturing environment. In this customer success story, the contract manufacturer is utilizing Keysight‘s Cloud platform for hosting the analytics to speed deployment and reduce the upfront server infrastructure investment costs and maintenance.

是德科技与您相约NEPCON Asia深圳,将带来涵盖SMT产线的系统化电子制造测试解决方案,推动工业4.0

Keysight的系统化电子制造测试解决方案涵盖SMT产线,包括ICT、功能测试和开创性的PathWave制造数据分析(PMA)软件-旨在推动您的工厂步入工业4.0时代,是推动运营改进的重要力量。PMA从设计到制造在各个层面提供全面支持,实现问题的主动检测和优化。

精密机械装配

描述- 本资料介绍了MinebeaMitsumi公司的精密机械组装产品(PMA),包括其定义、应用领域、技术优势、成本效益和环境责任。PMA利用公司积累的技术和知识,为客户提供定制化的机械部件,旨在减少生产时间、降低检查时间和提高产品质量。此外,还提供了全球服务网络和生产流程,以满足不同行业的需求,如汽车、医疗和家电等行业。

Root Cause Analysis on Return Merchandise Authorization (RMA) Boards

Sometimes early failure boards are returned to the factory for diagnostics,Keysight is going to talk about Root Cause Analysis on Return Merchandise Authorization (RMA) Boards.

是德科技即将亮相NEPCON China 2023,提供系统化电子制造测试解决方案

NEPCON China 2023将于7月19日-21日在上海世博展览馆隆重开幕。Keysight的系统化电子制造测试解决方案涵盖SMT产线,包括ICT、功能测试和开创性的PathWave制造数据分析(PMA)软件-旨在推动您的工厂步入工业4.0时代,是推动运营改进的重要力量。

【应用】是德科技PMA可帮助全球汽车零部件制造商把RCA过程从6个月减少到5分钟,还能对治具运行状况进行日常监控

使用Keysight PathWave制造分析,可以一目了然地查看适量的测试设备测量数据,用户还可以轻松捕获和报告数据,从而有助于加快调查过程并减少生产中的停机时间。因此,使用该分析软件,生产线可以重回正轨,甚至可以提高其能力。

PathWave设计和测试软件目录

描述- 该资料介绍了Keysight Technologies的PathWave设计测试软件系列,旨在提高设计测试效率。软件涵盖设计仿真、信号分析生成、组件和合规测试、测试自动化以及数据分析等方面,支持远程工作,并提供多种应用软件和工具,如PathWave Advanced Design System (ADS)、PathWave Signal Generation、PathWave Vector Signal Analysis (89600 VSA)、PathWave Oscilloscope Software、PathWave Network Analyzer Software、PathWave BenchVue、PathWave Test Automation、PathWave Waveform Analytics、PathWave Manufacturing Analytics和PathWave Measurement Analytics等。

型号- X-SERIES,89600

Boosting Your Manufacturing Analytics System with Keysight’s Pathwave Manufacturing Analytics (PMA)

With the recently launched feature that tracks all rework and scraps, PMA has helped manufacturers globally by working alongside their existing manufacturing systems to improve their cost of poor quality and leading towards lowering the defects of the test boards.

Loading data into PathWave Manufacturing Analytics

PathWave Manufacturing Analytics (PMA) is a backed by an experienced team of people at Keysight, who can help you achieve the goal of bringing in data from your manufacturing test equipment and software, for analysis and presentation, to help you to gain the necessary actionable insights that can be used from an operator on the line to the highest senior management levels of the business organization. PMA includes a scalable architecture that can grow with your business.

PathWave Manufacturing Analytics (PMA) Use Case: Faster diagnostics for Semiconductor recalls

Keysight has seen car recalls due to faulty semiconductor components. Within the PMA application, there is an RMA module that allows a user to retrieve the complete test history of the board and its batch.

PathWave Manufacturing Analytics许可证管理:使用许可证管理器查看和添加许可证应用说明

描述- 本文介绍了PathWave Manufacturing Analytics软件的许可管理功能,包括许可文件的读取、用户界面功能的访问控制、连接设备的数量限制等。详细说明了如何通过Keysight Software Manager进行许可兑换,以及如何通过PMA集群的master 1节点访问和登录许可管理器。此外,还提供了查看、添加和激活许可的步骤,以及一些常见问题的解答。

PathWave制造分析

描述- PathWave Manufacturing Analytics版本2.3.0新增了总结报告模块和投资回报模块,用于汇总工程师需要关注的重点问题和比较两个日期范围内的OEE、重测、首次通过和最终良率。版本2.2.0新增了探针热图、测试结果可视化、响应式网页设计和Firefox浏览器兼容性等功能。版本2.1.0进行了多项错误修复。版本2.0.0引入了数字质量、总体设备效能、吞吐量、过程分析和警报模块,以及新的警报通知和中文语言支持。

电子商城

现货市场

服务

提供是德(Keysight),罗德(R&S)测试测量仪器租赁服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器租赁服务;租赁费用按月计算,租赁价格按仪器配置而定。

提交需求>

朗能泛亚提供是德(Keysight),罗德(R&S)等品牌的测试测量仪器维修服务,包括网络分析仪、无线通讯综测仪、信号发生器、频谱分析仪、信号分析仪、电源等仪器维修,支持一台仪器即可维修。

提交需求>

登录 | 立即注册

提交评论